Agricultural wastewater treatment technology

A technology of treatment process and sewage treatment agent, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of unsatisfactory removal effect and complicated agricultural sewage pollutants, and achieve Realize the effect of ecological treatment and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

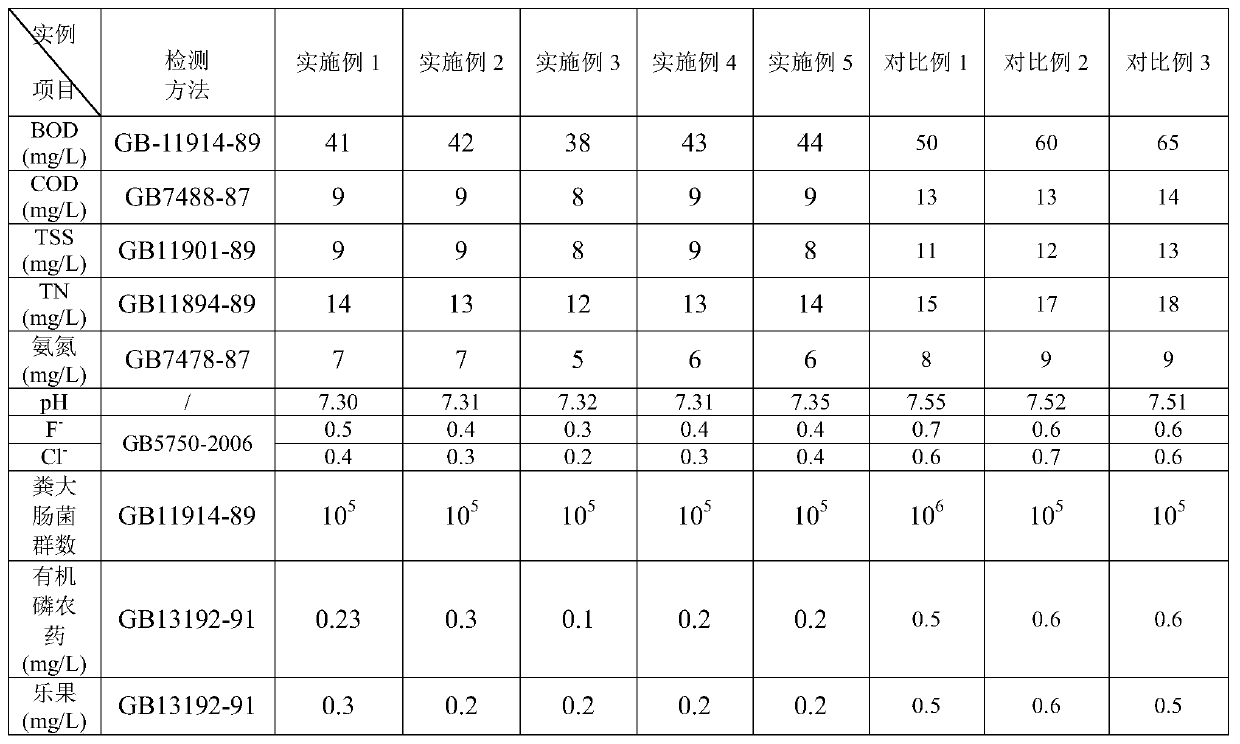

Examples

Embodiment 1

[0035] A treatment process for agricultural sewage, comprising the following steps:

[0036] 1. Initial inspection: Sampling to detect the amount of pollutants in the sewage;

[0037] 2. Filtration: Separation of solid insoluble matter in sewage;

[0038] 3. Disinfection, sterilization, sedimentation: add a disinfectant to the filtered water, stir for half an hour, and let it settle for 30 minutes; the disinfectant is nano-silver and unslaked lime in equal parts by weight; the disinfectant The dosage of fungicide is 1g / m 3 sewage;

[0039] 4. Electrolysis: Add a catalyst to the sewage after disinfection and sterilization treatment into the electrolytic cell, feed direct current, and ionize and decompose the pollutants; the catalyst is a composite catalyst, consisting of the following raw materials in parts by weight: 10 parts of iron oxide, 10 parts of ferrous iron, 10 parts of polyacrylamide and 10 parts of graphene oxide;

[0040] 5. Heavy metal treatment: add a heavy meta...

Embodiment 2

[0049] A treatment process for agricultural sewage, comprising the following steps:

[0050] 1. Initial inspection: Sampling to detect the amount of pollutants in the sewage;

[0051] 2. Filtration: Separation of solid insoluble matter in sewage;

[0052] 3. Disinfection, sterilization, and sedimentation: add a disinfectant to the filtered water, stir for half an hour, and let it settle for 50 minutes; the disinfectant is nano-silver and unslaked lime in equal parts by weight; the disinfectant The dosage of fungicide is 5g / m 3 sewage;

[0053] 4. Electrolysis: Add catalyst to the sewage after disinfection and sterilization treatment into the electrolytic cell, feed direct current, ionize and decompose the pollutants; the catalyst is a composite catalyst, consisting of the following raw materials in parts by weight: 15 parts of iron oxide, 15 parts of ferrous iron, 20 parts of polyacrylamide and 20 parts of graphene oxide;

Embodiment 3

[0063] A treatment process for agricultural sewage, comprising the following steps:

[0064] 1. Initial inspection: Sampling to detect the amount of pollutants in the sewage;

[0065] 2. Filtration: Separation of solid insoluble matter in sewage;

[0066] 3. Disinfection, sterilization, sedimentation: add a disinfectant to the filtered water, stir for half an hour, and let it settle for 40 minutes; the disinfectant is nano-silver and unslaked lime in equal parts by weight; the disinfectant The dosage of fungicide is 3g / m 3 sewage;

[0067] 4. Electrolysis: Add catalyst to the sewage after disinfection and sterilization treatment into the electrolytic cell, pass through direct current, ionize and decompose the pollutants; the catalyst is a composite catalyst, consisting of the following raw materials in parts by weight: 12 parts of iron oxide, 13 parts of ferrous iron, 15 parts of polyacrylamide and 15 parts of graphene oxide;

[0068] 5. Heavy metal treatment: add a heavy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com