A continuous system using microalgae and aquatic plants to jointly treat pig biogas slurry with high ammonia nitrogen

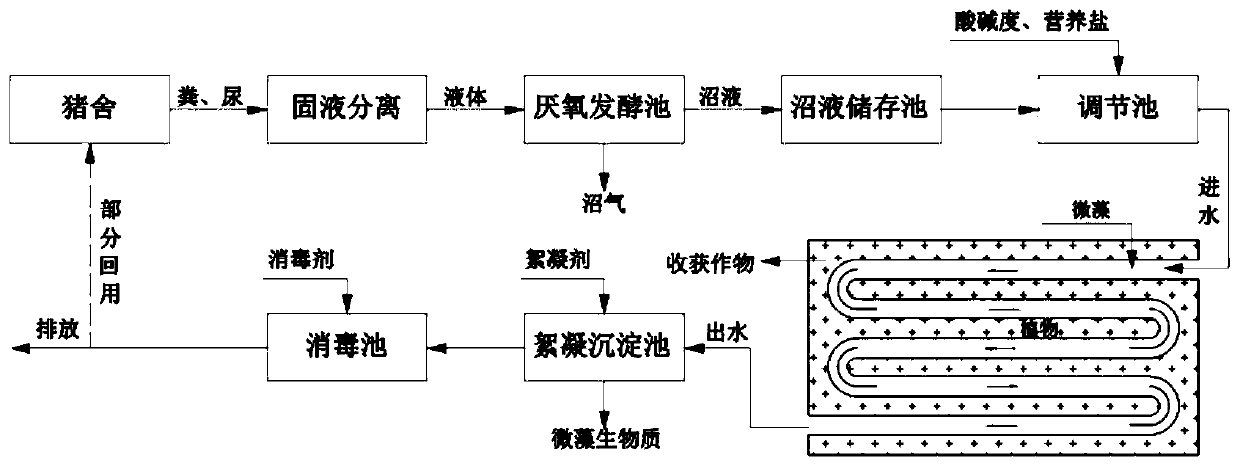

A technology of combined treatment of aquatic plants, applied in the field of continuous systems, can solve the problems of high ammonia nitrogen biogas slurry treatment costs, difficulty in popularization, and difficult operation, and achieve the effects of improving treatment efficiency, good effluent quality, and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Taking the biogas slurry treatment process of a certain large-scale pig farm as an example, the system of the present invention is used to process the biogas slurry.

[0029] The solid-liquid separation of 10 tons of pig farm waste water was carried out, and the liquid entered the anaerobic fermentation tank for fermentation. After the fermentation, the biogas slurry was temporarily stored in the biogas slurry storage tank. The measured initial COD was 1940mg / L, ammonia nitrogen was 330mg / L, and the total Phosphorus is 14mg / L, pH is 8.6, the ratio of nitrogen to phosphorus and pH are all within the appropriate range, and it can be used directly without adjustment.

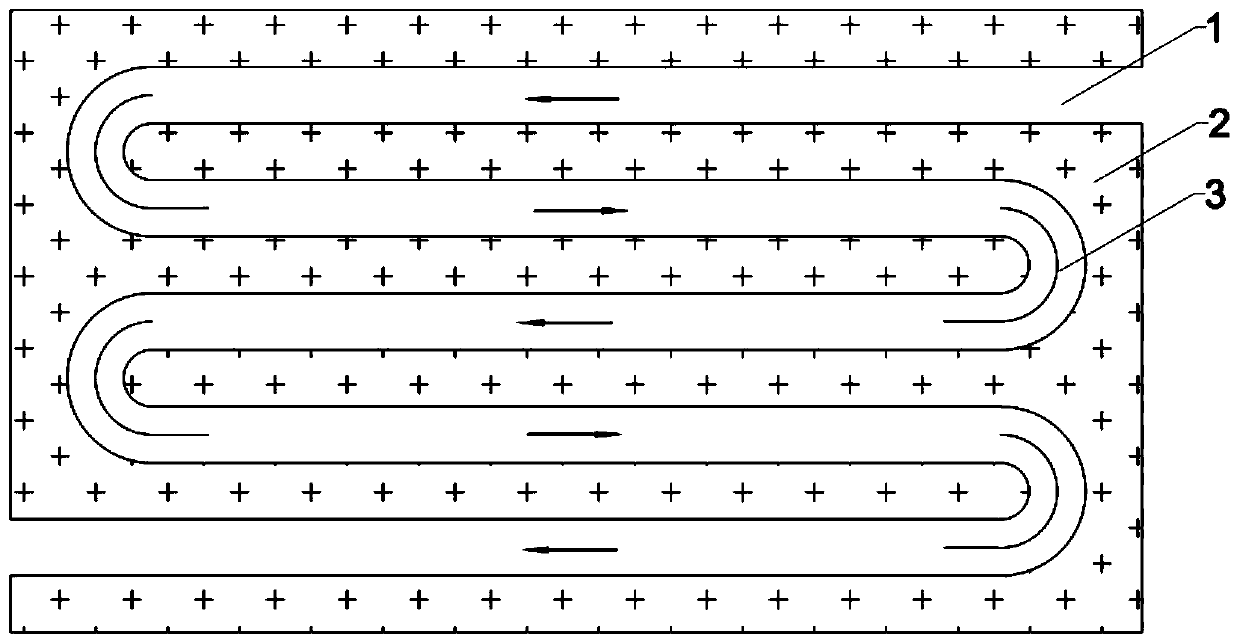

[0030] The biogas slurry enters the system from the water inlet and is treated under the joint action of microalgae and aquatic plants. The microalgae treatment area was inoculated with Scenedesmus, and the inoculation amount was 10% of the biogas slurry volume, and the plant treatment area was planted with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com