Method for purifying halide perovskite quantum dots based on dimethyl silicone oil

A technology of halide perovskite and dimethyl silicone oil, which is applied in the field of quantum dot technology, can solve the problems of low yield and reduced luminous efficiency, and achieve increased yield and stability, improved photoluminescence efficiency, and cheap raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

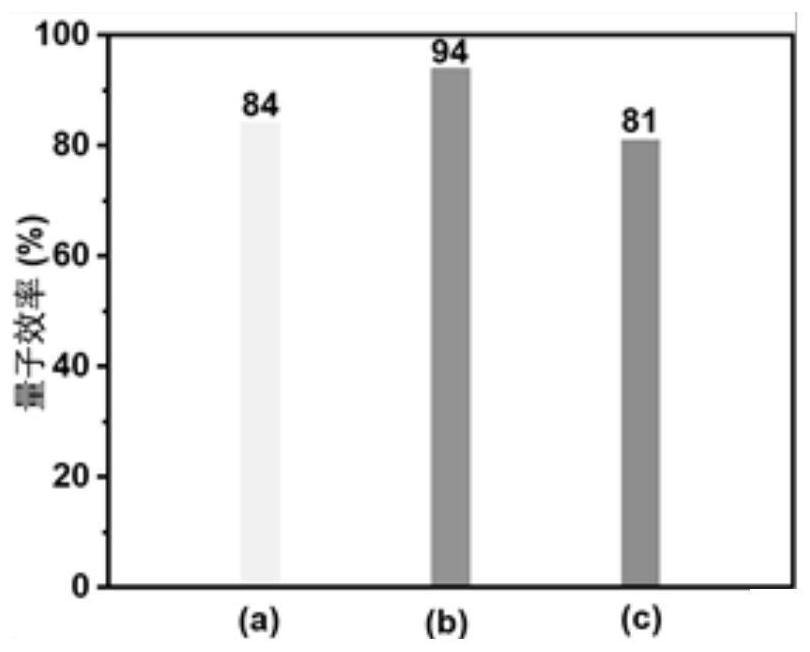

[0037] Embodiment 1 (according to method one):

[0038] CsPbI synthesized by thermal injection 3 Take 1 mL of the crude quantum dot solution, add 1 mL of dimethicone with a viscosity of 100 cs and 1 mL of n-hexane, and shake to obtain a mixed solution. The mixed solution was centrifuged at 8500 rpm / min for 5 min, the supernatant was discarded, and the precipitate was dissolved in 1 mL of n-hexane.

[0039] The component in the described 1mL crude solution mainly includes CsPbI 3 Quantum dots, 1-octadecene solvent, oleylamine, oleic acid and other ligands.

Embodiment 2

[0048] Embodiment 2 (according to method two): CsPbBr synthesized by room temperature synthesis 3 3 mL of quantum dot solution was taken out, 1 mL of dimethyl silicone oil with a viscosity of 100 cs was added, and a mixed solution was obtained by shaking. The mixed solution was centrifuged at 8000 rpm / min for 5 min, and the precipitate was dissolved in 1 mL of xylene.

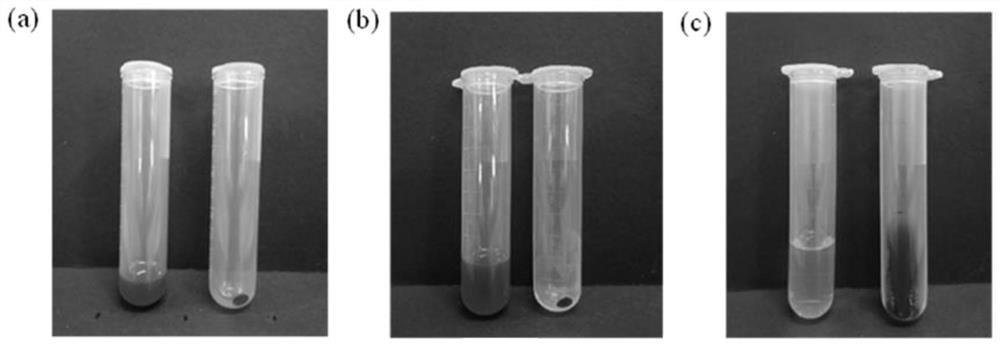

[0049] like figure 2 shown, figure 2 a is the result of direct centrifugation of the crude solution of quantum dots; figure 2 The b in it is a photo of the result of purifying the crude solution of quantum dots with dimethicone. It can be seen that the amount of the purified product based on simethicone is also higher than the amount of the product obtained by direct centrifugal purification.

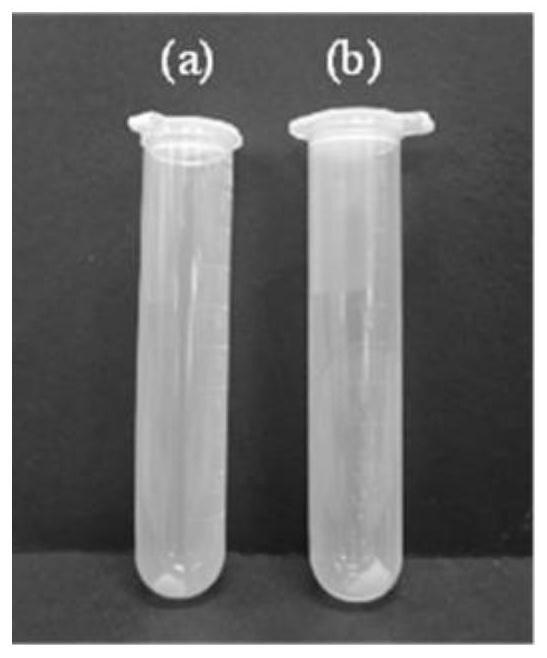

[0050] like Figure 5 As shown, the purified product was dissolved in 1 mL of xylene and stored at room temperature for more than five months, and the luminescence intensity remained about 60%.

Embodiment 3

[0051] Example 3: In addition to the CsPbI of method one in step 1 3 The crude solution of quantum dots was changed to CsPbBr 3 Quantum dot solution, others are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com