Process for producing same-plate two-tone superfine composite draw textured yarns

A processing technology and a technology of texturizing yarn, which is applied in the direction of conjugated synthetic polymer rayon, rayon manufacturing, filament/thread forming, etc., which can solve the problems of product quality damage, difficulty in dyeing dark colors, and cost increase , to achieve the effect of shortening the production process, eliminating the post-dyeing process and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

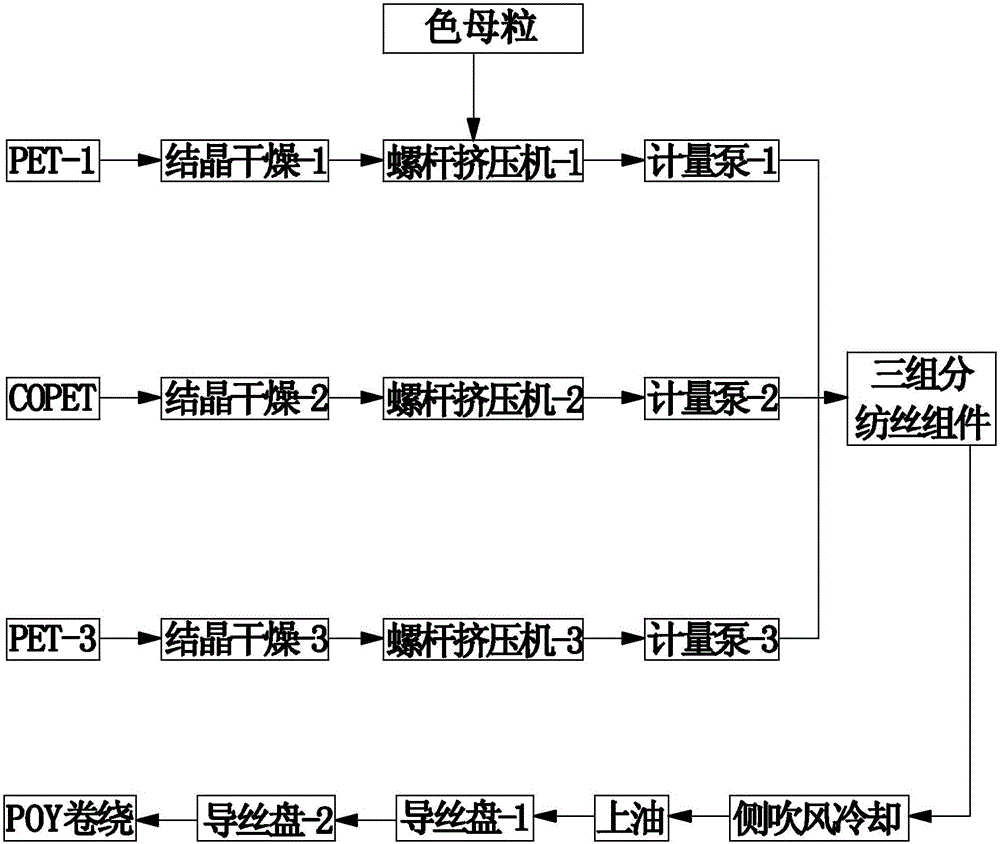

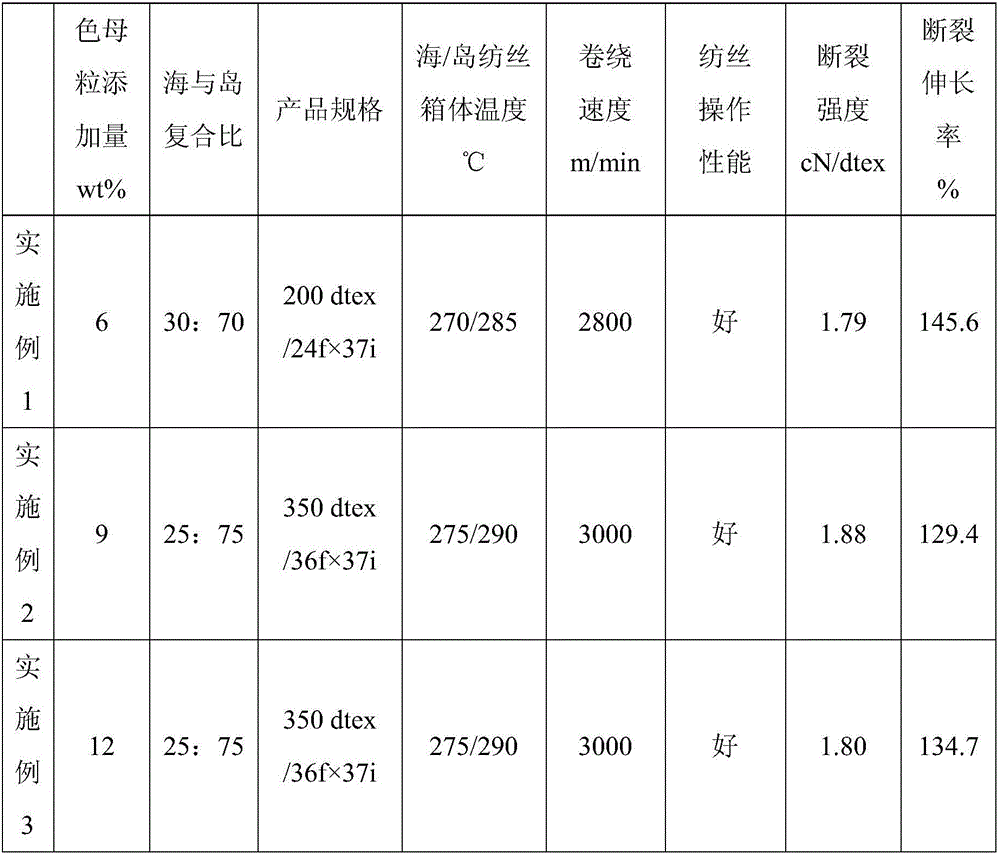

[0029] This embodiment is a processing technology of two-color stretched yarn on the same board. The intrinsic viscosity of the sea component COPET (according to GB / T 14190-2008, with phenol and tetrachloroethane 1:1 as solvent for detection) is 0.70dl / g, the moisture content of dry slices is less than 50ppm, the temperature of each zone of the screw is 260-280°C; the intrinsic viscosity of island component 1 (PET-3) is 0.685dl / g, the moisture content of dry slices is less than 50ppm, and the temperature of each zone of the screw is 270-290°C The intrinsic viscosity of the island component 2 (PET-1) is 0.685dl / g, the moisture content of the dry chip is less than 50ppm, the black masterbatch is added 6wt%, and the temperature of each zone of the screw is 270-290°C.

[0030] The ratio of the sea to the island is 30:70, the temperature of the sea / island spinning box is 270 / 285°C respectively, the side blowing wind speed is 0.4m / s, and the winding speed is 2800m / min, and the black...

Embodiment 2

[0032] The setting and working principle of this embodiment are the same as those of Embodiment 1, the difference is that: 9wt% of black color masterbatch is added, and the ratio of sea and island is 25:75. The temperature of the sea / island spinning box is 275 / 290°C, the wind speed of side blowing is 0.5m / s, and the winding speed is 3000m / min, and the black and white sea island POY of 350dtex / 36f×37i is produced. Example 3

Embodiment 3

[0033] The setting and working principle of this embodiment are the same as those of Embodiment 1, the difference is that: 12wt% of black color masterbatch is added, and the ratio of sea to island is 25:75. The temperature of the sea / island spinning box is 275 / 290°C, the wind speed of side blowing is 0.5m / s, and the winding speed is 3000m / min, and the black and white sea island POY of 350dtex / 36f×37i is produced. Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com