Synthesizing method for 4-amino-2-methyl-5-(brooethyl) pyrimidine hydrobromide

A technology of pyrimidine hydrobromide and synthesis method, which is applied in the field of synthesis of 4-amino-2-methyl-5-pyrimidine hydrobromide, can solve the problems of limited application, non-compliance with environmental protection requirements, cumbersome operation, etc. Achieve the effects of easy industrial scale production, green production method and low requirements for process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

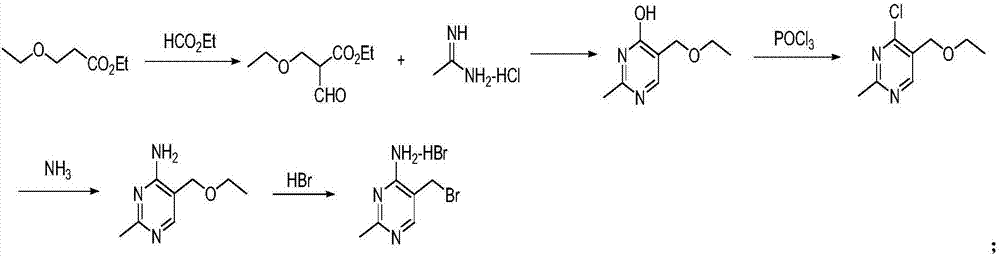

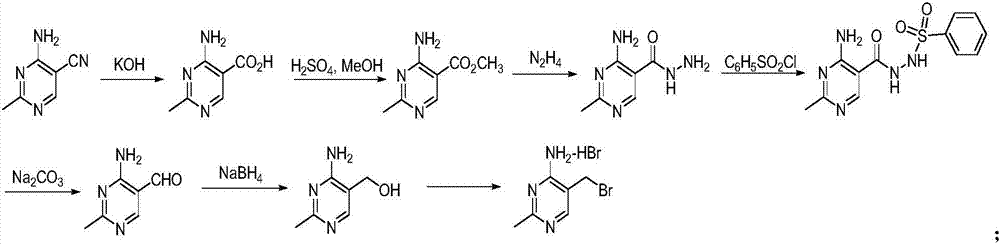

Problems solved by technology

Method used

Image

Examples

Embodiment 1

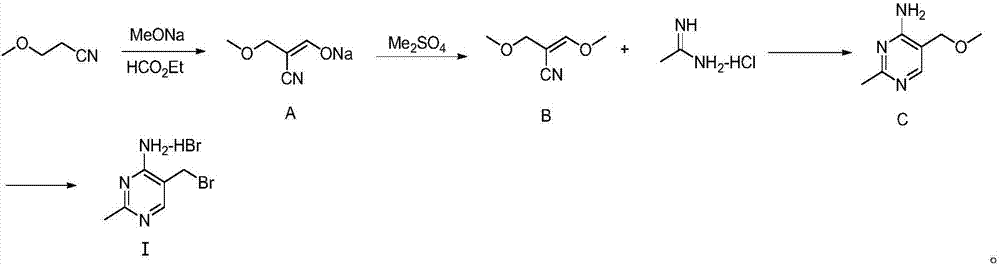

[0032] Embodiment 1: a kind of synthetic method of 4-amino-2-methyl-5-(bromomethyl) pyrimidine hydrobromide, comprises the following steps:

[0033] S1.3-Methoxypropionitrile and ethyl formate were subjected to the action of sodium methoxide to obtain formylated intermediate sodium salt A; the solvent used was tetrahydrofuran, and the reaction temperature was 0°C;

[0034] S2. Intermediate sodium salt A reacts with dimethyl sulfate to obtain intermediate B; the solvent used is dichloromethane, and the reaction temperature is 0°C;

[0035] S3. Intermediate B and acetamidine hydrochloride are condensed to obtain intermediate C; the solvent used is ethanol, and the reaction temperature is 0°C;

[0036] S4. Intermediate C reacts with hydrobromic acid to obtain the target product 4-amino-2-methyl-5-(bromomethyl)pyrimidine hydrobromide I; the solvent used is acetic acid, and the reaction temperature is 0°C.

Embodiment 2

[0037] Embodiment 2: a kind of synthetic method of 4-amino-2-methyl-5-(bromomethyl) pyrimidine hydrobromide, comprises the following steps:

[0038] S1.3-Methoxypropionitrile and ethyl formate were subjected to the action of sodium methoxide to obtain formylated intermediate sodium salt A; the solvent used was methyl tetrahydrofuran, and the reaction temperature was 100°C;

[0039] S2. The intermediate sodium salt A is reacted with dimethyl sulfate to obtain the intermediate B; the solvent used is dichloroethane, and the reaction temperature is 100°C;

[0040] S3. Intermediate B and acetamidine hydrochloride are condensed to obtain intermediate C; the solvent used is methanol, and the reaction temperature is 100° C.;

[0041] S4. Intermediate C reacts with hydrobromic acid to obtain the target product 4-amino-2-methyl-5-(bromomethyl)pyrimidine hydrobromide I; the solvent used is formic acid, and the reaction temperature is 150°C.

Embodiment 3

[0042] Embodiment 3: a kind of synthetic method of 4-amino-2-methyl-5-(bromomethyl) pyrimidine hydrobromide, comprises the following steps:

[0043] S1.3-Methoxypropionitrile and ethyl formate are obtained under the action of sodium methoxide to obtain formylated intermediate sodium salt A; the solvent used is diethyl ether, and the reaction temperature is 10°C;

[0044] S2. Intermediate sodium salt A reacts with dimethyl sulfate to obtain intermediate B; the solvent used is chloroform, and the reaction temperature is 10°C;

[0045] S3. Intermediate B and acetamidine hydrochloride are condensed to obtain intermediate C; the solvent used is isopropanol, and the reaction temperature is 10° C.;

[0046] S4. Intermediate C reacts with hydrobromic acid to obtain the target product 4-amino-2-methyl-5-(bromomethyl)pyrimidine hydrobromide I; the solvent used is propionic acid, and the reaction temperature is 15°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com