Economical, environment-friendly and efficient desulfurization refining slag system and preparation method

A production method and technology of refining slag, which is applied in the field of iron and steel metallurgy, can solve problems such as shortened service life of ladles, air pollution, and hazards to the health of operating workers, and achieve the effects of improving production efficiency, high desulfurization and deoxidation efficiency, and good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

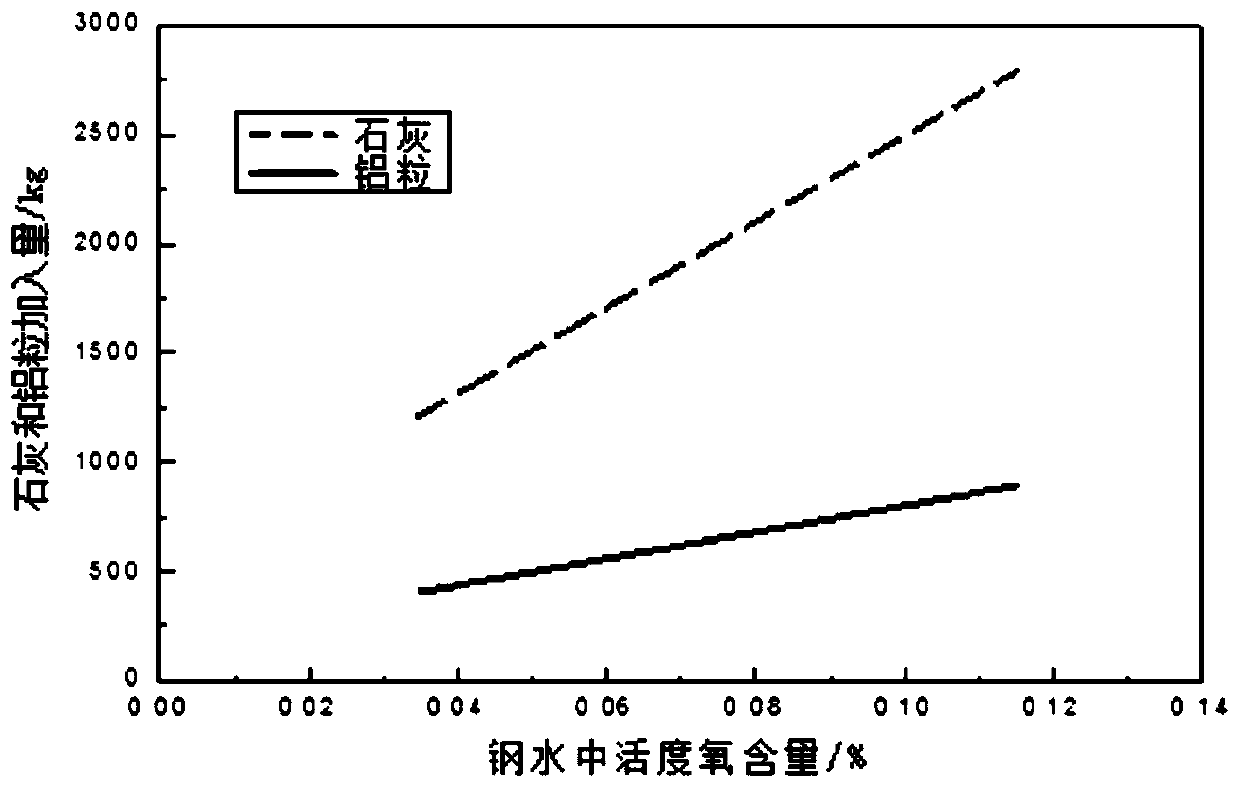

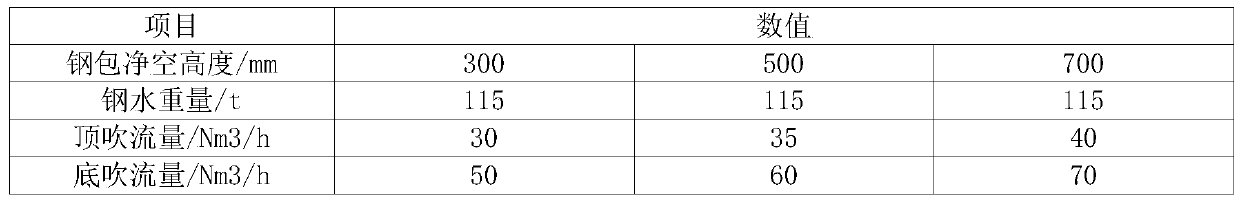

[0038] A smelting workshop utilizes steelmaking equipment with a nominal capacity of 120 tons to produce Q345D low-alloy high-strength steel, and obtains refining slag according to the method of the present invention. The specific conditions are shown in the following table.

[0039] Table 1 shows the argon gas supply system for the top and bottom double blowing of the alloy fine-tuning station

[0040]

[0041] Table 2 shows the change of slag composition before and after the alloy fine-tuning station

[0042]

[0043]

[0044] Table 2 shows the composition of the slag added when the molten steel is tapped (before the argon) and the composition of the primary slag after the top-bottom blowing of argon at the alloy fine-tuning station (after the argon); it can be seen from this that after the alloy fine-tuning station , the average content of slag FeO+MnO dropped from 26.38% to 3.48%; slag Al 2 o 3 The average value of content increased from 4.12% to 26.01%; the ave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com