Treatment system and treatment method for wastewater containing low-concentration sulfuric acid

The technology of a treatment system and a treatment method is applied in the field of treatment systems for wastewater containing low-concentration sulfuric acid, and can solve the problems of inability to biochemically treat wastewater, sulfuric acid that cannot be recycled and reused, and high energy consumption of an evaporator, and achieves easy implementation, simple structure, and high treatment efficiency. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

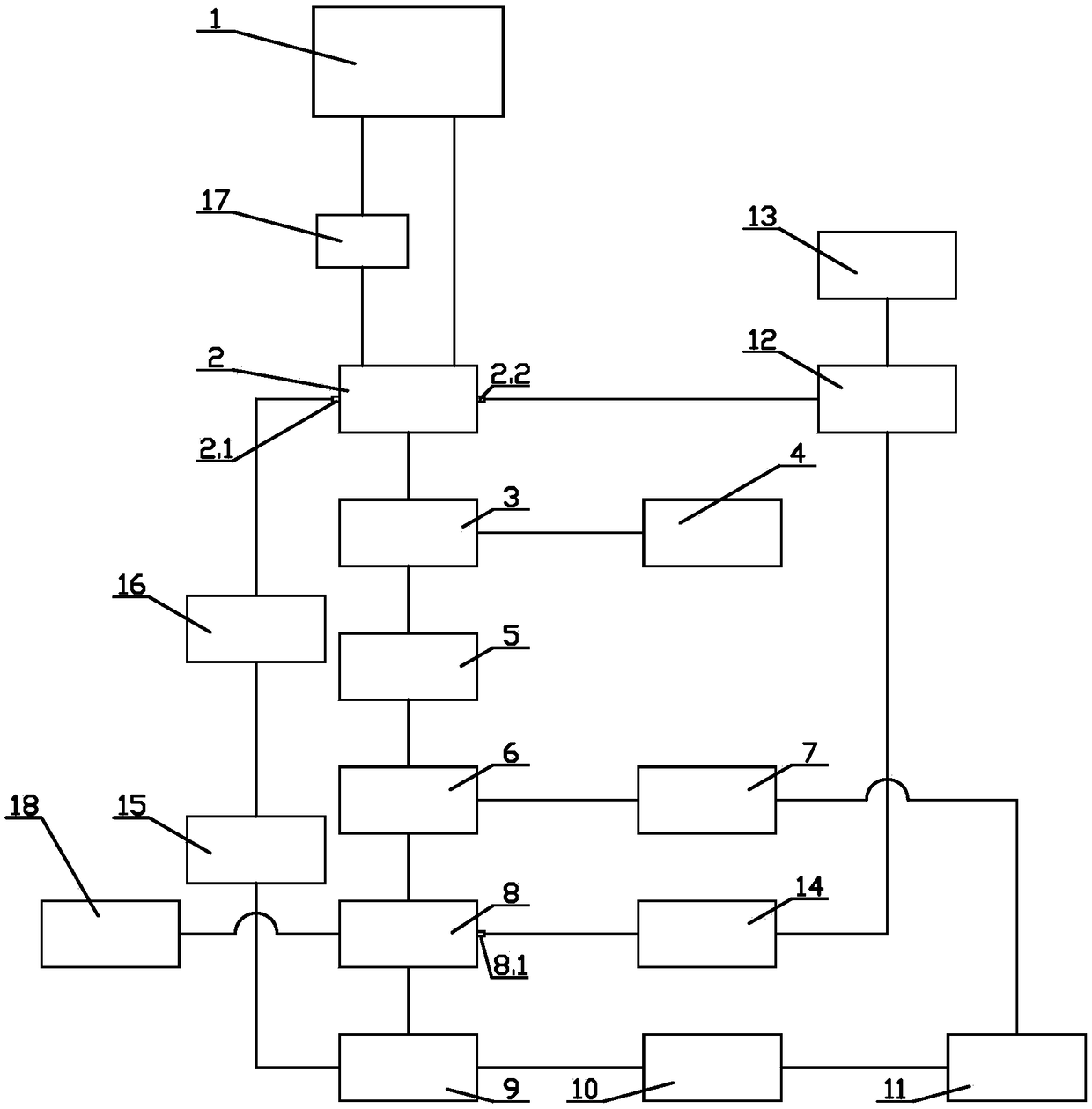

[0027] Embodiment 1: as figure 1 As shown, a treatment system for wastewater containing low-concentration sulfuric acid, which includes a collection pool 1, a neutralization tank 2, a first filter press 3, a sewage treatment system 4, a first conveyor belt 5, a beating tank 6, and a liquid storage tank 7 , metathesis reaction barrel 8, second filter press 9, cooling crystallizer 10, centrifuge 11, carbonization tower 12, ammonia water source 13, ammonium carbonate storage tank 14, calcium carbonate storage tank 15, second conveyor belt 16, activated carbon decolorization tower 17 and a steam source 18; the liquid outlet of the collection pool 1 is connected to the liquid inlet of the neutralization barrel 2 through pipelines; the neutralization barrel 2 is respectively provided with a calcium carbonate feed port 2.1 and a gas outlet 2.2; the neutralization barrel The liquid outlet of 2 is connected with the liquid inlet of the first filter press 3 through a pipeline; the liqui...

Embodiment 2

[0033] Embodiment 2: Utilize the method for the system described in embodiment 1 to handle low-concentration sulfuric acid wastewater, comprising the following steps: (1) neutralization reaction; (2) pressure filtration for the first time; (3) beating; (4) metathesis reaction (5) pressure filtration for the second time; (6) crystallization filtration; wherein:

[0034] When the chroma of the sulfuric acid waste water in the collection pool 1 was higher, it was transported to the activated carbon decolorization tower 17 for decolorization to form colorless waste water, in order to ensure that the appearance of the ammonium sulfate produced in the follow-up was up to standard;

[0035] (1) neutralization reaction: the colorless sulfuric acid waste water after the decolorization is pumped in the neutralization barrel 2, and then the calcium carbonate in the calcium carbonate storage tank 15 is regularly transported in the neutralization barrel 2 by the second conveyer belt 16, Ca...

Embodiment 3

[0041] Embodiment 3: Utilize the method for the system described in embodiment 1 to handle low-concentration sulfuric acid wastewater, comprising the following steps: (1) neutralization reaction; (2) pressure filtration for the first time; (3) beating; (4) metathesis reaction (5) pressure filtration for the second time; (6) crystallization filtration; wherein:

[0042] (1) Neutralization reaction: when the sulfuric acid wastewater in the collection pond 1 was colorless, the colorless sulfuric acid wastewater in the collection pond 1 was directly pumped into the neutralization bucket 2, and then the sulfuric acid wastewater in the calcium carbonate storage tank 15 was Calcium carbonate is regularly transported to the neutralization barrel 2 through the second conveyor belt 16. The calcium carbonate reacts with the sulfuric acid in the wastewater to generate calcium sulfate emulsion and carbon dioxide gas. The mass ratio of calcium carbonate to sulfuric acid is 1:1; the generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com