Artificial marble polishing waste residue-based ceramic glazed tiles and preparation method thereof

A technology for artificial marble and polishing waste residue, applied in the field of ceramic tile production, can solve problems such as environmental hazards and difficult resin degradation, and achieve the effects of simple operation, simple process and commercial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The raw materials for traditional ceramic glazed tiles include four types of raw materials: feldspar, black mud, wollastonite and limestone. However, the present invention completely replaces limestone with artificial marble polishing slag, which is beneficial to reduce the cost of the formula and turn waste into treasure.

[0033] As a further embodiment, the preparation raw materials also include auxiliary materials, and the auxiliary materials include methyl cellulose, sodium tripolyphosphate and water; the amount of methyl cellulose and sodium tripolyphosphate is 0.05-0.5% of the sum of the weight of the main components; The consumption of water is 30-35% of the sum of main component weight. Methyl cellulose can increase the strength of the green body, which is beneficial to the suspension of slurry; while sodium tripolyphosphate is a water reducing agent, which can help grinding.

[0034] As a further embodiment, the artificial marble material polishing slag includ...

Embodiment 1-5

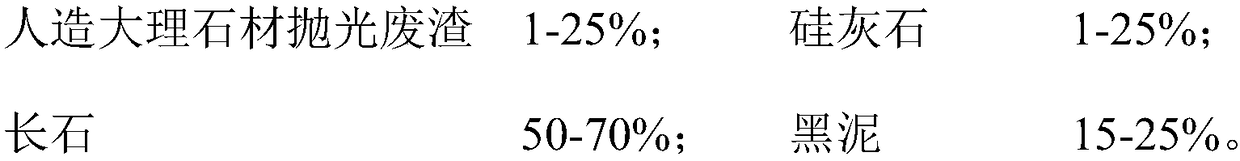

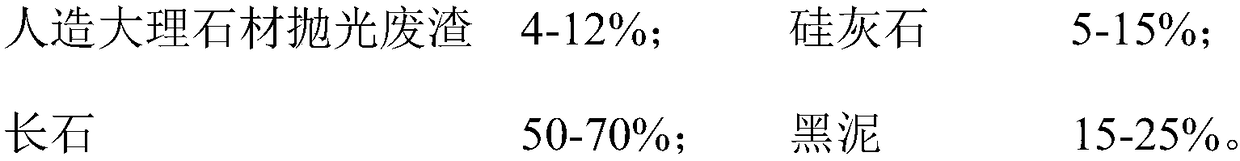

[0050] A ceramic glazed tile based on artificial marble polishing slag, consisting of main components (artificial marble polishing slag 1-25%; wollastonite 1-25%; feldspar 50-70%; black mud 15-25%) and The auxiliary material () is prepared, and the specific formula table is shown in the following table 1.

[0051] The formula table of the ceramic glazed tile of table 1 embodiment 1-5

[0052]

[0053] Note: The amount of auxiliary materials refers to the percentage of the sum of the weight of the main components

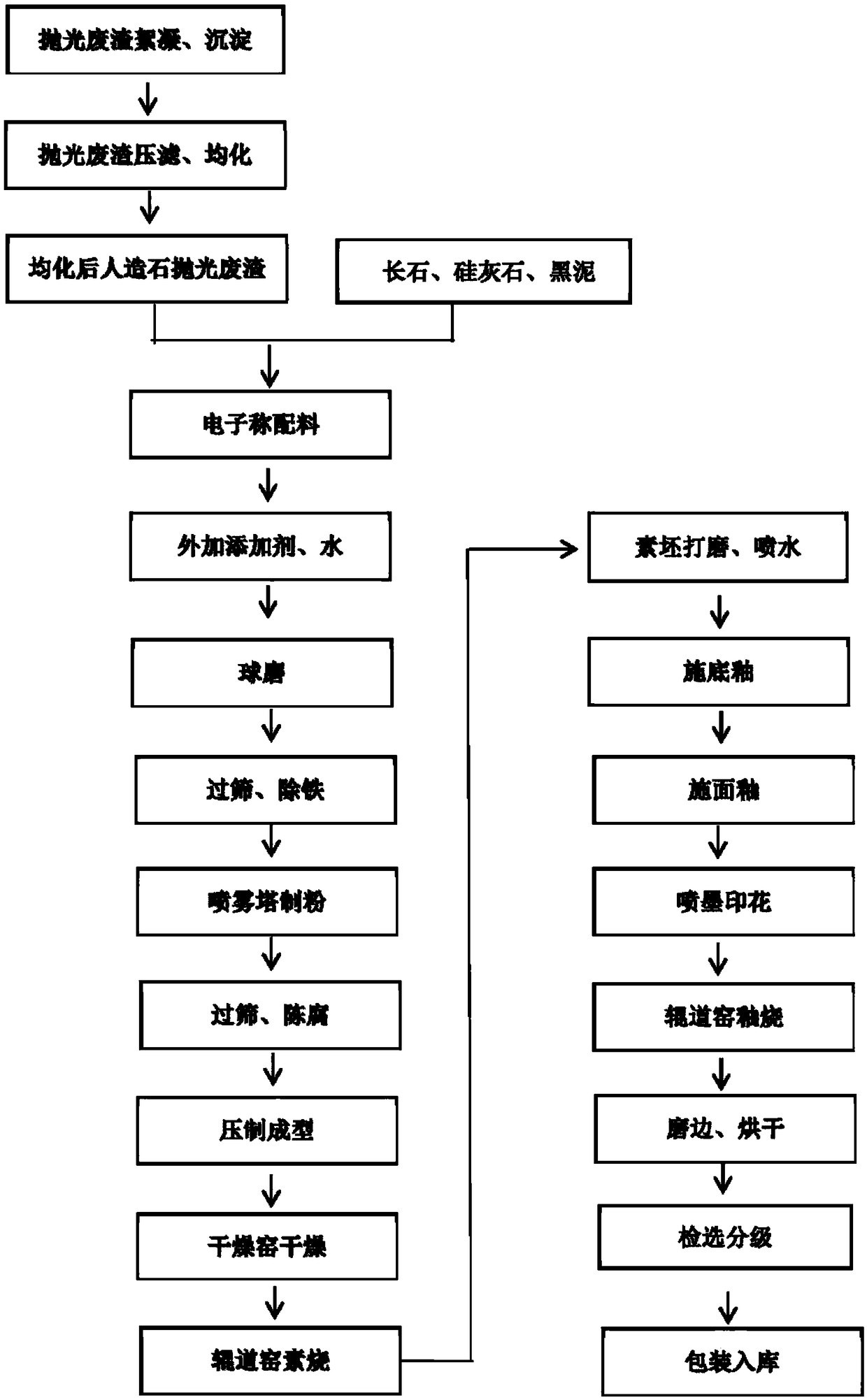

[0054] The ceramic glazed tile based on the artificial marble material polishing slag of embodiment 1-5 is prepared according to the following method:

[0055] Marble material polishing waste preparation steps: After collecting the waste water produced in the process of artificial marble material processing and polishing, adding flocculant, after sedimentation, pressure filtration and uniform treatment in sequence, the marble material polishing waste slag is obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com