Method for producing simulation plants by utilizing non-woven cloth

A technology of simulating plants and non-woven fabrics, applied in the field of simulating plants, can solve problems such as environmental pollution and pollutants that are difficult to deal with, and achieve the effects of realistic hand feeling, environmentally friendly production methods, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The leaf preparation of embodiment 1 simulation plant

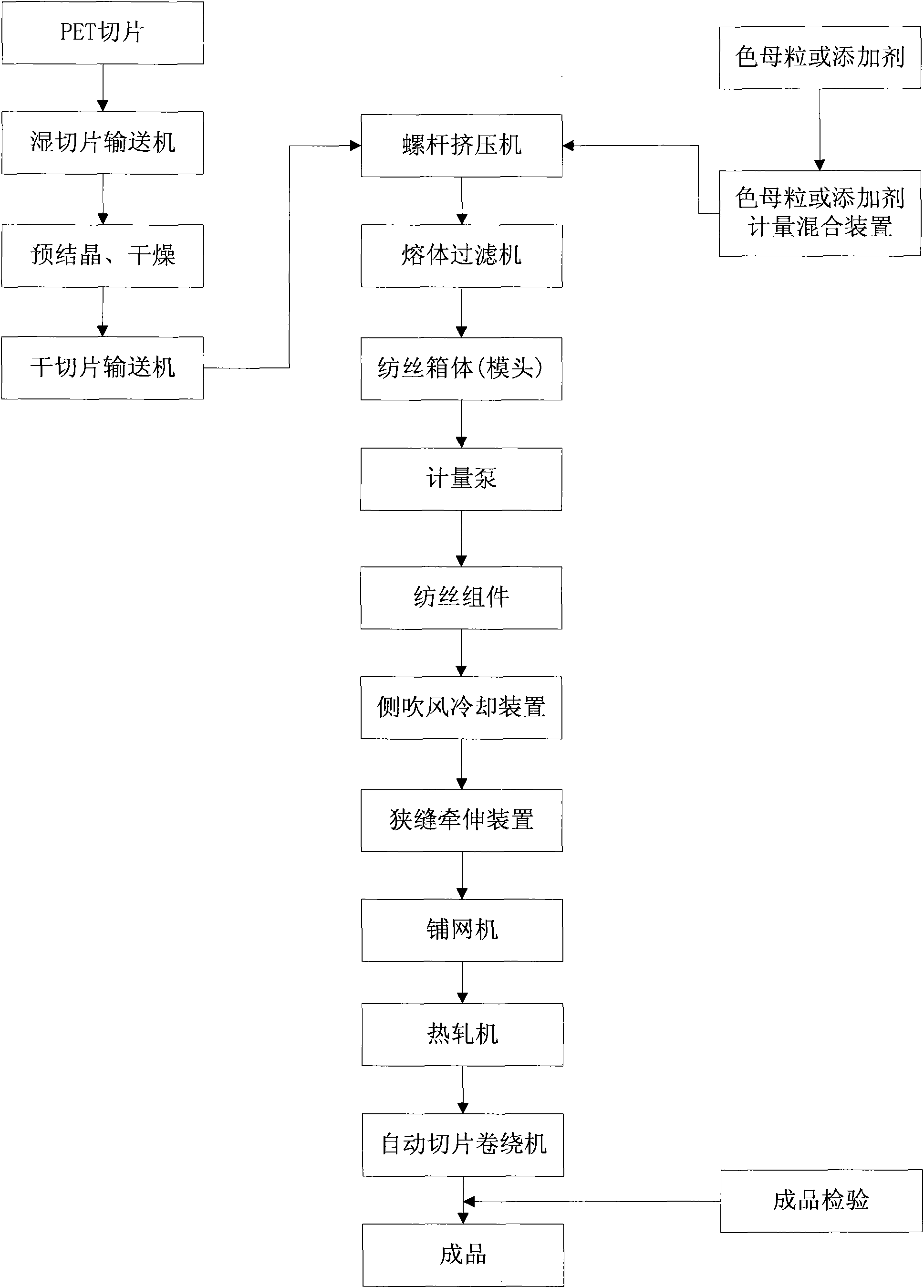

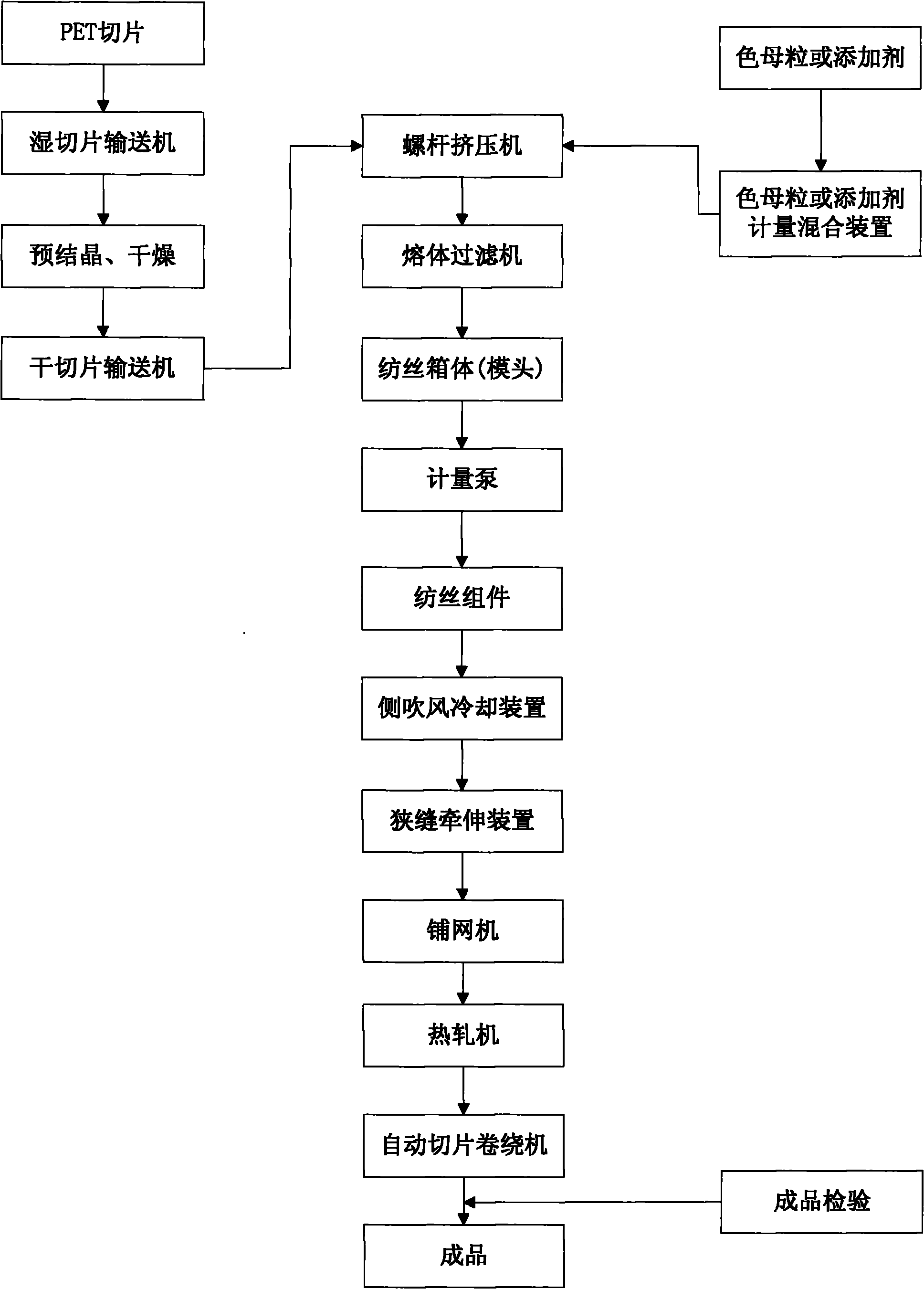

[0028] After the polyester chips are dried, the dried chips fall into the screw by their own weight for melting. At the entrance of the screw, a color masterbatch machine is used to add green masterbatch, and melt together with the polyester chips. After passing through the melt filter, the spinning box , spinning assembly, air stretching, web forming machine, hot rolling mill, and winding machine are directly rolled into cloth. This green non-woven fabric is stamped into various shapes of flower leaves by dies, and then after 180 The temperature of the stamping die can be set at a high temperature, and various flowers and leaves can be made. Therefore, using non-woven fabrics instead of woven fabrics to make simulated plants, compared with traditional production processes, the production method is more environmentally friendly and lower carbon.

Embodiment 2

[0029] The rhizome preparation of embodiment 2 simulation plants

[0030] After the polyester chips are dried, the dried chips fall into the screw by their own weight for melting. At the entrance of the screw, a color masterbatch machine is used to add green masterbatch, and melt together with the polyester chips. After passing through the melt filter, the spinning box , spinning components, air stretching, web forming machine, hot rolling mill, and winding machine are directly rolled into cloth. This green non-woven fabric is stamped into rhizomes of various shapes by molds, and then passed through 180 degrees The temperature of the stamping die can be set to make various flowers and leaves. Therefore, using non-woven fabrics instead of woven fabrics to make simulated plants, compared with traditional production processes, the production method is more environmentally friendly and lower carbon.

[0031] The leaf preparation of embodiment 2 simulation plants

[0032] After th...

Embodiment 3

[0033] Petal preparation of embodiment 3 simulation plants

[0034] Production of plant leaves: After drying polyester slices, the dried slices fall into the screw by their own weight for melting. At the entrance of the screw, use a color masterbatch machine to add pink masterbatch, melt together with the polyester slices, and pass through the melt filter. , spinning box, spinning assembly, air stretching, web forming machine, hot rolling mill, and winding machine are directly rolled into cloth. This green non-woven fabric is stamped into flowers of various shapes by molds. The leaves can be made into various petals after the temperature of the stamping die is set at 170 degrees. Therefore, non-woven fabrics are used instead of woven fabrics to make simulated plants. Compared with traditional production processes, the production method is more environmentally friendly and low-carbon. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com