Preparation method of vinyl carboxylate

A technology of vinyl carboxylate and vinyl acetate, which is applied in the field of fine chemical new catalysts, can solve the problems of high price, high cost, and pollution, and achieve the advantages of simple preparation method, low equipment corrosion, and improved dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

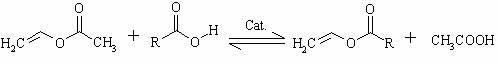

Method used

Image

Examples

example 1

[0030] Weigh HgSO 4 1 g of powder was dissolved in 0.1 mol / L HCl and placed in a flask, and 5 g of treated activated carbon was added (the activated carbon was pretreated with 30% nitric acid solution), stirred and impregnated at 60 °C for 10 h, evaporated The solvent was removed, dried at 100 °C to constant weight, and calcined at 200 °C for 2 h to obtain supported HgSO 4 / C solid catalyst.

[0031] Add 23.7 g (0.15 mol) of nonanoic acid, 90.3 g (1.05 mol) of vinyl acetate, and 3.42 g (3.0 %) of catalyst into a 500 mL four-neck flask equipped with a thermometer, a condenser tube and a stirrer, accounting for the total mass of the reactants. Mass percent, the same below), heated to reflux, stirred for 10 h, cooled to room temperature, filtered to separate the catalyst, and gas chromatography analyzed the contents of each component of the reaction product as follows:

[0032] components content(%) vinyl acetate 69.6 nonanoic acid 3.1 acetic acid 6...

example 2

[0035] Weigh HgSO 4 1 g of powder, dissolved in 0.1 mol / L HCl, was placed in a flask, 5 g of activated carbon treated with 30% nitric acid solution was added, stirred and impregnated at 60 °C for 10 h, evaporated to remove the solvent, and dried at 100 °C to Constant weight, calcined at 200 °C for 2 h to obtain supported HgSO 4 / C solid catalyst.

[0036] Add 17.4 g (0.15 mol) of hexanoic acid, 90.3 g (1.05 mol) of vinyl acetate, and 3.23 g (3.0%) of catalyst into a 500 mL four-necked flask equipped with a thermometer, condenser and stirrer, and heat up to reflux. Stir the reaction for 10 h, cool to room temperature, filter and separate the catalyst, and analyze the contents of each component of the reaction product by gas chromatography as follows:

[0037] components content(%) vinyl acetate 73.3 caproic acid 1.9 acetic acid 7.4 product 17.4

[0038] The calculated yield of vinyl hexanoate was 87.9%.

example 3

[0040] Weigh HgSO 4 1 g of powder, dissolved in 0.1 mol / L HCl, was placed in a flask, 5 g of activated carbon treated with 30% nitric acid solution was added, stirred and impregnated at 60 °C for 10 h, evaporated to remove the solvent, and dried at 100 °C to Constant weight, calcined at 200 °C for 2 h to obtain supported HgSO 4 / C solid catalyst.

[0041] Add 13.2 g (0.15 mol) of butyric acid, 90.3 g (1.05 mol) of vinyl acetate, and 3.11 g (3.0%) of catalyst into a 500 mL four-necked flask equipped with a thermometer, condenser and stirrer, and heat up to reflux. Stir the reaction for 10 h, cool to room temperature, filter and separate the catalyst, and analyze the contents of each component of the reaction product by gas chromatography as follows:

[0042] components content(%) vinyl acetate 76.2 butyric acid 1.5 acetic acid 7.7 product 14.6

[0043] The calculated vinyl butyrate yield was 88.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com