Production method of high strength heat bonding non-woven fabric

A production method and technology of non-woven fabrics, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of non-woven fabrics such as heavy weight, high cost, and low air permeability, and achieve simple and environmentally friendly production methods, good air permeability, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

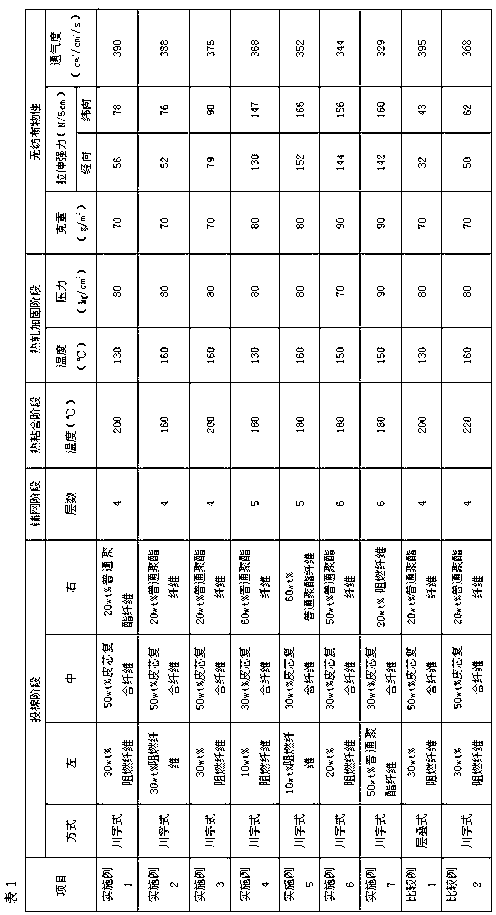

[0022] 30% by weight of flame-retardant fibers, 50% by weight of skin-core composite fibers, and 20% by weight of ordinary polyester fibers are fed and opened side by side in a Sichuan-style pattern, left, middle, and right, and cross-laid to form fibers after two passes of carding. Then lay 4 layers of the above-mentioned fiber webs, and thermally bond the obtained 4 layers of fiber webs through a hot air box with a temperature of 200 ° C, and then heat the thermally bonded fiber webs at a temperature of 130 ° C , the pressure is 80kg / cm 2 Reinforced under a hot metal roller, and finally a high-viscosity thermally bonded non-woven fabric is obtained. The physical properties of the non-woven fabric are shown in Table 1.

Embodiment 2

[0024] 30% by weight of flame-retardant fibers, 50% by weight of skin-core composite fibers, and 20% by weight of ordinary polyester fibers are fed and opened side by side in a Sichuan-style pattern, left, middle, and right, and cross-laid to form fibers after two passes of carding. Then lay 4 layers of the above-mentioned fiber webs, and thermally bond the obtained 4 layers of fiber webs through a hot air box with a temperature of 160°C. , the pressure is 80kg / cm 2 Reinforced under a hot metal roller, and finally a high-viscosity thermally bonded non-woven fabric is obtained. The physical properties of the non-woven fabric are shown in Table 1.

Embodiment 3

[0026] 30% by weight of flame-retardant fibers, 50% by weight of skin-core composite fibers, and 20% by weight of ordinary polyester fibers are fed and opened side by side in a Sichuan-style pattern, left, middle, and right, and cross-laid to form fibers after two passes of carding. Then lay 4 layers of the above-mentioned fiber webs, and thermally bond the obtained 4 layers of fiber webs through a hot air box with a temperature of 200°C, and then place the thermally bonded fiber web layers at a temperature of 160°C , the pressure is 80kg / cm 2 Reinforced under a hot metal roller, and finally a high-viscosity thermally bonded non-woven fabric is obtained. The physical properties of the non-woven fabric are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com