Genetically engineered bacterium for high yield of farnesene and construction method and application thereof

A technology of genetically engineered bacteria and construction methods, applied in the field of genetically engineered bacteria with high farnesene production and its construction, can solve the problems of low catalytic efficiency and host toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

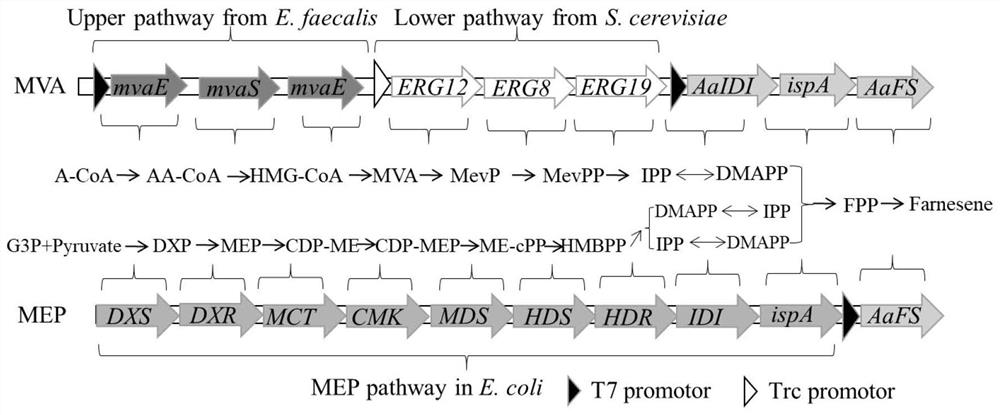

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1. The construction method of the genetically engineered bacteria of synthesizing farnesene.

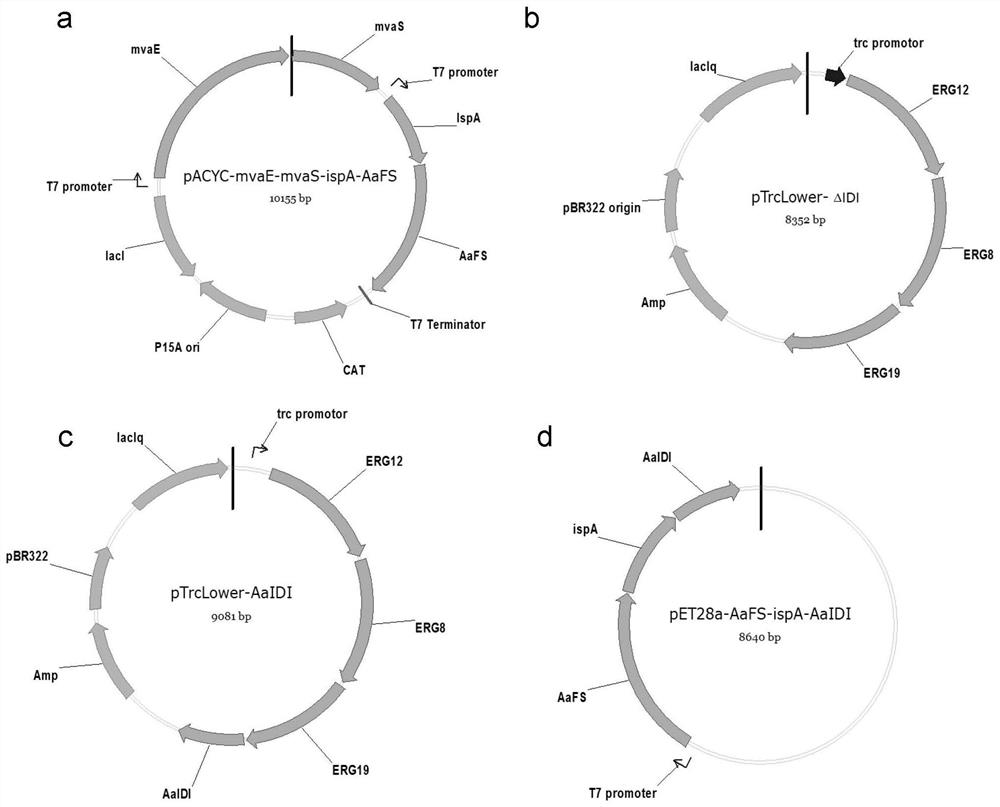

[0049]1) Construction of plasmid pACYC-mvaE-mvaS-ispA-AaFS: The gene sequence of β-farnesene synthase AaFS from Artemisia annua was optimized by codon preference in Escherichia coli, and restriction endonucleases BglII and XhoI were added at both ends The restriction site was synthesized by BGI. The synthesized sequence is shown in SEQ ID No: 4, and cloned into the pUC57-simple vector to obtain the plasmid pUC57-AaFS. Plasmid pACYC-mvaE-mvaS-ispA-AaFS (attached figure 2 The construction shown in a) adopts the method of enzyme cutting-ligation. Firstly, the plasmids pACYC-mvaE-mvaS-ispA-Sab1 and pUC57-AaFS were double-digested with restriction endonucleases BglII and XhoI respectively. The restriction enzyme digestion system was as follows:

[0050]

[0051] The digested product was recovered by agarose gel electrophoresis and gel tapping of the target band. Th...

Embodiment 2

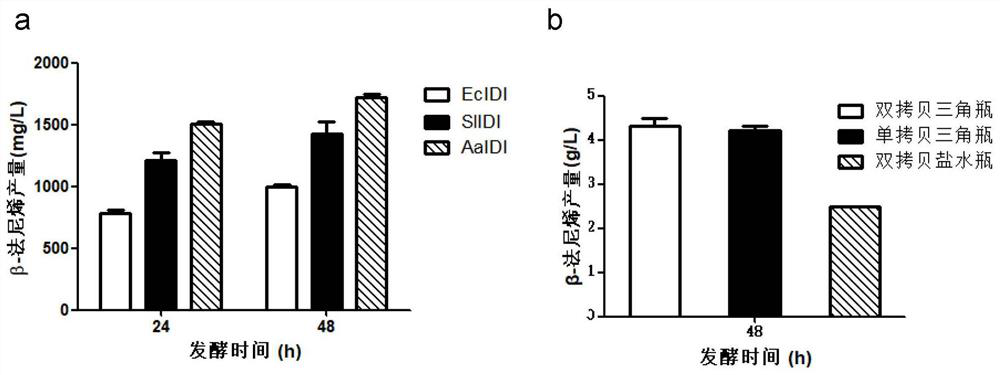

[0079] Embodiment 2. Application of each genetically engineered bacterium constructed in embodiment 1 in the synthesis of farnesene.

[0080] For the quantitative detection of farnesene by gas chromatography described in this example, the chromatographic column is an Agilent DB-5MS (30m×0.25mm×0.25μm) capillary column. The temperature was raised to 300°C at a rate of ℃ / min and kept for 2 minutes, and then lowered to the initial temperature. The standard curve of β-farnesene (y=0.4582x+0.3383, x is the concentration of β-farnesene standard in g / L; y is the peak area of β-farnesene) was used for quantification.

[0081] The primary seed medium described in this example is LB medium, and its composition is: 10g / L NaCl, 10g / L peptone, 5g / L yeast extract, and the rest is water.

[0082] The shake flask fermentation medium composition is: 20g / L glucose, 9.8g / L K 2 HPO 4 , 5g / L beef extract, 0.3g / L ferric ammonium citrate, 2.1g / L citric acid monohydrate, 0.06g / L MgSO 4 , 1mL / L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com