Equipment and method for continuously producing vulcanization accelerator CBS

A technology of vulcanization accelerator and accelerator, which is applied in the direction of chemical instruments and methods, feeding devices, organic chemistry, etc., can solve the problems of low product yield, heavy labor workload, product quality fluctuations, etc., and achieve high safety performance, The effect of stable product quality and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

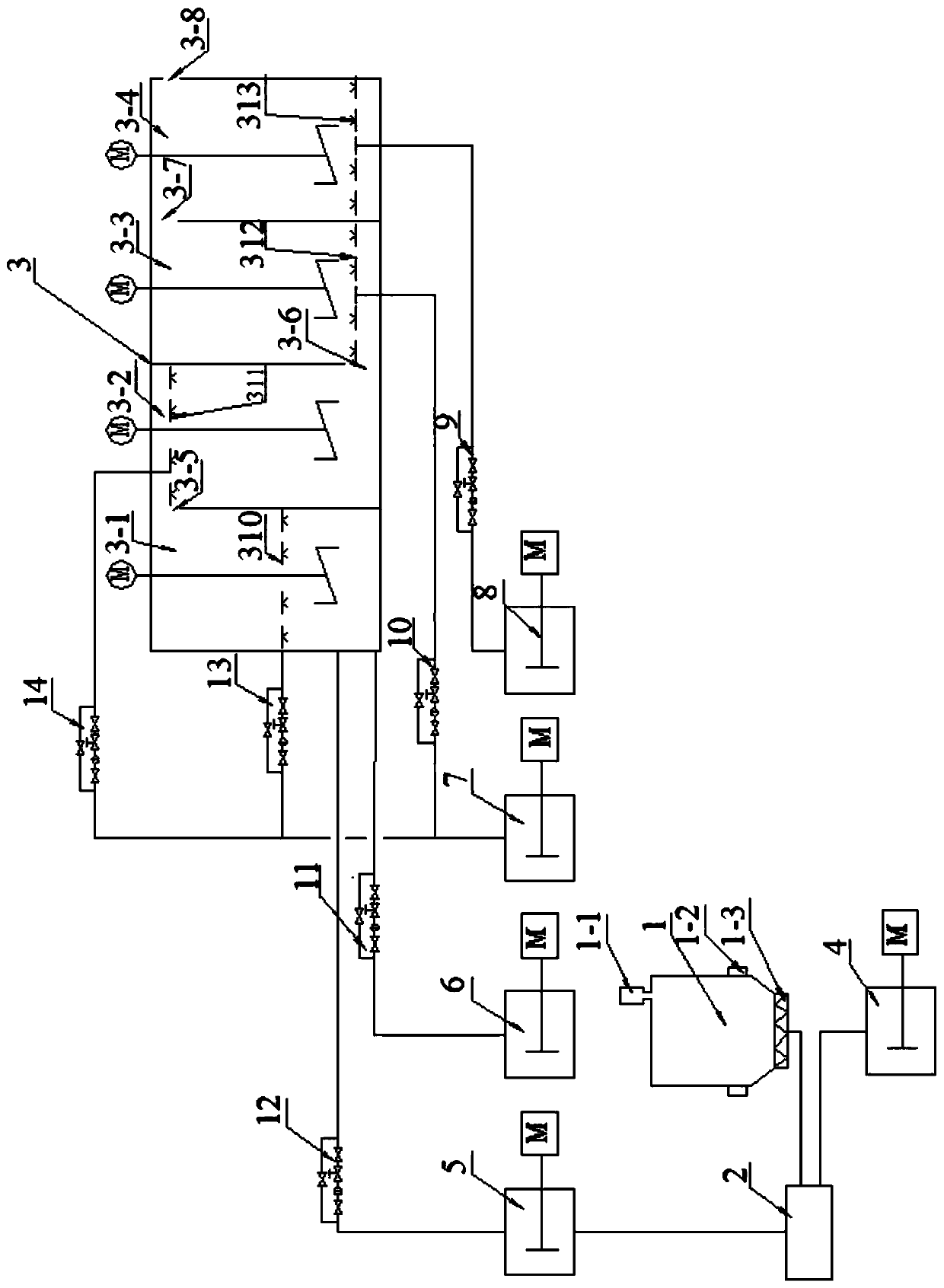

[0045] Equipment for continuous production of vulcanization accelerator CBS

[0046] Such as figure 1 As shown, a kind of equipment for continuous production of vulcanization accelerator CBS, including accelerator M silo 1, water metering pump 4, continuous mixing device 2, continuous reaction device 3, M slurry metering pump 5, cyclohexylamine metering pump 6. Hydrogen peroxide metering pump 7. Sodium hypochlorite metering pump 8.

[0047] The continuous reaction device 3 is composed of a first reaction chamber 3-1, a second reaction chamber 3-2, a third reaction chamber 3-3 and a fourth reaction chamber 3-4.

[0048]The top of the first reaction chamber 3-1 is provided with the first opening 3-5 communicating with the second reaction chamber 3-2; the bottom of the second reaction chamber 3-2 is provided with the first opening 3-5 communicating with the third reaction chamber 3-3. Two openings 3-6; the top of the third reaction chamber 3-3 is provided with the third opening...

Embodiment 2

[0061] Adopt the method for the continuous production vulcanization accelerator CBS of equipment among the embodiment 1, comprise steps:

[0062] 1) The accelerator M enters the continuous mixing device from the accelerator M silo, and at the same time, the water enters the continuous mixing device through the water metering pump; the accelerator M and water are mixed evenly in the continuous mixing device at a mass ratio of 1:1. forming M slurry;

[0063] 2) Transport the M slurry to the first reaction chamber 3-1, and add a certain amount of cyclohexylamine to the first reaction chamber 3-1, and send it to the first reaction chamber 3-1 and the second reaction chamber 3-2 1. Pump hydrogen peroxide into the third reaction chamber 3-3, and pump sodium hypochlorite into the fourth reaction chamber 3-4;

[0064] M slurry flow regulating valve group 12 and cyclohexylamine flow regulating valve group 11 regulate the volume ratio of M slurry and cyclohexylamine; the flow of hydrog...

Embodiment 3

[0072] Adopt the method for the continuous production vulcanization accelerator CBS of equipment among the embodiment 1, comprise steps:

[0073] 1) The accelerator M enters the continuous mixing device from the accelerator M silo, and at the same time, the water enters the continuous mixing device through the water metering pump; the accelerator M and water are mixed evenly in the continuous mixing device at a mass ratio of 1:1. forming M slurry;

[0074] 2) Transport the M slurry to the first reaction chamber 3-1, and add a certain amount of cyclohexylamine to the first reaction chamber 3-1, and send it to the first reaction chamber 3-1 and the second reaction chamber 3-2 1. Pump hydrogen peroxide into the third reaction chamber 3-3, and pump sodium hypochlorite into the fourth reaction chamber 3-4;

[0075] M slurry flow regulating valve group 12 and cyclohexylamine flow regulating valve group 11 regulate the volume ratio of M slurry and cyclohexylamine; the flow of hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com