Method for preparing two-component pre-mixed mortar by mixing twice

A technology for ready-mixed mortar and production method, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as too large difference in specific gravity and particle size, inability to guarantee engineering quality, and impact on mortar quality, etc. To achieve the effect of increasing the utilization rate of bulk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

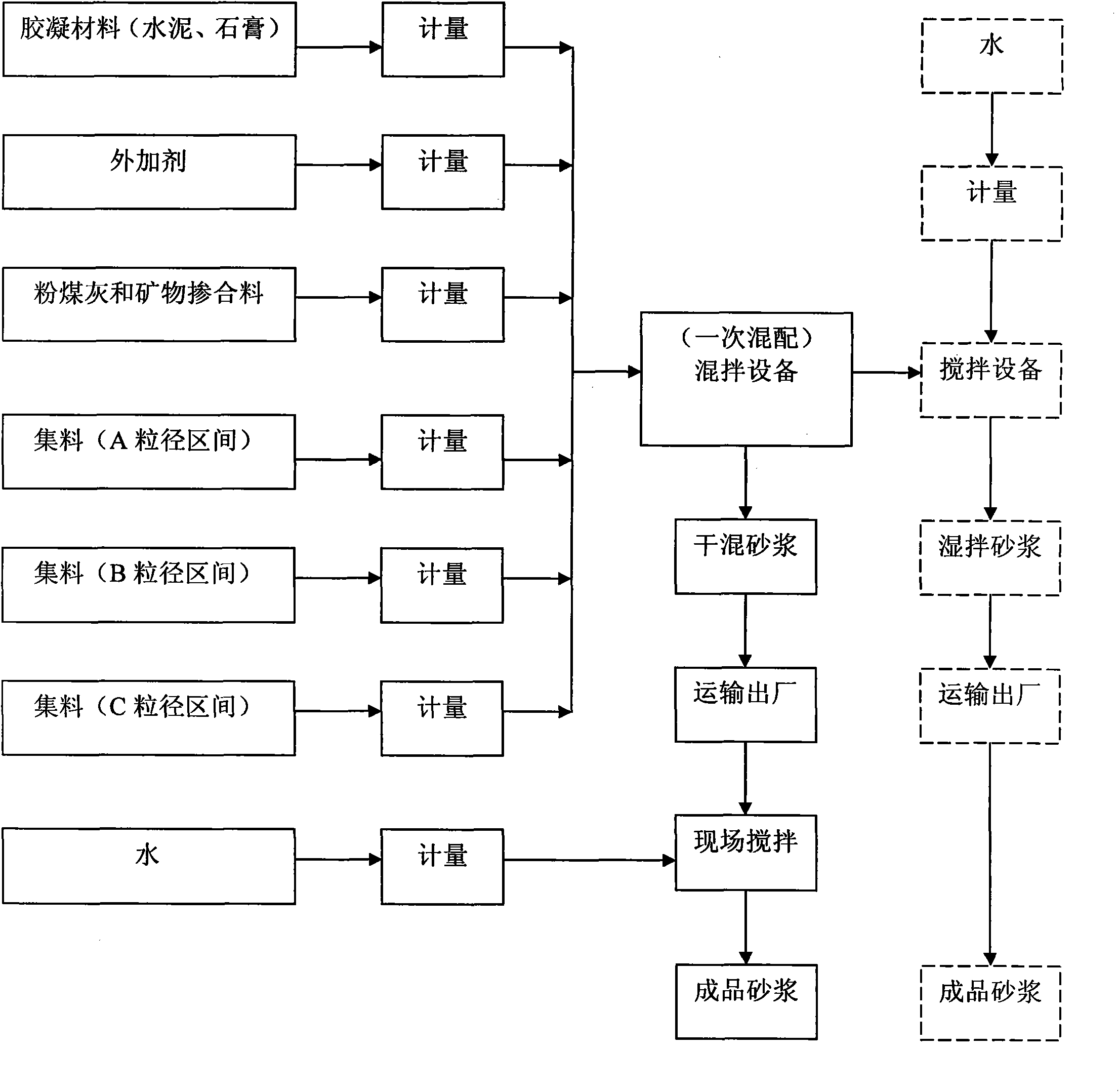

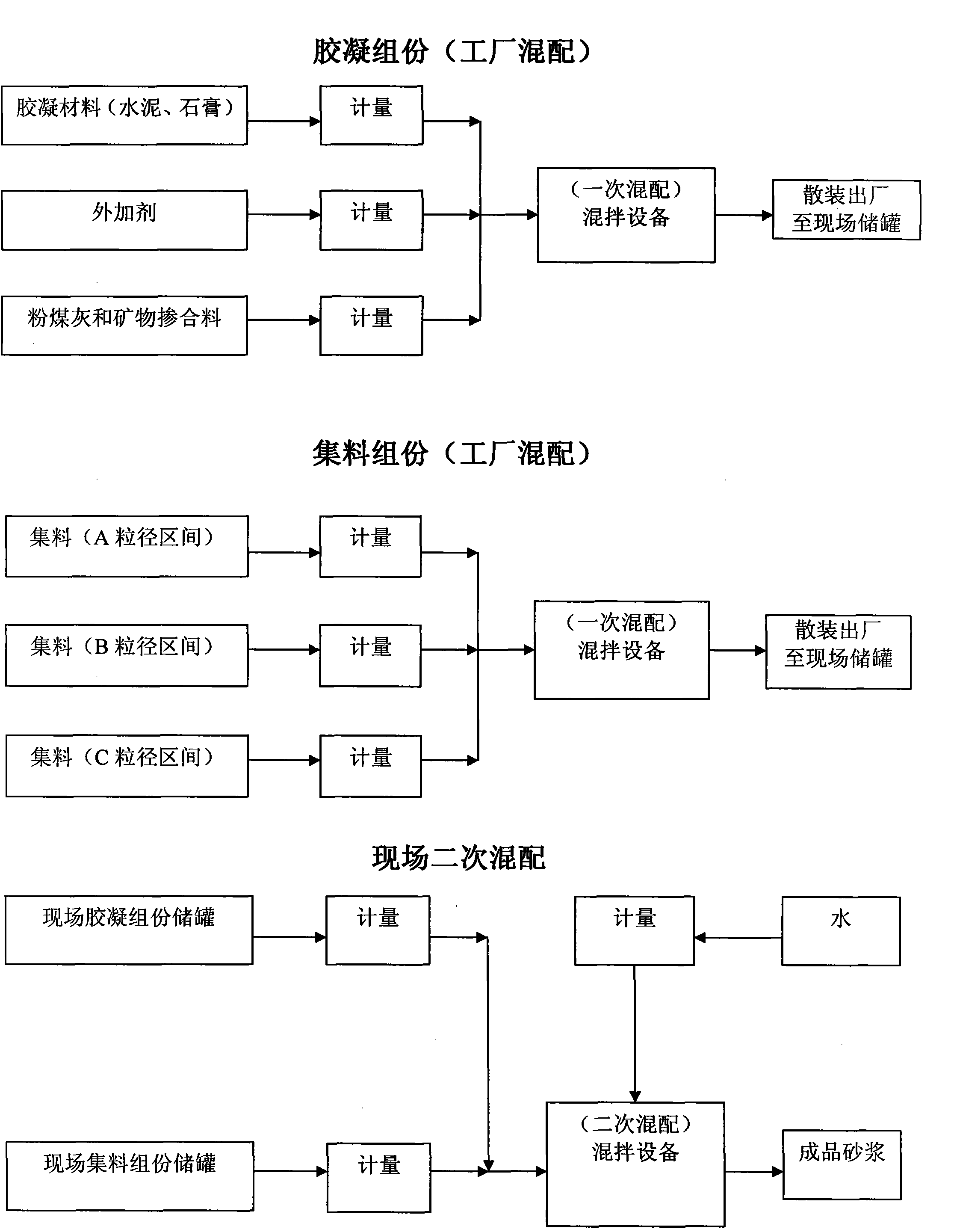

[0025] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0026] attached figure 2 The technical process of the present invention is given. In the present invention, components such as cement or gypsum, additives for improving mortar properties, fly ash or other mineral admixtures are separately measured, mixed and stirred to form a cementitious component, The aggregates that meet the requirements of various particle sizes are measured, mixed and stirred in a certain proportion to make aggregate components, and 30% of the gelling components and 70% of the aggregate components are transported to the respective storage on the construction site with bulk equipment. After being measured, it is mixed for the second time, and then mixed with 15% of the water of the mortar weight to form a two-component ready-mixed mortar (two pairs of mortar).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com