A kind of preparation method of conductive hydrogel based on one-dimensional nano polypyrrole

A technology of nano polypyrrole and conductive hydrogel, which is applied in the field of preparing conductive hydrogel, can solve the problems that conductive polymer hydrogel is difficult to have a weave structure, interfere with conductive polymer, etc., so as to avoid swelling and have strong applicability , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

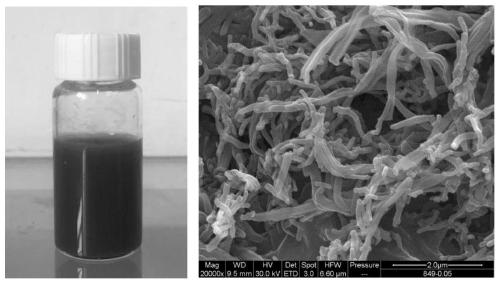

[0031] A preparation method based on one-dimensional nano polypyrrole conductive hydrogel, the steps of which are:

[0032] Step 1: According to parts by mass, add 0.1 parts of methyl orange to 50 parts of deionized water, apply ultrasonic waves to dissolve and disperse evenly, and then add 2 parts of pyrrole to the solution;

[0033] Step 2: take ferric chloride, the mol ratio of ferric chloride and pyrrole in step 1 is 1:1, ferric salt is dissolved in 50 parts of deionized water;

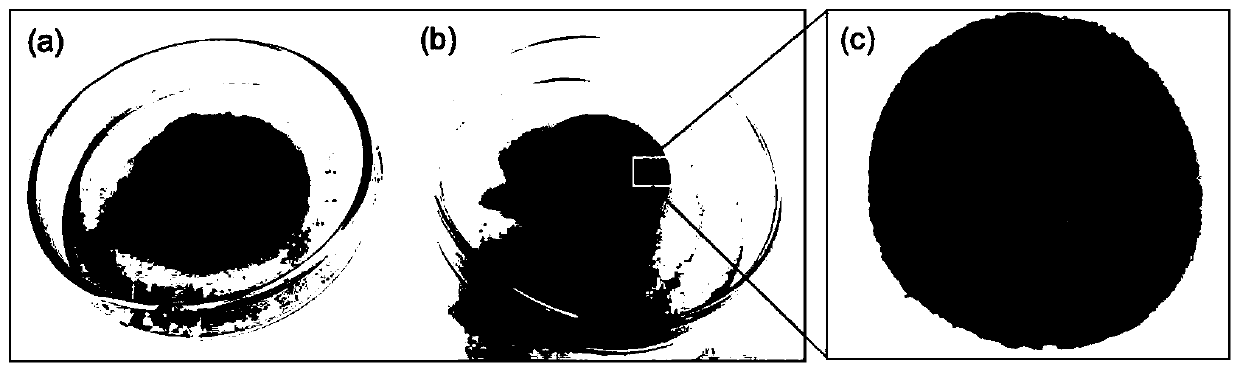

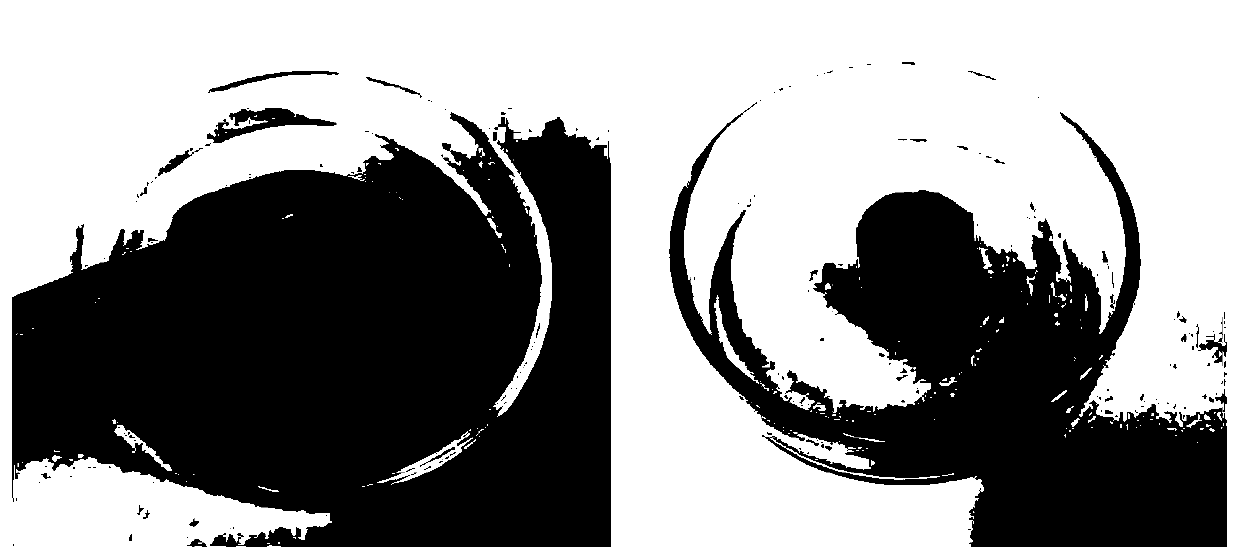

[0034]Step 3: quickly mix the solution obtained in step 1 and step 2, leave it at room temperature for 6h, depressurize the resulting product to 0.7atm, and filter with suction to obtain a filter cake, while washing and filtering with 0.2mol / L hydrochloric acid solution Cake until the filtrate is nearly colorless, and the filter cake is condensed to a porous sponge-like structure by pumping air to obtain a one-dimensional nano-polypyrrole;

[0035] Step 4: Under the condition of decompression and...

Embodiment 2

[0037] A preparation method based on one-dimensional nano polypyrrole conductive hydrogel, the steps of which are:

[0038] Step 1: According to parts by mass, add 0.2 parts of methyl orange to 50 parts of deionized water, apply ultrasonic waves to dissolve and disperse evenly, and then add 1.5 parts of pyrrole to the solution

[0039] Step 2: take ferric sulfate, the mol ratio of ferric sulfate and the pyrrole in step 1 is 2:1, ferric salt is dissolved in 50 parts of deionized water;

[0040] Step 3: quickly mix the solution obtained in step 1 and step 2, leave it at room temperature for 12h, depressurize the product obtained by 0.6atm, and filter with suction to obtain a filter cake, while washing and filtering with 0.2mol / L hydrochloric acid solution Cake until the filtrate is nearly colorless, and the filter cake is condensed to a porous sponge-like structure by pumping air to obtain a one-dimensional nano-polypyrrole;

[0041] Step 4: Under the condition of decompression...

Embodiment 3

[0043] A preparation method based on one-dimensional nano polypyrrole conductive hydrogel, the steps of which are:

[0044] Step 1: According to parts by mass, add 0.3 parts of Orange I to 50 parts of deionized water, apply ultrasonic waves to make it dissolve and disperse evenly, and then add 1.5 parts of pyrrole to this solution

[0045] Step 2: take ferric nitrate, the mol ratio of ferric nitrate salt and pyrrole in step 1 is 2:1, ferric salt is dissolved in 50 parts of deionized water;

[0046] Step 3: quickly mix the solution obtained in step 1 and step 2, leave it at room temperature for 24h, depressurize the product obtained by 0.5atm, and filter with suction to obtain a filter cake, while washing and filtering with 0.5mol / L hydrochloric acid solution Cake until the filtrate is nearly colorless, and the filter cake is condensed to a porous sponge-like structure by pumping air to obtain a one-dimensional nano-polypyrrole;

[0047] Step 4: Under the condition of decompre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com