Refining ladle flow diverter and preparation method thereof

A diverter and ladle technology, which is applied in casting equipment, manufacturing tools, metal processing equipment, etc., can solve the problem of low self-opening rate of ladle, and achieve the effect of large proportion, stable use quality, and market use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

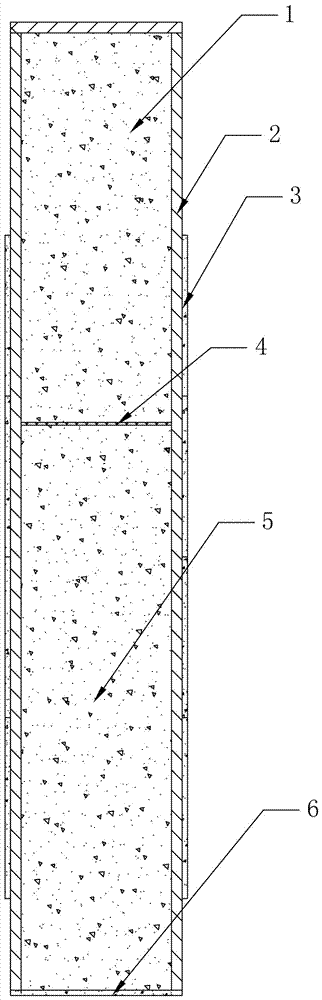

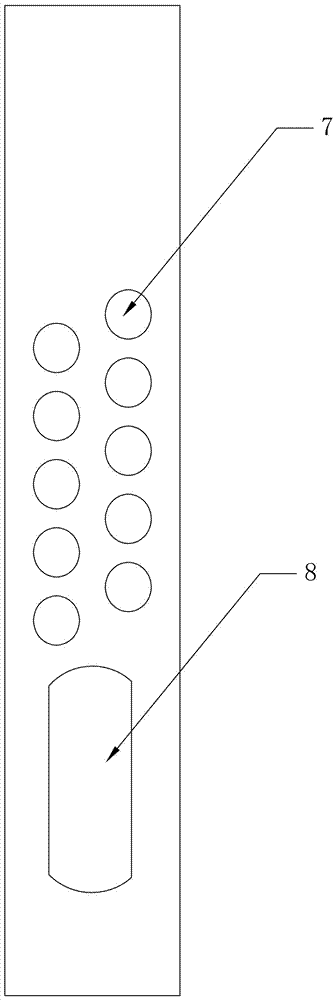

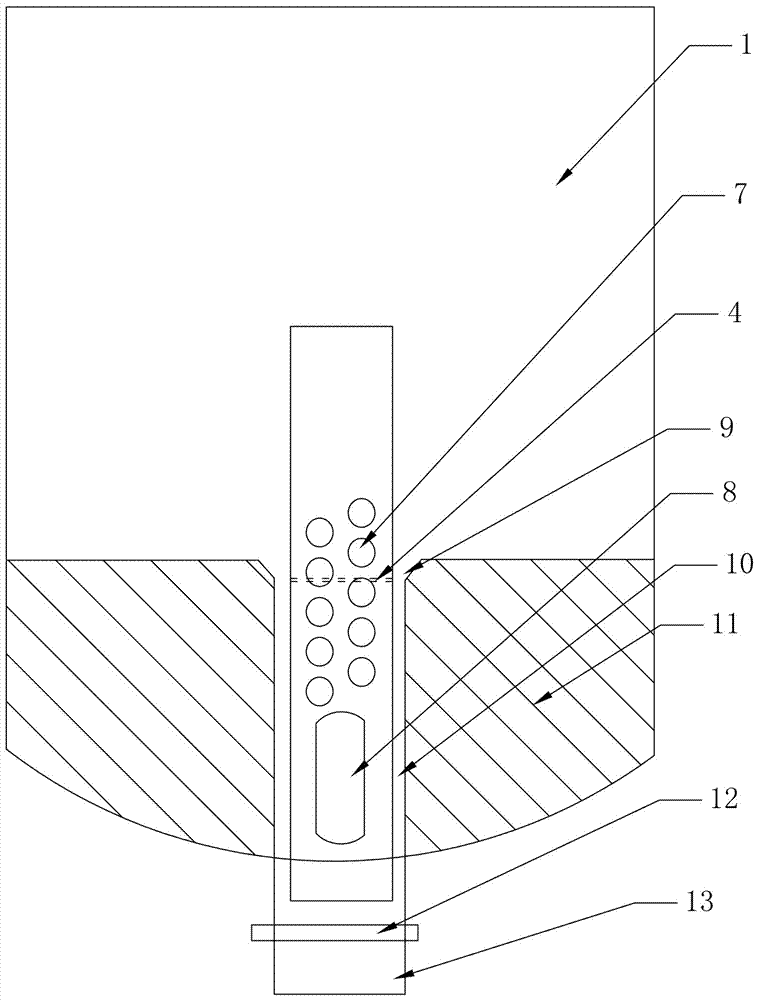

[0030] A refining ladle diverter, comprising a diverter main body 2, the diverter main body 2 is a hollow cylindrical steel pipe with one end sealed, the diverter main body 2 is provided with a diversion hole 7 and a diversion window 8, the The inner wall of the diverter main body 2 is coated with a carbon layer, the diversion hole 7 and the diversion window 8 are sealed by the fusible sheet 3 of the diverter, the open end of the diverter body 2 is sealed by the fusible sheet 6 at the open end, and is located at the drain 13 and the drainer main body 2 of the seat brick 11 are filled with lower filling sand 5, and the drainer main body 2 above the bottom of the bowl of the seat brick 11 is filled with upper filling sand 1, and the upper filling sand 1 and the lower filling sand 5 pass through the middle easily. The melt sheets 4 are separated.

[0031] The outer diameter of the diverter main body 2 is 3-5mm smaller than the inner diameter of the water bag, the height is 1.5-2....

Embodiment 2

[0047] It is basically the same as Example 1, except that the carbon layer includes 96% of flake graphite and 4% of corn dextrin in terms of weight percentage.

[0048] The upper filling sand 1 is calculated by weight percentage, including 75% of foundry chrome sand, 5% of potassium feldspar sand, 8% of washed sea sand, 11% of quartz sand, 0.6% of carbon black, and 0.4% of phosphorus flake graphite.

[0049] The lower filling sand is calculated by weight percentage, 85% of foundry chrome sand, 6% of ceramsite sand, 8% of desert silica sand, and 1% of phosphorus flake graphite.

Embodiment 3

[0051] It is basically the same as Example 1, except that the carbon layer includes 97% of flake graphite and 3% of corn dextrin in terms of weight percentage.

[0052] The upper filling sand 1 is calculated by weight percentage, including 80% of foundry chrome sand, 3% of potassium feldspar sand, 6% of washed sea sand, 10% of quartz sand, 0.7% of carbon black, and 0.3% of phosphorus flake graphite.

[0053] The lower filling sand is calculated by weight percentage, 90% of foundry chrome sand, 4.2% of ceramsite sand, 5% of desert silica sand, and 0.8% of phosphorus flake graphite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com