Patents

Literature

51results about How to "Improve self-opening rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon-free steel ladle drainage agent for extremely-low carbon steel

ActiveCN102233412AReasonable particle size matchingImprove high temperature fluidityMelt-holding vesselsTO-18BULK ACTIVE INGREDIENT

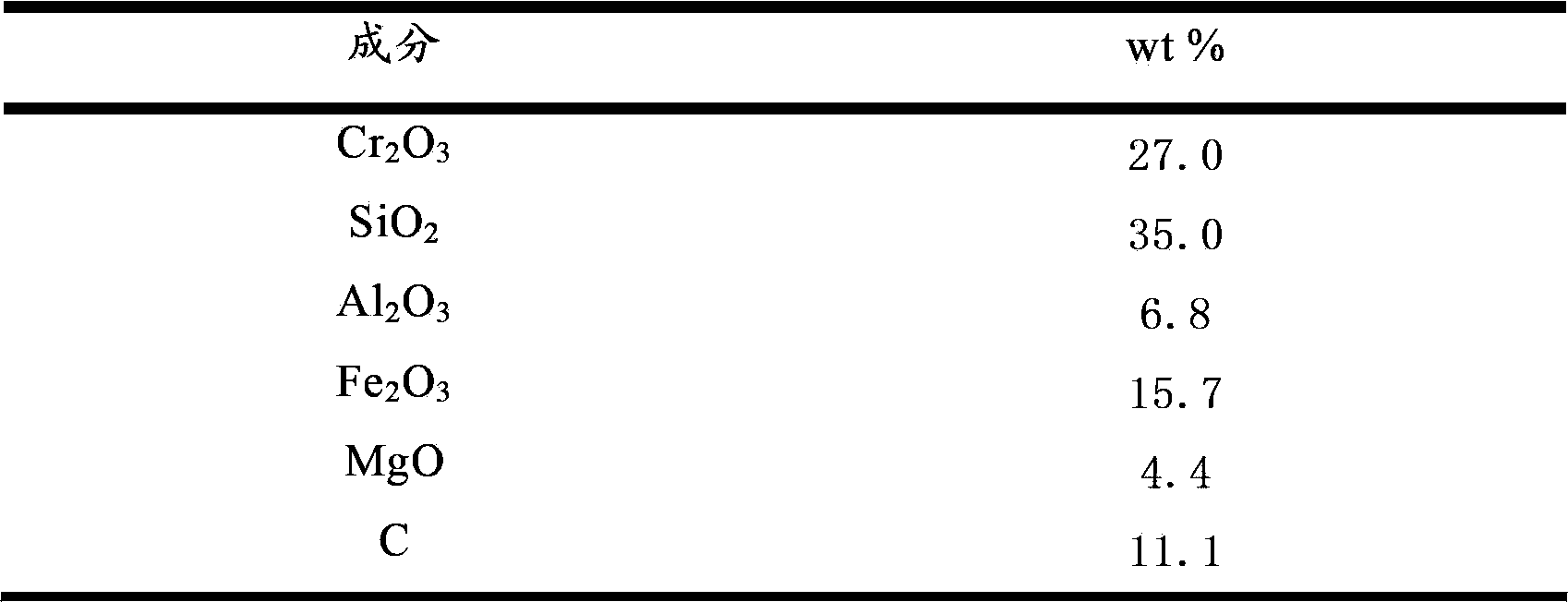

The invention discloses a carbon-free steel ladle drainage agent for extremely-low carbon steel. The carbon-free steel ladle drainage agent for the extremely-low carbon steel comprises the following active ingredients in percentage by mass: 20 to 36 percent of Cr2O3, 10 to 40 percent of SiO2, 10 to 25 percent of Fe2O3, 5 to 18 percent of Al2O3 and 10 to 20 percent of MgO. The carbon-free steel ladle drainage agent for the extremely-low carbon steel comprises the following active ingredients of 31.28 percent of Cr2O3, 23.52 percent of SiO2, 14.71 percent of MgO, 19.09 percent of Fe2O3 and 9.86percent of Al2O3. The carbon-free steel ladle drainage agent for the extremely-low carbon steel is prepared from the following raw materials in percentage by mass: 50 to 80 percent of chromite sand, 10 to 30 percent of white quartz and 8 to 20 percent of electro-fused magnesia.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

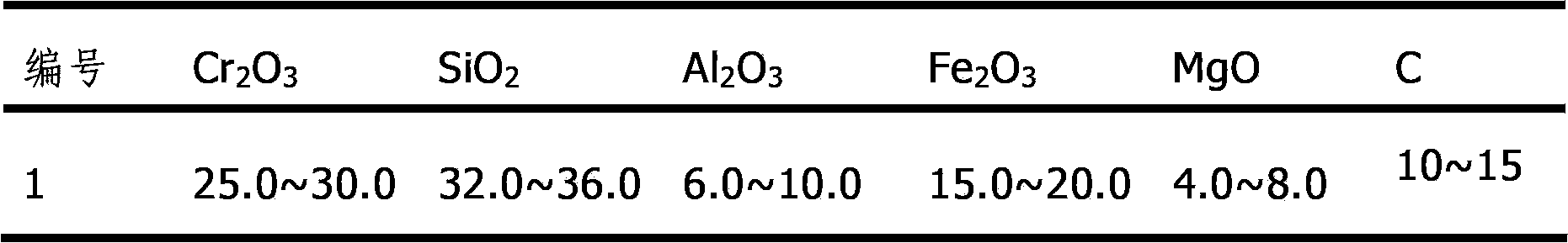

Chrome drainage sand for special steel and preparation technology thereof

InactiveCN101972847AImprove self-opening rateSuitable for sinteringMelt-holding vesselsTO-18Graphite

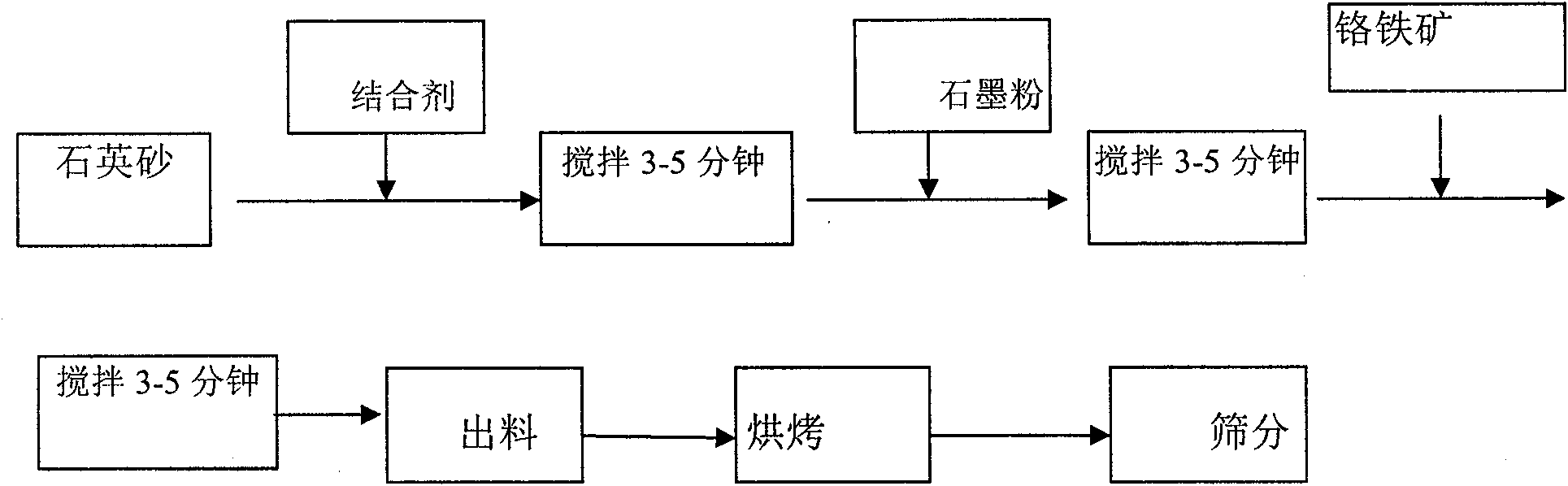

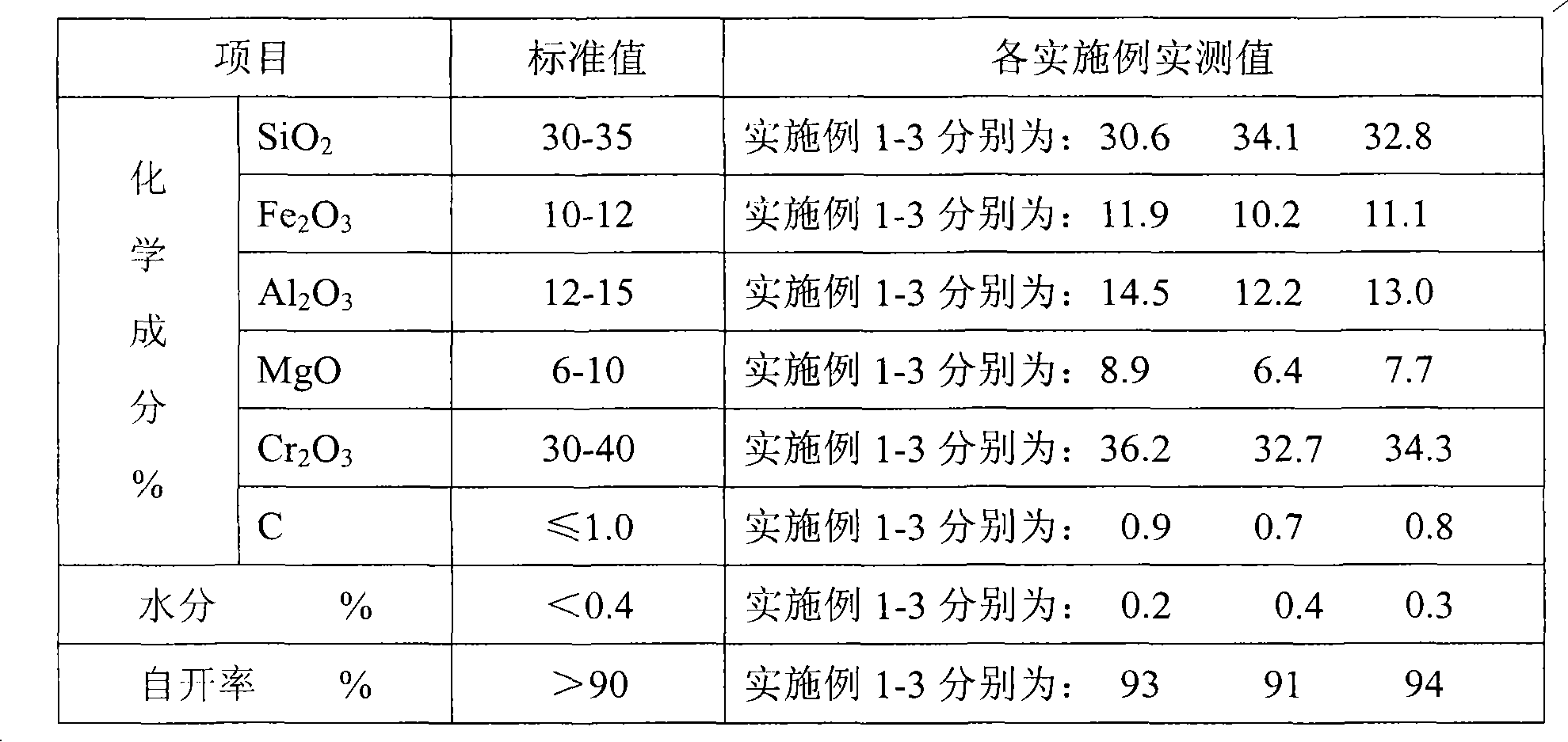

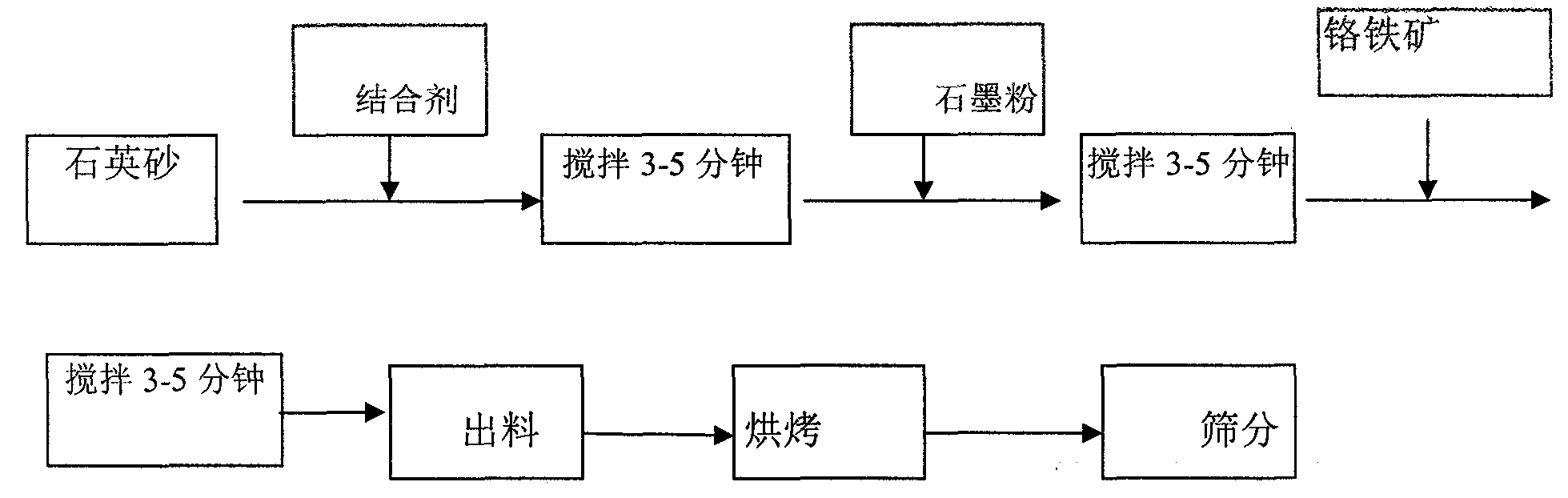

The invention relates to chrome drainage sand for special steel and a preparation technology thereof, belonging to the technical field of steel smelting. The chrome drainage sand for special steel comprises the following components in percentage by mass: 28-33 % of quartz sand as aggregate, 62-70 % of ferrochrome as a base material, 1-1.5 % of graphite powder as an additive and 0.5-1.5 % of phenolic resin as a bonding agent. The preparation technology comprises: 1) in mixing equipment, adding 28-33 % of quartz sand and 0.5-1.5 % of bonding agent phenolic resin, stirring, and adding 1-1.5 % of graphite powder and stirring after the quartz sand particles are completely wetted; after the graphite powder and the quartz sand particles are evenly mixed, adding 62-70 % of ferrochrome ore, and continuously stirring to obtain an even mixture; 2) adding the well mixed chrome drainage sand into a roasting kiln for roasting, wherein the highest roasting temperature is 200 DEG C, and the total roasting time is equal to 18 hours; and 3) removing fake particles in the chrome drainage sand, and screening the product particles to cause the product particles to have suitable bulk density. Aiming at the requirement of smelting special steel, the invention develops special chrome drainage sand and causes self opening rate of the chrome drainage sand to be above 90%.

Owner:上海盛江特种耐火材料有限公司

Special steel ladle draining sand for stainless steel and production process thereof

ActiveCN102001854AContinuous casting processReduce steelmaking costsMelt-holding vesselsOxygenMolten steel

The invention discloses a special steel ladle draining sand for stainless steel and a production process thereof. The product and the process can effectively improve the self-opening rate of a steel ladle, greatly relieve the labor intensity of workers, reduce oxygen-blast draining times, improve the quality of molten steel and ensure the progressive execution of a continuous casting process. When the stainless steel is produced by using the steel ladle draining sand, the self-opening rate of the steel ladle can reach above 98% so that the purposes of fewer oxygen-blast draining times, high quality of molten steel and progressive execution of the continuous casting process are achieved, and simultaneously, the total steel-making cost of a steel mill is also reduced.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Passivated drainage sand with coating for ladle refining and preparation method thereof

InactiveCN102659425AIncrease surface tensionReduce penetrationMelt-holding vesselsRefractoryConstruction aggregate

The invention relates to passivated drainage sand with a coating for ladle refining and a preparation method thereof. The drainage sand comprises an aggregate composed of chromite sand and silica sand; the surface of the aggregate is coated with an impregnating compound; refractory powder is adhered to the surface of the impregnating compound, and passivation solution is coated outside the refractory powder. The preparation method comprises the following steps: uniformly agitating the aggregate prepared by mixing the chromite sand with the silica sand; then spraying the impregnating compound into the aggregate by adopting an atomizer, uniformly agitating, adding a refractory material and uniformly agitating; and finally spraying the passivation solution by adopting the atomizer and uniformly agitating. Through the drainage sand, the aggregate can be ensured to be better bonded with the refractory powder under the action of the impregnating compound, and the segregation of the refractory material can not occur during the use, so that an excessively-thick sintering layer is prevented from being formed due to long refining time; and the preparation method is simple, and the industrialization is easily realized.

Owner:沈阳东大净宇环保科技有限公司

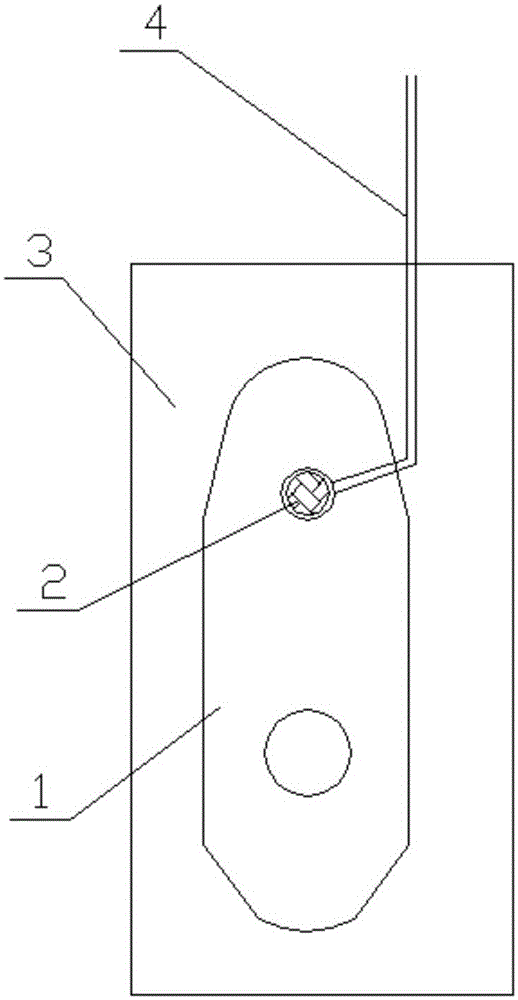

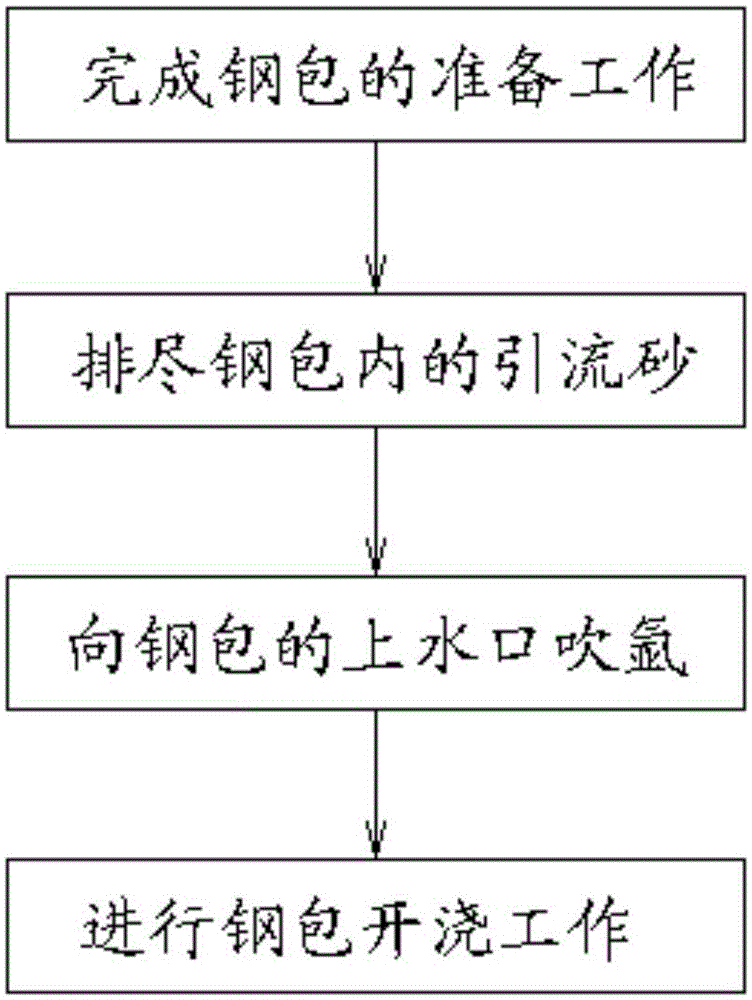

Ladle filler sand discharge device and continuous casting ladle casting starting method

ActiveCN105033236AReduce self-opening rateReduce the probability of being forced to pour nakedMelt-holding vesselsSlide plateTundish

The invention relates to a ladle filler sand discharge device and a continuous casting ladle casting starting method. The ladle filler sand discharge device comprises a sliding plate, a vent plug and an argon supply component. The sliding plate is fixed into a movable frame of a ladle mechanism and provided with a vent plug hole. The vent plug is fixed into the vent plug hole. The argon supply component is communicated with the vent plug through an argon pipeline. The continuous casting ladle casting starting method comprises the steps of completing ladle preparation work, discharging ladle filler sand in a ladle completely, blowing argon into an upper nozzle of the ladle and starting casting of the ladle. By the adoption of the ladle filler sand discharge device and the continuous casting ladle casting starting method, the ladle filler sand can be effectively prevented from entering into a tundish, the quality of casting blanks is guaranteed, the free opening rate of the ladle is improved, and forced naked casting probability of the ladle is lowered, and the quality of molten steel is guaranteed.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Chrome stuffing sand for refining ladles, and production method thereof

ActiveCN107651968AImprove thermal shock resistanceImprove thermal conductivityMelt-holding vesselsSteelmakingTitanium

The invention provides a chrome stuffing sand for refining ladles, and a production method thereof. The problems of low automatic casting rate, high production cost and large environmental impact of stuffing sands are solved. The chrome stuffing sand for refining ladles comprises, by mass, 1-20% of chrome ores, 40-60% of calcium alumino-titanate electromelted balls, 30-40% of fractured quartz sands and 0.6-1% of a carbon additive, and the carbon additive is a carbon black and graphite mixture. The introduced calcium alumino-titanate which is industrial steelmaking waste slag is applied to thestuffing sand, so the waste slag is effectively recycled, and the manufacturing cost is greatly reduced. The calcium alumino-titanate electromelted balls are adopted to partially substitute the chromeores, so the pollution is reduced, molten steel is cleaned, and the problems of dependence on importance and high cost of raw materials are solved.

Owner:北京利尔高温材料股份有限公司

Preparation method of siliceous stuffing sand

The invention discloses a preparation method of siliceous stuffing sand, belonging to the field of stuffing sand. The preparation method comprises the following steps: step I, weighing the following components in percentage by mass: 75-95% of quartz sand, 1-5% of potassium feldspar and 1-8% of graphite micro powder, adding the components into stirring equipment in sequence to stir for 15-20 minutes at a high speed, and then adding 3-12% of a regulator to stir for 8-12 minutes at a high speed, and adding water which accounts for 8-10% of the total weight of the components to stir and mix uniformly at a high speed to obtain a mixture A; and step II, putting the mixture A in the step I in a rotary drying oven to roast for 1.5-2 hours at a roasting temperature of 170-200 DEG C to obtain the siliceous stuffing sand. The preparation method of the siliceous stuffing sand is simple, reasonable in component selection, easily available in raw material, good in high-temperature sintering performance, uniform in particle granularity distribution, good in mobility, relatively small in coefficient of thermal expansion and high in self-opening rate.

Owner:马鞍山市欣隆炉料有限责任公司

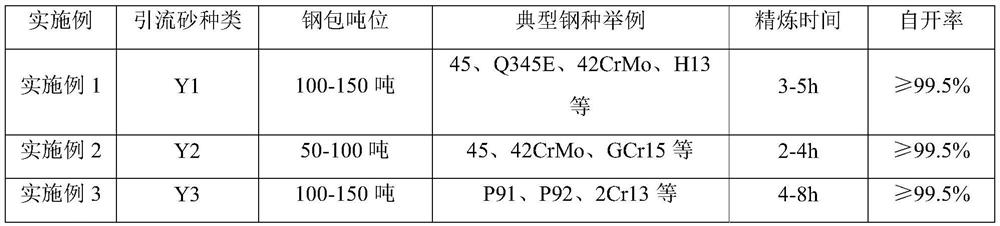

Special steel drainage agent and preparation method thereof

ActiveCN109202055AAppropriate refractorinessImprove liquidityMelt-holding vesselsGranularityNuclear power

The invention provides a special steel drainage agent and a preparation method thereof and belongs to the technical field of metallurgical fireproof materials. The special steel drainage agent is prepared by following raw materials of, by weight, 22-75 parts of natural zircon sand with granularity of 0.1-0.5mm, 8-40 parts of chrome ore with granularity of 0.1-0.5mm, 15-35 parts of desert sand withgranularity of 0.3-0.6mm and 1-3 parts of liquid graphite. According to the invention, the pouring rate of a product can be effectively improved; compared with the existing drainage agent, the automatic pouring rate can be improved by 10% or over and the basic automatic pouring rate can reach 100%; requirements are met that there are many types of special steel currently, the difference of components is big and long-time smelting is required; and the drainage agent and better drainage effects for steel types in war industry, nuclear power and special high-quality products are achieved.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Ladle filler sand for continuous-casting high aluminum steel and use method thereof

The invention discloses ladle filler sand for continuous-casting high aluminum steel. The sand is formed by evenly mixing, by weight, 29-37% of quartz sand used as skeleton materials, 52-60% of chromium ore used as base materials, 9-12% of carbon powder used as addition agents, and 0.5-2% of phenolic resin used as binding agents. The invention further discloses a use method of the ladle filler sand for the continuous-casting high aluminum steel. The method comprises the steps of firstly conducting roasting pretreatment on the ladle filler sand, then adding the ladle filler sand into a water opening, and enabling the ladle filler sand to exceed5-15mm relative to the plane of a well block of the water opening. By the adoption of the ladle filler sand and the use method, the steel ladle self-opening rate is effectively improved, efficiency is improved, operation is convenient, labor intensity is reduced, the sand is free of pollution and meets the process requirement, in the sand discharging process, the ladle filler sand can smoothly flow out along with molten steel, and slag inclusion in a steel ingot is reduced.

Owner:宝武特种冶金有限公司

Preparation method of ladle filler sand

ActiveCN110496959AReduce manufacturing costImprove self-opening rateMelt-holding vesselsPotassiumGraphite

The invention discloses preparation, packaging and layered adding methods of ladle filler sand. The ladle filler sand is prepared from the following components in percent by weight: 30-50% of chromiumladle filler sand and 50-70% of compound ladle filler sand. The compound ladle filler sand is magnesium ladle filler sand or silicon ladle filler sand. The chromium ladle filler sand is prepared fromthe following components in percent by weight: 65-80% of first chromium ore, 12-16% of first quartz sand, 4-6% of first magnesite, 6-8% of first aluminum oxide spheres, 3-5% of first potassium feldspar and 1-3% of a first carbon proportioning agent. Cr2O3 content of the first chromium ore is greater than or equal to 46-51wt%, and the granularity is 0.15-2 mm; SiO2 content of the first quartz sandis greater than or equal to 98.0wt%; MgO content in the first magnesite is greater than or equal to 98.0wt%; Al2O3 content of the first aluminum oxide spheres is greater than or equal to 75.0wt%; K2Ocontent of the first potassium feldspar is greater than 8wt%; C contents of first graphite and first carbon black are greater than 92wt%. The ladle filler sand is added quantitatively in layers, so that the self-opening rate of a steel ladle is improved and the production cost of the ladle filler sand is lowered. The ladle filler sand made from different materials is added uniformly in layers andat a fixed speed under constraint of a packaging barrel.

Owner:乌兰察布市西蒙鼎新技术开发有限公司

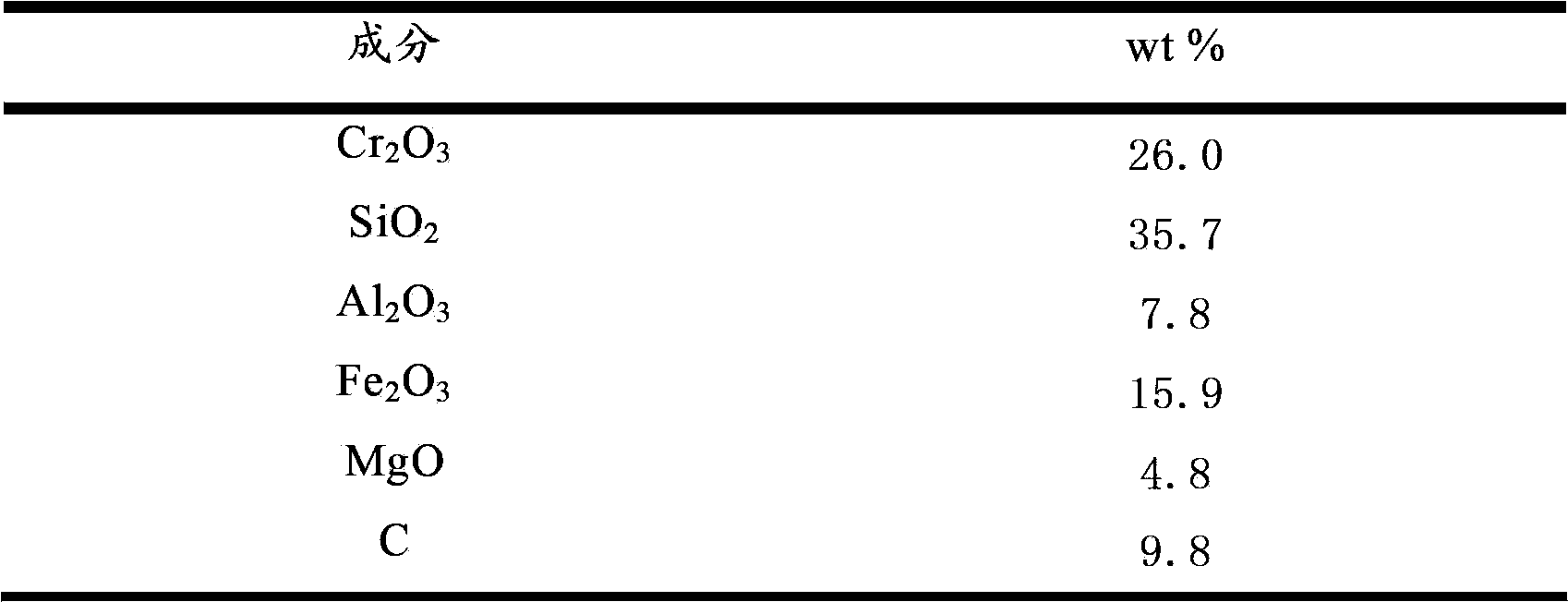

Preparation method of drainage agent for refining in three phases

ActiveCN100581683CReasonable particle size compositionImprove liquidityMelt-holding vesselsGranularityRefractory

The invention relates to a flow guiding agent used for a three-step refining and a preparation method thereof. The flow guiding agent mainly consists of the components with the following weight percentages: 23 to 35 percent of Cr2O3, 13 to 45 percent of SiO2 and 3 to 15 percent of Zr2O3. The forming of the granularity of the flow guiding agent is reasonable and the flowing capability is good; the refractory degree is not less than 1780 DEG C and agglomeration can be resisted; the capability of steel liquid penetration resisting is strong and the specific gravity is high; a proper thickness of an agglomeration layer can be formed and the self-opening rate of a steel bundle can be effectively enhanced; the component composing is reasonable and impurities brought into a casting-start process can be avoided. The invention is suitable for the manufacturing of high clean steels.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

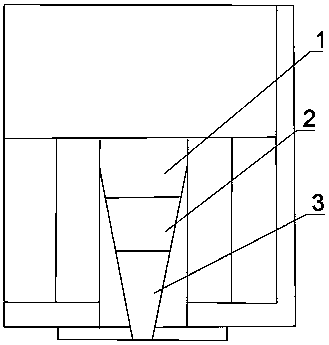

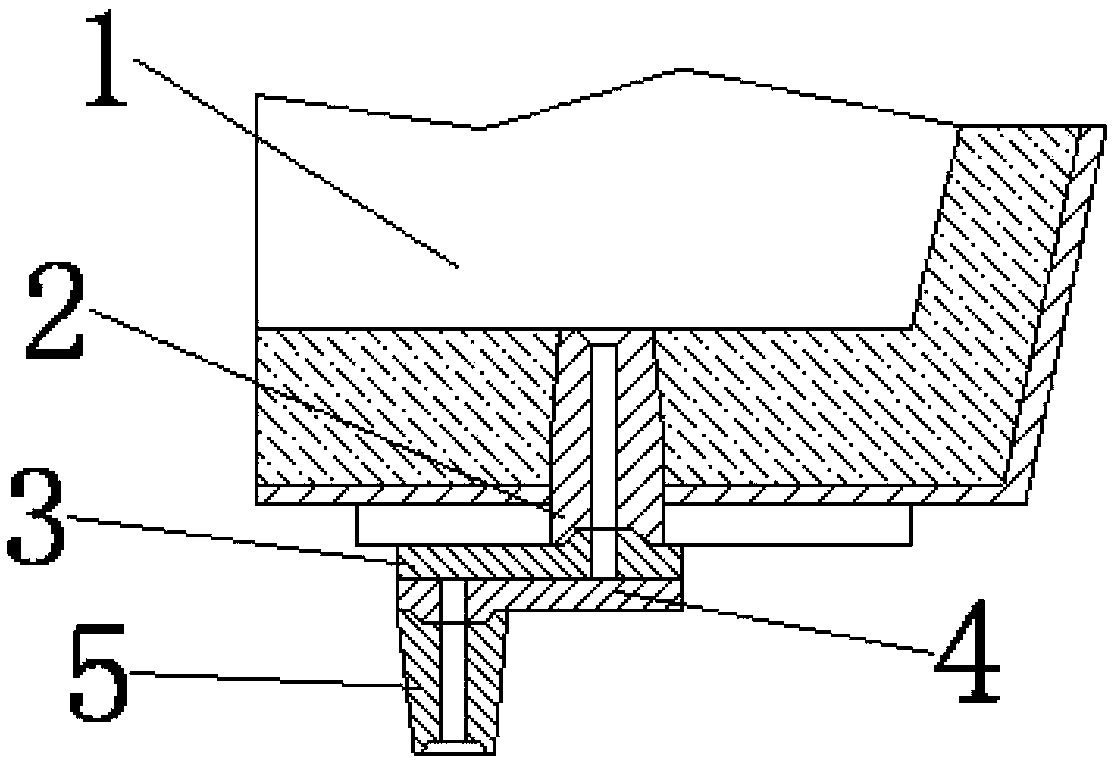

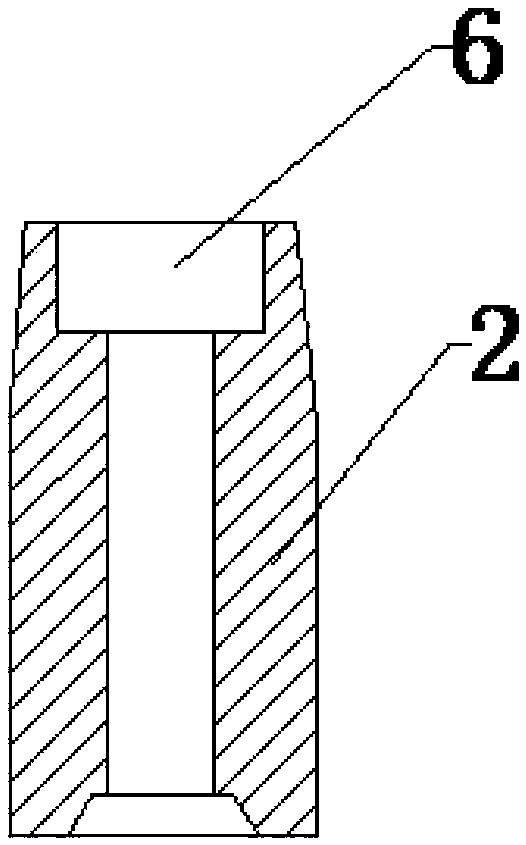

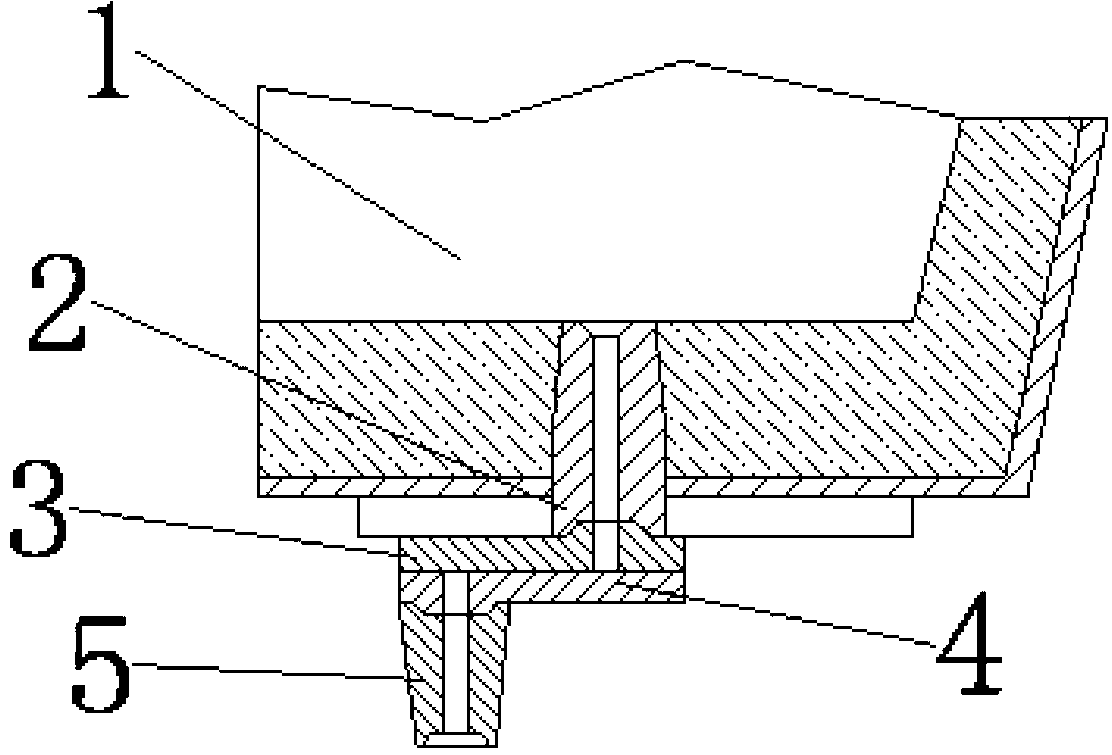

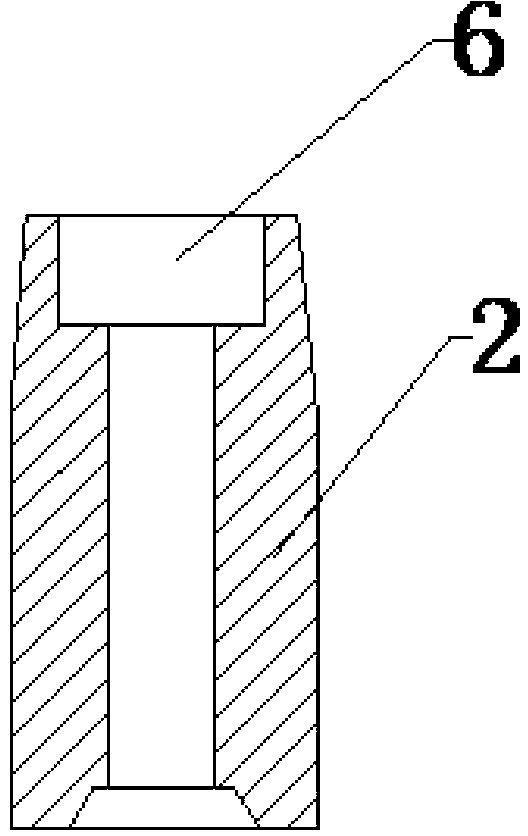

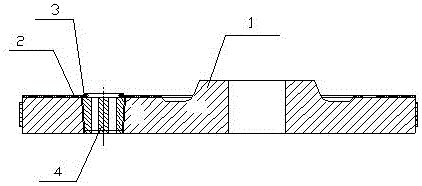

A ladle nozzle capable of increasing self-opening rate

The invention discloses a ladle nozzle applied to the steel casting technology and particularly relates to a ladle nozzle capable of improving the automatic casting rate. A variable-diameter stuffing sand flowing channel is arranged at an upper water inlet. The upper water inlet is composed of an upper portion and a lower portion, and the inner diameter of the upper portion of the upper water inlet is larger than that of the lower portion of the upper water inlet. By means of the ladle nozzle, upper arch drainage sand piles are not produced, flowing of stuffing sand is facilitated, and the automatic casting rate is improved, the defect of manual oxygen burning casting in the prior art is overcome, the molten steel automatic casting rate is improved, the production rhythm is stabilized, effects of oxygen burning on the quality of molten steel are reduced, residual slag of steel ladles is reduced, and the like.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

A kind of silicon carbon drainage agent and preparation method thereof

The invention discloses a silicon-carbon drainage agent and a preparation method thereof, and relates to the field of metallurgy. The drainage agent is composed of, by weight, 60-80 parts of quartz sand with the particle size being 0.3-0.6 mm, 1-10 parts of phosphorus slice graphite powder with the particle size being 325 meshes and the passing rate being 97%, 10-28 parts of silicon carbide with the particle size being 0.3-0.6 mm and 1-5 parts of binding agent. The preparation method of the silicon-carbon drainage agent comprises the following steps of dry mixing, wet mixing and drying. Various raw materials used for preparing the silicon-carbon drainage agent do not pollute the environment and molten steel, no impurity can be introduced in the molten steel smelting process, the purity of the molten steel of fine steel is ensured, and the requirements for using of market quality goods and cleaner production are met. The drainage agent prepared through the method is stable in performance, good in liquidity, low in heat conductivity coefficient, good in penetration resistance at high temperatures, and the free opening rate of steel ladles is increased. On the premise that the product performance is not lowered, low-price materials are used for replacing high-grade materials, and the cost is reduced.

Owner:ZHENGZHOU DONGSHENG METALLURGY NEW MATERIAL

Drainage agent special for alloy bushing and preparation method thereof

InactiveCN106495720ALow costSmall expansion coefficientMelt-holding vesselsGranularityAdditive ingredient

The invention discloses drainage agent special for an alloy bushing. The drainage agent consists of the following ingredients in parts by weight: 15-17% of Gr2O3, 12-25% of SiO2, 8-15% of MgO, 6-15% of Al2O3 and 2-8% of Fe2O3. Compared with the prior art, the drainage agent is characterized in that deficiencies in the prior art are overcome, a proportion and a production technology are reasonably set to provide the drainage agent special for the alloy bushing. The drainage agent special for the alloy bushing has the advantages of low cost, stable coefficient of expansion of silica quartz sand at a high temperature, good high-temperature sintering performance, good molten steel and molten slag corrodibility resistance, even particle granularity distribution, good mobility, small thermal expansivity and high free-opening rate.

Owner:潜山市凯创橡塑机械制造有限公司

Zirconium-silicon-chromium-based ladle stuffing sand and preparation method thereof

InactiveCN113105253AMix well and evenlySolve the impact of self-opening rateMelt-holding vesselsZirconMaterials science

The invention discloses zirconium-silicon-chromium-based ladle stuffing sand and a preparation method thereof. The preparation method comprises the following steps: mixing raw materials consisting of zircon sand, quartz sand, chromite sand and carbon black according to a certain weight ratio, and carrying out mechanical stirring, spray granulation, screening and cooling treatment to obtain target ladle stuffing sand powder. The obtained stuffing sand contains 24%-40% of ZrO2, 27%-37% of SiO2, 10%-20% of Cr2O3, 1%-8% of Al2O3, 4%-16% of Fe2O3 and less than 0.5% of H2O; the refractoriness of the stuffing sand is larger than 1850 DEG C; and the proportion of particles with particle sizes ranging from 0.1-1 mm is controlled to be 98% or above. According to the ladle stuffing sand prepared through the method, the raw materials can be fully and evenly mixed, and the influence of the segregation problem caused by uneven components on a self-opening rate is solved; and particularly, the self-opening rate of a high-quality special steel ladle with the refining time exceeding 3-8 hours is increased, and influence on the quality of molten steel caused by later oxygen burning and drainage is avoided.

Owner:JIANGSU YONGGANG GROUP CO LTD

Production process of stuffing sand

PendingCN113387711AReduce manufacturing costImprove self-opening rateMelt-holding vesselsBrickIron removal

The invention discloses a production process of stuffing sand. The method comprises the following steps of: (1) adopting recycled waste magnesite-chrome bricks, carrying out primary separation and iron removal, jaw crushing and rough addition into 8mm granules by using a roller machine to remove iron, and then processing into 3mm granules by using a crusher to remove iron, so as to obtain a semi-finished magnesite-chrome sand material; (2) sequentially adding the semi-finished magnesium-chromium sand, quartz sand and an additive into a planetary stirrer according to the technical proportioning requirement, and stirring for 5 minutes to obtain a finished product; and (3) matching and packaging according to the size of customer stuffing sand. The method has the beneficial effects that the waste magnesite-chrome bricks are used as raw materials, the effects of environmental protection and production cost reduction can be achieved, and in addition, the self-opening rate of the ladle filler sand prepared from the magnesite-chrome bricks through the process can be greatly improved.

Owner:冷水江市高科窑炉耐火材料有限公司

Ladle nozzle capable of improving automatic casting rate

The invention discloses a ladle nozzle applied to the steel casting technology and particularly relates to a ladle nozzle capable of improving the automatic casting rate. A variable-diameter stuffing sand flowing channel is arranged at an upper water inlet. The upper water inlet is composed of an upper portion and a lower portion, and the inner diameter of the upper portion of the upper water inlet is larger than that of the lower portion of the upper water inlet. By means of the ladle nozzle, upper arch drainage sand piles are not produced, flowing of stuffing sand is facilitated, and the automatic casting rate is improved, the defect of manual oxygen burning casting in the prior art is overcome, the molten steel automatic casting rate is improved, the production rhythm is stabilized, effects of oxygen burning on the quality of molten steel are reduced, residual slag of steel ladles is reduced, and the like.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

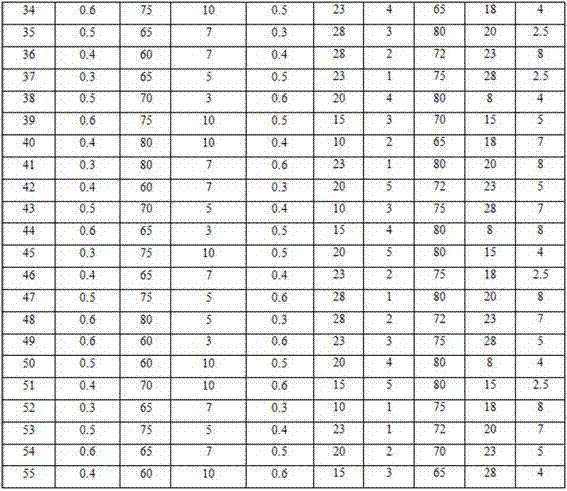

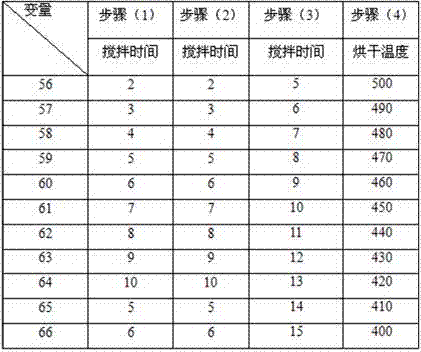

A kind of preparation method of refined chrome drainage sand

ActiveCN104148625BImprove turnover rateReduce labor intensityMelt-holding vesselsPotassiumMolten slag

The invention discloses a preparation method of refined chromite-based stuffing sand and belongs to the technical field of iron and steel smelting. The method comprises the steps that 60-65 wt% of chromium ore and 25-33 wt% of quartz sand are blended for 3-5 minutes in a mixing device, 4-7 wt% of potash feldspar is added and blended for 12-15 minutes, 2-3 wt% of low-grade silicon carbide is added and blended for 10-15 minutes, 1-2 wt% of carbon black is added and blended for 10-15 minutes, and then a chromite-based stuffing sand mixture is obtained; the mixture is placed into a rotary drying furnace for baking, the baking temperature ranges from 170 DEG C to 200 DEG C, the baking time ranges from 25 minutes to 30 minutes, the mixture is sieved, and then the chromite-based stuffing sand with the particle size ranging from 0.15 mm to 1.5 mm is obtained. The chromite-based stuffing sand has the advantages of being good in high-temperature sintering performance, good in erosion resistance to molten steel and molten slag, uniform in particle size distribution, good in fluidity, low in thermal expansivity and high in automatic casting ratio.

Owner:MAANSHAN NINGSHENG REFRACTORIES

Alkaline flow guiding sand used in steel ladle

InactiveCN101444842BHigh refractorinessStrong corrosion resistanceMelt-holding vesselsChemical compositionCalcite

The invention relates to an alkaline flow guiding sand used in a steel ladle, which belongs to the metallurgy technical field, and comprises the chemical compositions as follows (by weight percentage): passive limes account for 30 to 50 percent, calcites account for 5 to 15 percent, corundum accounts for 5 to 10 percent, calcined olivine sands account for 20 to 40 percent, and flaky graphite accounts for 1 to 5 percent; and all components are confected according to the proportions and then are mixed to form the alkaline flow guiding sand. The prepared alkaline flow guiding sand used in the steel ladle has the characteristics of high refractability, strong erosion-resistence, high ladle free opening rate, low cost, no environmental pollution, no damage to pouring box metallurgy environment,and convenient use.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

White olivine ladle draining sand and method for preparing the same

InactiveCN100475387CImprove high temperature resistanceImprove self-opening rateMelt-holding vesselsPotassiumOlivine

The invention relates to a forsterite ladle drainage sand and a preparation method thereof. The technical scheme adopted is: first mix 86-96wt% forsterite sand, 1-6wt% flake graphite, 1-8wt% potassium feldspar powder, and 0.5-2wt% carbonaceous micropowder, and then 5~15kg bags are packed in separate bags to prevent material segregation. Among them: MgO content of forsterite sand ≥ 41.0wt%, particle size 0.3 ~ 2.5mm, C content of flake graphite ≥ 95.0wt%, particle size 0 ~ 0.15mm, K2O content of potassium feldspar powder ≥ 10.0wt% , The particle size is 0-0.045mm, the C content of the carbonaceous micropowder is ≥85.0wt%, and the particle size is 0-0.020mm. The invention uses forsterite sand as the base material, and the prepared product has the characteristics of good high temperature resistance, high self-opening rate, low price, no adverse effect on human body, no segregation and convenient use.

Owner:WUHAN UNIV OF SCI & TECH

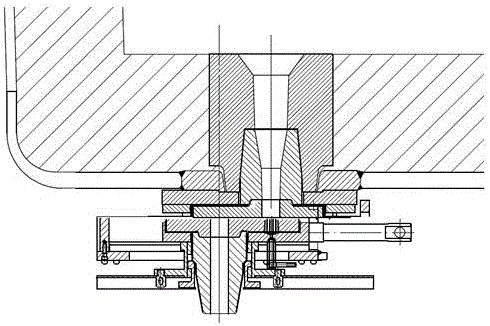

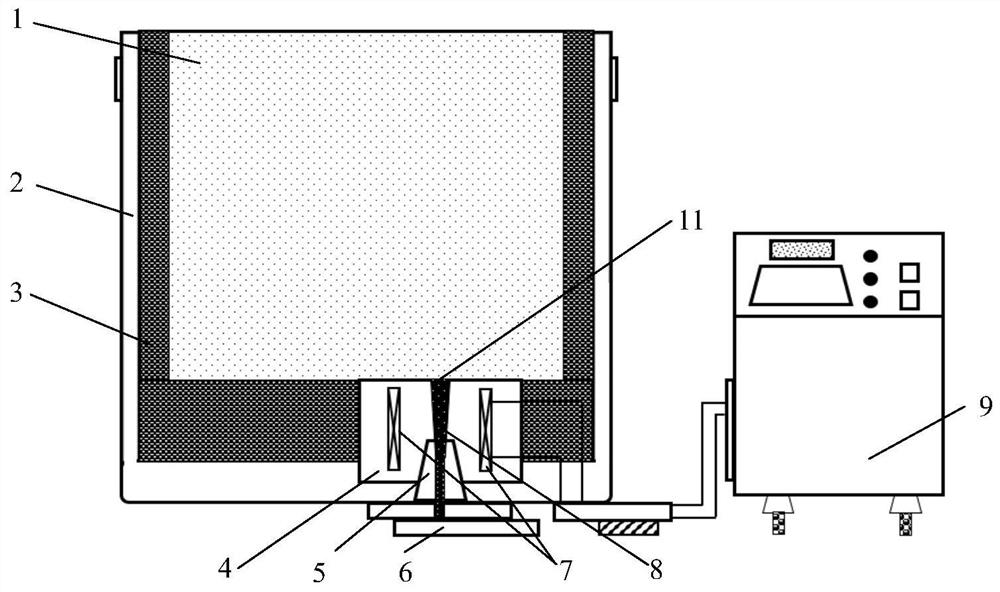

Continuous casting steel ladle no-drainage casting device

InactiveCN105945274AImprove self-opening rateReduce secondary pollutionMelt-holding vesselsSlide plateMetallurgy

The invention relates to a continuous casting steel ladle no-drainage casting device. The continuous casting steel ladle no-drainage casting device comprises an upper water port mechanism and a lower water port mechanism; the upper water port mechanism is fixed at the bottom of a steel ladle, and has an upper water port connected with the steel ladle; the lower water port mechanism is correspondingly arranged below the upper water port mechanism; the lower water port mechanism has a lower water port and an argon blowing port; and the lower water port mechanism can transversely move corresponding to the upper water port mechanism to realize alternative communication between the lower water port or the argon blowing port and the upper water port. The continuous casting steel ladle no-drainage casting device facilitates increment of the self-open rate of continuous casting ladles, wherein a novel argon blowing slide plate for continuous casting steel ladles can realize a no-drainage sand casting process, so that the secondary pollution of molten steel is reduced.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

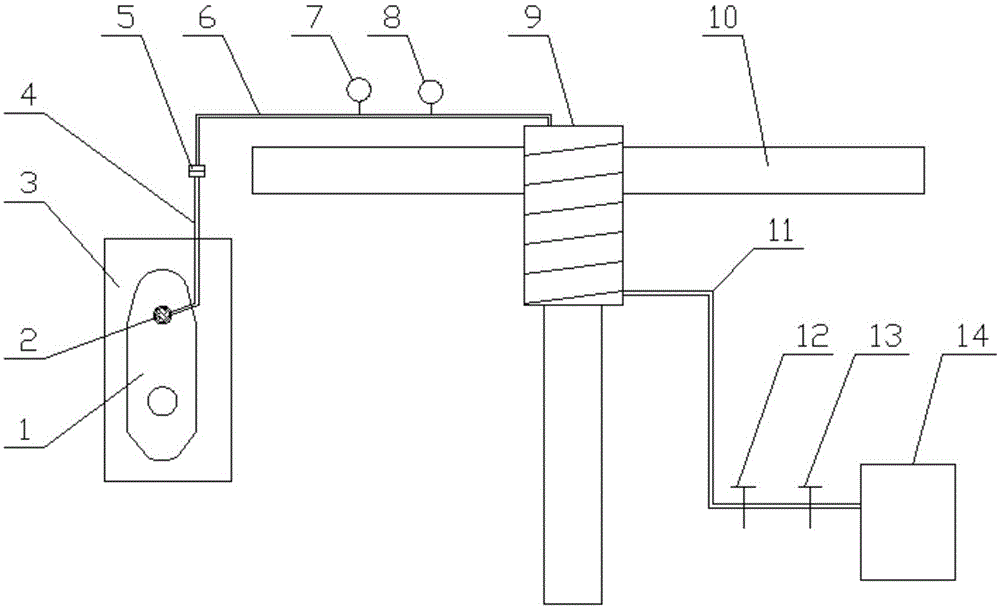

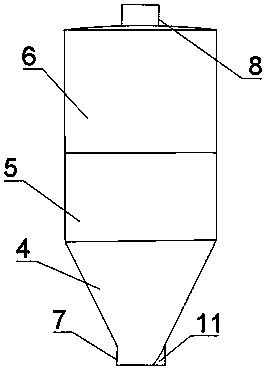

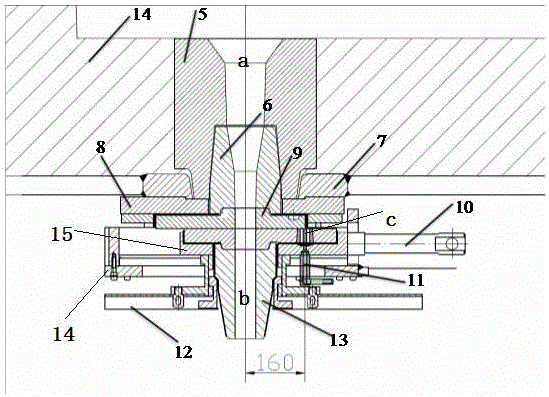

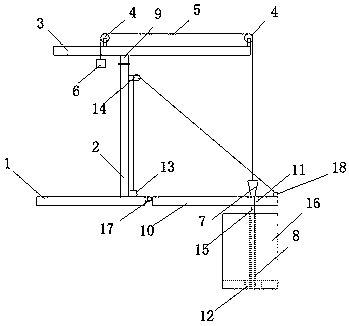

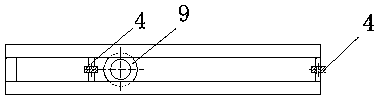

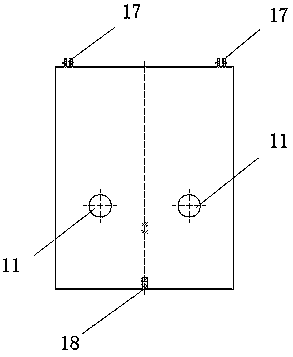

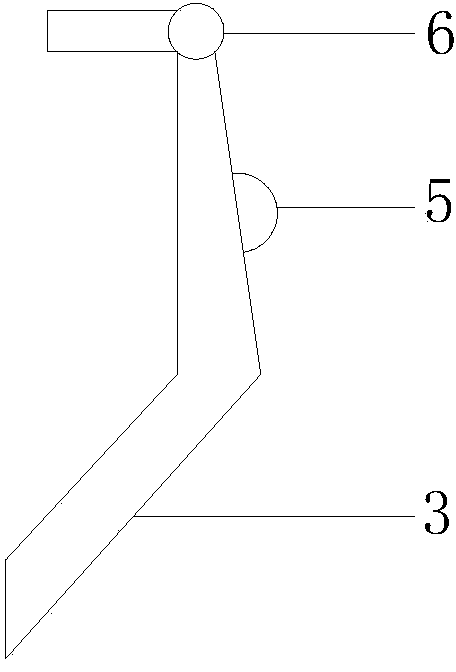

Cantilever type steel ladle drainage sand adding device

InactiveCN110000369APrecise control of reasonable shapeControl reasonable shapeMelt-holding vesselsEngineeringCantilever

The invention relates to a cantilever type steel ladle drainage sand adding device, and belongs to the technical field of steelmaking accessory equipment. The cantilever type steel ladle drainage sandadding device comprises a platform, a stand column fixed on the platform and a cantilever rotationally connected with the top end of the stand column, two fixed pulleys are fixed on the cantilever, asteel wire rope is arranged on the two fixed pulleys, and the two ends of the steel wire rope are connected with a counterweight and a sand adding funnel respectively; and the sand adding funnel canbe positioned above a steel ladle nozzle through the rotation of the cantilever, and the axis of the sand adding funnel is overlapped with the axis of the steel ladle nozzle at the vertical position.The cantilever type steel ladle drainage sand adding device can realize accurate addition of drainage sand, ensure the drainage sand to form a reasonable shape, improve the self-opening rate of the steel ladle nozzle, reduce the labor intensity of workers and ensure the normal production rhythm.

Owner:HANDAN IRON & STEEL GROUP +1

Draining sand for steelworks and its preparing process

InactiveCN1209214CGuaranteed lubrication effectImprove the lubrication effectMelt-holding vesselsSteelmakingSoil science

Owner:宝钢集团上海梅山有限公司

A kind of excellent special steel drainage agent and preparation method thereof

ActiveCN109202055BAppropriate refractorinessImprove liquidityMelt-holding vesselsMining engineeringRefractory

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

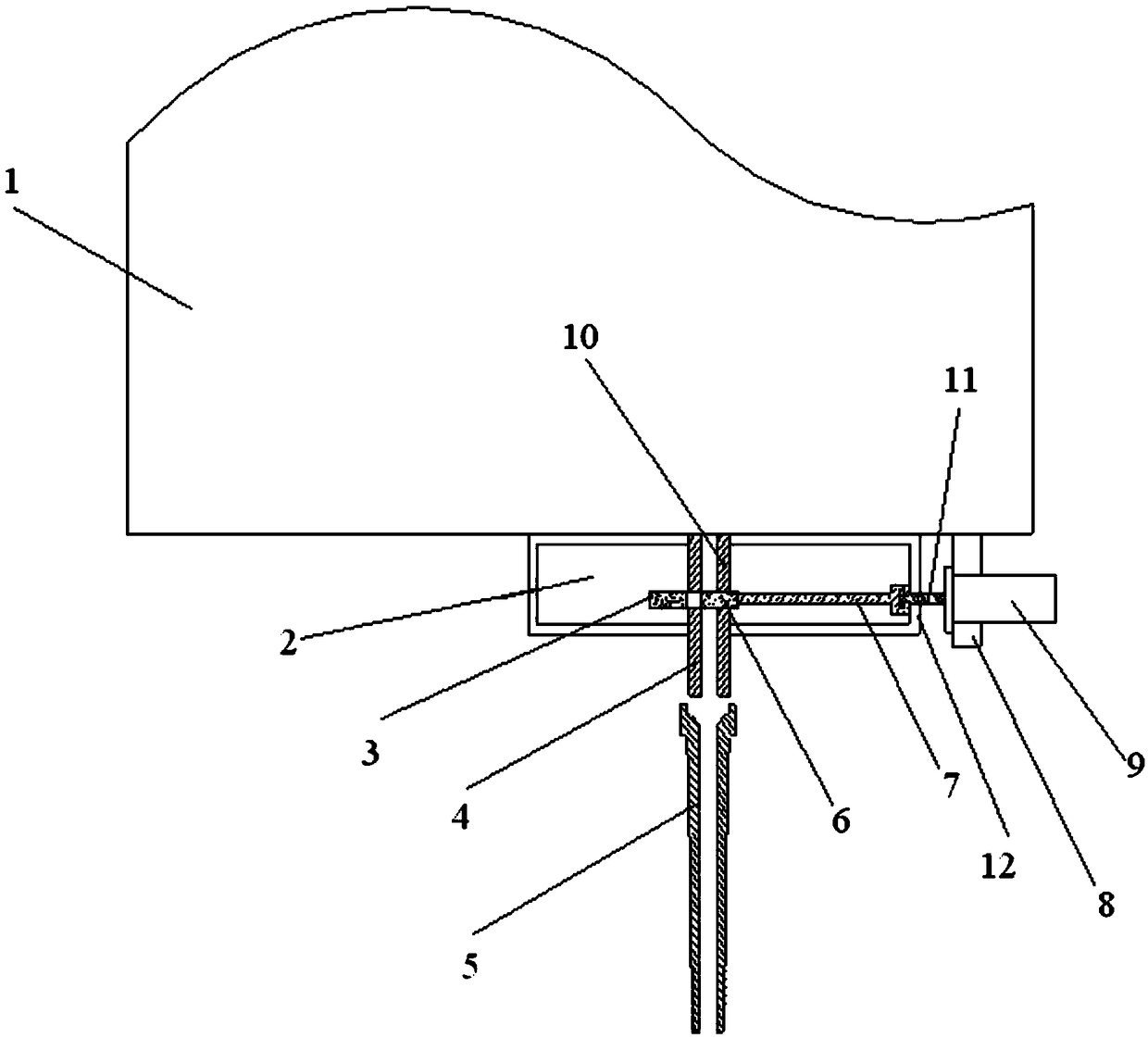

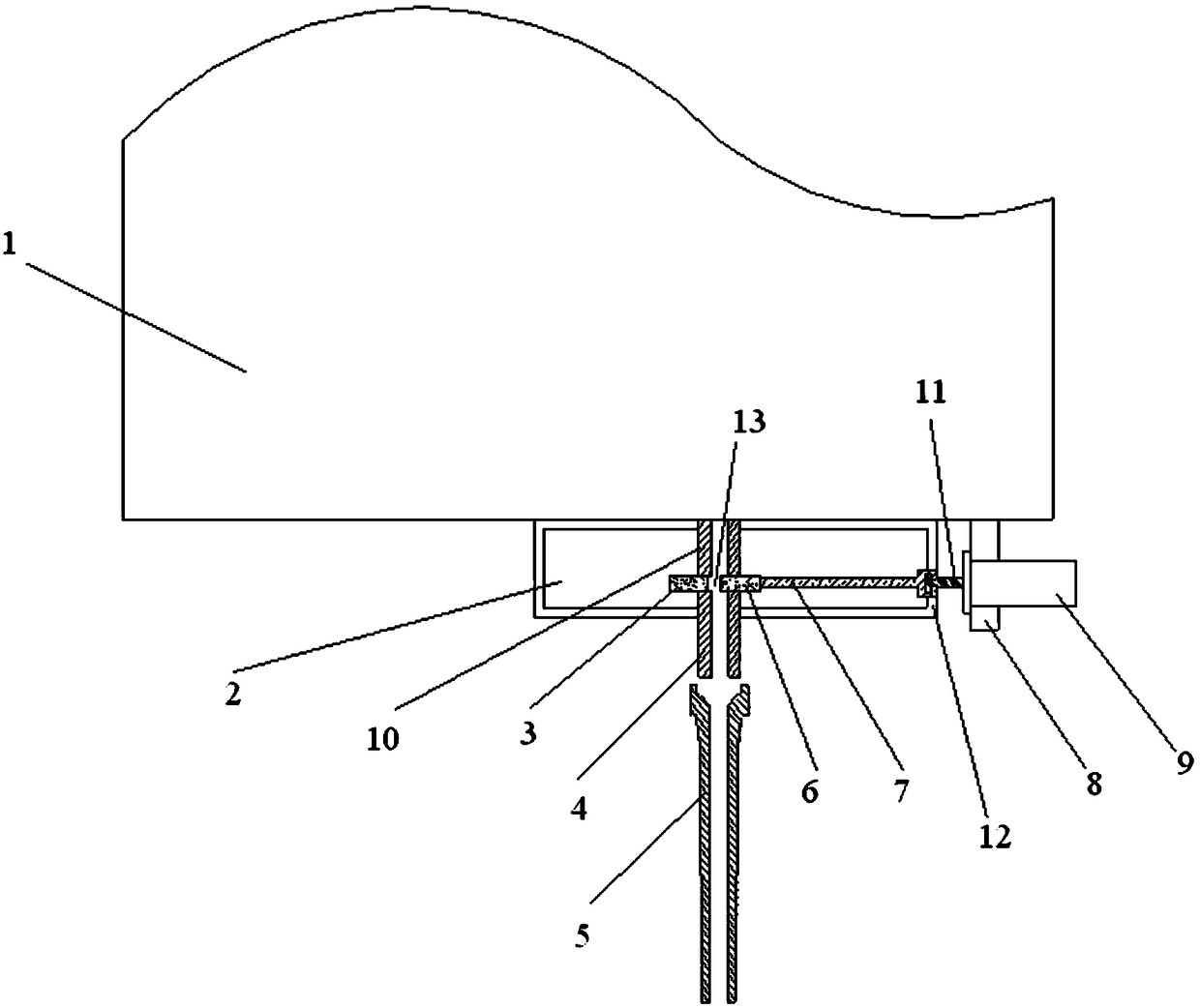

Device and method for preventing molten steel from splashing during casting starting

ActiveCN108746577AAvoid safety accidentsImprove self-opening rateMelt-holding vesselsHydraulic cylinderMachine parts

The invention relates to a device for preventing molten steel from splashing during casting starting. The device comprises a large ladle water gap machine part (2), a large ladle water gap, a first large ladle water gap sliding plate (3), a second large ladle water gap sliding plate (6), a sliding operating rod (7), a large ladle water gap fixing device (12), a hydraulic shaft (11), a hydraulic cylinder (9), a hydraulic cylinder fixing device (8) and a large ladle long water gap (5), wherein the large ladle water gap machine part (2) is mounted at the bottom of a steel ladle (1); the large ladle water gap fixing device (12) is arranged at the external part of the large ladle water gap machine part (2) in a sleeving manner; part of large ladle water gaps in the large ladle water gap machinepart (2) is provided with an opening; the large ladle long water gap (5) is hung at the lower part of a large ladle lower water gap (4); the first large ladle water gap sliding plate (3) is fixed onone side of the opening; the second large ladle water gap sliding plate (6) is fixedly connected with one end of the sliding operating rod (7); the other end of the sliding operating rod (7) is connected with the hydraulic shaft (11) in a sleeving manner; and the hydraulic cylinder (9) is fixed at the bottom of the steel ladle (1) through the hydraulic cylinder fixing device (8).

Owner:SHANDONG IRON & STEEL CO LTD

High-self-opening-rate stuffing sand suitable for high-manganese steel continuous casting production and using method

PendingCN113979759AEffective and economical improvement of self-opening rateImprove self-opening rateMelt-holding vesselsManganeseMolten steel

The invention belongs to the technical field of high-manganese steel continuous casting production, and particularly relates to high-self-opening-rate stuffing sand suitable for high-manganese steel continuous casting production and a using method. The stuffing sand comprises, by mass, smaller than 25% of SiO2, smaller than 15% of Fe2O3, larger than 32% of Cr2O3, larger than 10% and smaller than 18% of Al2O3, larger than 8% of ZrO2, larger than or equal to 0.3% and smaller than or equal to 1.0% of carbon black and smaller than or equal to 0.3% of H2O; and according to the granularity of the stuffing sand, the proportion of 0.25 mm-1. 2mm is larger than 95%, and the proportion of the stuffing sand with the granularity smaller than 0.25 mm is within 2%, and the proportion of the particle size of 1.2-1.5 mm is within 3%. According to the stuffing sand, the probability of the drainage phenomenon in the continuous casting production process of the high manganese steel is greatly reduced, and the cleanliness and stability of the steel are improved while efficient continuous casting production of the stuffing sand is achieved. In addition, the using method is improved, so that the occurrence probability of molten steel permeation and the use cost of the special stuffing sand are further reduced.

Owner:ZENITH STEEL GROUP CORP +1

A kind of drainage sand and its preparation method and application

ActiveCN111545738BHigh refractorinessEnhance the ability to resist high temperature molten steelMelt-holding vesselsSteelmakingPhysical chemistry

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

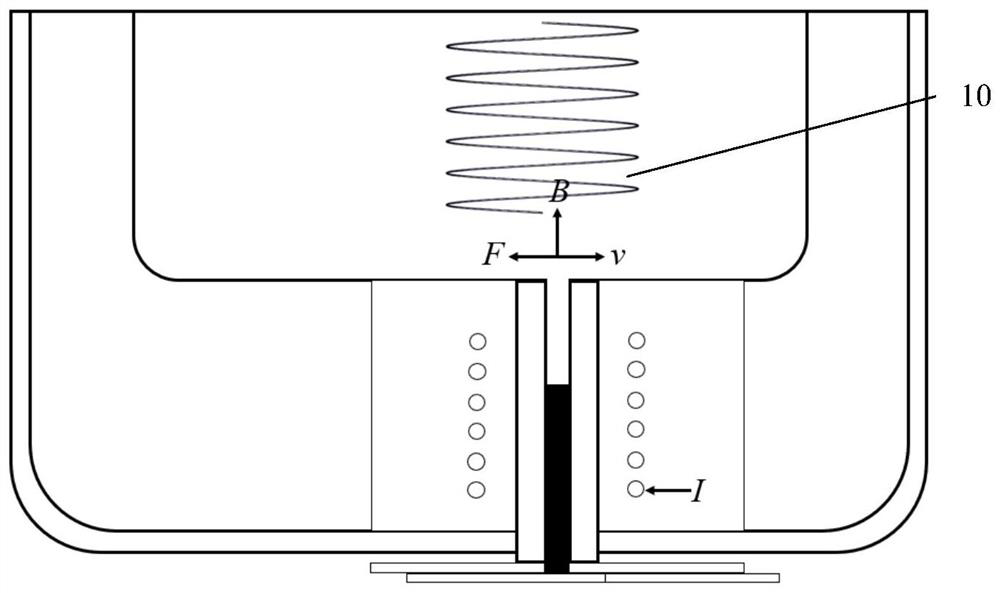

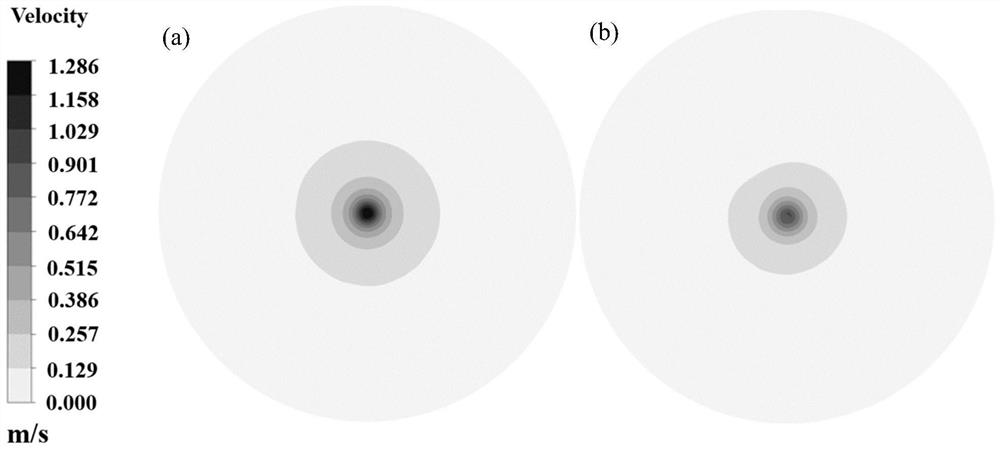

Method for electromagnetically controlling steel ladle drainage and vortex slag entrapment at last stage of molten steel pouring

PendingCN113798485AImprove cleanlinessAvoid secondary oxidationMelt-holding vesselsSteelmakingDC - Direct current

The invention belongs to the technical field of steelmaking and molten steel pouring, and particularly relates to a method for electromagnetically controlling steel ladle drainage and vortex slag entrapment at the last stage of molten steel pouring. In order to overcome the defects in the prior art, the invention provides the method for controlling automatic drainage and tapping of a steel ladle by applying alternating currents to a coil for induction heating in the drainage process, and applying direct currents to the coil at the last stage of molten steel pouring so as to generate a stable magnetic field around a water gap to inhibit vortexes. Pollution of stuffing sand to molten steel can be avoided, the automatic casting rate of the steel ladle is increased to 100%, slag entrapment caused by the vortexes can be restrained at the last stage of molten steel pouring, the cleanliness and the yield of the molten steel are increased, and the automation degree of steel production is also increased.

Owner:NORTHEASTERN UNIV

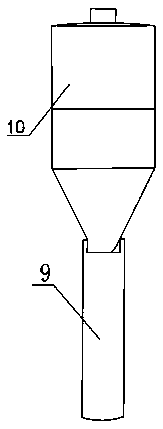

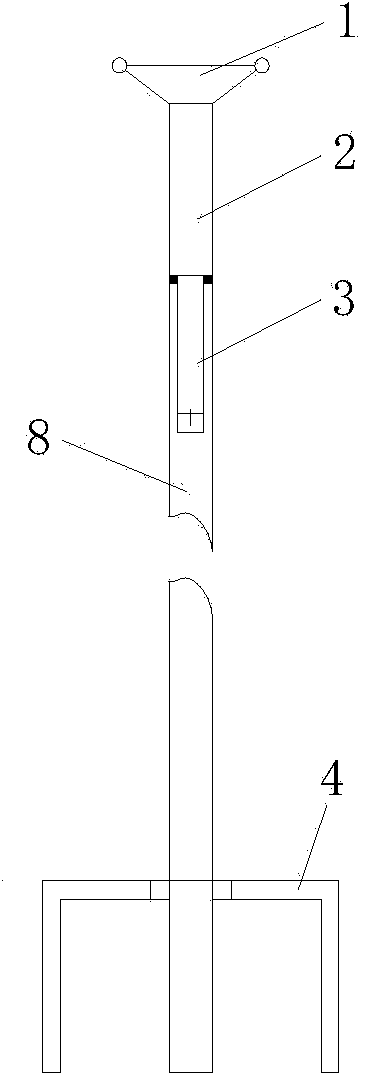

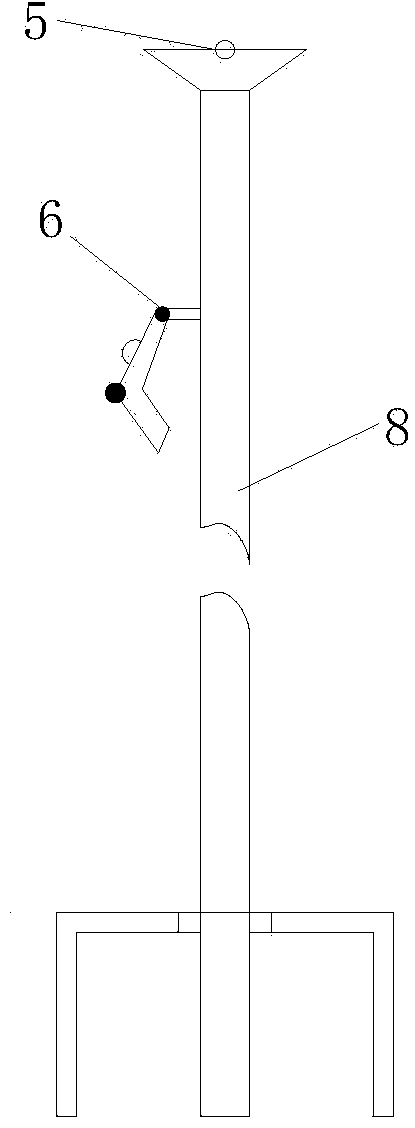

Honeycomb duct for ladle filler sand and sand adding method for ladle filler sand

The invention relates to a honeycomb duct for ladle filler sand. The honeycomb duct (8) comprises a funnel (1), a hollow metal tube (2), a pendulum bob (3), a support (4), two flying rings (5) and a hinge (6); the funnel (1) is located at the top part of the hollow metal tube (2), and is in the shape of a horn mouth; the two flying rings (5) are symmetrically distributed at the outer edge of the funnel (1); the pendulum bob (3) is located on the hollow metal tube (2); the pendulum bob (3) and the hollow metal tube (2) are connected by the hinge (6), so that the pendulum bob (3) can conveniently swing to knock the hollow metal tube (2); the support (4) is located at the tail part of the hollow metal tube (2), and is used for fixing the honeycomb duct (8) in position. According to the honeycomb duct disclosed by the invention, accurate feeding of the ladle filler sand can be ensured, the usage amount of the ladle filler sand is reduced, and the self-opening rate of a ladle is increased.

Owner:SHANDONG IRON & STEEL CO LTD +2

Carbon-free steel ladle drainage agent for extremely-low carbon steel

ActiveCN102233412BReasonable particle size matchingImprove high temperature fluidityMelt-holding vesselsTO-18BULK ACTIVE INGREDIENT

The invention discloses a carbon-free steel ladle drainage agent for extremely-low carbon steel. The carbon-free steel ladle drainage agent for the extremely-low carbon steel comprises the following active ingredients in percentage by mass: 20 to 36 percent of Cr2O3, 10 to 40 percent of SiO2, 10 to 25 percent of Fe2O3, 5 to 18 percent of Al2O3 and 10 to 20 percent of MgO. The carbon-free steel ladle drainage agent for the extremely-low carbon steel comprises the following active ingredients of 31.28 percent of Cr2O3, 23.52 percent of SiO2, 14.71 percent of MgO, 19.09 percent of Fe2O3 and 9.86percent of Al2O3. The carbon-free steel ladle drainage agent for the extremely-low carbon steel is prepared from the following raw materials in percentage by mass: 50 to 80 percent of chromite sand, 10 to 30 percent of white quartz and 8 to 20 percent of electro-fused magnesia.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com