Chrome drainage sand for special steel and preparation technology thereof

A technology for draining sand and special steel, applied in manufacturing tools, foundry equipment, metal processing equipment, etc., can solve problems such as threats to employee safety production, production losses, and disrupted production rhythms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

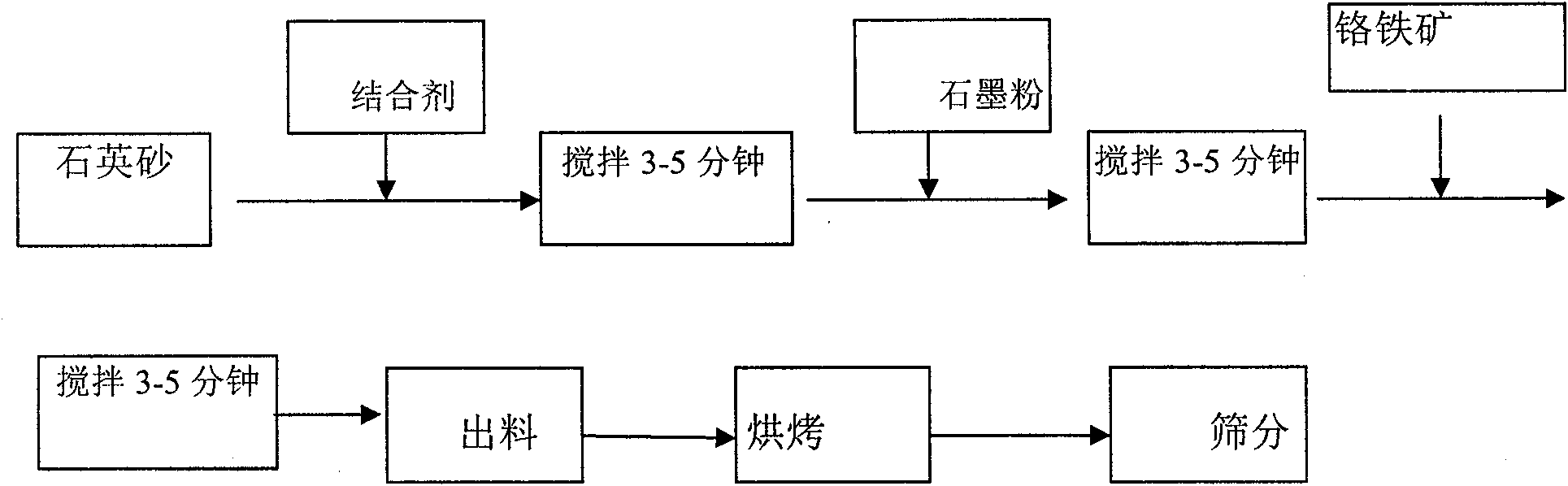

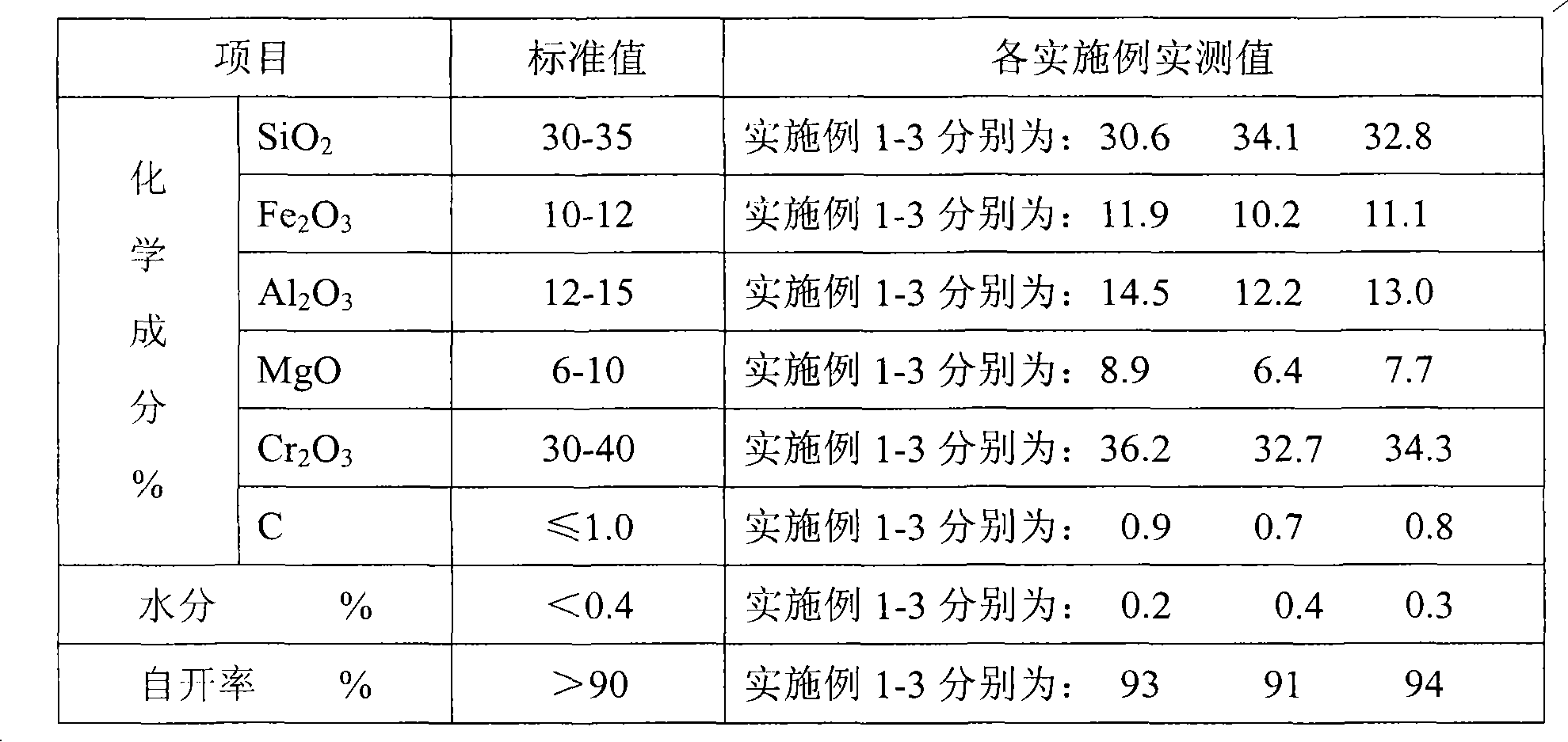

[0022] Embodiment 1 preparation technology such as figure 1 As shown, the details are: ① Add 28KG quartz sand and 0.5KG phenolic resin to the mixing equipment, stir for 3 minutes until the quartz sand particles are completely wetted, add 1.5KG graphite powder, stir for 3 minutes until the graphite powder and quartz After the sand particles are mixed evenly, add 70KG chromite and stir for 3 minutes until uniform.

[0023] ②Put the mixed chrome drainage sand into the baking kiln and bake at a maximum temperature of 200°C for 18 hours.

[0024] ③Sieve the baked chrome drainage sand to remove false particles. The particle size physical ratio of the final product:

[0025] Particle size range (mm)

[0026] In this embodiment, the weight ratio between chromite and quartz sand is selected to be 2.5: 1, so that the product has suitable high-temperature performance, 1.5KG of graphite is added to make the product have suitable sintering performance, and 0.5KG of phenolic ald...

Embodiment 2

[0028] ①Add 33KG quartz sand and 1.5KG phenolic resin to the mixing equipment, stir for 5 minutes until the quartz sand particles are completely wetted, then add 1.25KG graphite powder, stir for 5 minutes until the graphite powder and quartz sand are evenly mixed, then add 64.25 KG of chromite, stir for 5 minutes until uniform.

[0029] ②Put the mixed chrome drainage sand into a baking kiln and bake at a maximum temperature of 200°C for 18 hours.

[0030] ③Sieve the baked chrome drainage sand to remove false particles. The particle size physical ratio of the final product:

[0031] Particle size range (mm)

[0032] In this embodiment, the weight ratio between chromite and quartz sand is selected to be 1.95: 1 so that the product has suitable high-temperature performance, and 1.25KG of graphite is added to make the product have suitable sintering performance, and 1.5KG of phenolic aldehyde is added resin bond. Due to the adoption of the technical solution of this e...

Embodiment 3

[0034] ①Add 31KG quartz sand particles and 1KG phenolic resin to the mixing equipment, stir for 4 minutes, add 1.1KG graphite powder after the quartz sand particles are completely wetted, stir for 4 minutes, and add 66.9 KG of chromite, stir for 4 minutes until uniform.

[0035] ②Put the mixed chrome drainage sand into a baking kiln and bake at a maximum temperature of 200°C for 18 hours.

[0036] ③Sieve the baked chrome drainage sand to remove false particles. The particle size physical ratio of the final product:

[0037] Particle size range (mm)

>1

1-0.5

0.5-0.21

0.21-0.15

0.15-0.09

<0.09

Mass percentage after sieving (%)

2.0

18

68

11.3

0.7

-

[0038] In this embodiment, the weight ratio between chromite and quartz sand is selected to be 2.16:1 so that the product has suitable high-temperature performance, 1.1KG of graphite is added to make the product have suitable sintering performance, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com