Honeycomb duct for ladle filler sand and sand adding method for ladle filler sand

A technology of diversion tube and sand drainage, applied in metal processing equipment, casting melt container, casting equipment, etc., can solve the problems of inaccurate positioning, uneven sand surface, poor flow of drainage sand in the tube, etc. Effect of weight, smooth sand surface, stable center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

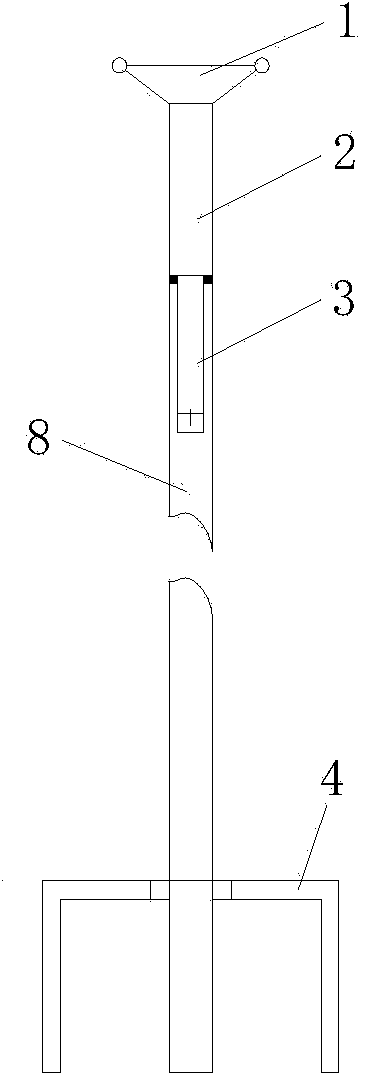

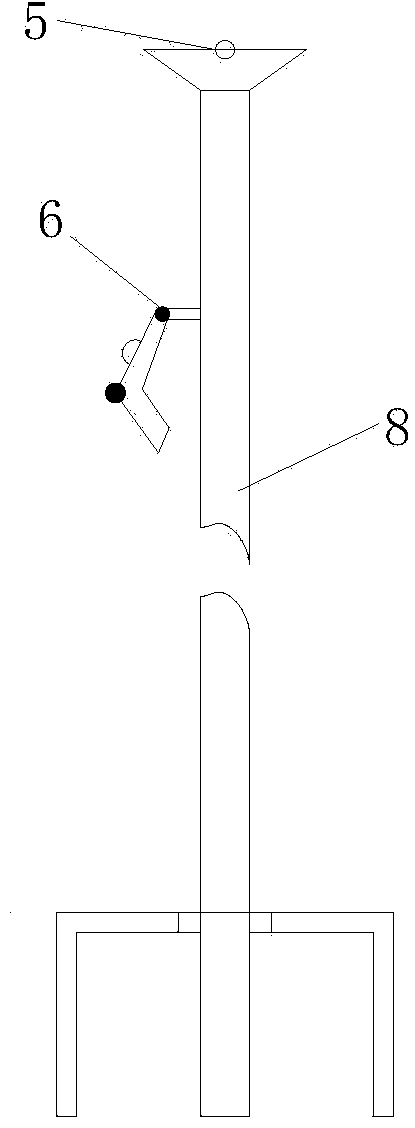

[0028] Such as figure 1 and figure 2 As shown, a ladle drainage sand diversion pipe, the diversion pipe 8 includes: a funnel 1, a hollow metal pipe 2, a pendulum 3, a bracket 4, a suspension ring 5, and a hinge 6.

[0029] The funnel 1 is located on the top of the hollow metal tube 2 and is in the shape of a bell mouth. Its inner wall is smooth, which facilitates the flow of drainage sand. On the outer edge of the funnel 1, two suspension rings 5 are symmetrically distributed.

[0030] The length of the hollow metal pipe 2 is greater than the height of the ladle, and the difference between the length of the hollow metal pipe 2 and the height of the operating platform is in the range of 1m˜1.5m.

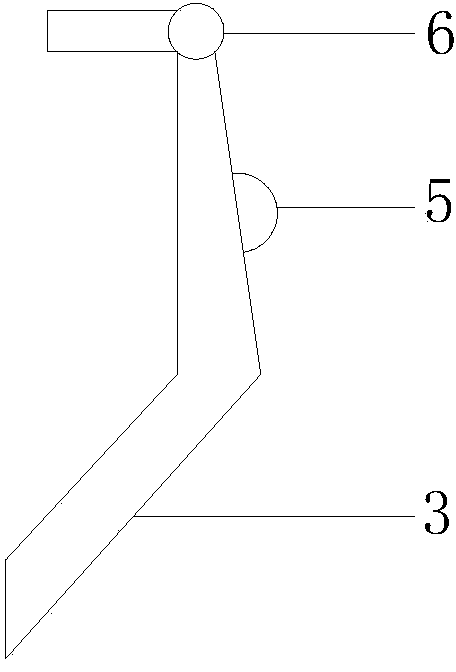

[0031] Such as image 3 As shown, the pendulum 3 is located at 1 / 3 of the upper part of the hollow metal tube 2, and the pendulum 3 and the hollow metal tube 2 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com