Device and method for preventing molten steel from splashing during casting starting

A fixing device and ladle technology, which is applied in the direction of casting melt containers, manufacturing tools, metal processing equipment, etc., can solve problems such as refractory consumption, hydraulic cylinder stroke control is not in place, ladle nozzle is too small or too large, etc., to achieve The effect of reducing the consumption of refractory materials, preventing safety accidents and improving the self-opening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

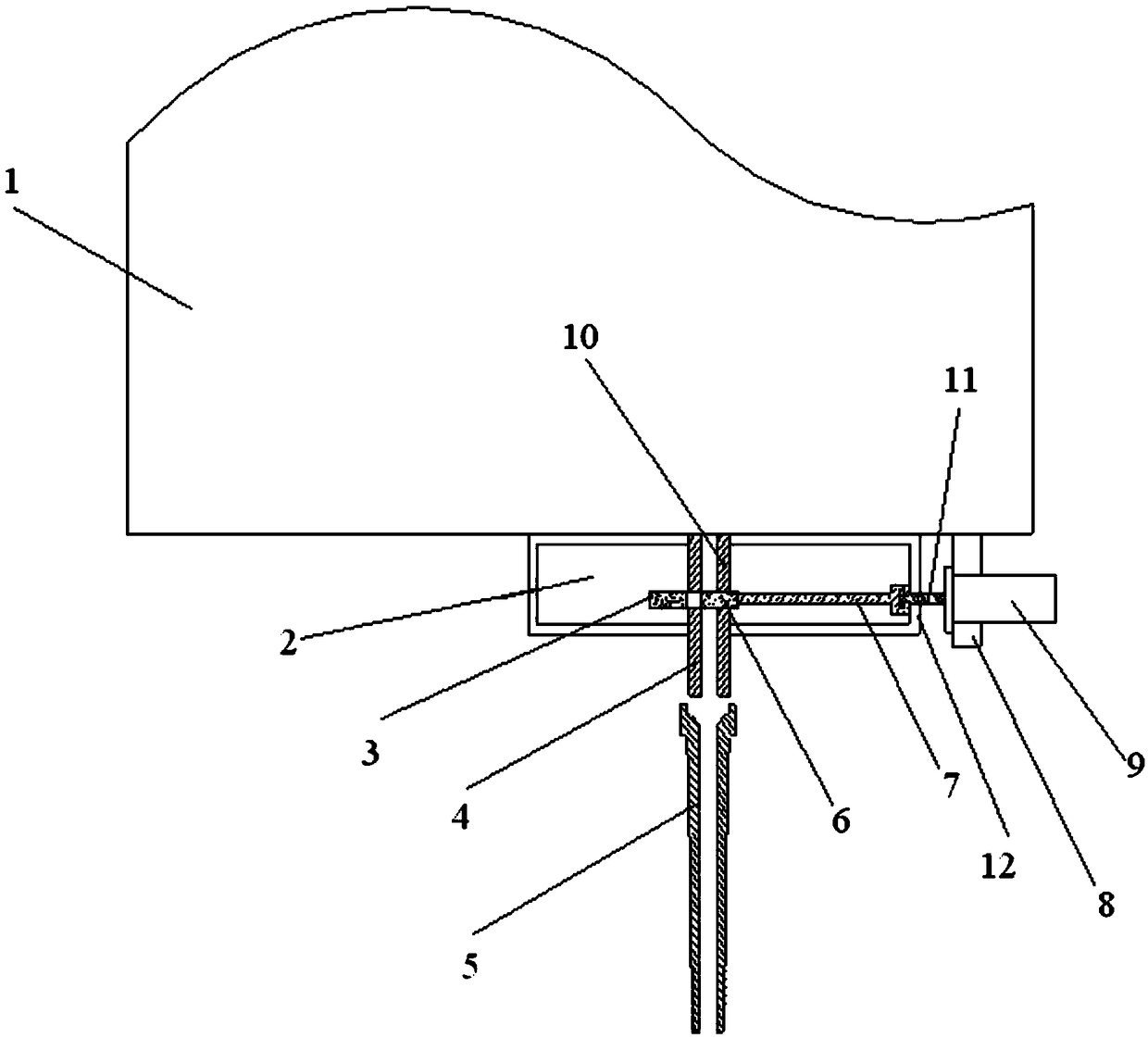

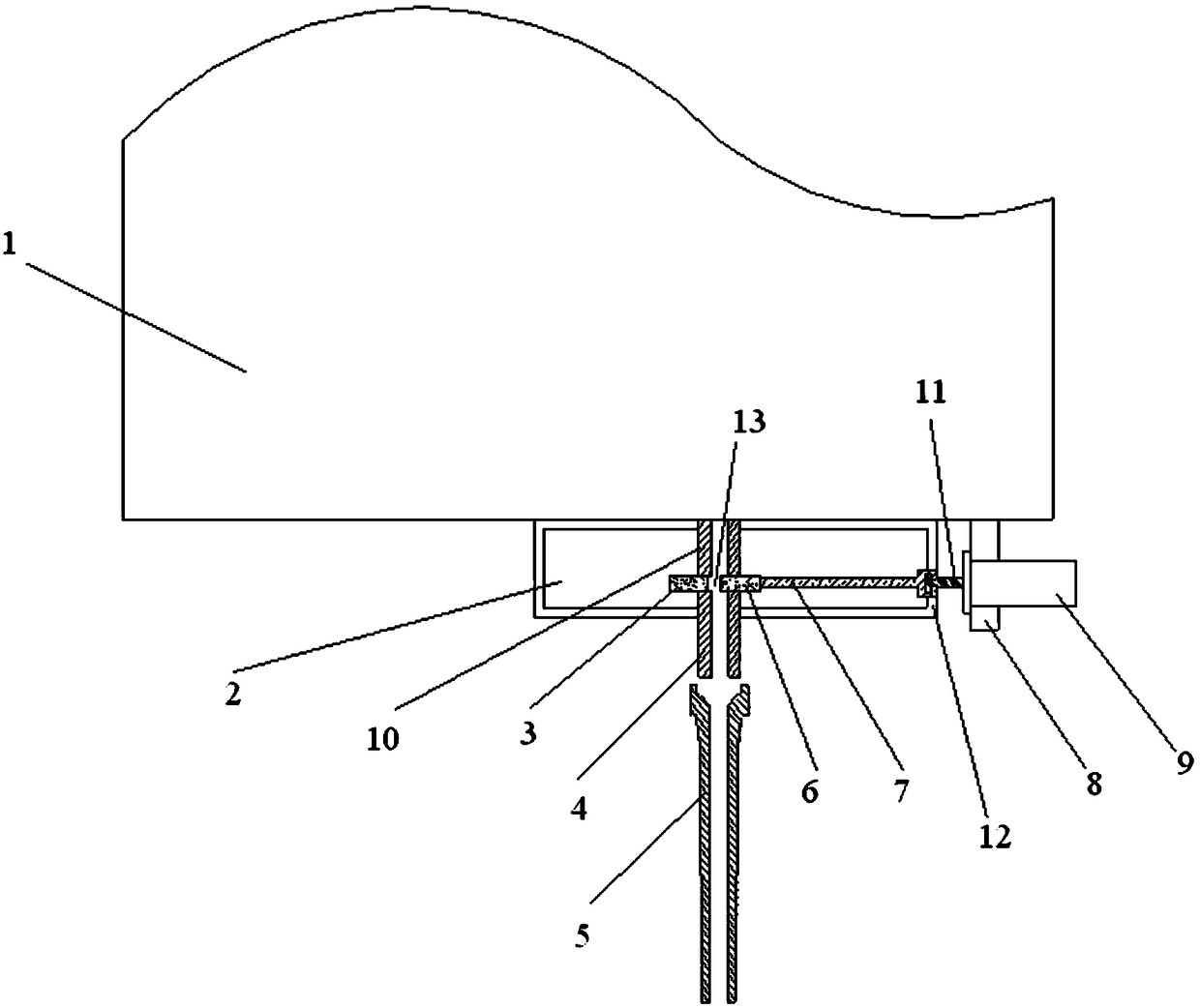

[0026] Such as figure 1 and 2 As shown, the present invention provides a device for preventing pouring and spraying steel, which includes: ladle nozzle mechanism 2, ladle nozzle, first ladle nozzle slide plate 3, second ladle spout slide plate 6, sliding Operating rod 7, ladle nozzle fixing device 12, hydraulic shaft 11, hydraulic cylinder 9, hydraulic cylinder fixing device 8 and ladle nozzle 5; the ladle nozzle mechanism 2 is installed at the bottom of the ladle 1, and the ladle nozzle is fixed The device 12 is set outside the ladle nozzle mechanism 2 and fixed on the bottom of the ladle 1. The ladle nozzle fixing device 12 fixes the ladle nozzle mechanism 2 on the bottom of the steel ladle 1; the ladle nozzle is inserted vertically into the ladle nozzle and fixed The device 12 and the ladle nozzle mechanism 2 are fixed on the bottom of the ladle 1; part of the ladle nozzle located inside the ladle nozzle mechanism 2 is provided with an opening 13, and the opening 13 divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com