Ladle filler sand discharge device and continuous casting ladle casting starting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

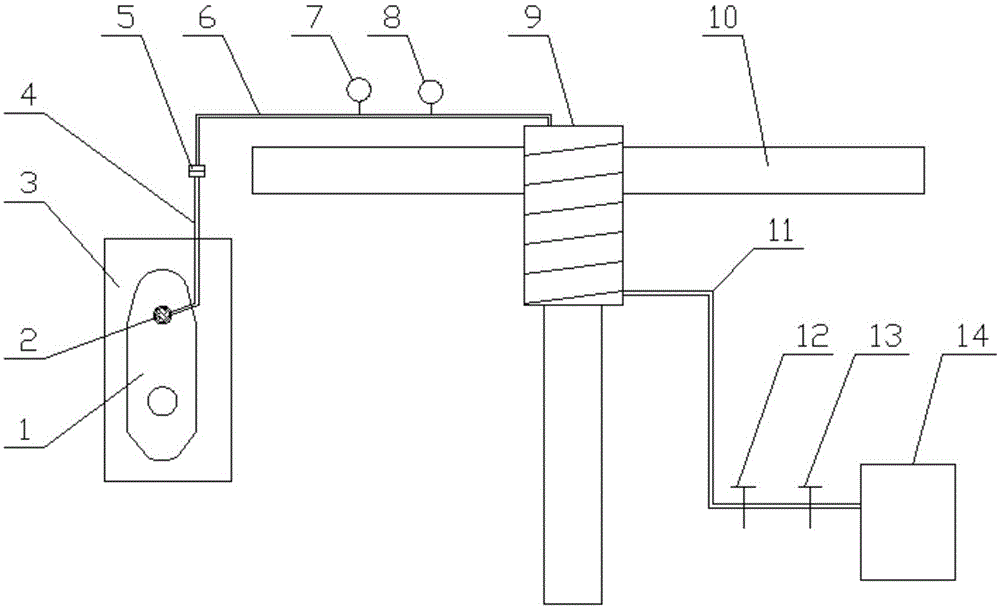

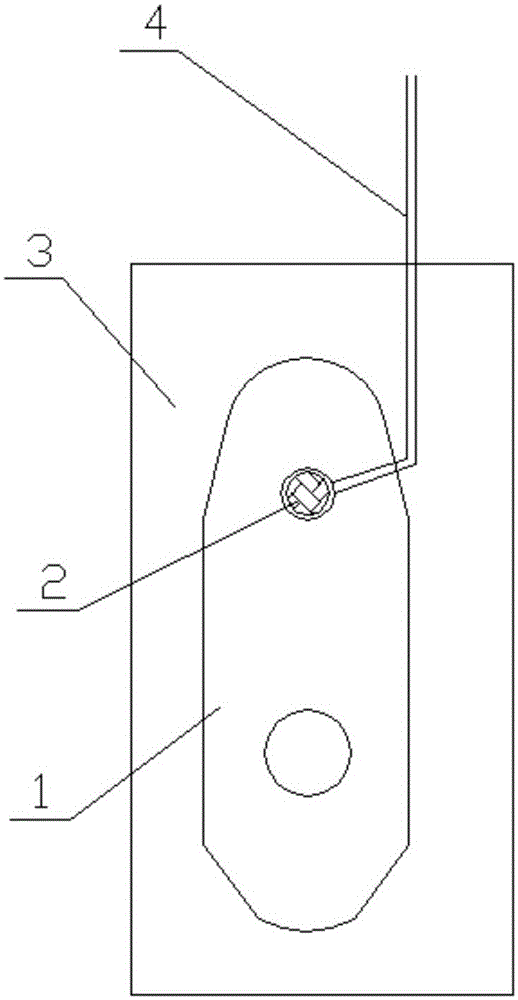

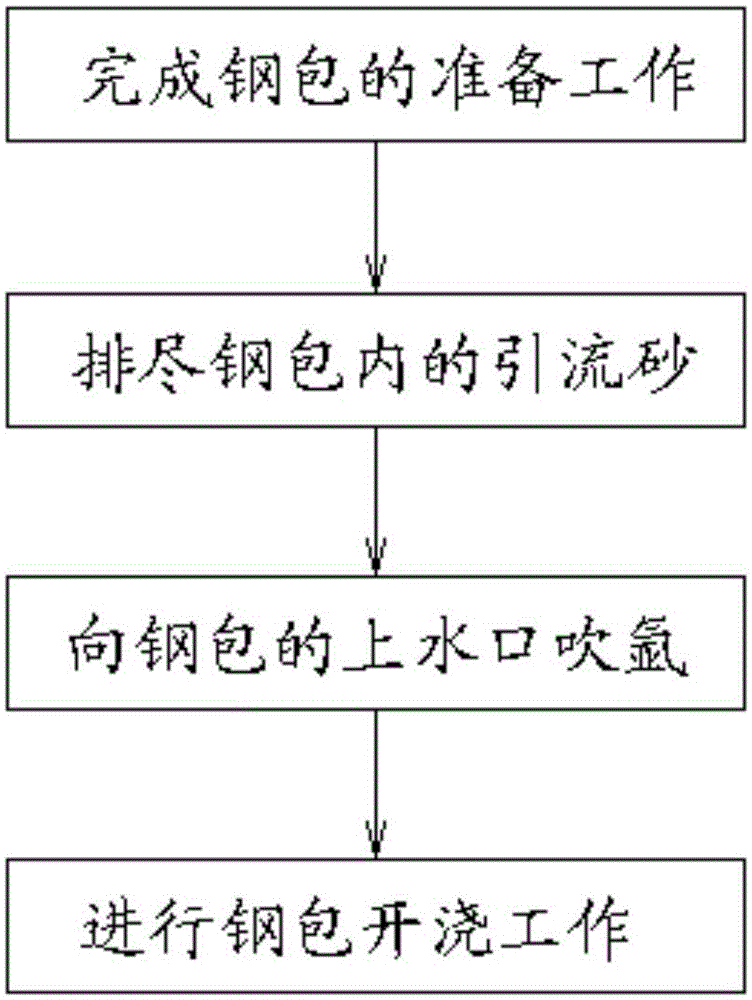

Embodiment 1

[0063] Fix the ladle on the fork wall seat of the ladle turret 10 above the accident ladle, and the oil cylinder of the ladle drives the movable frame 3, so that the upper nozzle of the ladle mechanism is connected with the lower nozzle, and the drainage sand in the ladle is exhausted. When the ladle mechanism flows out When the molten steel forms a circular flow, immediately slide the movable frame 3 so that the vent plug 2 on the slide plate 1 is located at the position of the upper nozzle of the ladle mechanism, connect the second argon pipe 6 and the third argon pipe 4 through the quick joint 5, and open the pressure regulating valve 13 and The flow regulating valve 12, the argon gas supply part 14 continuously feed argon gas into the upper nozzle through the argon gas pipeline and the vent plug 2, control the pressure of the argon gas at 0.8Mpa through the pressure detection part 8, and control the flow rate of the argon gas through the flow detection part 7 At 150L / min, t...

Embodiment 2

[0065] Fix the ladle on the fork wall seat of the ladle turret 10 above the accident ladle, and the oil cylinder of the ladle drives the movable frame 3, so that the upper nozzle of the ladle mechanism is connected with the lower nozzle, and the drainage sand in the ladle is exhausted. When the ladle mechanism flows out When the molten steel forms a circular flow, immediately slide the movable frame 3 so that the vent plug 2 on the slide plate 1 is located at the position of the upper nozzle of the ladle mechanism, connect the second argon pipe 6 and the third argon pipe 4 through the quick joint 5, and open the pressure regulating valve 13 and The flow regulating valve 12, the argon gas supply part 14 continuously feed argon gas into the upper nozzle through the argon gas pipeline and the vent plug 2, control the pressure of the argon gas at 1.2Mpa through the pressure detection part 8, and control the flow rate of the argon gas through the flow detection part 7 At 300L / min, t...

Embodiment 3

[0067] Fix the ladle on the fork wall seat of the ladle turret 10 above the accident ladle, and the oil cylinder of the ladle drives the movable frame 3, so that the upper nozzle of the ladle mechanism is connected with the lower nozzle, and the drainage sand in the ladle is exhausted. When the ladle mechanism flows out When the molten steel forms a circular flow, immediately slide the movable frame 3 so that the vent plug 2 on the slide plate 1 is located at the position of the upper nozzle of the ladle mechanism, connect the second argon pipe 6 and the third argon pipe 4 through the quick joint 5, and open the pressure regulating valve 13 and The flow regulating valve 12, the argon gas supply part 14 continuously feed argon gas into the upper nozzle through the argon gas pipeline and the vent plug 2, control the pressure of the argon gas at 1.5Mpa through the pressure detection part 8, and control the flow rate of the argon gas through the flow detection part 7 At 400L / min, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com