Continuous casting steel ladle no-drainage casting device

A technology for continuous casting of steel and ladles, applied in casting equipment, casting molten material containers, metal processing equipment, etc., can solve problems affecting the quality of molten steel, pollution of molten steel quality, increasing the workload of continuous casting operators, etc., and achieve improvement Self-opening rate and the effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

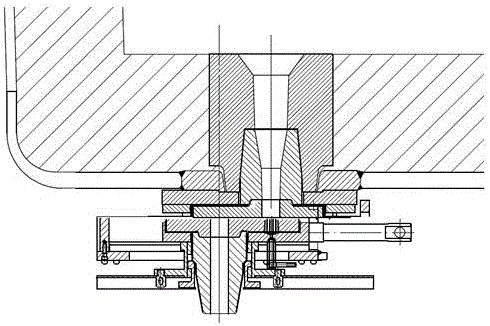

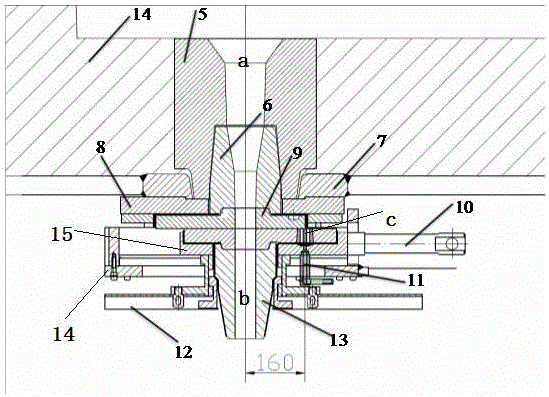

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

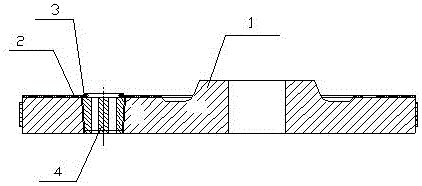

[0017] like Figures 1 to 3 As shown, the continuous casting ladle in this embodiment has no drainage and pouring device, including an upper nozzle mechanism and a lower nozzle mechanism. The upper nozzle mechanism is fixedly arranged at the bottom of the ladle 14 and has an upper nozzle a connected to the ladle 14. The lower nozzle mechanism is correspondingly arranged below the upper nozzle mechanism. The lower nozzle mechanism has a lower nozzle b and an argon blowing port c. (not shown) can make the lower nozzle mechanism move laterally relative to the upper nozzle mechanism to realize the alternate connection between the lower nozzle b and the argon blowing port c and the upper nozzle a.

[0018] Specifically, the upper nozzle mechanism includes a seat brick 5, which is fixedly arranged on the bottom of the ladle 14 through the seat bric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com