Preparation method of ladle filler sand

A technology for drainage sand and magnesia, applied in the field of drainage sand, can solve the problems of high cost and high price of zircon, and achieve the effects of reducing the number of times of oxygen blowing and drainage, improving the self-opening rate, and adding simplicity and convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

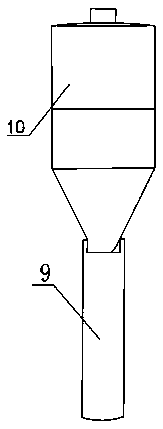

[0068] Embodiment 1: first put the lower port of the long pipe funnel 9 into the sliding nozzle of the ladle;

[0069] Then the bottle cap 7 of the conical plastic packaging barrel 10 is opened, put it upside down into the upper port of the conical long tube funnel 9, under the action of gravity, the drainage sand is directly added in the ladle sliding nozzle through the long tube funnel 9, and The process is uniform, stable, accurate and reliable. After the addition is complete, lift the funnel upwards slowly and evenly to make the drainage agent form a high left and right ball crown. The specific joining process is attached image 3 shown.

[0070] Preferably, this patent uses a long tube funnel 9 to add, the pipe diameter is 100mm, and the inclination angle of the funnel is 60°C. When adding, the bottle cap 7 is opened, and the plastic bucket is placed on the top of the funnel, under the influence of gravity and the better fluidity of the drainage sand Next, the air ente...

Embodiment 2

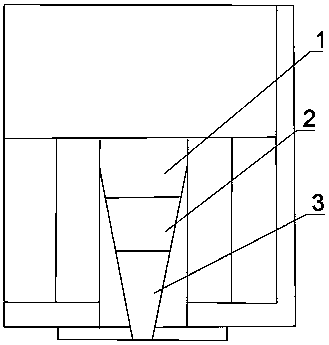

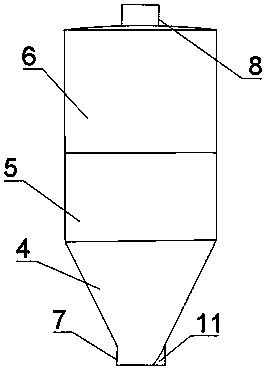

[0073] Embodiment 2: the volume of the packaging drum 10 of conical plastic can be determined according to the volume of drainage sand used in each furnace of ladles of different sizes in each steel plant, and the loading capacity is about 5-20% more than the theoretical usage, so as to ensure that the addition is inaccurate Meet the use requirements under abnormal conditions. Drainage sand is added in a certain proportion and order. The chrome drainage sand is located at the bottom of the packaging barrel 10, the composite drainage sand is the upper part of the packaging barrel 10, and the mixed drainage sand layer 2 is in the middle. When packaging, ensure that the drainage sand fills the conical plastic packaging barrel 10, and then perform vacuum sealing. Ensure that the upper and lower drainage sands do not undergo violent mixing and movement during transportation and use; figure 2 shown.

[0074] The bottom of the packaging barrel is provided with a bottle cap 7, and...

Embodiment 3

[0077] Embodiment 3: The diameter of the bottle mouth of the packaging drum 10 adopting conical plastic is about 70mm, the inclination angle of the cone is 60°C, the diameter of the cylinder is 250mm, the height of the conical section is about 180mm, the height of the whole body is about 300mm, the overall height is 480mm, and the volume It is 18L, suitable for adding drainage sand to a 120-ton ladle in a steel factory.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com