Cantilever type steel ladle drainage sand adding device

A technology of drainage sand and cantilever type, which is applied in the direction of metal processing equipment, casting molten material container, casting equipment, etc., can solve the problems of high labor intensity, poor working environment, large consumption of refractory materials, etc., and achieve the prospect of wide application and saving Consumption of refractory materials and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

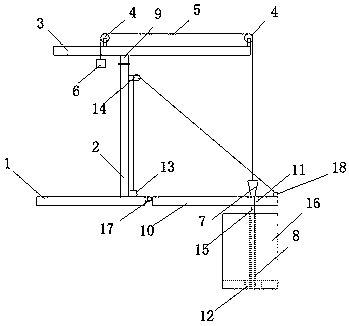

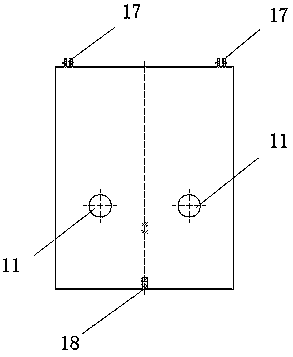

[0021] figure 1 It is shown that a cantilever type ladle adding drainage sand device of the present invention includes a rectangular platform 1, a column 2 vertically fixed on the center line in the width direction of the platform 1, a rotary bearing 9 installed on the top of the column 2, and a fixed connection with the rotary bearing 9 And the cantilever 3 in the horizontal state and the turning platform 10 connected to the right side of the platform 1 through the hinge shaft 17;

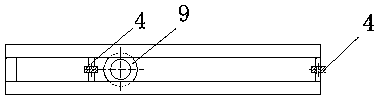

[0022] figure 1 and figure 2 It shows that after the cantilever 3 is fixedly connected with the rotary bearing 9, the cantilever 3 is perpendicular to the column 2, and the cantilever 3 can rotate on the horizontal plane with the rotary bearing 9 as the center of circle; the right end of the cantilever 3 and the positions close to the left end are respectively fixed with two fixed pulleys 4; figure 1 It shows that the steel wire rope 5 passes through two fixed pulleys 4, and the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com