A kind of silicon carbon drainage agent and preparation method thereof

A drainage agent and silicon carbon technology, applied in the field of metallurgy, can solve the problems of low self-opening rate, over-sintering, high heat transfer coefficient, etc., and achieve the effect of improving self-opening rate, ensuring purity, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

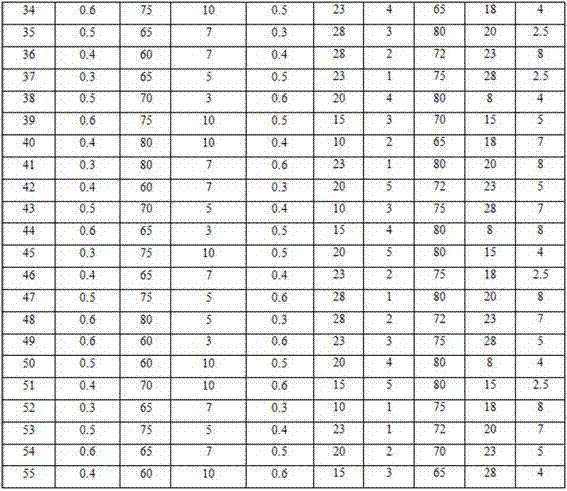

[0014] A silicon-carbon draining agent, consisting of the following raw materials in parts by weight: 60-80 parts of quartz sand with a particle size of 0.3-0.6 mm, 1-10 parts of phosphor flake graphite powder with a particle size of 325 mesh and a pass rate of 97%, and a particle size of 10-28 parts of 0.3-0.6mm silicon carbide, 1-5 parts of adhesive.

[0015] SiO in the quartz sand 2 The weight percentage is greater than or equal to 98%, Fe in quartz sand 2 o 3 The weight percentage is less than 0.3%.

[0016] The weight percentage of silicon carbide in the silicon carbide is greater than 90%.

[0017] The weight percentage of fixed carbon in the phosphor flake graphite powder is greater than 90%.

[0018] The mass percent of its active ingredient is: SiO 2 65-80%, SiC 8-28%, C 2.5-8%, and the rest are trace elements. The trace elements are iron oxide, calcium oxide and magnesium oxide.

[0019] The draining agent prepared from the raw materials in the present invent...

Embodiment 2

[0023] A silicon-carbon draining agent, consisting of the following raw materials in parts by weight: 65-75 parts of quartz sand with a particle size of 0.4-0.5 mm, 3-7 parts of phosphorus flake graphite powder with a particle size of 325 mesh and a pass rate of 97%, and a particle size of 15-23 parts of 0.4-0.5mm silicon carbide, 1-3 parts of adhesive.

[0024] SiO in the quartz sand 2 The weight percentage is greater than or equal to 98%, Fe in quartz sand 2 o 3 The weight percentage is less than 0.3%.

[0025] The weight percentage of silicon carbide in the silicon carbide is greater than 90%.

[0026] The weight percentage of fixed carbon in the phosphor flake graphite powder is greater than 90%.

[0027] The mass percent of its active ingredient is: SiO 2 70-75%, SiC 15-20%, C 4-7%, and the rest are trace elements. The trace elements are iron oxide, calcium oxide and magnesium oxide.

[0028] The draining agent prepared from the raw materials in the present invent...

Embodiment 3

[0032] A silicon-carbon draining agent, consisting of the following raw materials in parts by weight: 70 parts of quartz sand with a particle size of 0.4mm, 5 parts of phosphorus flake graphite powder with a particle size of 325 mesh and a pass rate of 97%, and silicon carbide with a particle size of 0.4mm 20 parts, 2 parts adhesive.

[0033] SiO in the quartz sand 2 The weight percentage is greater than or equal to 98%, Fe in quartz sand 2 o 3 The weight percentage is less than 0.3%.

[0034]The weight percentage of silicon carbide in the silicon carbide is greater than 90%.

[0035] The weight percentage of fixed carbon in the phosphor flake graphite powder is greater than 90%.

[0036] The mass percent of its active ingredient is: SiO 2 72%, SiC 18%, C 5%, and the rest are trace elements. The trace elements are iron oxide, calcium oxide and magnesium oxide.

[0037] The draining agent prepared from the raw materials in the present invention has no pollution to molte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com