Equipment for continuously producing accelerator TMTD and a method for continuously producing accelerator TMTD

A technology of accelerators and equipment, applied in the direction of organic chemistry, can solve problems such as low labor efficiency, product quality differences, and long reaction cycles in intermittent production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

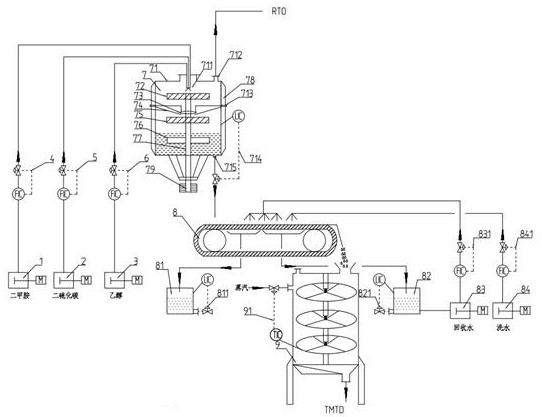

[0048]A continuous production accelerator TMTD equipment includes a high-gravity reactor, a water washing device and a drying device.

[0049] A feed port 711 and an exhaust port 712 are set on the top of the supergravity reactor. The feed port 711 is connected to a dimethylamine metering pump 1, a carbon disulfide metering pump 2, and an ethanol metering pump 3 through pipelines, and each metering pump is connected through a pipeline. Corresponding raw material storage tanks, and dimethylamine flow regulating valve group 4, carbon disulfide flow regulating valve group 5 and ethanol flow regulating valve group 6 are respectively installed on the pipeline, and different raw materials are pumped into the feed port 711 for reaction with respective metering pumps , in order to ensure that the raw materials are evenly mixed, the feed port 711 is equipped with a distributor at the end of the three pipelines, and the exhaust port 712 is connected to the RTO through the pipeline.

[0...

Embodiment 2

[0057] A method for continuous production of accelerator TMTD, using the above-mentioned continuous production of accelerator TMTD equipment, the specific steps include:

[0058] S1, open the feed port of the supergravity reactor 7, the exhaust port 712 and the discharge port 715, open the supergravity reactor 7, open the supergravity reactor jacket 78, the first rotating disk 72, and the second rotating disk 75 , The chilled water inlet and outlet valves of the fixed plate 74.

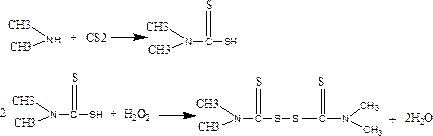

[0059] S2, open dimethylamine flow regulating valve group 4, carbon disulfide flow regulating valve group 5 and ethanol flow regulating valve group 6, open dimethylamine metering pump 1, carbon disulfide metering pump 2 and ethanol metering pump 3, simultaneously dimethylamine with 0.1L / min (the content of dimethylamine is 40%), carbon disulfide at 0.06L / min and ethanol at 0.20L / min are pumped into the supergravity reactor 7, the reaction temperature of dimethylamine and carbon disulfide is 20-30℃, tw...

Embodiment 3

[0066] A method for continuous production of accelerator TMTD, using the above-mentioned continuous production of accelerator TMTD equipment, the specific steps include:

[0067] S1, open the feed port of the supergravity reactor 7, the exhaust port 712 and the discharge port 715, open the supergravity reactor 7, open the supergravity reactor jacket 78, the first rotating disk 72, and the second rotating disk 75 , The chilled water inlet and outlet valves of the fixed plate 74.

[0068] S2, open dimethylamine flow regulating valve group 4, carbon disulfide flow regulating valve group 5 and ethanol flow regulating valve group 6, open dimethylamine metering pump 1, carbon disulfide metering pump 2 and ethanol metering pump 3, simultaneously dimethylamine with 0.15L / min (dimethylamine content is 40%), carbon disulfide at 0.09L / min and ethanol at 0.40L / min are pumped into the supergravity reactor, the reaction temperature of dimethylamine and carbon disulfide is 20-30℃, dimethylam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com