Method and equipment for producing paper towels from sugarcane pulp

A technology for paper towels and sugarcane pulp, applied in the field of papermaking, can solve the problems of uneven product quality, different process technologies, and insufficient consumer satisfaction, and achieves the effects of firm hand, good water absorption, and good uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

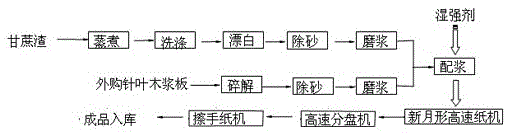

Method used

Image

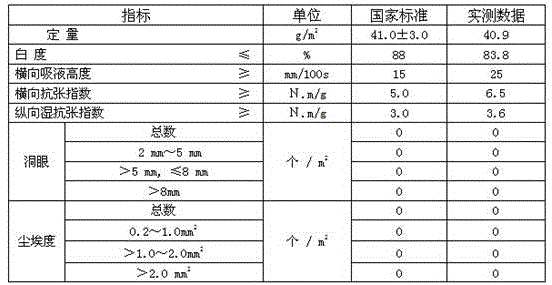

Examples

Embodiment 1

[0031] 1. The present invention adopts raw material proportioning:

[0032]Bagasse pulp and coniferous wood pulp are used as raw materials, ratio: 80-90% bagasse pulp + 10-20% coniferous wood pulp, bagasse pulp is cooked by kraft method and oxygen delignification, and kraft method is used for cooking and oxygen delignification Lignin, coniferous wood pulp When purchasing commercial pulp, the main consideration is that if whole sugarcane pulp is used for papermaking, although it has better water absorption, it has higher hardness and slightly weaker tensile force. After adding 10-20% coniferous wood pulp, it can improve paper quality. softness and toughness.

[0033] 2. Treatment of slurry:

[0034] 1) Use a hydraulic pulper to crush the pulping board;

[0035] 2) The high-concentration desander purifies the slurry and removes sand and other impurities;

[0036] 3) Use a double disc mill to loosen the slurry, reduce the degree of beating, and improve water absorption;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com