Device and production method for continuously producing rubber vulcanization accelerator diphenylguanidine

A technology for rubber vulcanization and production methods, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as the inability to precisely control the reaction temperature, the uneven stirring of the reaction liquid, and the inability to release heat in time, so as to improve the The effect of equipment utilization efficiency, avoiding quality fluctuation and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

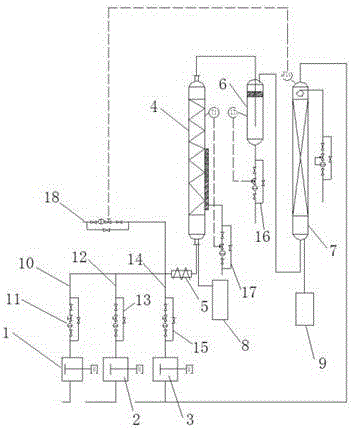

[0033] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises diphenylthiourea, ammonia-water mixed liquid metering pump 1, catalyst peristaltic metering pump 2, pipeline reactor 4, preheater 5, oxygen compressor 3, gas-liquid separator 6, gas-liquid washing tower 7, Continuous filtering device 8, ammonia water receiver 9. Diphenylthiourea, ammonia-water mixed solution metering pump 1 is connected to the bottom of pipeline reactor 4 through mixed solution pipeline 10, and mixed solution pipeline 10 is provided with diphenylthiourea, ammonia-water mixed solution flow regulating valve group 11; Catalyst peristaltic metering pump 2 is connected to the bottom of the pipeline reactor 4 through the catalyst pipeline 12, and the catalyst flow regulating valve group 13 is provided on the catalyst pipeline 12; the oxygen compressor 3 is connected to the bottom of the pipeline reactor 4 through the oxygen pipeline 14, and the oxygen pip...

Embodiment 2

[0039] Adopt the equipment shown in embodiment, the production method of continuous production rubber vulcanization accelerator diphenyl guanidine comprises:

[0040] Make diphenylthiourea and ammonia water at a molar ratio of 1:8, and the concentration of ammonia water at 20% to make a slurry, and use a metering pump at a rate of 1m per hour. 3 The amount of feed is pumped into the pipeline reactor, the catalyst is made into a 30% aqueous solution, and the peristaltic metering of 0.34L per hour is pumped into the pipeline reactor, and the new oxygen pressure is adjusted to 0.45Mpa, and the reactor is slowly boosted, and the pipeline reaction is opened at the same time When the steam in the jacket of the device is heated up to 50°C, the pressure of the belt system begins to drop. When the temperature starts to rise, change the heating steam to circulating water in time, and continue to pass oxygen. When the liquid level appears in the belt gas-liquid separator, when the pressur...

Embodiment 3

[0042] Adopt the equipment shown in embodiment, the production method of continuous production rubber vulcanization accelerator diphenyl guanidine comprises:

[0043] Make a slurry of diphenylthiourea and ammonia water at a molar ratio of 1:5 and a concentration of ammonia water of 30%, and use a metering pump at a rate of 1m per hour. 3The amount of feed is pumped into the pipeline reactor, the catalyst is made into a 30% aqueous solution, and the peristaltic metering of 0.34L per hour is pumped into the pipeline reactor, and the new oxygen pressure is adjusted to 0.45Mpa, and the reactor is slowly boosted, and the pipeline reaction is opened at the same time The steam in the jacket jacket is heated to 55°C, and the system pressure begins to drop. When the temperature begins to rise, change the heating steam to circulating water in time, and continue to pass oxygen. When the liquid level appears in the belt gas-liquid separator, when the pressure rises to 0.4Mpa, Turn on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com