Method for controlling hot rolling aluminum plate quality

A quality control method and technology for aluminum sheets, applied in metal rolling, profile control, metal rolling, etc., can solve problems such as unfavorable product market competitiveness, affecting product grade and price, affecting product quality and output, etc., to reduce maintenance. Cost, good washing and cleaning ability, low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

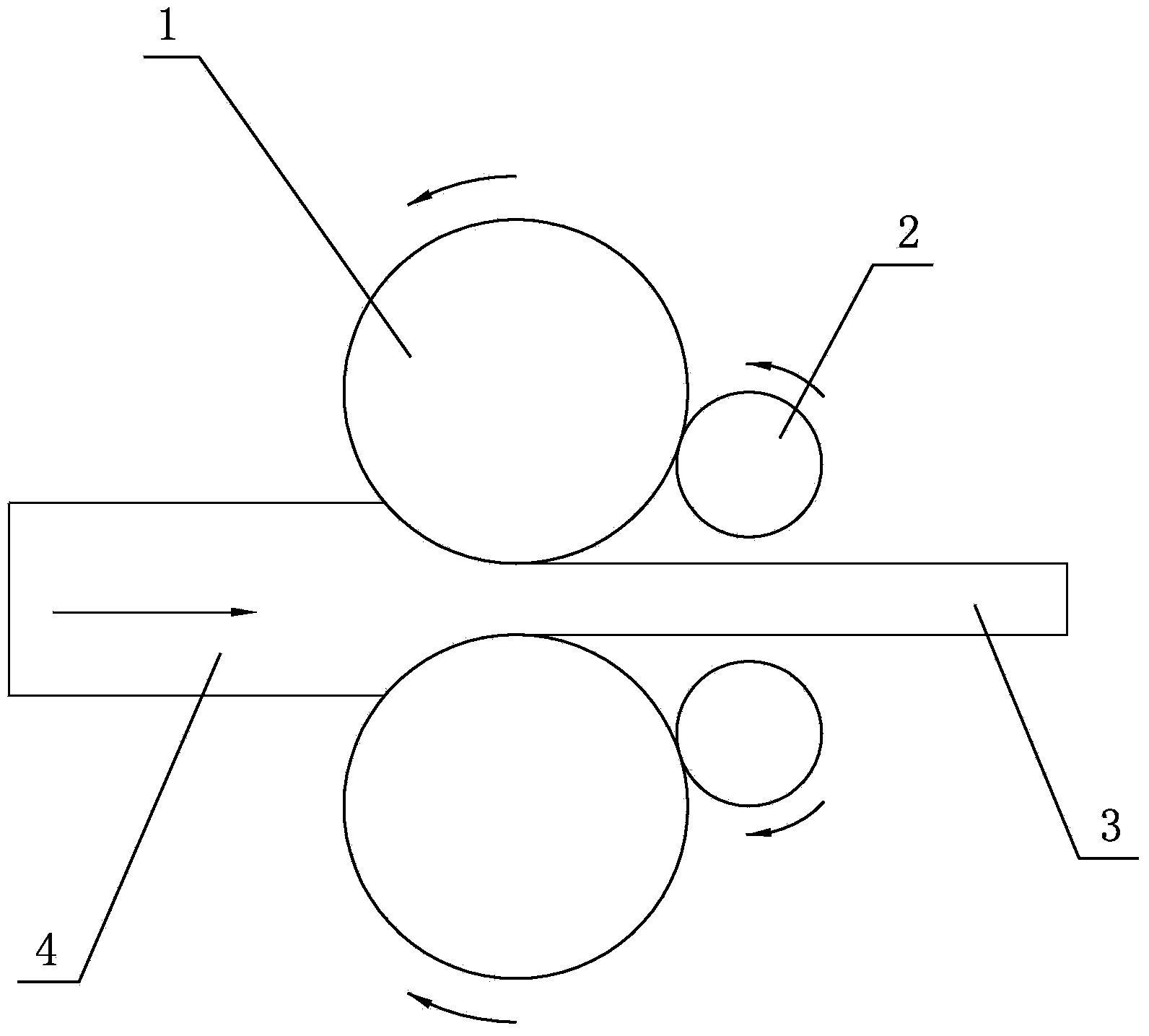

[0028] Control the concentration of lubricating fluid to 3.5%; slowly add 7000L of base oil, and then add a certain amount of additives to adjust the lubricating grease content in the lubricating fluid to 28.6%; adjust the PH value of the lubricating fluid to 5.5; heat the steam flow, and control the temperature of the lubricating fluid to 50°C; turn on the lubrication system to circulate for more than 8 hours, the lubricating liquid is continuously circulated through the mechanical shearing action of the pump and the nozzle, and the particle size gradually decreases and stabilizes between 0.9 and 1.1 μm. Such as figure 1 As shown, the number of work rolls 1 and 2 are two each, located on the exit side, and used in the last few rolling passes. Adjust the direction of the roller cleaner 2 so that the rotation tangent direction is opposite to the rotation tangent direction of the work roll 1. The ingot is heated to 500° C. and held for 8 hours before rolling out of the furnace. ...

Embodiment 2

[0030] Control the lubricating fluid concentration to 2.5%; slowly add base oil 5000L, then add a certain amount of additives, adjust the grease content in the lubricating fluid to 30.0%; adjust the PH value of the lubricating fluid to 7; heat the steam flow to control the lubricating fluid The temperature was 65°C. All the other are with embodiment 1.

Embodiment 3

[0032] Control the concentration of lubricating fluid to 4%; slowly add base oil 8000L, then add a certain amount of additives, adjust the grease content in the lubricating fluid to 25%; adjust the PH value of the lubricating fluid to 7.5; heat the steam flow to control the lubricating fluid The temperature is 60°C. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com