Corn starch sugar production method

A technology for corn starch sugar and a production method, which is applied in the direction of fermentation and the like, can solve the problems of adverse effects on the quality of finished starch sugar products, reduce the added value of sugar residue, and have no practical application value, so as to avoid the quality fluctuation of sugar residue and low residual sugar content. , The effect of solving the drying difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

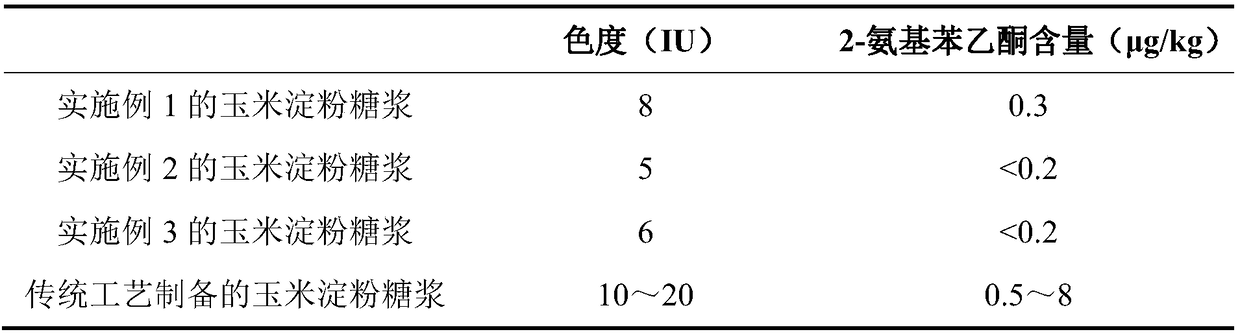

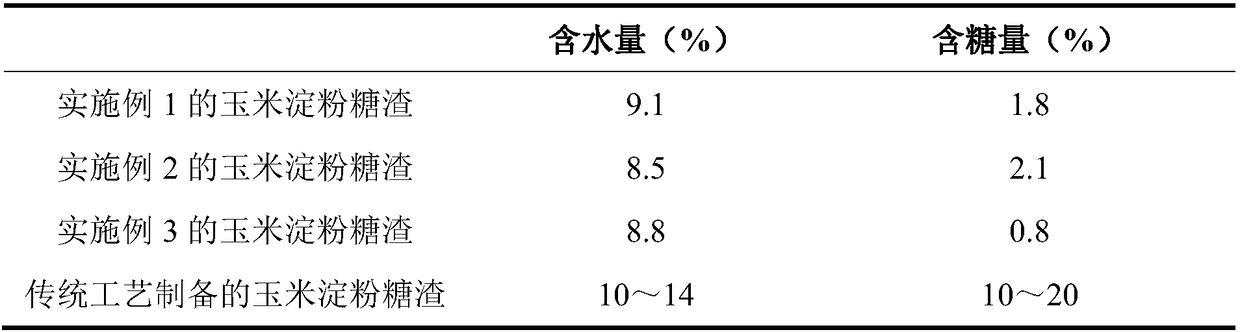

Examples

Embodiment 1

[0047] A kind of production method of corn starch sugar, comprises the following steps:

[0048] 1) Liquefaction: Add 60-62°C process water to cornstarch to form starch milk at 19°Bé, adjust the pH value to 5.6, add Liquozyme supraα-amylase (the amount added is 0.03% of the cornstarch mass), and then Continuous jet liquefaction of starch milk at 107-108°C, after flash cooling, add Liquozyme supraα-amylase (addition amount is 0.03% of the mass of corn starch), and keep the liquefied solution at 92-94°C for 100 minutes;

[0049] 2) Primary centrifugation: cool down the liquefied liquid in step 1) to 65-66°C and then transfer it to a decanter centrifuge (model: Flottweg DECANTER Z6EF-4 / 441) for centrifugation to obtain clear liquid and sugar residue. The liquid is saccharified, refined and concentrated to obtain corn starch syrup;

[0050] 3) Washing sugar residue: add process water at 65-66°C to the sugar residue in step 2) and then transfer to a stirring disperser for homogeni...

Embodiment 2

[0055] A kind of production method of corn starch sugar, comprises the following steps:

[0056] 1) Liquefaction: Add 63-65°C process water to the cornstarch to make starch milk at 20°Bé, adjust the pH value to 5.9, add Liquozyme supraα-amylase (the amount added is 0.02% of the cornstarch mass), and then Continuous jet liquefaction of starch milk at 105-106°C, after flash cooling, add Liquozyme supraα-amylase (addition amount is 0.01% of the mass of corn starch), and keep the liquefied solution at 96-97°C for 110 minutes;

[0057] 2) Primary centrifugation: cool down the liquefied liquid in step 1) to 72-73°C and then transfer it to a decanter centrifuge (model: Flottweg DECANTER Z6EF-4 / 441) for centrifugation to obtain clear liquid and sugar residue. The liquid is saccharified, refined and concentrated to obtain corn starch syrup;

[0058] 3) Washing sugar residue: add process water at 72-73°C to the sugar residue in step 2) and transfer to a stirring disperser for homogeniz...

Embodiment 3

[0063] A kind of production method of corn starch sugar, comprises the following steps:

[0064] 1) Liquefaction: Add 62-63°C process water to cornstarch to make starch milk at 21°Bé, adjust the pH value to 5.8, add Liquozyme 2.2Xα-amylase (addition amount is 0.02% of the mass of cornstarch), Continuous spray liquefaction of starch milk at 108-109°C, after flash cooling, add Liquozyme 2.2Xα-amylase (addition amount is 0.02% of the mass of corn starch), and keep the liquefied solution at 98-99°C for 115 minutes;

[0065] 2) Primary centrifugation: cool down the liquefied liquid in step 1) to 70-71°C and then transfer it to a decanter centrifuge (model: Flottweg DECANTER Z6EF-4 / 441) for centrifugation to obtain clear liquid and sugar residue. The liquid is saccharified, refined and concentrated to obtain corn starch syrup;

[0066] 3) Washing sugar residue: add process water at 70-71°C to the sugar residue in step 2) and transfer to a stirring disperser for homogenization to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com