Novel optical bioreactor

A photobioreactor, reactor technology, applied in photobioreactor, bioreactor/fermenter combination, bioreactor/fermenter for specific purposes, etc., can solve the problem of high cost, large volume, and insufficient natural light. and other problems to achieve the effect of improving yield and quality and meeting growth needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

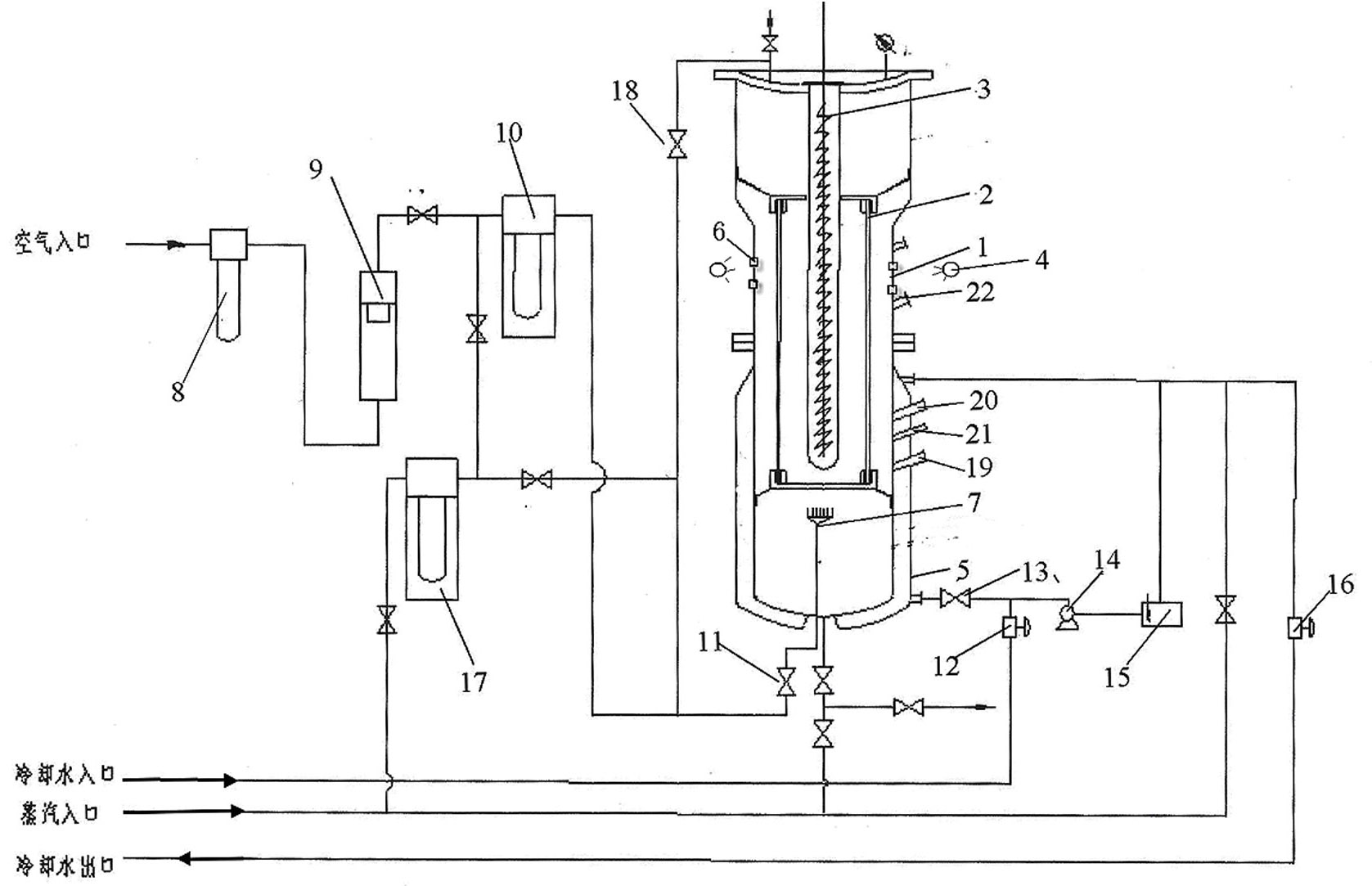

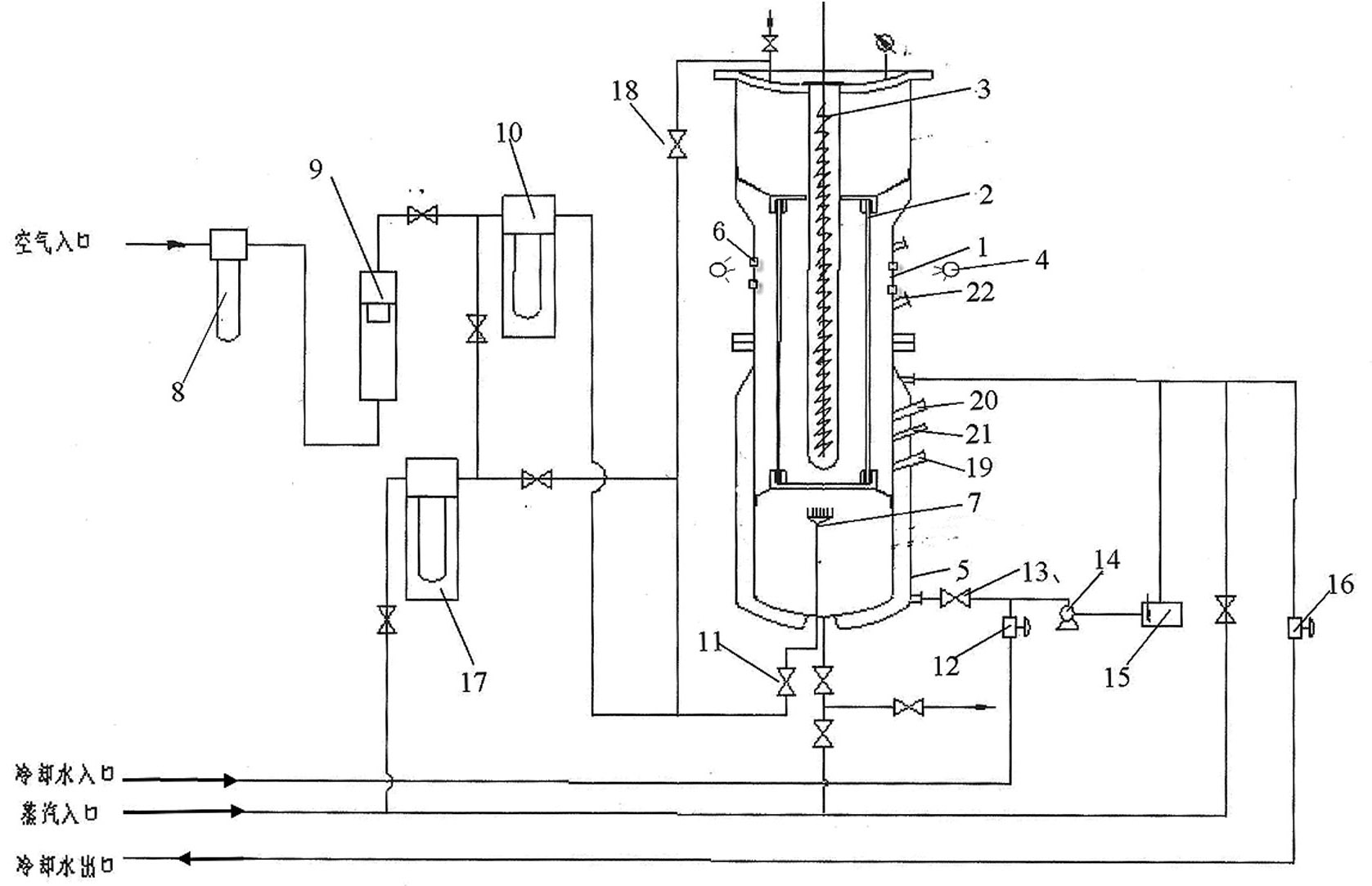

[0007] refer to figure 1 , a new type of photobioreactor, including a reactor cylindrical shell 1, the inner cavity of the reactor cylindrical shell 1 is equipped with a light-transmitting flow guide tube 2, and the light-transmitting flow guide tube 2 is installed with adjustable high light intensity and An LED lamp 3 for high temperature, and a xenon lamp 4 as a light source is arranged on the outer periphery of the cylindrical shell 1 of the reactor.

[0008] An air nozzle 7 connected to an external gas supply pipeline is installed in the inner cavity of the lower part of the cylindrical shell 1 of the reactor.

[0009] The air supply pipeline includes a pre-filter 8 , an air flow meter 9 , an air filter 10 and a valve part 11 in sequence along the air flow direction, and the valve part 11 is connected with the air nozzle 7 .

[0010] A jacket 5 is provided on the outer periphery of the lower part of the cylindrical shell 1 of the reactor. The lower part of the jacket 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com