A process and system for continuous production of rubber vulcanization accelerator tetramethylthiuram disulfide

A technology of tetramethylthiuram disulfide and rubber vulcanization, which is applied in the direction of organic chemistry, can solve the problems of low production efficiency and heavy pollution, and achieve the effects of improving output efficiency, uniform distribution, and avoiding quality fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

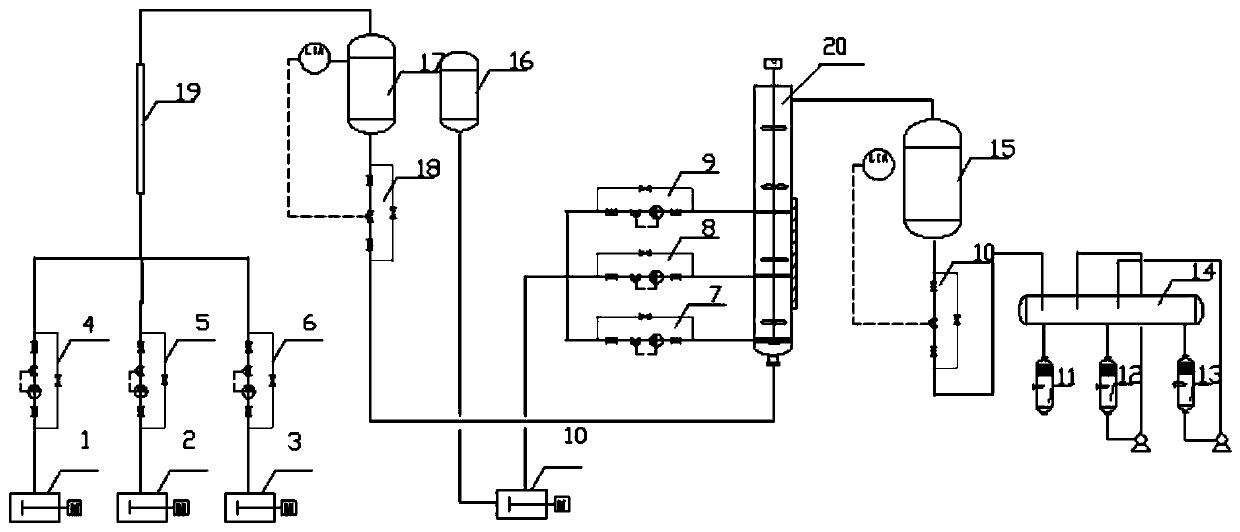

[0030] This embodiment provides a system for continuous production of rubber vulcanization accelerator tetramethylthiuram disulfide, see figure 1 shown, including:

[0031] Material delivery components, including solvent delivery components, dimethylamine delivery components and carbon disulfide delivery components;

[0032] a material mixing component, the input port of which is connected to the output end of the conveying component;

[0033] A tower reactor, the input port of which is connected to the output end of the material mixing assembly, and the hydrogen peroxide delivery assembly is communicated with the tower reactor;

[0034] An eluting device, the input end of which is connected to the output end of the tower reactor.

[0035] The solvent delivery component includes a solvent metering pump 1, and a solvent flow valve group 4, the carbon disulfide delivery component includes a carbon disulfide metering pump 3, and a carbon disulfide flow valve group 6, and the di...

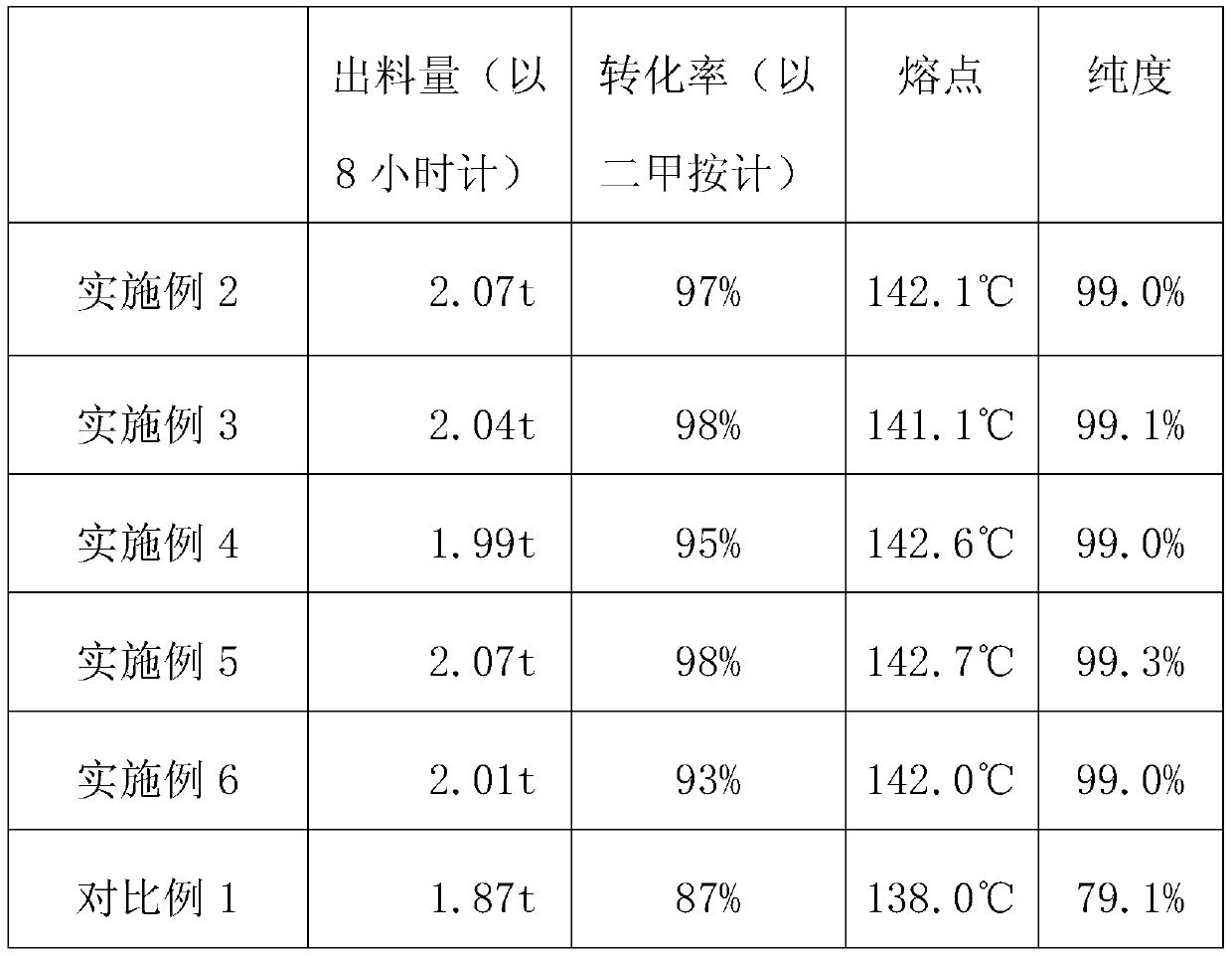

Embodiment 2

[0037] The present embodiment provides a kind of continuous production rubber vulcanization accelerator tetramethyl thiuram disulfide technology, comprises the steps:

[0038] S1. Transport dimethylamine, carbon disulfide and solvent to the mixing tank for ionization reaction to obtain a mixed solution. The molar ratio of dimethylamine to carbon disulfide is 0.8:1, and the mass ratio of solvent to dimethylamine is 3:1; Said solvent is not limited to methyl alcohol, ethanol or isopropanol, and the solvent of the present embodiment is ethanol;

[0039] S2. After the mixed solution enters the tower reactor, the hydrogen peroxide with a concentration of 8wt% enters the tower reactor in three sections, and the reaction temperature is controlled at 20° C. to obtain the reaction solution; wherein, the molar ratio of hydrogen peroxide to dimethylamine 1:0.5;

[0040] S3. When the reaction liquid begins to overflow from the top of the tower reactor to the middle of the reaction liquid...

Embodiment 3

[0043] The present embodiment provides a kind of continuous production rubber vulcanization accelerator tetramethyl thiuram disulfide technology, comprises the steps:

[0044] S1. Transport dimethylamine, carbon disulfide and ethanol to the mixing tank for ionization reaction to obtain a mixed solution. The molar ratio of dimethylamine to carbon disulfide is 0.95:1, and the mass ratio of ethanol to dimethylamine is 6:1;

[0045] S2. After the mixed solution enters the tower reactor, the hydrogen peroxide with a concentration of 20wt% enters the tower reactor in three sections, and the reaction temperature is controlled at 35° C. to obtain the reaction solution; wherein, the molar ratio of hydrogen peroxide to dimethylamine 0.6:1;

[0046] S3. When the reaction liquid begins to overflow from the top of the tower reactor to the middle of the reaction liquid storage tank, start feeding to the eluting device, the mother liquor enters the distillation process, and the primary and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com