Automatic fabric placing and laminating device of artificial leather and PVC (polyvinyl chloride) floor

A technology of artificial leather and bonding device, which is applied to the device for coating liquid on the surface, transportation and packaging, winding strips, etc., and can solve the problem of no automatic cloth placing and bonding device, product quality impact, and high labor intensity and other issues to achieve outstanding economic benefits, stabilize product quality, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

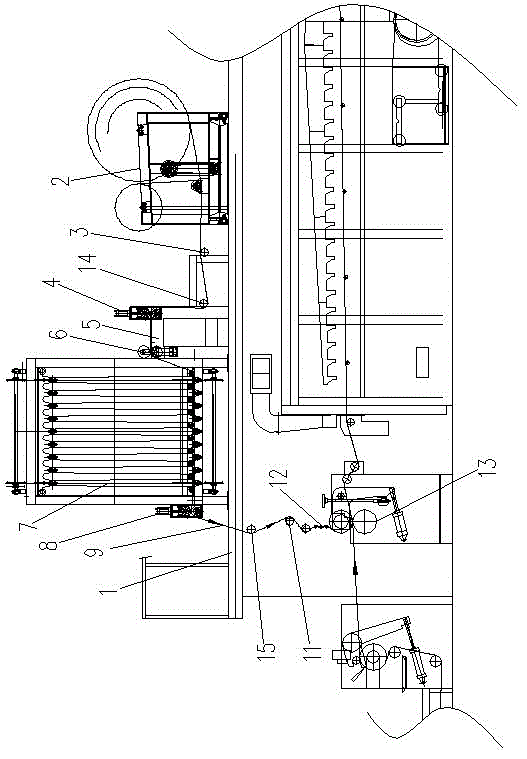

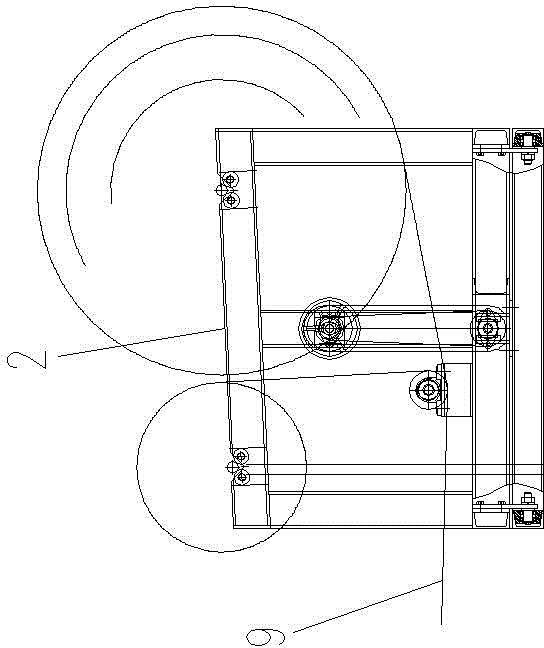

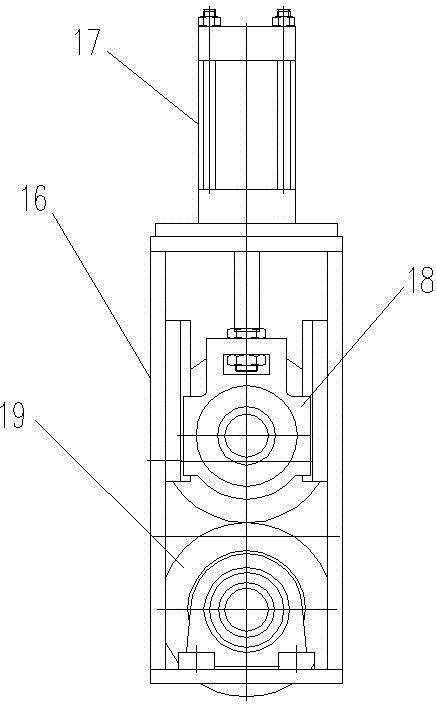

[0028] Such as Figure 1 to Figure 6 As shown, the artificial leather and PVC floor automatic laying and laminating device of the present invention include an operating platform 1, on which a double-station unwinding mechanism 2, a carrier roller 3, a first A traction device 4, a cloth receiving platform 5, a pressing device 6 and a cloth storage device 7, a second traction device 8 is provided on the cloth outlet side of the cloth storage device 7, and a second traction device 8 is provided on the side of the cloth storage device 7 along the moving direction of the base cloth 9. The active spiral spreading device 11, the three-finger edge stripper 12 and the bonding mechanism 13, the base cloth 9 is spread by the active spiral spreading device 11 after being sent out by the second traction device 8; the base cloth 9 is stripped by the three fingers The edge cutter 12 is sent out into the bonding mechanism 13 after stripping. A cloth support roller 3 and a first cloth guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com