Kiln capable of enhancing sintering quality of coloring material

A kiln and pigment technology, applied in the field of pigment firing equipment, can solve problems such as unreasonable structure setting, increase equipment energy consumption, and affect firing quality, so as to avoid quality fluctuation, smooth hot air flow, and improve temperature rise speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

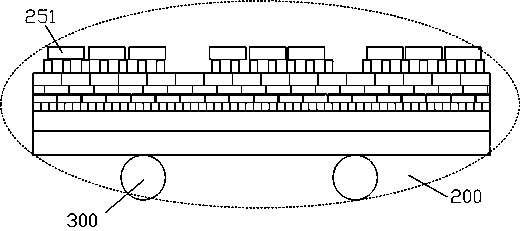

[0022] Such as Figure 1-8 As shown, the kiln that can improve the firing quality of the pigment includes a kiln body and a kiln car 200. The kiln car 200 is pushed into the kiln body for firing. The car 200 forms a sealed kiln together as the kiln bottom and the kiln body.

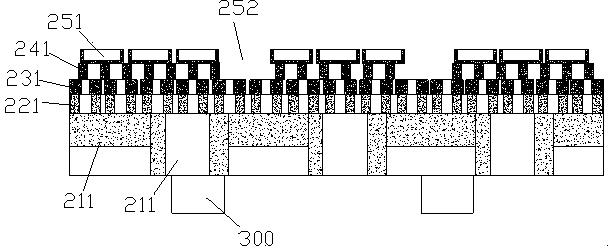

[0023] The kiln car 200 includes a steel plate layer, a refractory brick layer, a hole brick layer, a fireway brick layer and a circular sagger layer from bottom to top, and a plurality of flue channels 211 penetrating through the steel plate layer are arranged in the steel plate layer A plurality of refractory bricks 221 are arranged in the refractory brick layer, and a certain gap is set between adjacent refractory bricks 221; a plurality of hole bricks 231 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com