Box assembling production line, box assembling method, production system and production method for arm joint

A production system and production line technology, applied to other manufacturing equipment/tools, welding equipment, metal processing equipment, etc., can solve problems such as site layout confusion, low operating efficiency, and scattered parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

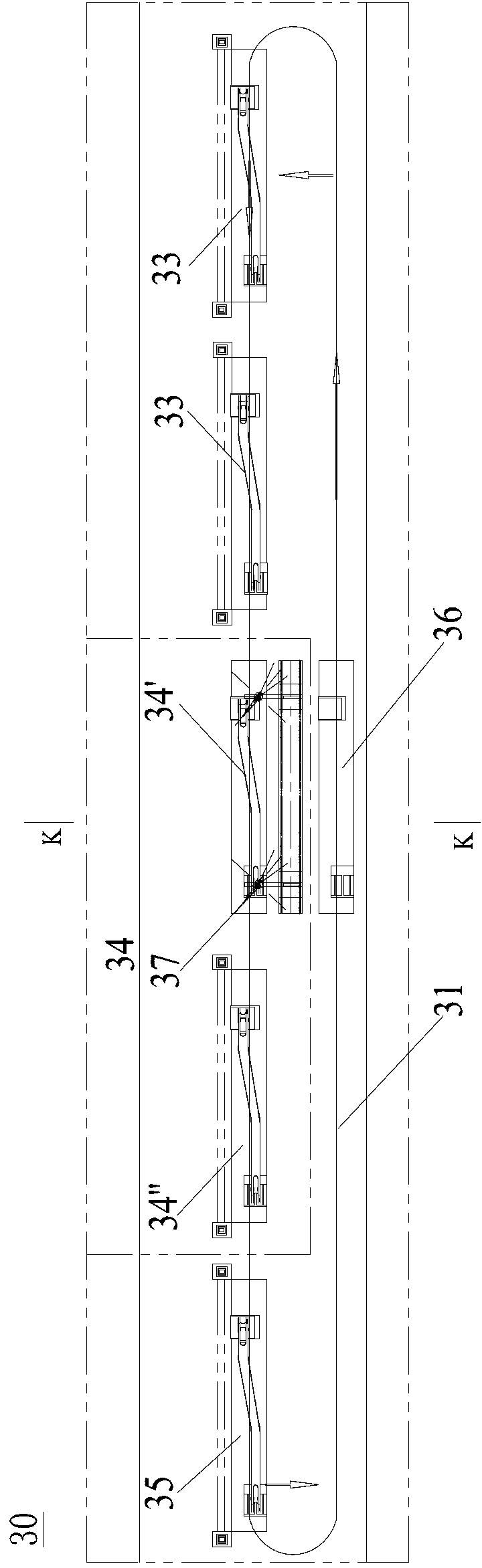

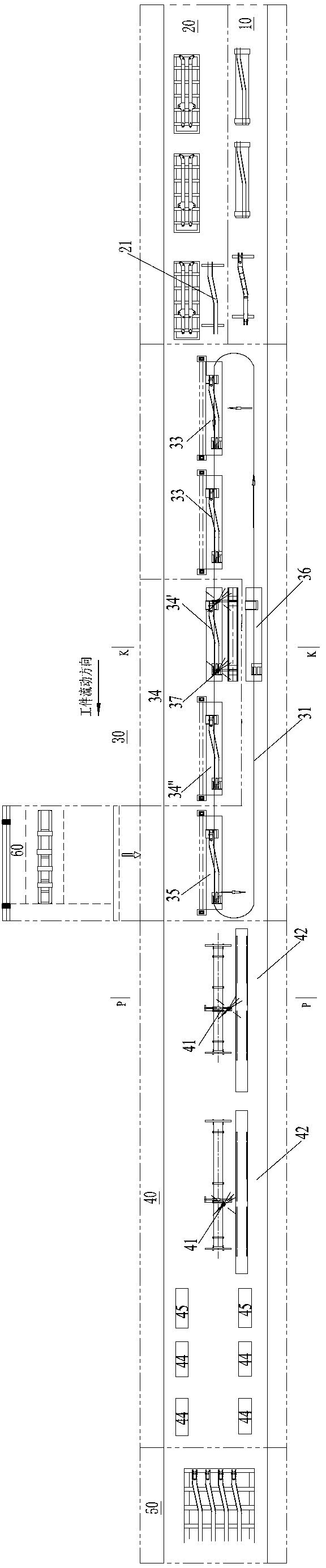

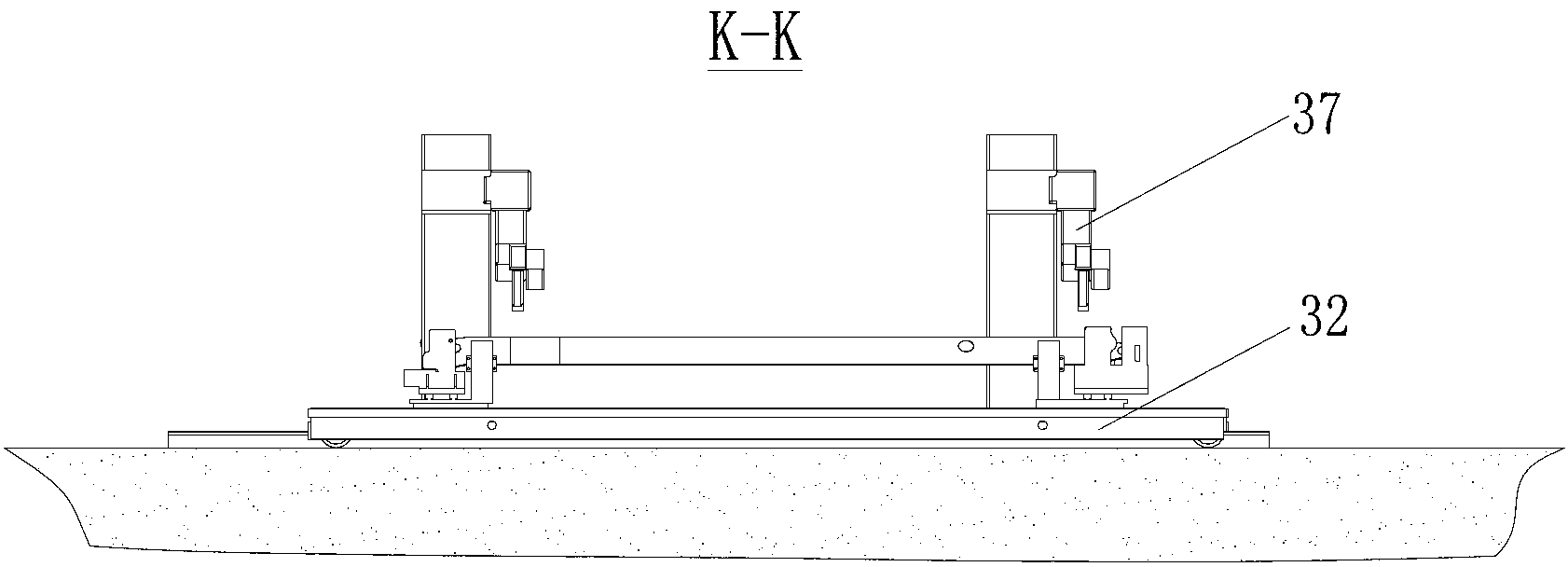

[0072] In the web assembly area 20, a plurality of blanks are assembled and welded to form a web to be assembled, and operations such as bending the welded web can be performed, and the web to be assembled can be stored for subsequent assembly Production line use. In particular, as a preferred embodiment of the present invention, the web assembling area 20 includes a web preliminary positioning station 21 having a web preliminary positioning tool, and the web preliminary positioning station 21 is used to pass through the web The panel initial positioning tool erects the web to be assembled for initial positioning. Before the webs to be assembled are hoisted to the assembly production line 30 for assembly, the web initial positioning tool will turn the flat webs along the axis at a certain angle (such as 90°) and erect them, so that the webs are in an upright position. state, so that the initial positioning is carried out before the web enters the box assembly production line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com