Processing method of pipe clamp parts

A processing method and parts technology, which is applied in the processing field of catheter clamp parts, can solve the problems of unguaranteed product quality, difficult to meet the opening size, and large springback of parts, so as to achieve good product roundness and ensure the outer circle size and high appearance quality and shape precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

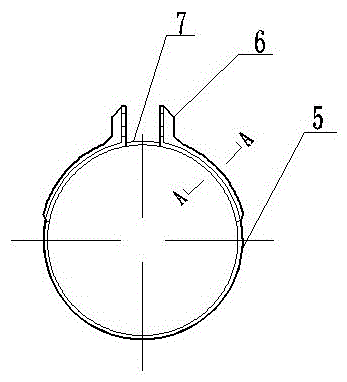

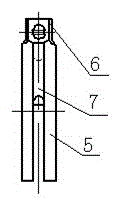

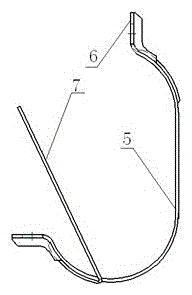

[0028] First introduce the product of the present invention, that is, the structure of the catheter clamp parts, first look at figure 1 , figure 1 It is the structural representation of the product of the present invention, that is, the catheter clamp part. We can see from the figure that the main part of the catheter clamp part of the present invention is an annular hoop 5, and the closed ends of the hoop ring 5 are respectively provided with There are two small ears 6, and a tongue 7 is embedded inside the hoop 5. When the hoop 5 is rolled and closed, the tongue 7 closes the opening between the small ears 6 of the hoop 5. Look figure 2 , Figure 4 , from the side and cross-section, there is a groove in the center of the hoop 5, and the tongue 7 is embedded in the groove. In addition, two small ears 6 are respectively provided with a wais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com