Extensible and retractable inner supporting tool

A technology of tooling and mounting holes, which is applied to auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to effectively control welding deformation, and the inability to put the overall inner supporting tooling into the shell, so as to achieve convenient operation and increase expansion and contraction Amplitude, the effect of eliminating welding stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

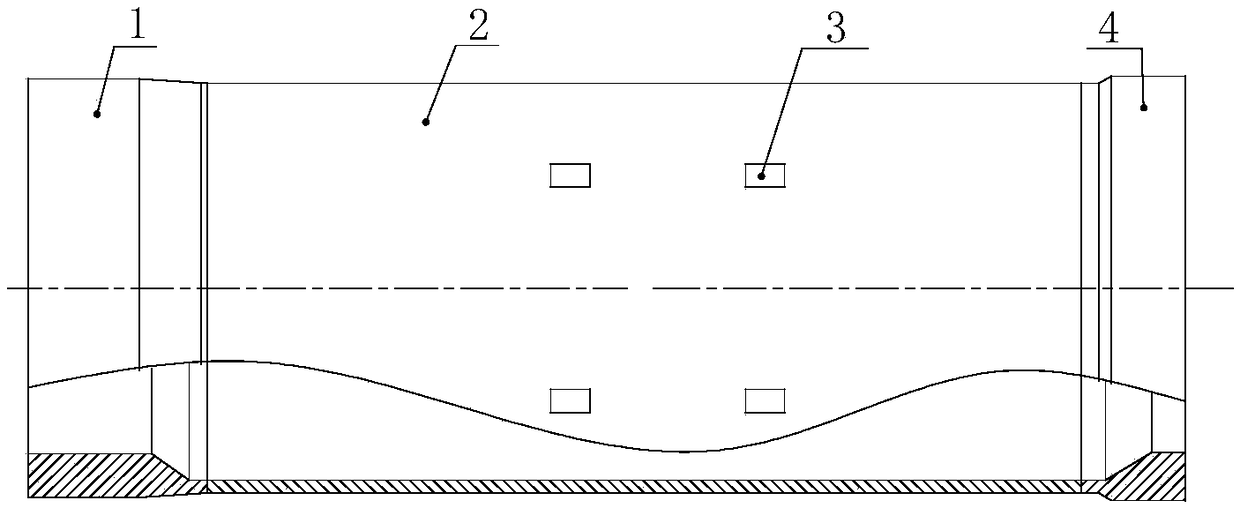

[0022] This embodiment is used for welding deformation control inner support tooling of a certain solid rocket motor. The length of the front flange is l=300mm, inner diameter=230mm, the length of the cylinder is l=800mm, inner diameter=300mm, the length of the rear flange is l=200mm, inner diameter=220mm, the external parts The length is l=30mm, the width=18mm, and the height=30mm. After assembling and welding the external parts, the roundness of the cylinder is required to be no more than 3mm, and the material of the parts is 30CrMnSiA high-strength steel.

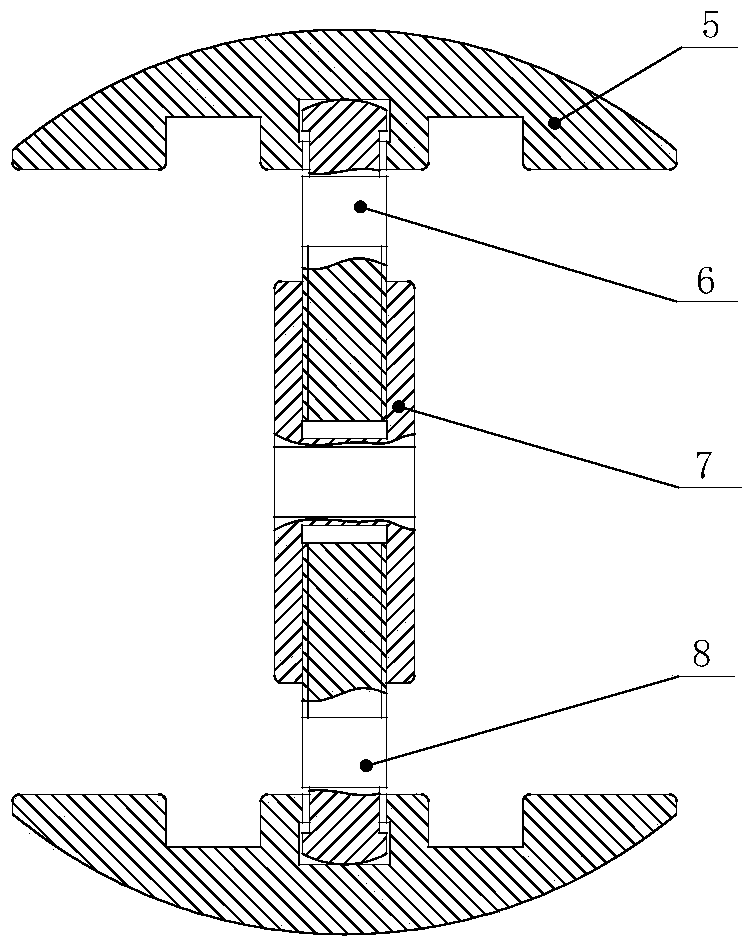

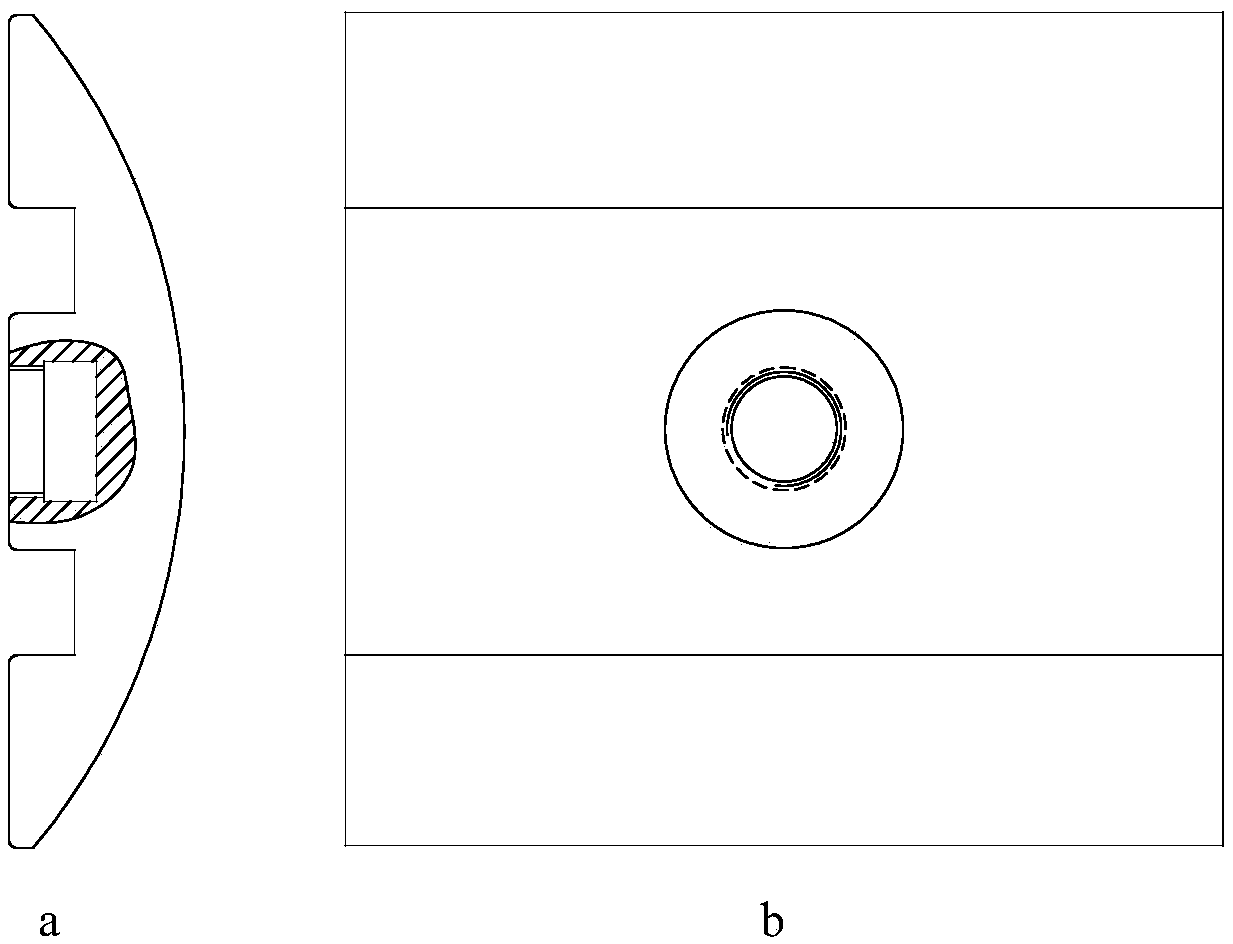

[0023] The tooling of this embodiment includes two support plates 5, a sleeve 7 and a screw rod. Described screw rod has two, is respectively left-handed screw rod 6 and right-handed screw rod 8. Wherein: one end of the left-handed screw 6 is installed in a screw installation hole at the plane geometric center of a support plate, and the left-handed screw is rotated and matched with the screw installation hole; the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com