High power density piezoelectric transducer for ultrasonic surgical instrument

A high power density, piezoelectric transducer technology, applied in the field of medical devices, can solve the problems of severe cutting drop and low ultrasonic power, and achieve the effect of increasing ultrasonic energy, improving directivity, and improving electroacoustic conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

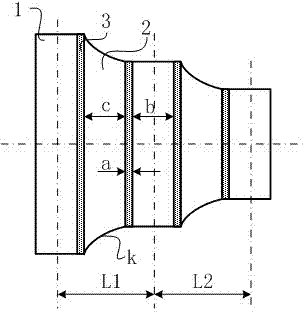

[0019] Such as figure 1 As shown, the high power density piezoelectric transducer for ultrasonic surgical instruments includes three groups of piezoelectric transducer units 1 and two deformation transformation blocks 2, and each deformation transformation block 2 is arranged between two adjacent piezoelectric transducers. An insulating layer 3 with a thickness a is arranged between the units 1 , between the piezoelectric transducer unit 1 and the deformation transformation block 2 . The center distance L1 between the first group of piezoelectric transducing units and the second group of piezoelectric transducing units is equal to the center distance L2 between the second group of piezoelectric transducing units and the third group of piezoelectric transducing units.

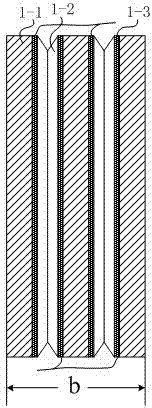

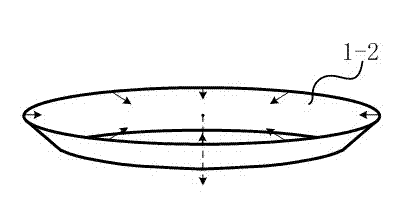

[0020] Such as figure 2 As shown, the piezoelectric transduction unit 1 adopts a piezoelectric stack structure, which is cylindrical in shape as a whole, and includes three coaxially arranged disc-shaped piezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com