Electronic horn for motor vehicle or motor boat

A technology for electronic horns and motor vehicles, which is applied to sound-producing apparatuses, instruments, etc., can solve the problems of complex horn structure, low energy utilization rate, unfavorable energy conservation and environmental protection, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

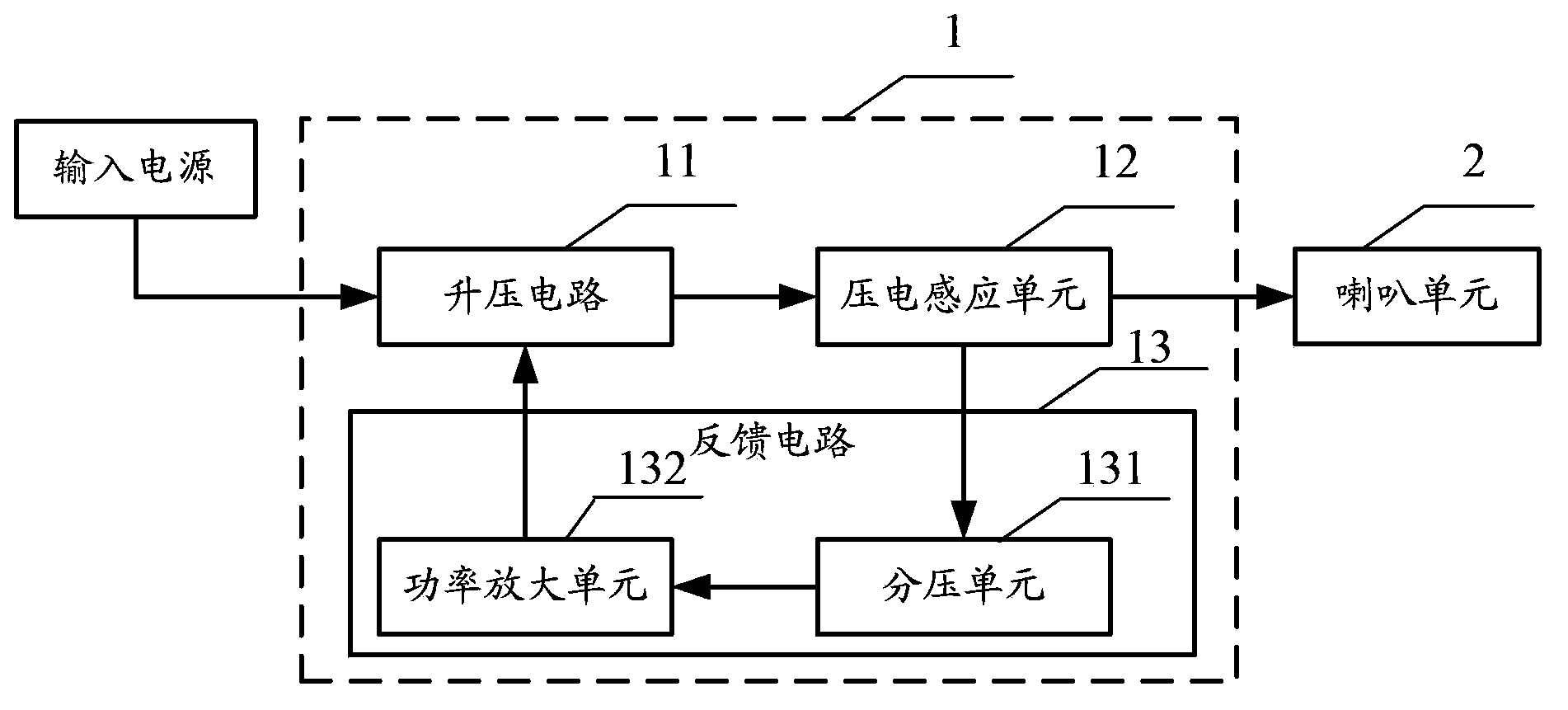

[0016] figure 1 It is the functional block diagram of the motor vehicle marine electronic horn provided by the present embodiment, as figure 1 As shown, the electronic horn for motor vehicles and ships in this embodiment includes a drive device 1 and a horn unit 2 .

[0017] Wherein, the driving device 1 includes a boost circuit 11 , a piezoelectric sensing unit 12 , and a feedback circuit 13 .

[0018] The boost circuit 11 is used for boosting the input voltage to generate a boosted driving voltage. One end of the input end of the boost circuit 11 is connected to the input power supply, and the other end is connected to the feedback circuit 13, so that the working state of the boost circuit 11 is controlled by the feedback circuit 13, and the output terminal of the boost circuit 11 and the piezoelectric induction unit 12 connected to provide the boosted driving voltage to the piezoelectric sensing unit 12 to provide the piezoelectric sensing unit 12 with a driving voltage o...

Embodiment 2

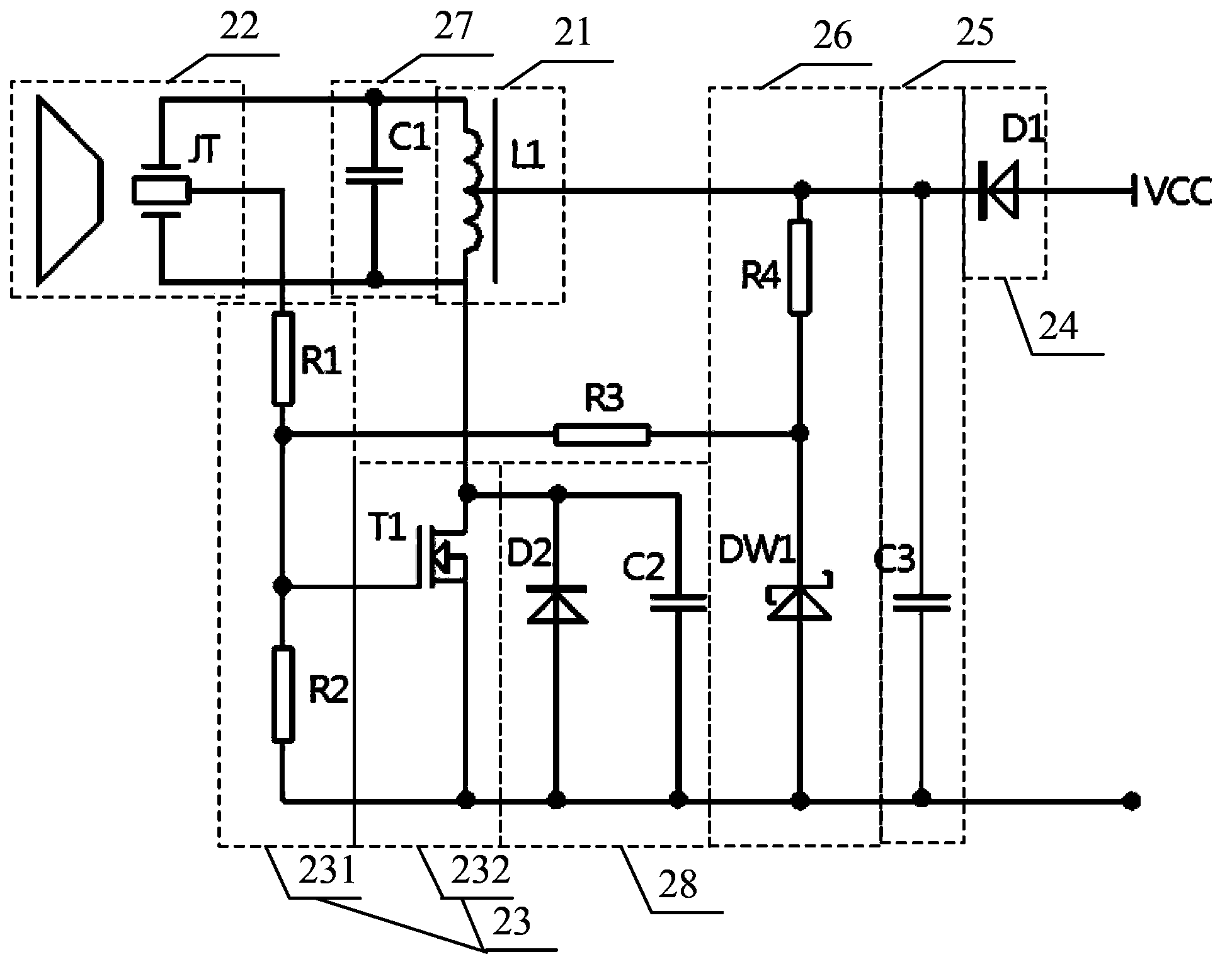

[0025] figure 2 It is the circuit schematic diagram of the motor vehicle marine electronic horn provided by the present embodiment, as figure 2 As shown, the motor vehicle marine electronic horn provided in this embodiment includes a boost circuit 21, a piezoelectric horn 22, a feedback circuit 23, a polarity protection circuit 24, a filter circuit 25, a voltage stabilizing circuit 26, a resonant circuit 27 and an overvoltage protection circuit 28 .

[0026] The boost circuit 21 is used for boosting the input voltage to generate a boosted driving voltage. The boost circuit 21 includes a boost transformer L1, one end of the primary coil of the boost transformer L1 is connected to the input voltage, and the other end of the primary coil of the boost transformer L1 is connected to the output of the feedback circuit, thus the working state of the boost circuit Controlled by the feedback circuit; the secondary coil of the step-up transformer L1 is output to the two poles of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com