Ultrasonic radiator

An ultrasonic and radiator technology, which is applied to other ultrasonic liquid treatment fields, can solve the problems of low electroacoustic efficiency, small radiation area and long cleaning time of ultrasonic vibration system, so as to improve electroacoustic conversion efficiency, increase radiation area, and clean and processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

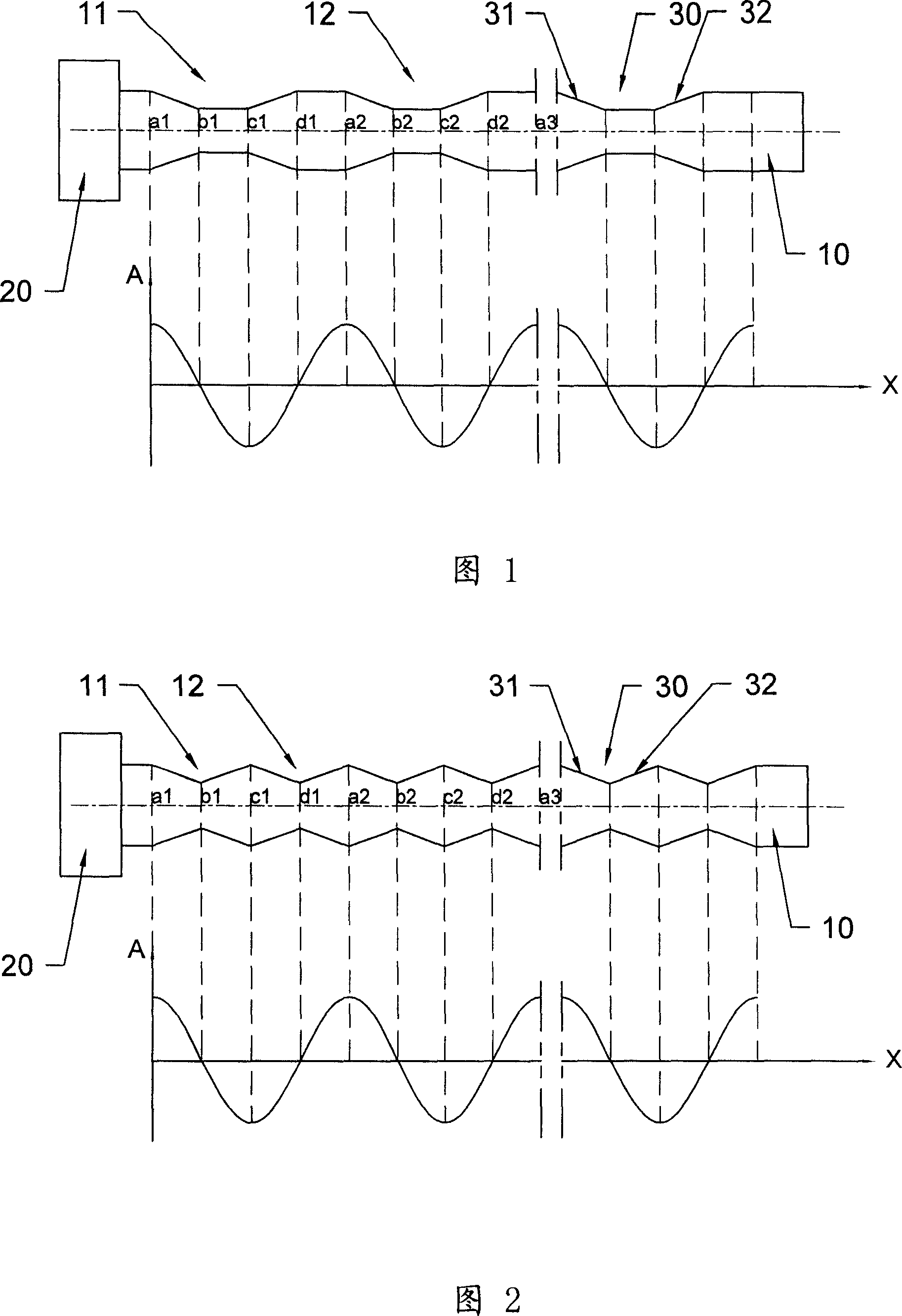

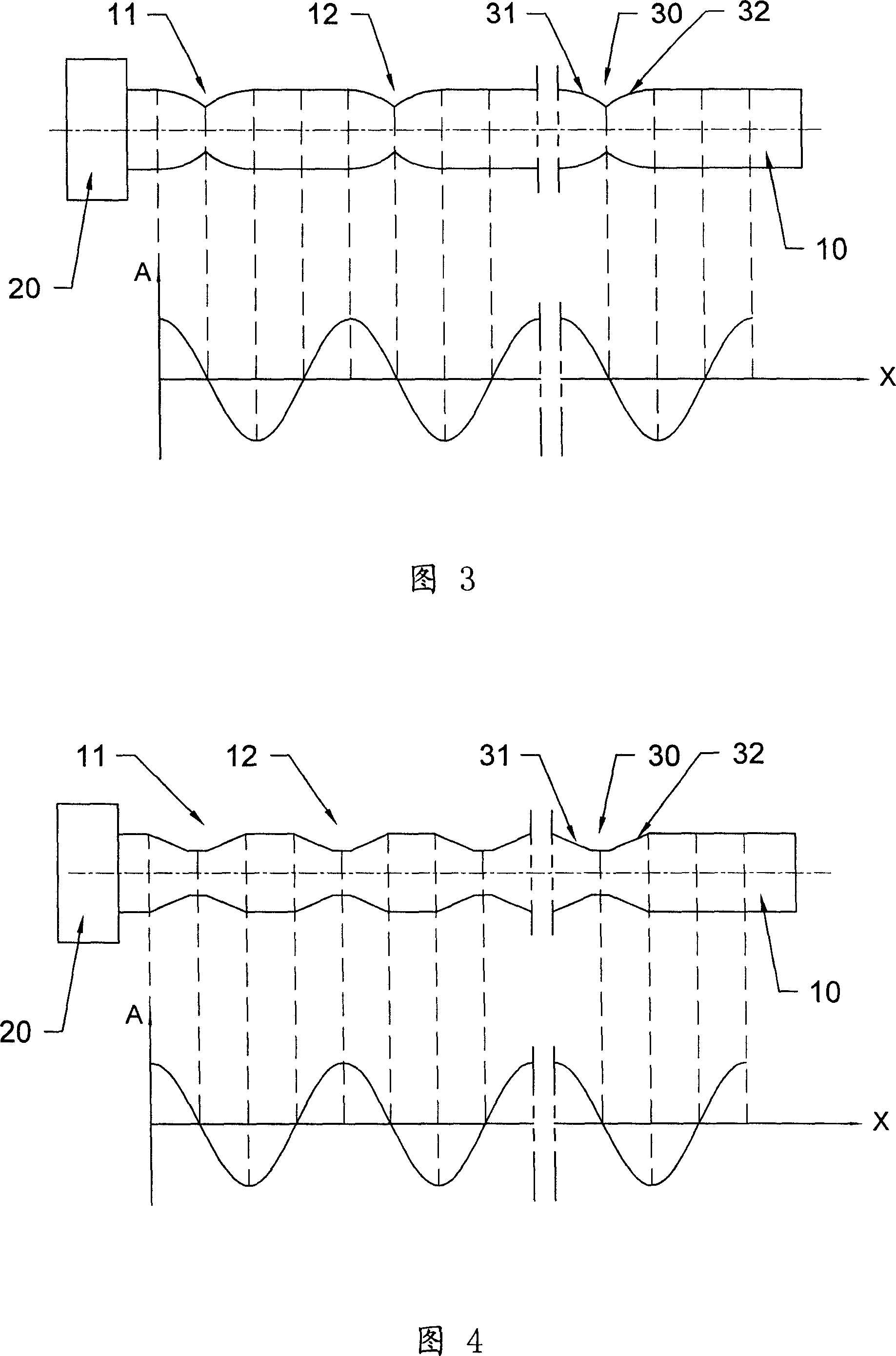

[0019] The upper part shown in FIG. 1 is a schematic structural diagram of the first embodiment of the ultrasonic radiator according to the present invention, and the lower part is a schematic diagram of amplitude distribution. As shown in the upper part of FIG. 1 , in the first embodiment of the ultrasonic radiator of the present invention, it includes a radiation rod 10 and a transducer 20 arranged at one end of the radiation rod 10 . Wherein, the transducer 20 can provide high-frequency mechanical vibration to the radiation rod 10 , and transducers can also be arranged at both ends of the radiation rod 10 . The cross-sectional shape of the radiation rod 10 can be circular, rectangular, and other shapes adapted to the shape of the elongated tube or the wall of the deep hole to be processed, and a plurality of annular grooves 30 are opened around the radiation rod 10, the The cross-sectional shape of the annular groove 30 is trapezoidal, including two annular radiating surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com