Fixed shaft type outer rotor brushless motor

A brushless motor, outer rotor technology, applied in synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc., can solve problems such as increased power consumption, increased noise, and increased mechanical loss , to achieve the effect of extending service life, increasing reliability and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

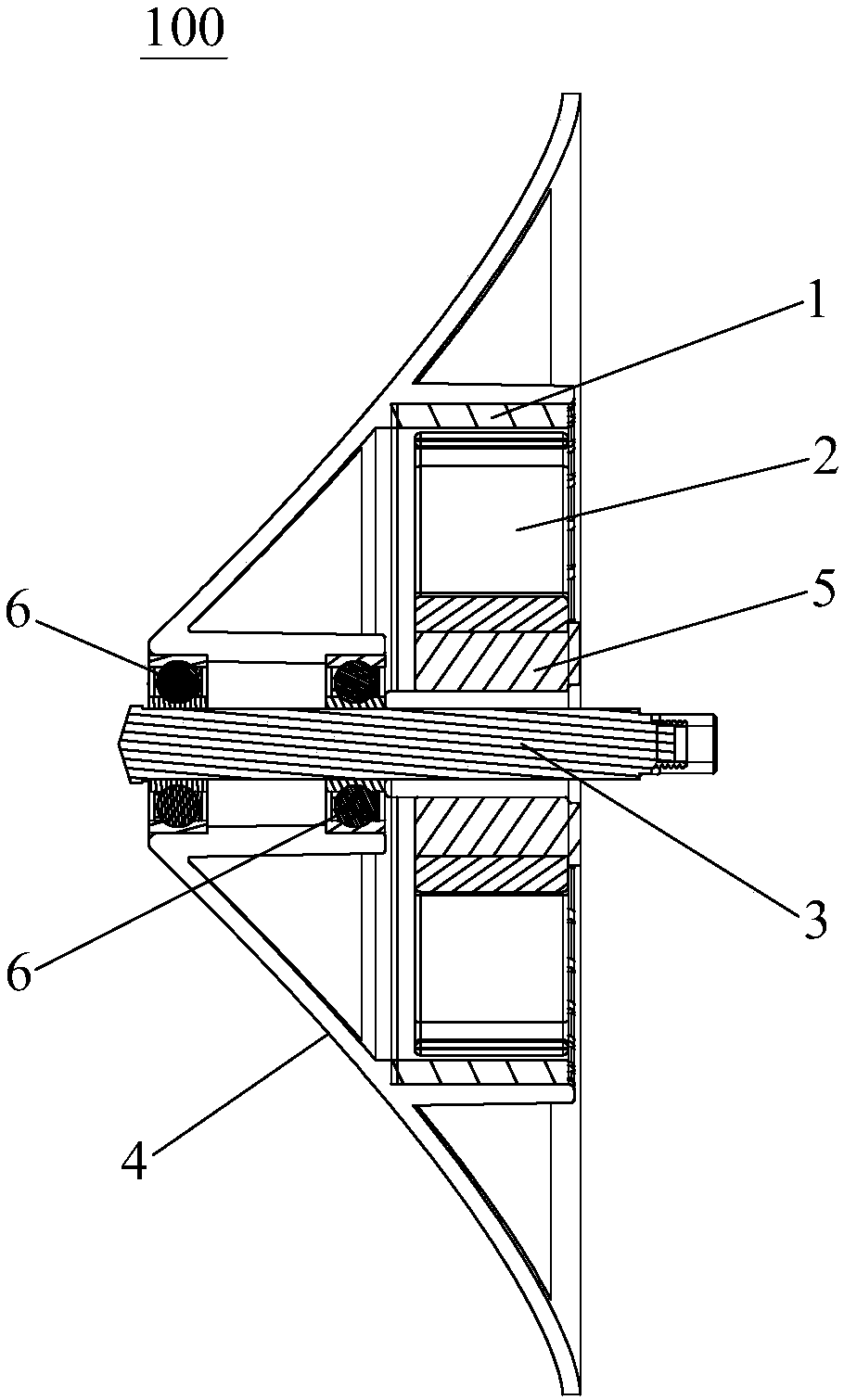

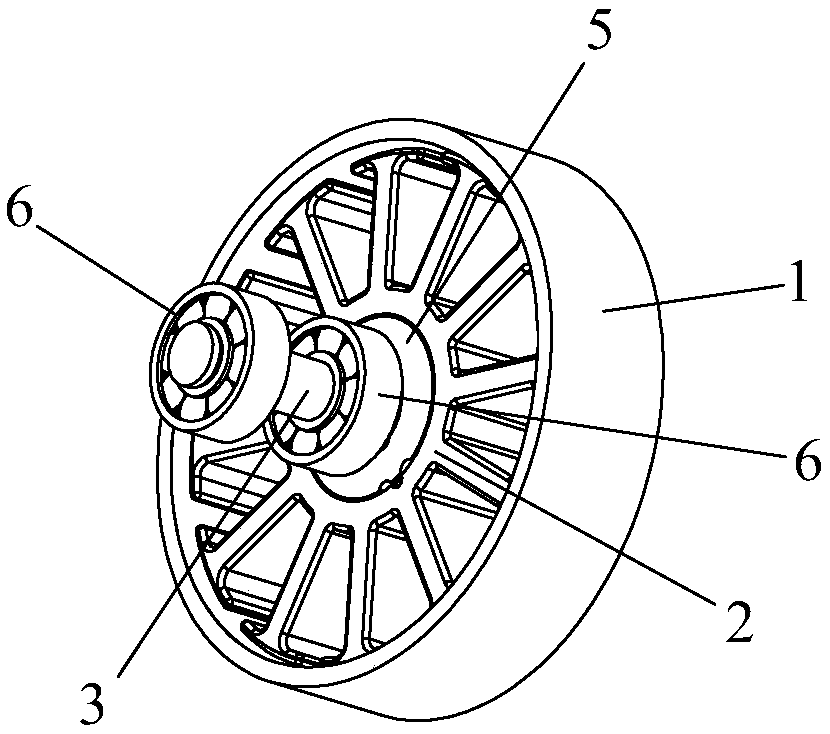

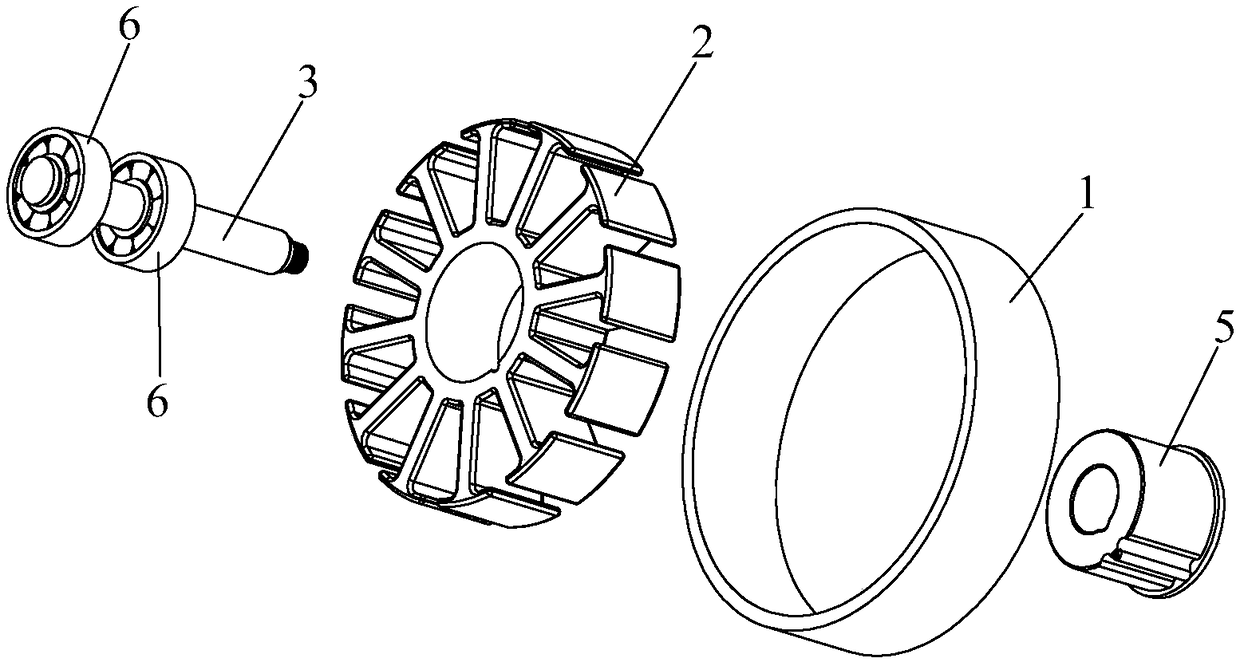

[0011] Such as figure 1 , figure 2 and image 3 As shown, the fixed shaft type outer rotor brushless motor 100 of the present invention includes a permanent magnet rotor 1, a winding stator 2, a fixed shaft 3 and a casing 4, the fixed shaft 3 is fixedly arranged, and the winding stator 2 is fixed on the On the fixed shaft 3, specifically, between the fixed shaft 3 and the winding stator 2, there is a fixing piece 5 for fixing the former two. The fixing piece 5 is in the shape of an annular sleeve, and the fixed shaft 3 is sleeved and fixed Inside the fixing part 5 , the winding stator 2 is sleeved on the outside of the fixing part 5 . Bearings 6 are provided between the fixed shaft 3 and the housing 4, and the number of the bearings 6 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com