Patents

Literature

94results about How to "Reduce concentricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

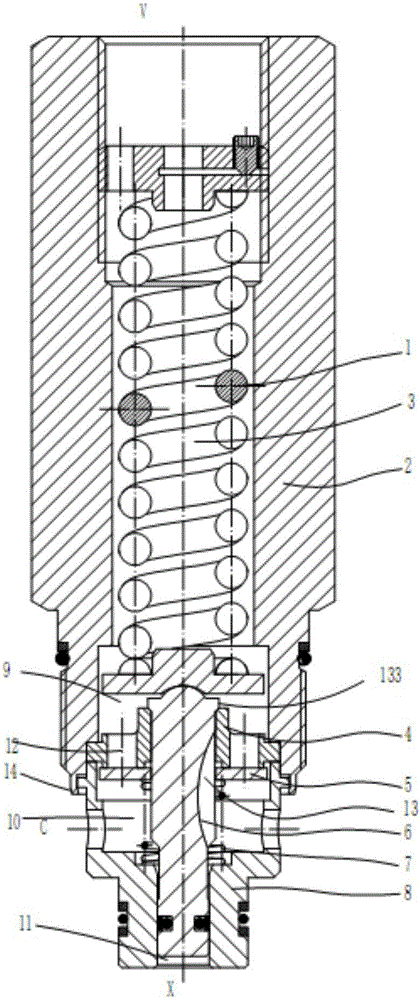

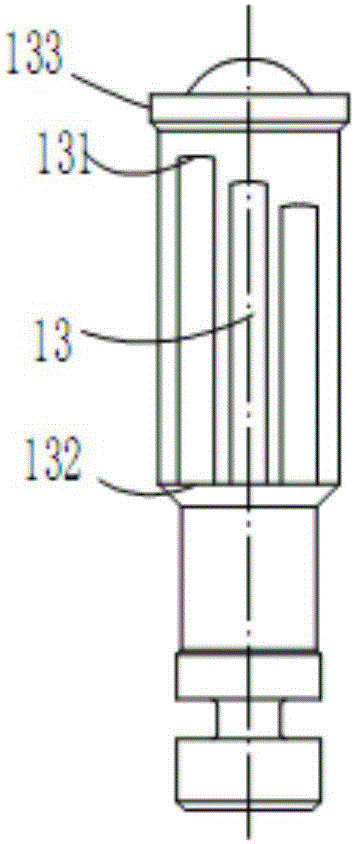

Precision metering ceramic plunger liquid charge pump

ActiveCN103967733AReduce wearAvoid it happening againPositive displacement pump componentsPump controlSurface roughnessDrive motor

The invention discloses a precision metering ceramic plunger liquid charge pump which structurally comprises a pump head, two single-direction valves, a pump body, a driving mechanism and a control driving unit. The singe-direction valves are connected into thread holes in the pump head through threads on upper valve bases and lower valve covers. The pump head penetrates through four through holes through inner hexagonal bolts, and the pump head and a pump body outer shell are fastened on a driving outer shell. A motor base is fastened on the driving outer shell by the fact that inner hexagonal bolts penetrate through four through holes. A driving motor is fastened on the motor base by the fact that inner hexagonal bolts penetrate through four through holes. One end of a plunger core in the pump body is connected with inner threads of a floating connector in the driving mechanism through outer threads. The driving mechanism is connected with the control driving unit. The liquid charge pump has corrosion resistance and abrasion resistance, impurities are not mixed into ceramic, so that the fact that medicine liquid is not contaminated during a liquid-charge process is guaranteed, the roughness of the surface of the ceramic is low, on-line washing is easy, and accuracy and speed are improved.

Owner:山东海燕医用材料制造有限公司

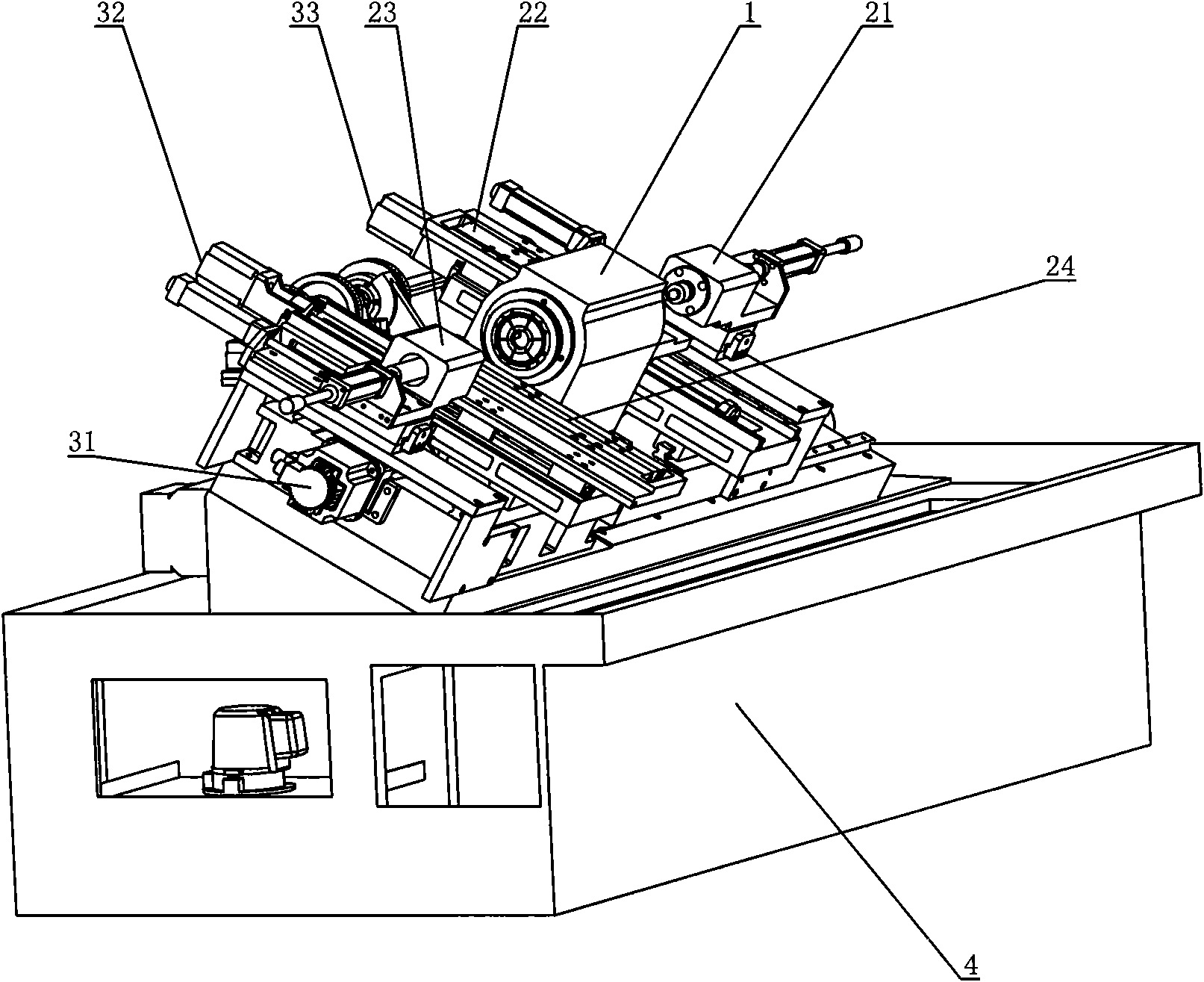

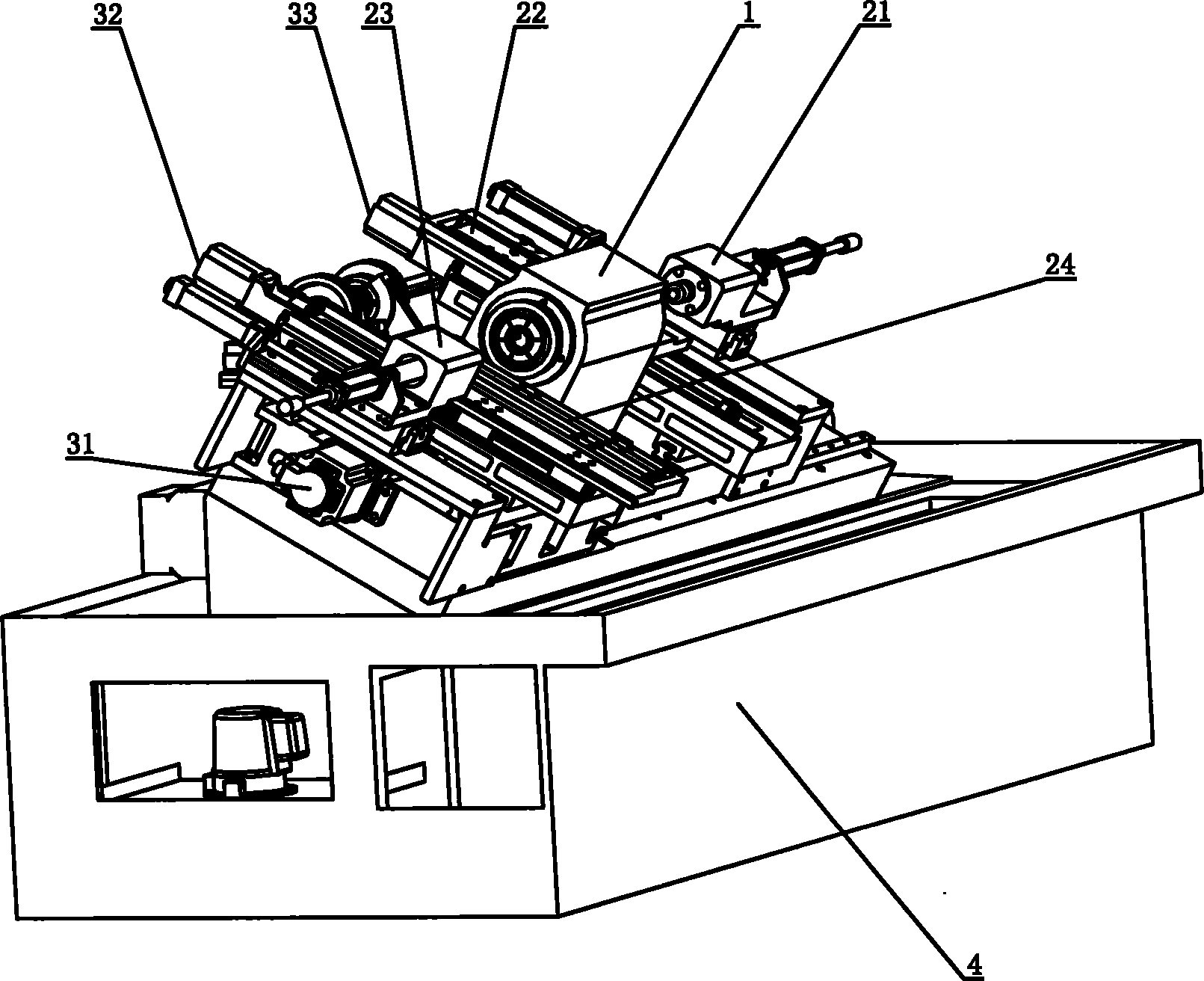

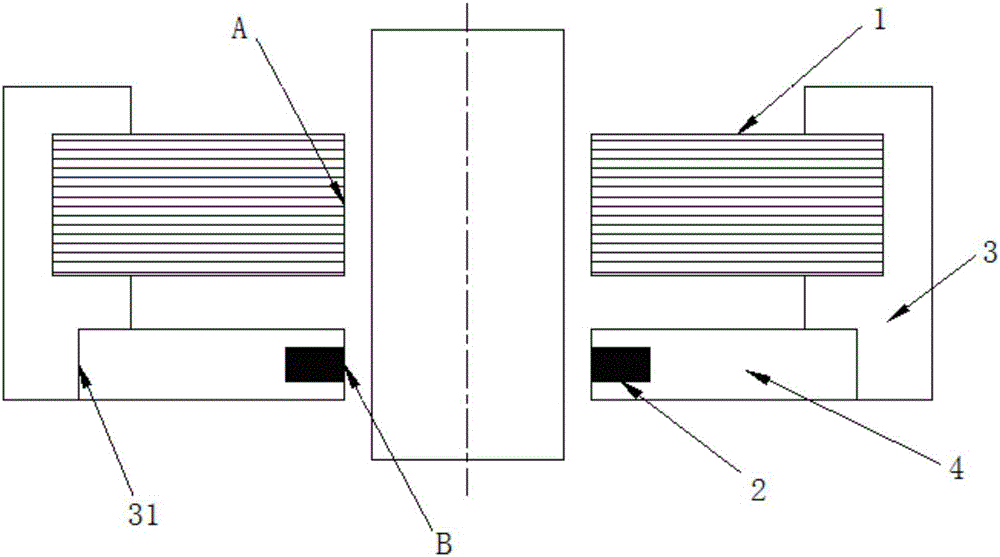

CNC (computerized numerical control) lathe

InactiveCN102601389AReduce concentricityImprove work efficiencyAutomatic/semiautomatic turning machinesNumerical controlSlide plate

The invention belongs to the technical field of machining technology, in particular discloses a CNC (computerized numerical control) lathe for separately controlling and processing two ends of shaft parts at the same time, wherein the CNC lathe comprises a main spindle box which is arranged in the middle of the lathe body, left and right sliding plate devices which are respectively arranged at the two sides of the main spindle box, a servo driving device, a CNC tool which is installed on the sliding plate devices for processing workpieces and a dual CNC device. The CNC lathe provided by the invention can not only reduce workpiece clamping times and improve work efficiency but also can reduce second clamping error, ensure consistency of workpiece processing and improve workpiece accuracy.

Owner:东莞市嘉坤机械有限公司

Turning positioning fixture for thin-wall rotational parts and clamping method

ActiveCN101972943AReduce distortionNot easy to damagePositioning apparatusMetal-working holdersEngineeringAxial force

The invention relates to a turning positioning fixture for thin-wall rotational parts and a clamping method. The fixture comprises a cylindrical positioning body and threaded rings, wherein an external thread is lathed on the external surface of the positioning end; the threaded rings are circular rings with internal diameter the same as the external diameter of the positioning body; the internal surfaces of the threaded rings are provided with internal threads matched with the external thread on the positioning body; and during positioning, one end of the positioning body is clamped on a machine tool and the positioning end is closely contacted with the part, and the positioning body is closely matched with the part through the external thread on the external surface and the internal threads on the threaded rings. In the embodiment, the clamp force on the part is mainly axial force, thus overcoming the negative effect that radial force leads to workpiece deformation during traditional machining; and the positioning body is clamped and lathed at the site, and during positioning and clamping, firstly the positioning body is ensured to be fit with the end face of the part and the end face runout of the part is ensured to be identical with that of the spindle of the machine tool, thus ensuring the flatness and the parallelism of the part. The fixture can carry out automatic alignment and positioning while screwing the threaded rings, is convenient to operate and reduces artificial operation errors.

Owner:BEIJING RES INST OF TELEMETRY

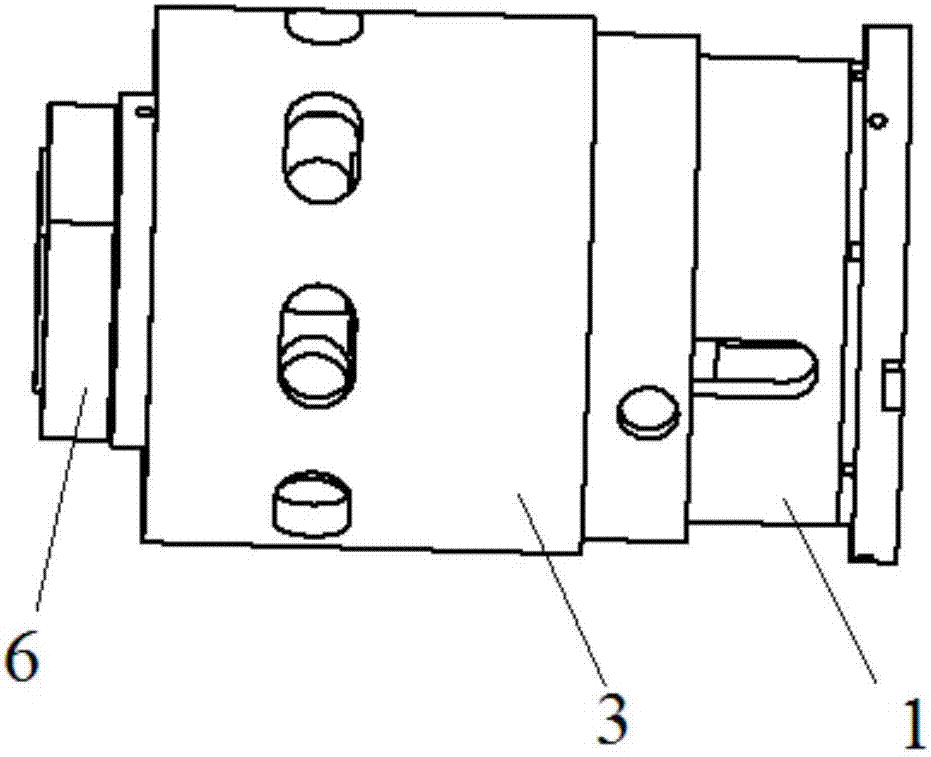

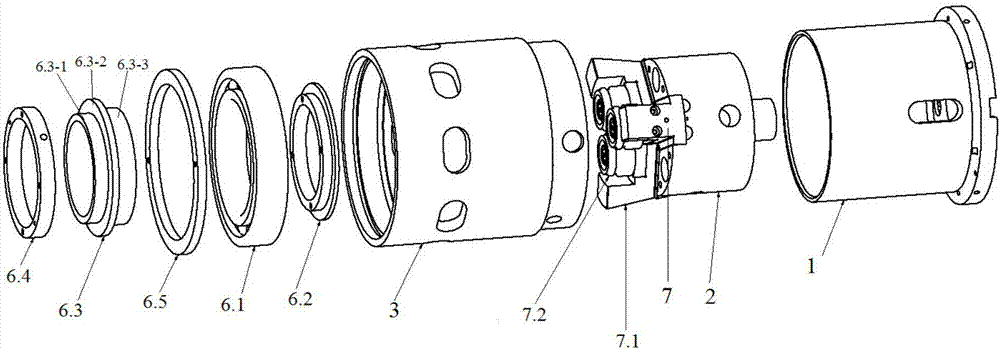

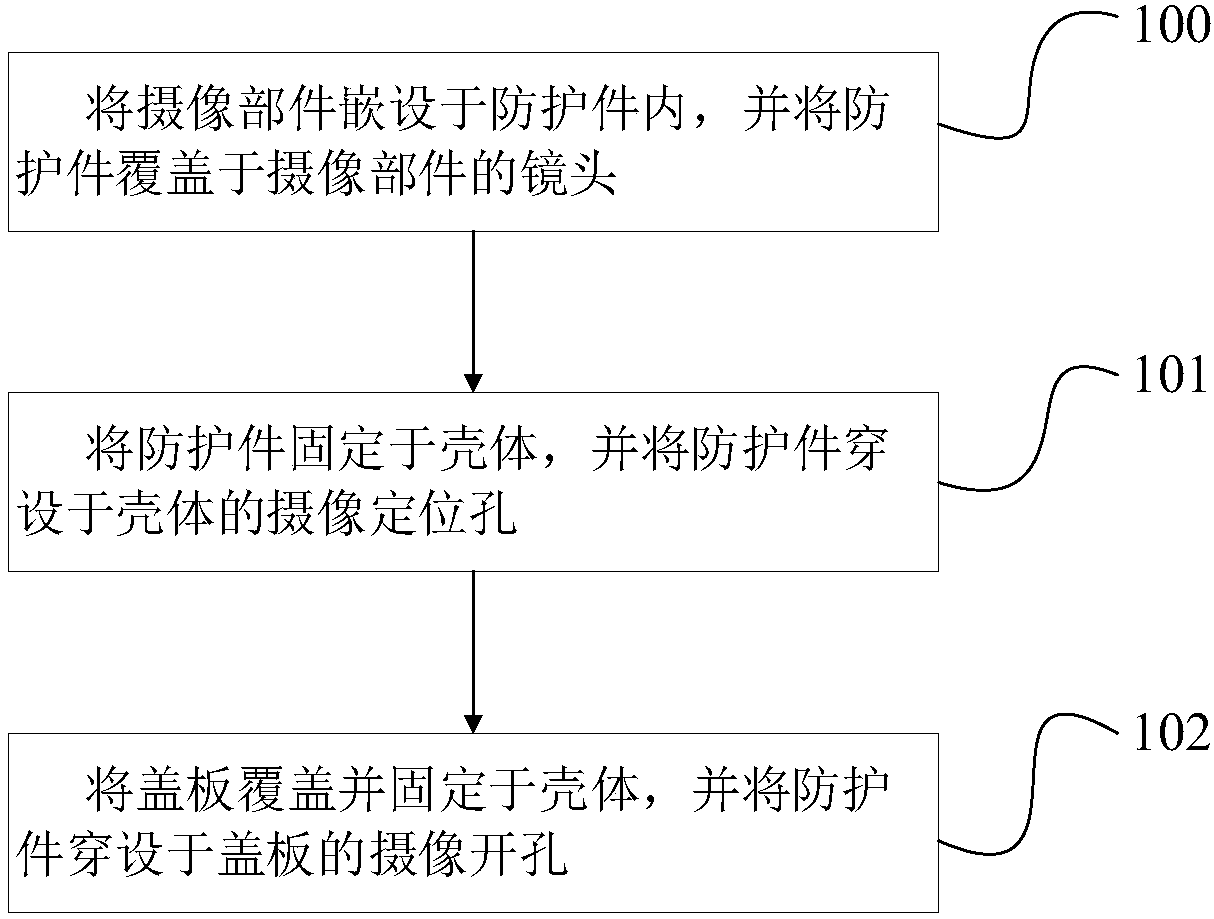

Camera module, mobile terminal, and method for assembling camera module

InactiveCN107707805AImprove assembly accuracyGood lookingTelevision system detailsColor television detailsCamera moduleEngineering

The invention discloses a camera module, a mobile terminal, and a method for assembling a camera module. The camera module includes a casing provided with a photographing positioning hole, a cover plate provided with a photographing hole, a photographing part, and a protective part. The photographing part is embedded into the protective part. The protective part is used for light to pass through,is fixed to the casing, and sequentially passes through the photographing positioning hole and the photographing hole. The assembling method includes the following steps: embedding the photographing part into the protective part; fixing the protective part equipped with the photographing part to the casing, and making the protective part pass through the photographing positioning hole of the casing; and covering the casing with the cover plate, fixing the cover plate to the casing equipped with the protective part, and making the protective part pass through the photographing hole of the coverplate. Through the setting of the protective part, the deviation of the photographing part from the photographing hole of the cover plate is reduced, the concentricity between the photographing partand photographing hole is ensured, and the assembly precision of the camera module and the mobile terminal is improved.

Owner:SHANGHAI MORUAN COMM TECH

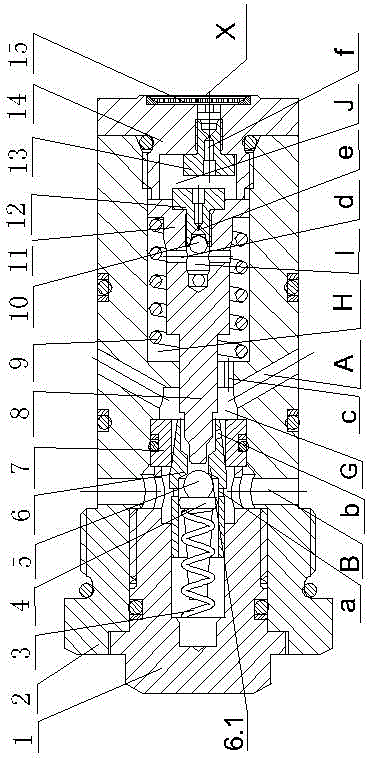

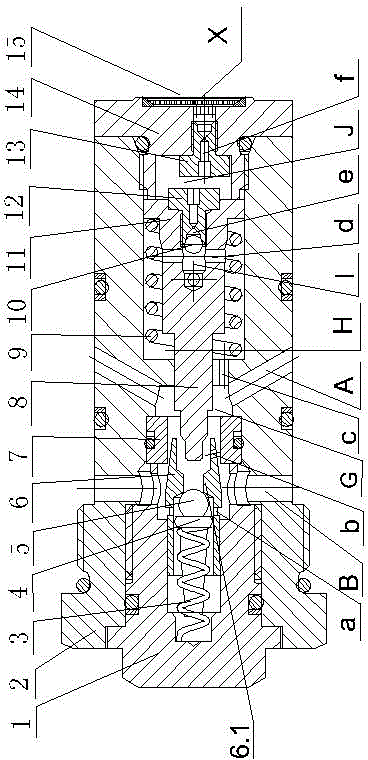

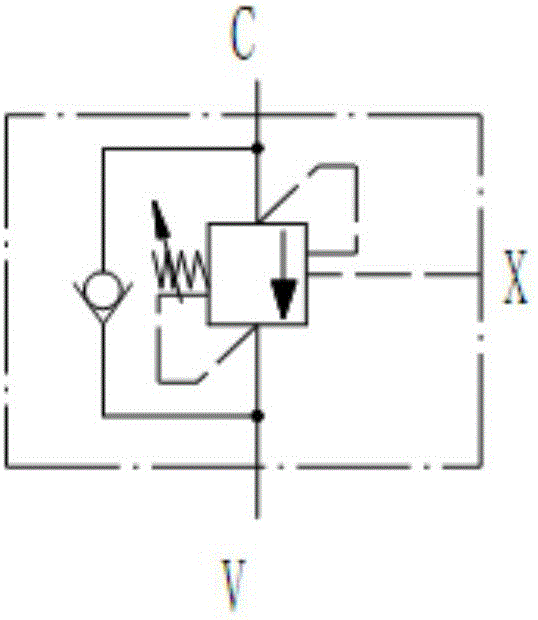

Balance valve

A balance valve comprises a valve body, an end cover, a plug, a valve core, a valve seat and a piston, wherein the end cover and the plug are respectively connected with the two ends of the valve body in a sealing mode. A third oil port is formed in the rear end of the plug, a filter screen and a damper are arranged at the third oil port, and the valve seat is arranged in a first cavity of the valve body and located between a first oil port and a second port. The front section of the valve core is matched in the end cover in a sliding mode, the rear section of the valve core is matched in a through-hole of the valve seat, an inner cavity which is axially penetrating is formed in the valve core, a steel ball which is matched with the inner cavity of the valve core is arranged in the valve core, a boss for axially limiting the steel ball is arranged in the inner cavity of the valve core, a first spring which is abutted against the steel ball is arranged in the inner cavity of the valve core, and the other end of the first spring is abutted in the end cover. The piston is matched in a second cavity in a sliding mode, the ladder end of the piston penetrates a cavity wall between the first cavity and the second cavity and is matched in the inner cavity of the valve core in a sliding mode, and a one-way throttling device is arranged at the rear end of the piston. The balance valve is simple in structure, compact in size and stable in working.

Owner:NINGBO JIANGDONG SIKAO TECH SERVICES

Balance valve

A balance valve comprises a valve body, an end cover, a plug, a valve core, a valve seat and a piston, wherein the end cover and the plug are respectively connected with the two ends of the valve body in a sealing mode. A third oil port is formed in the rear end of the plug, a filter screen and a damper are arranged at the third oil port, and the valve seat is arranged in a first cavity of the valve body and located between a first oil port and a second port. The front section of the valve core is matched in the end cover in a sliding mode, the rear section of the valve core is matched in a through-hole of the valve seat, an inner cavity which is axially penetrating is formed in the valve core, a steel ball which is matched with the inner cavity of the valve core is arranged in the valve core, a boss for axially limiting the steel ball is arranged in the inner cavity of the valve core, a first spring which is abutted against the steel ball is arranged in the inner cavity of the valve core, and the other end of the first spring is abutted in the end cover. The piston is matched in a second cavity in a sliding mode, the ladder end of the piston penetrates a cavity wall between the first cavity and the second cavity and is matched in the inner cavity of the valve core in a sliding mode, and a one-way throttling device is arranged at the rear end of the piston. The balance valve is simple in structure, compact in size and stable in working.

Owner:NINGBO JIANGDONG SIKAO TECH SERVICES

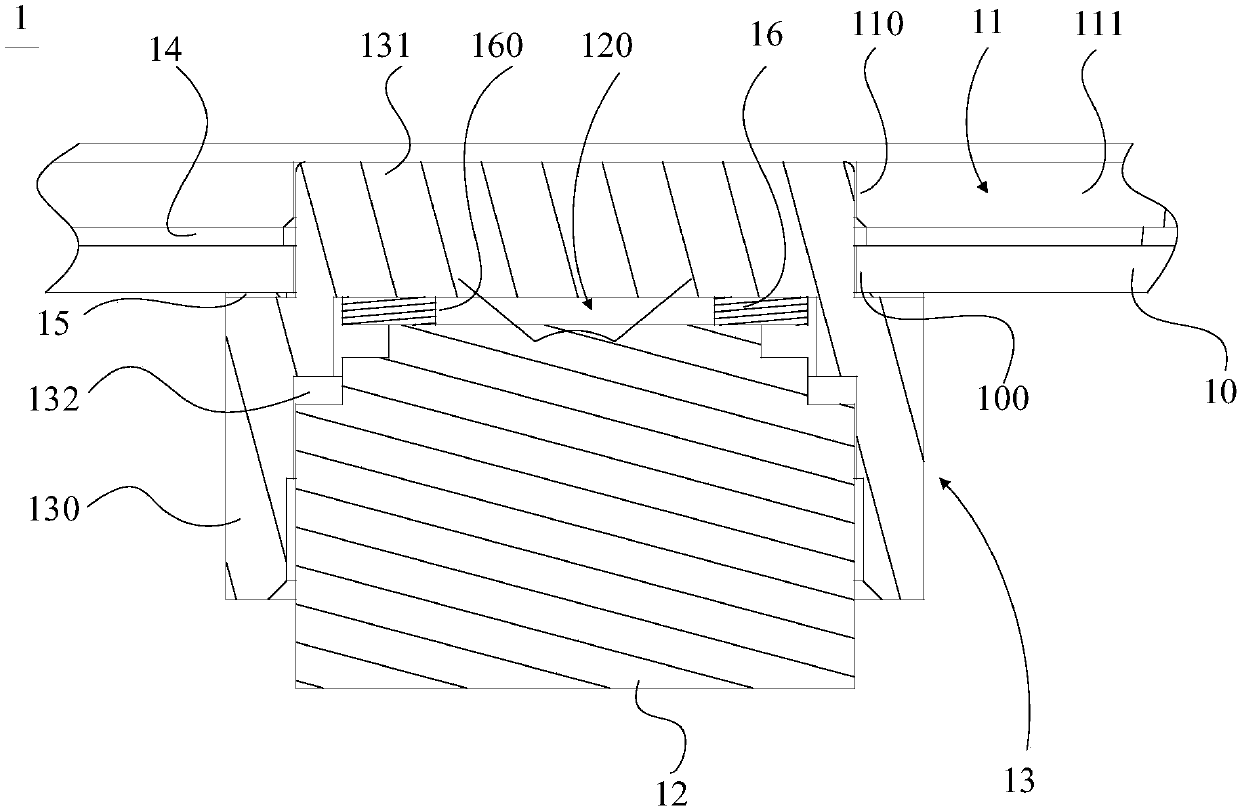

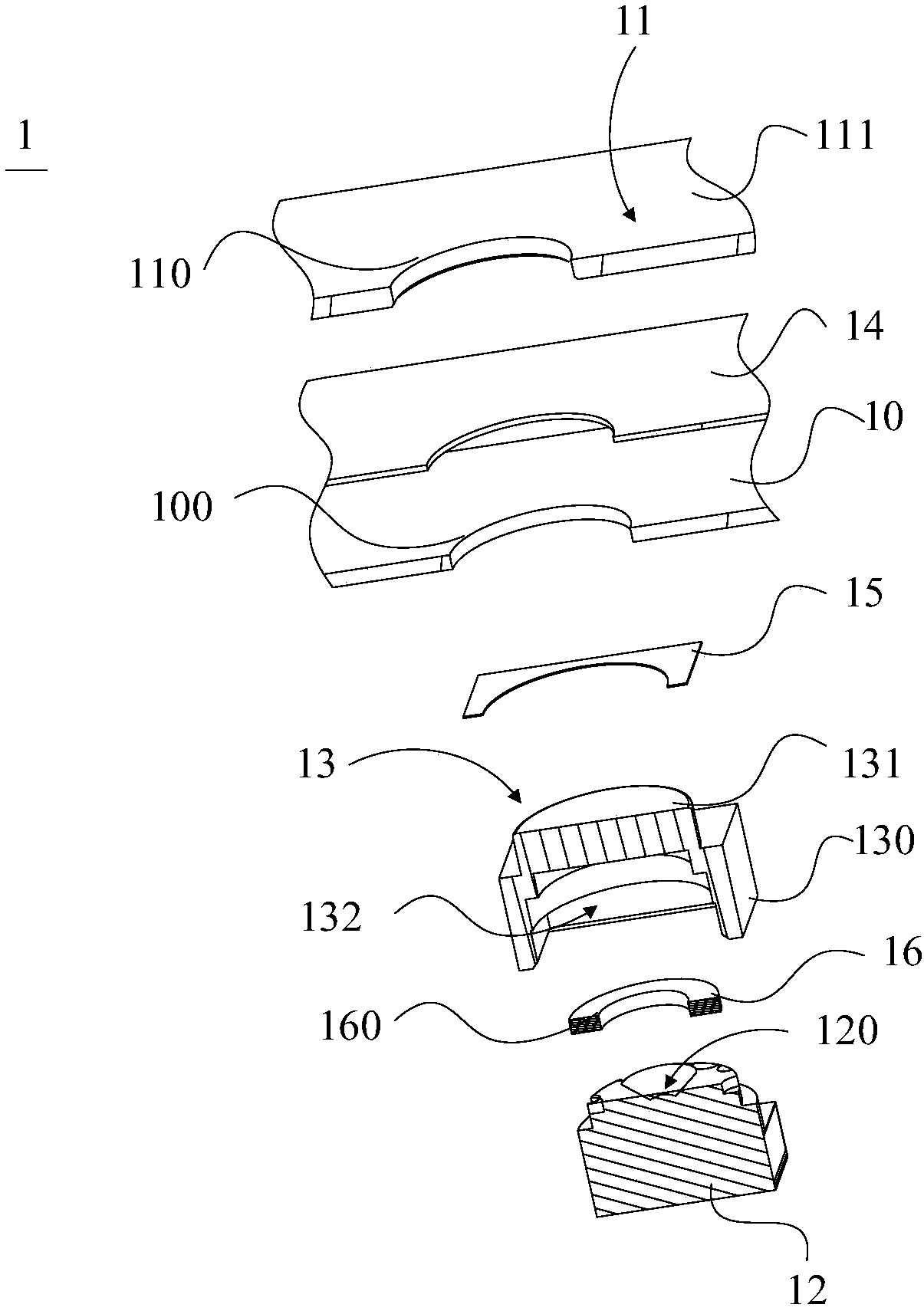

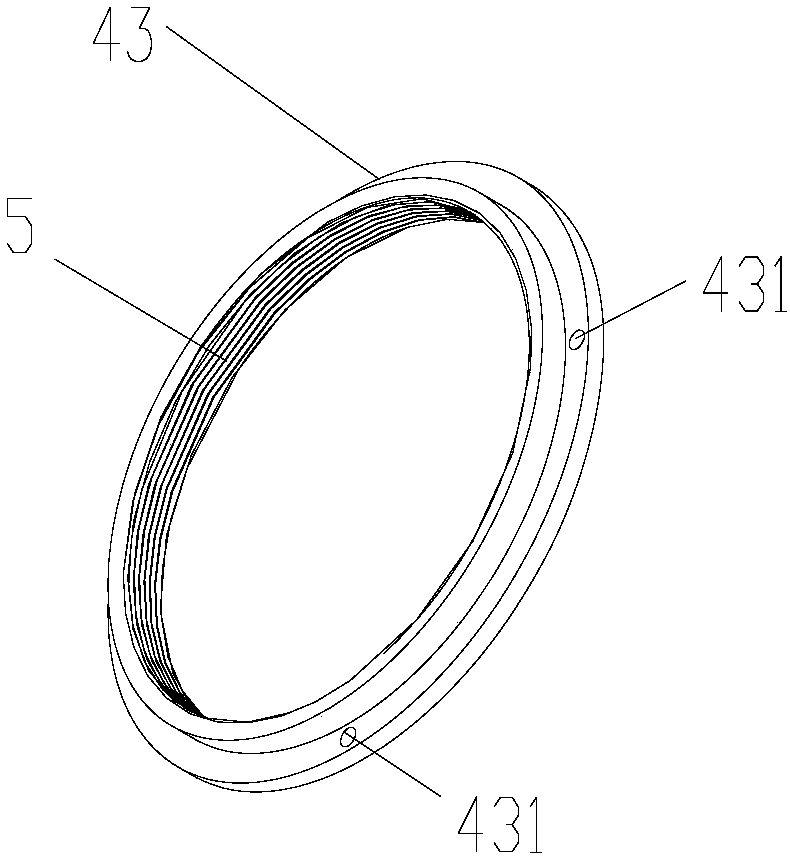

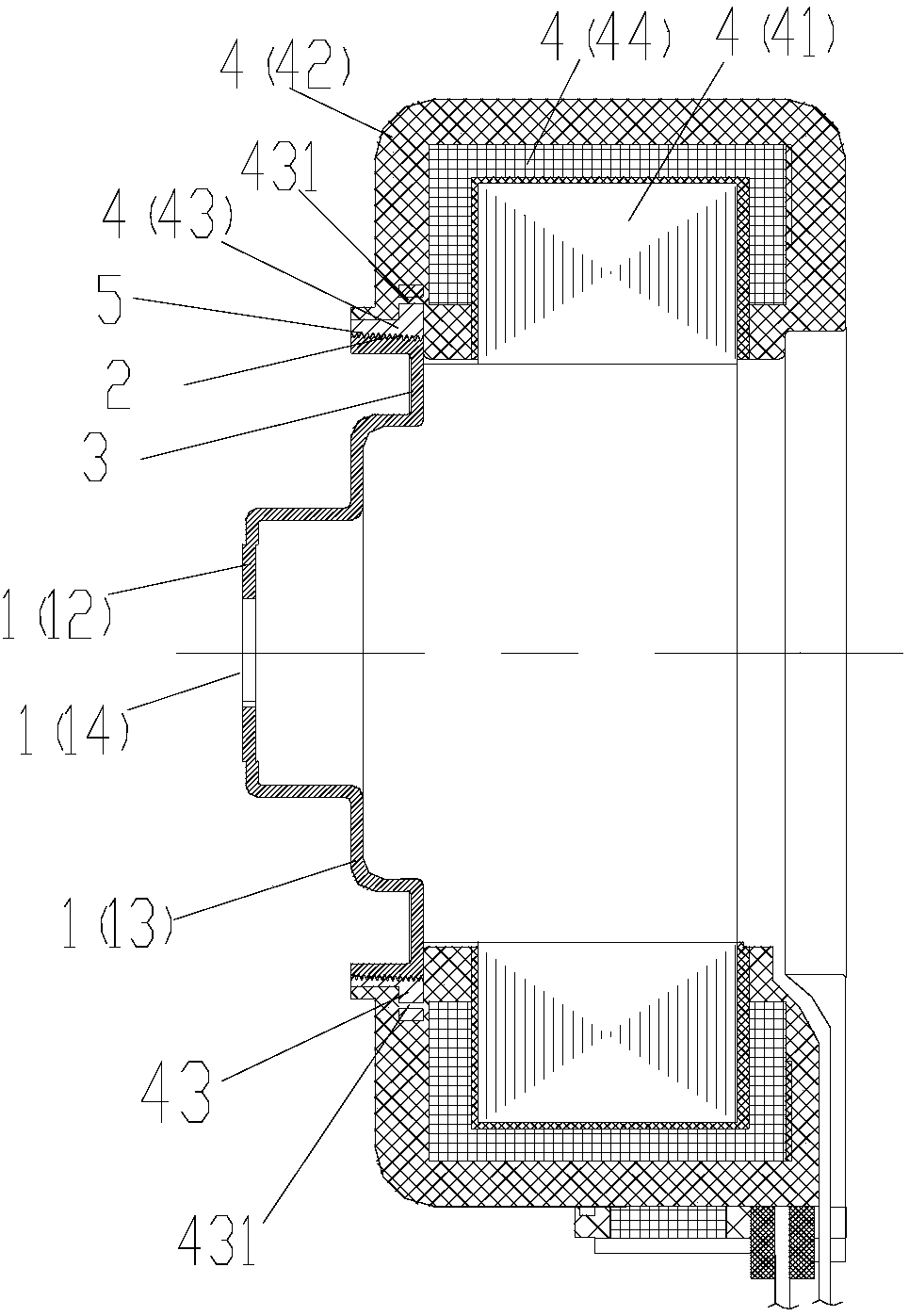

Motor end cover, stator assembly and motor

PendingCN107834740AImprove securitySolve the hidden danger of looseningMagnetic circuit rotating partsSupports/enclosures/casingsElectric machineStructural engineering

The invention provides a motor end cover, a stator assembly and a motor. The motor end cover (1) comprises a flange (11), an external thread (2) is arranged on an outer peripheral wall of the flange (11), and the motor end cover is in threaded connection with the stator assembly through the external thread (2) when the motor end cover and the stator assembly of the motor are connected. Through themotor end cover, the stator assembly and the motor, compared with the prior art, a mode of pressing a motor end cover and a motor to combine in the past can be substituted, defects of looseness between the motor end cover and the stator assembly and the unfirm fixation are effectively solved, especially a hidden danger of end cover looseness of a back end cover after the motor runs and generatesheats is solved, the product quality is improved, after-sales problems are reduced, a hidden danger of axial looseness during a motor damping ring transportation process is eliminated, the tightness of a damping ring and the end cover is improved, and the safety performance of the motor is improved.

Owner:ZHUHAI KAIBANG MOTOR MFR +1

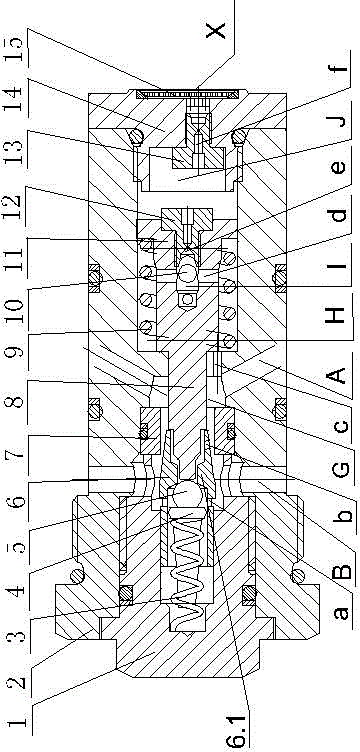

Plug-in mounting type balance valve

A plug-in mounting type balance valve comprises a valve body, an end cover, a plug, a valve core, a valve seat and a piston, wherein a third oil port is formed in the rear end of the plug, a filter screen and a damper are arranged at the position of the third oil port, the valve seat is arranged in a first chamber of the valve body and is located between a first oil port and a second oil port, the front section of the valve core is arranged in the end cover in a sliding fit mode, the rear section of the valve core is arranged in a through hole of the valve seat in a matched mode, the valve core is provided with an inner cavity which is through along the axial direction, a steel ball matched with the inner cavity of the valve core is arranged in the valve core, a boss used for axial positioning of the steel ball is arranged in the inner cavity of the valve core, a first spring which abuts against the steel ball is arranged in the inner cavity of the valve core, the other end of the first spring is arranged in the end cover in an abutting mode, the piston is arranged in a second chamber in a sliding fit mode, an step end of a piston rod penetrates through a room wall between the first chamber and the second chamber and is arranged in the inner cavity of the valve core, the rear end of the piston is provided with a one-way throttling gear, and the diameter of the outer circumference of the valve body decreases from the end cover end to the plug end gradually to form a step shape. The balance valve is simple in structure, compact in structure, and stable in working.

Owner:NINGBO JIANGDONG SIKAO TECH SERVICES

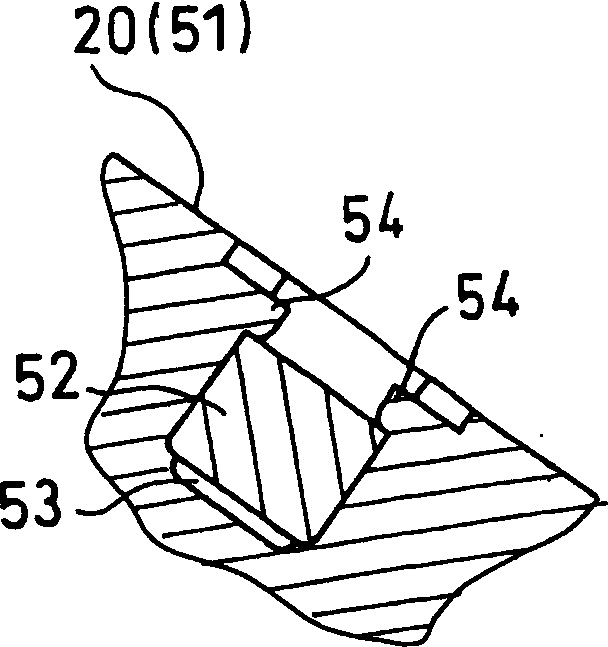

Core mold for manufacturing intermediate tubular shaft of coupler and manufacturing method of intermediate tubular shaft of coupler

A core mold for manufacturing an intermediate tubular shaft of a coupler comprises a static mold and a movable mold. The static mold and the movable mold are detachably assembled. The static mold comprises a static mold cylinder, a static mold seal head and a static mold shaft fixedly installed in the middle of the static mold seal head. A first cutting seam is formed in the joint of the static mold cylinder and the static mold seal head. The movable mold comprises a movable mold cylinder and a movable mold seal head. A second cutting seam is formed in the joint of the movable mold cylinder and the movable mold seal head. The static mold and the movable mold are assembled together, the static mold shaft penetrates through the static mold and the movable mold, and the static mold cylinder and the movable mold cylinder are assembled to form an intermediate cylinder; the inner surface of the intermediate cylinder is a cylindrical surface, the two ends of the outer surface of the intermediate cylinder are conical surfaces, and the middle portion of the outer surface of the intermediate cylinder is a cylindrical surface. The core mold does not deform in the wind-forming process of the intermediate tubular shaft, the internal conical surface is formed while the intermediate tubular shaft is formed through winding, and the procedure of conical surface machining is omitted, so that the production cost is reduced, the production efficiency is improved, and the coaxiality of the intermediate tubular shaft is guaranteed. The invention further provides a manufacturing method of the intermediate tubular shaft of the coupler.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

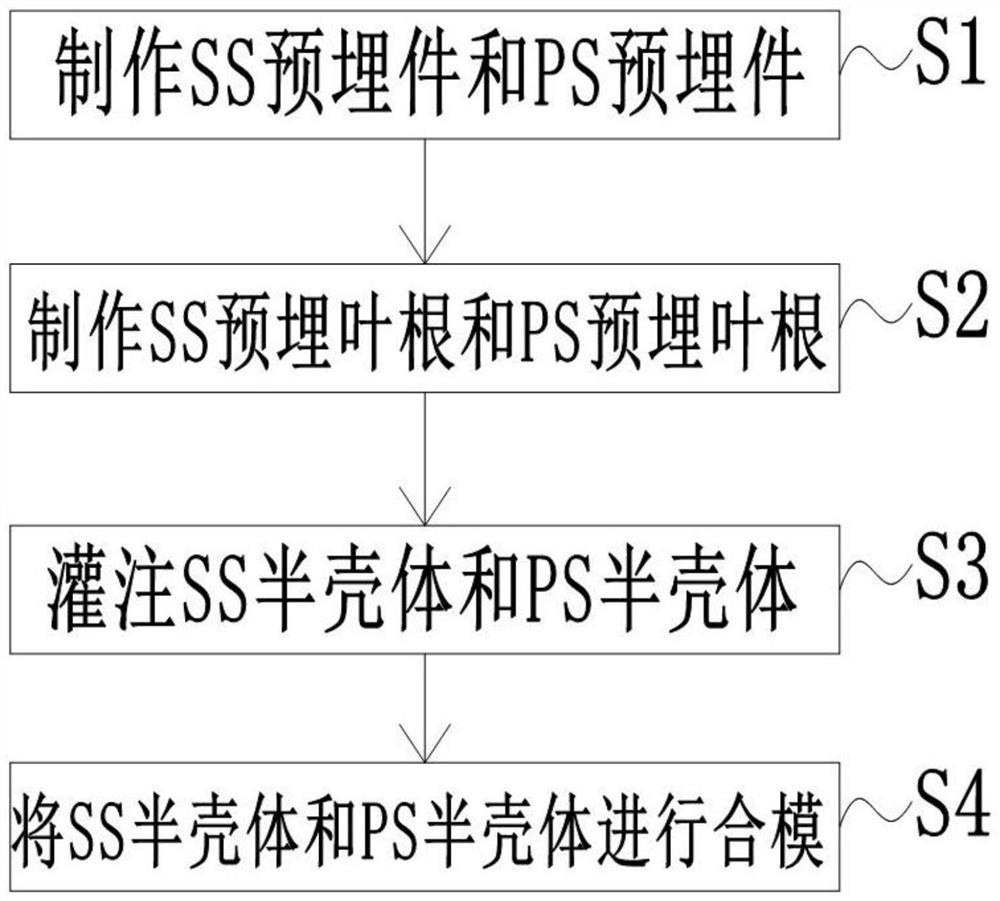

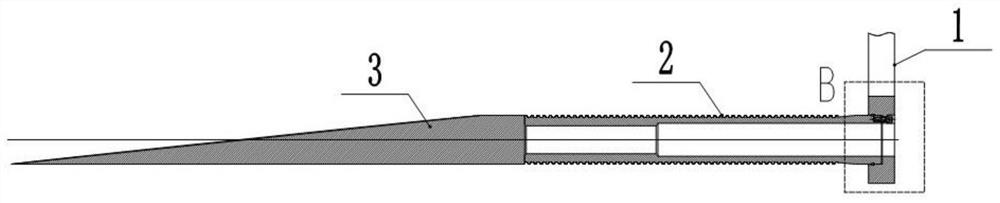

Preparation method of wind power blade

ActiveCN113733607AAvoid deformationReduce distortionFinal product manufactureDomestic articlesWind powerMold removal

The invention belongs to the technical field of wind power blades, and particularly discloses a preparation method of a wind power blade. The preparation method comprises the following steps that at S1, an SS embedded part and a PS embedded part are manufactured, specifically, the SS embedded part and the PS embedded part each comprise a connecting flange, a plurality of sets of thread inserts, a UD block, a wedge-shaped block and a sealing ring; at S2, an SS embedded blade root and a PS embedded blade root are manufactured; at S3, an SS half shell and a PS half shell are poured; and at S4, the SS half shell and the PS half shell are subjected to mold closing, specifically, the position of an embedded blade root flange is adjusted on a blade mold, and then the SS half shell and the PS half shell are bonded, and after bonding and curing, the embedded blade root flange is removed, demolding is performed, and finally the blade is manufactured. A positioning tool is arranged on the blade mold, and the positioning tool can position and adjust the position of the embedded blade root flange. According to the method, the problems that the deformation amount is large, and installation interference is caused by dislocation of thread insert holes and a connecting hole of a main engine bearing due to the adoption of an existing blade root embedding technology can be solved.

Owner:JILIN CHONGTONG CHENGFEI NEW MATERIAL

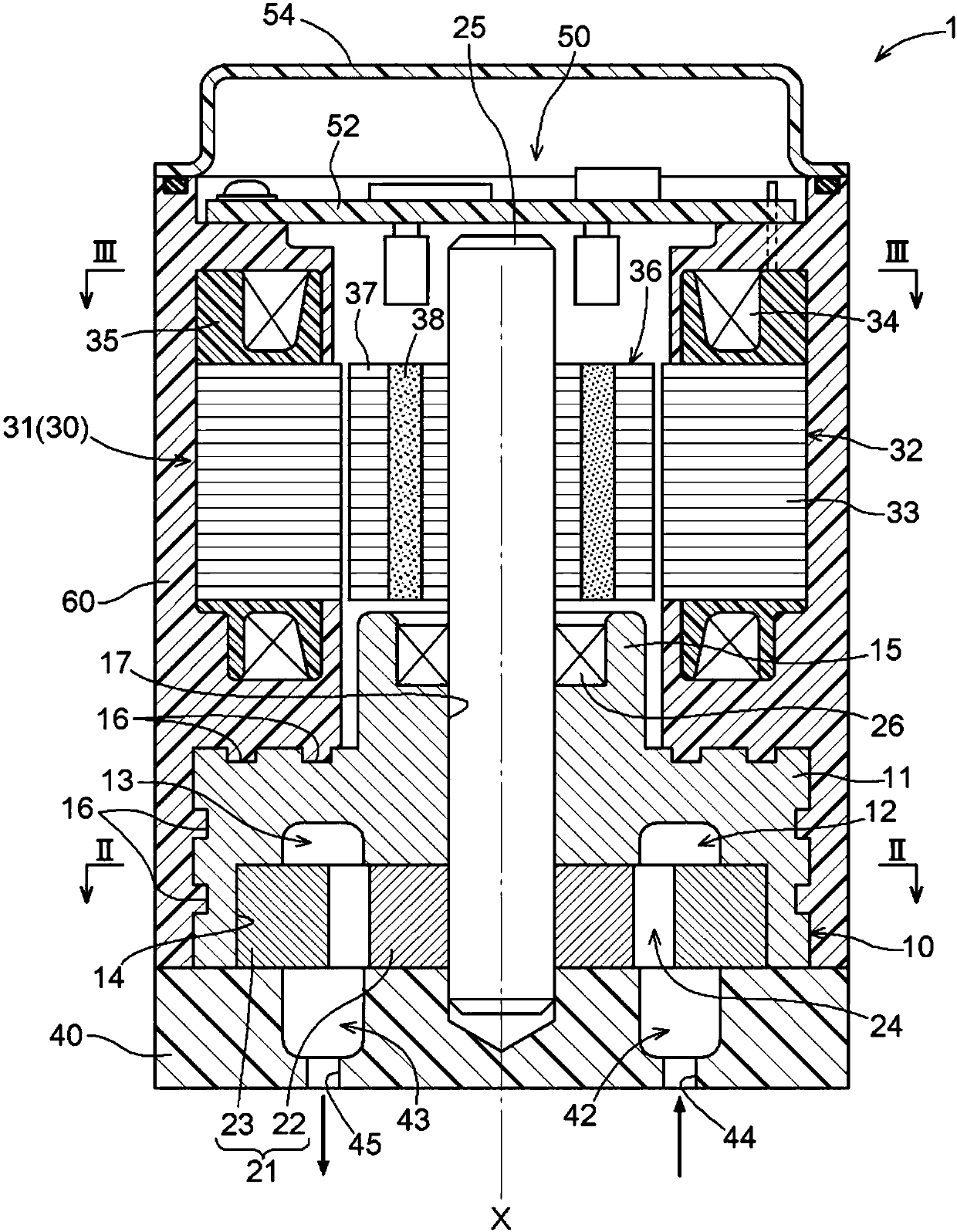

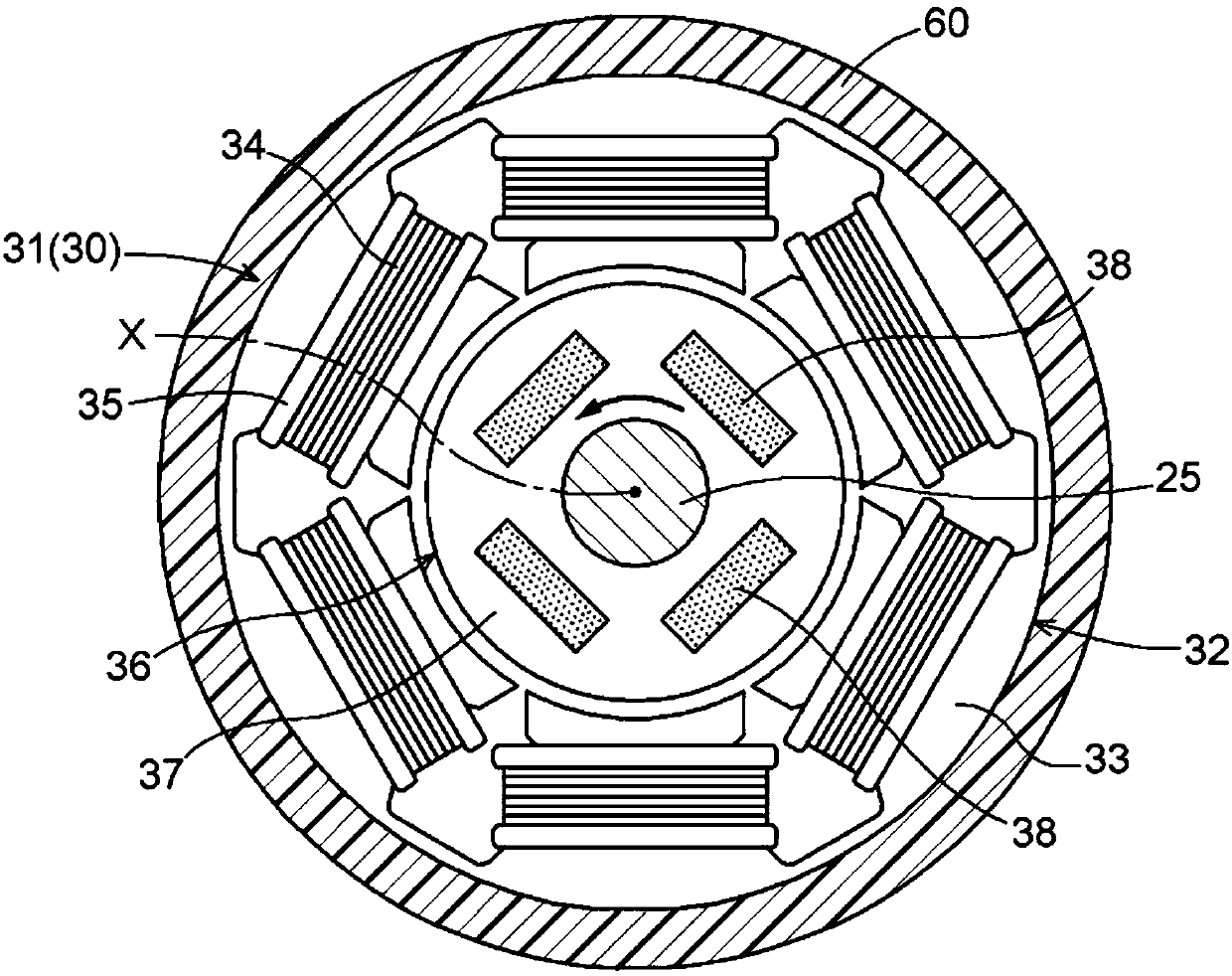

Electric pump and method for producing same

ActiveCN107923389ALow flow resistanceCool evenlyRotary piston pumpsRotary piston liquid enginesGear pumpWorking fluid

Provided is an electric pump comprising a pump unit that has a pump housing and a gear pump accommodated in the pump housing and that suctions in and discharges a working fluid due to rotation of thegear pump. The electric pump is also provided with a motor unit that has a rotor which is arranged adjacent to the pump unit in a direction along the axis of the pump unit and which rotates coaxiallywith the axis and synchronously with the gear pump, and a stator which is disposed coaxially with the axis on the outer periphery of the rotor and which imparts rotational driving force to the rotor.The electric pump is further provided with a resin part integrally covering at least the outer periphery of the pump housing and the outer periphery of the stator.

Owner:AISIN SEIKI KK

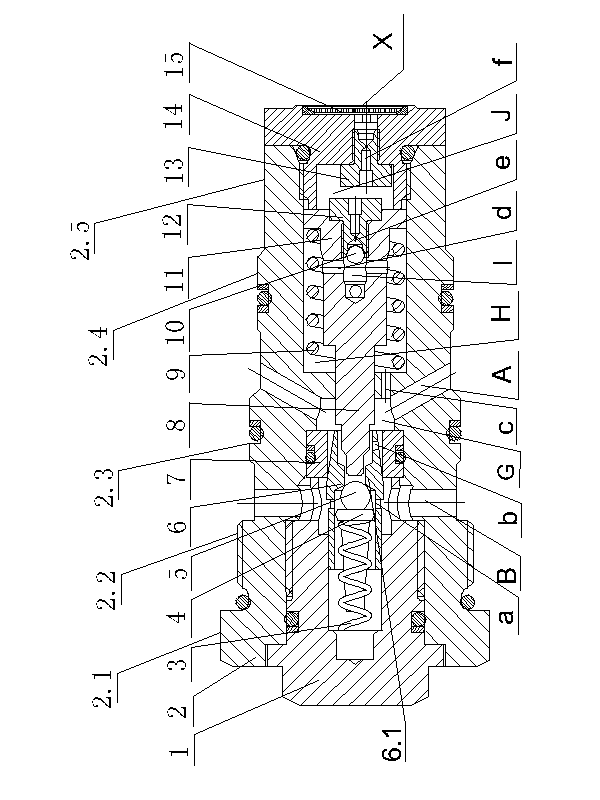

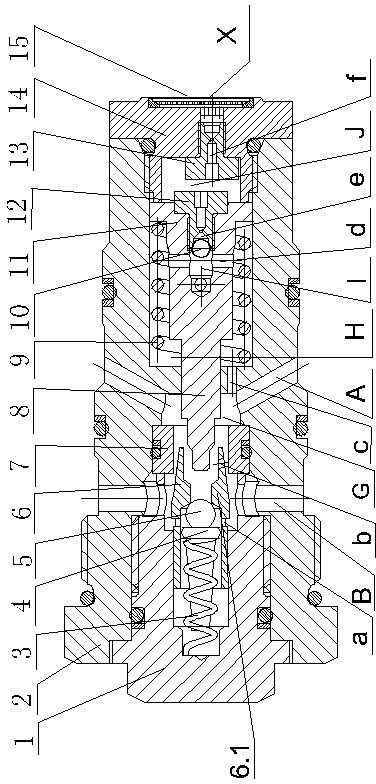

Plug-in type balance valve

ActiveCN106015674ASimple structureOverall small sizeServomotor componentsValve members for absorbing fluid energyEngineeringValve seat

The invention discloses a plug-in type balance valve. The plug-in type balance valve comprises a valve body, a main valve element, a first valve seat, a second valve seat, a valve pocket, a first elastic part and a second elastic part. The first valve seat is fixedly arranged in the valve body, and the main valve element is in sliding fit with the first valve seat and the valve pocket. Oil pushes open the second valve seat when the oil flows into a V oil port, and the oil flows to a C oil port through a first through hole. The first elastic part is installed in the valve body, the valve body and the valve pocket are fixedly connected, and multiple arc-shaped grooves are formed in the circumferential face of the valve element in the axial direction. When the oil flowing into an X oil port pushes the main valve element to move in the direction of compressing the first elastic part, the open area of the oil, flowing to the V oil port through the arc-shaped grooves, at the C oil port is gradually increased. The plug-in type balance valve is simple in structure and low in manufacturing cost, and the load descending speed can be precisely controlled without affecting the ascending speed.

Owner:FANGYUAN VALVE GROUP

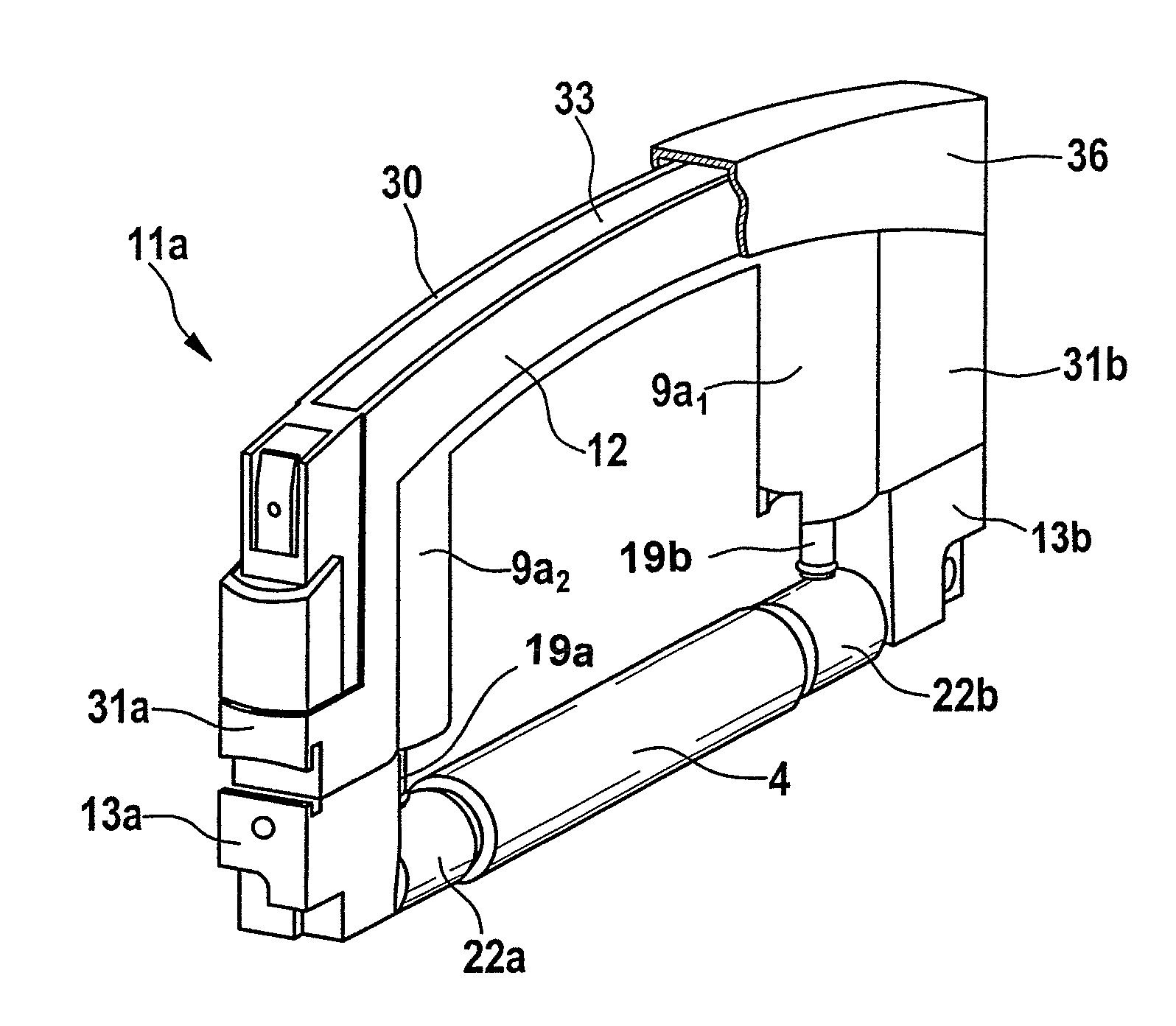

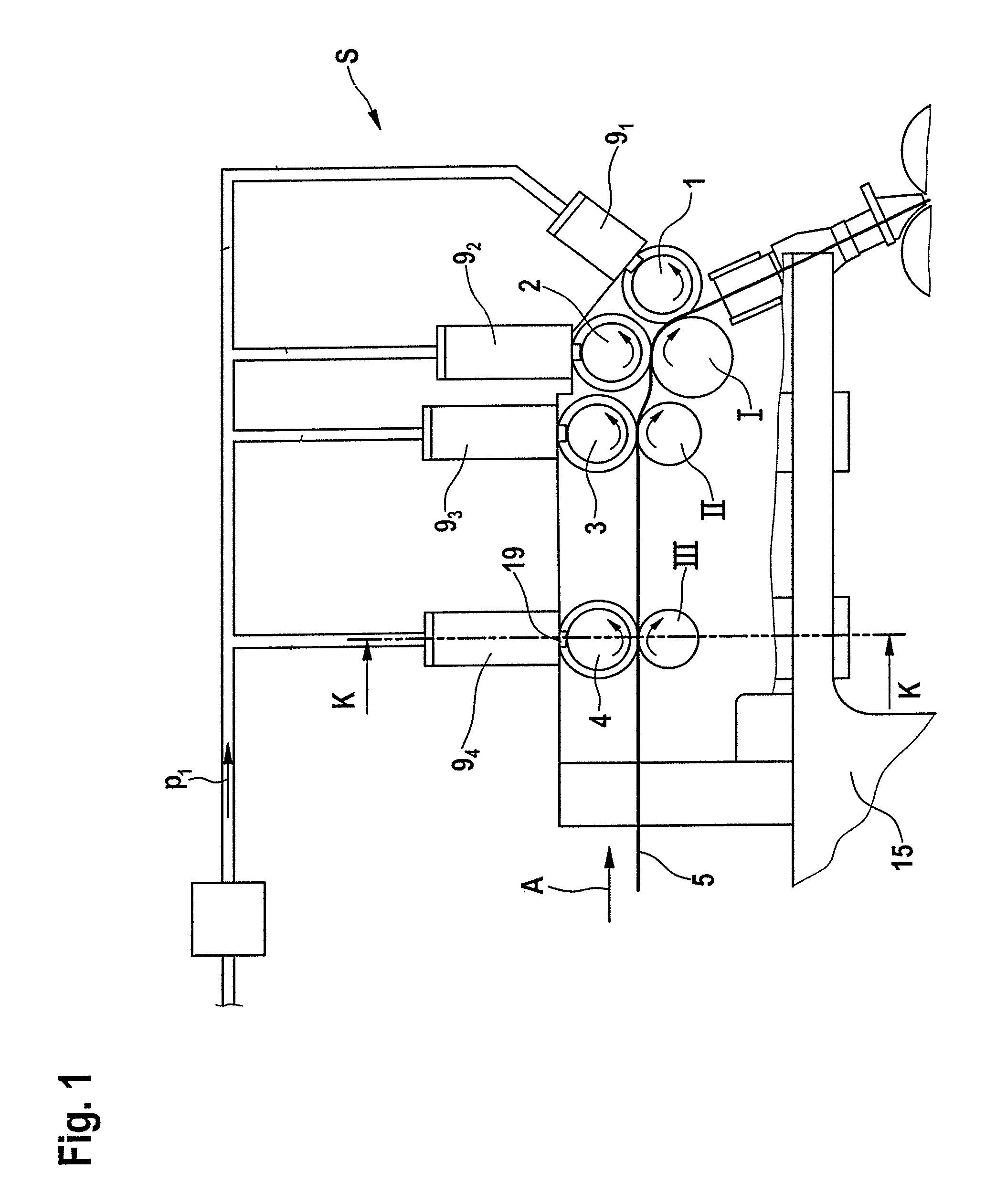

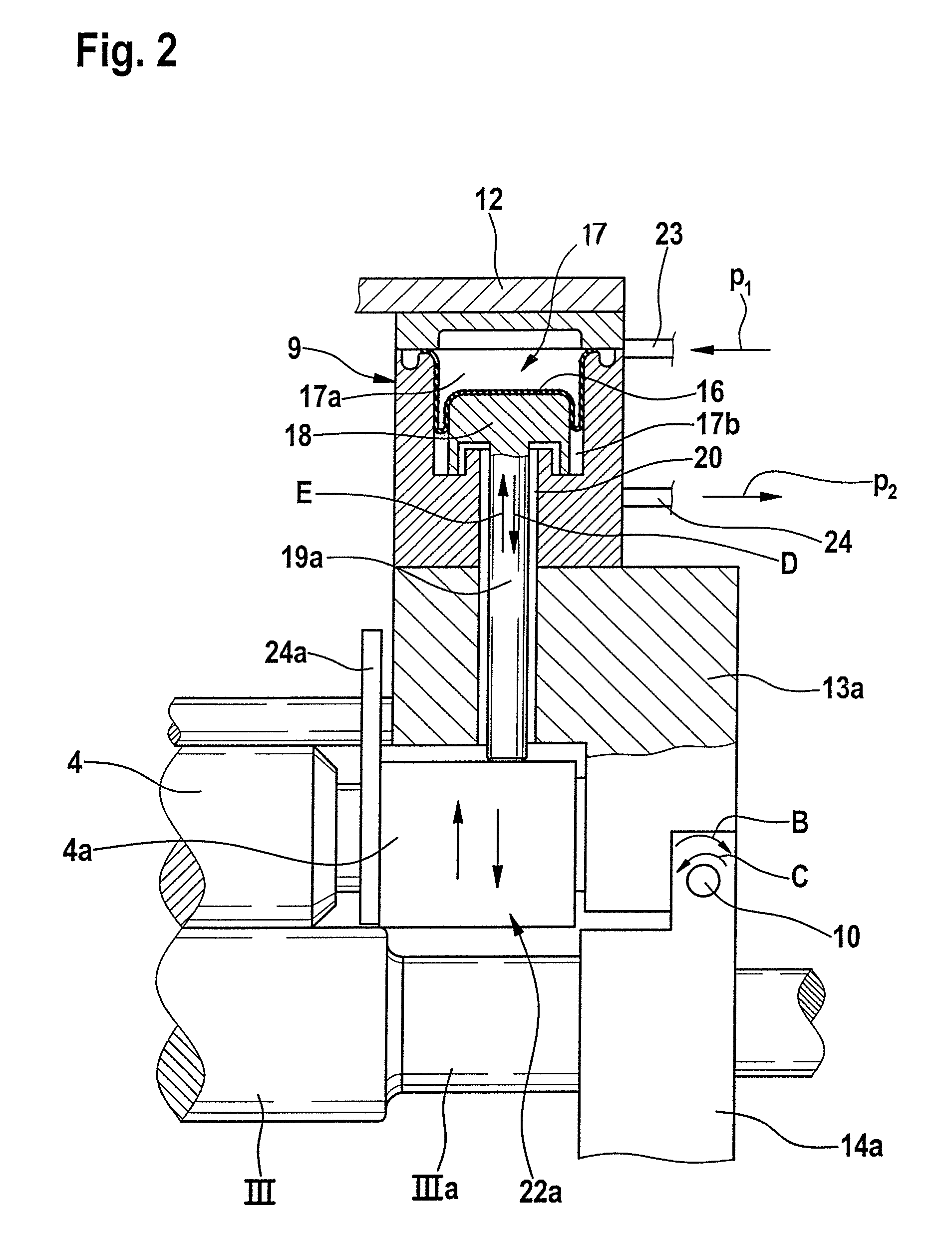

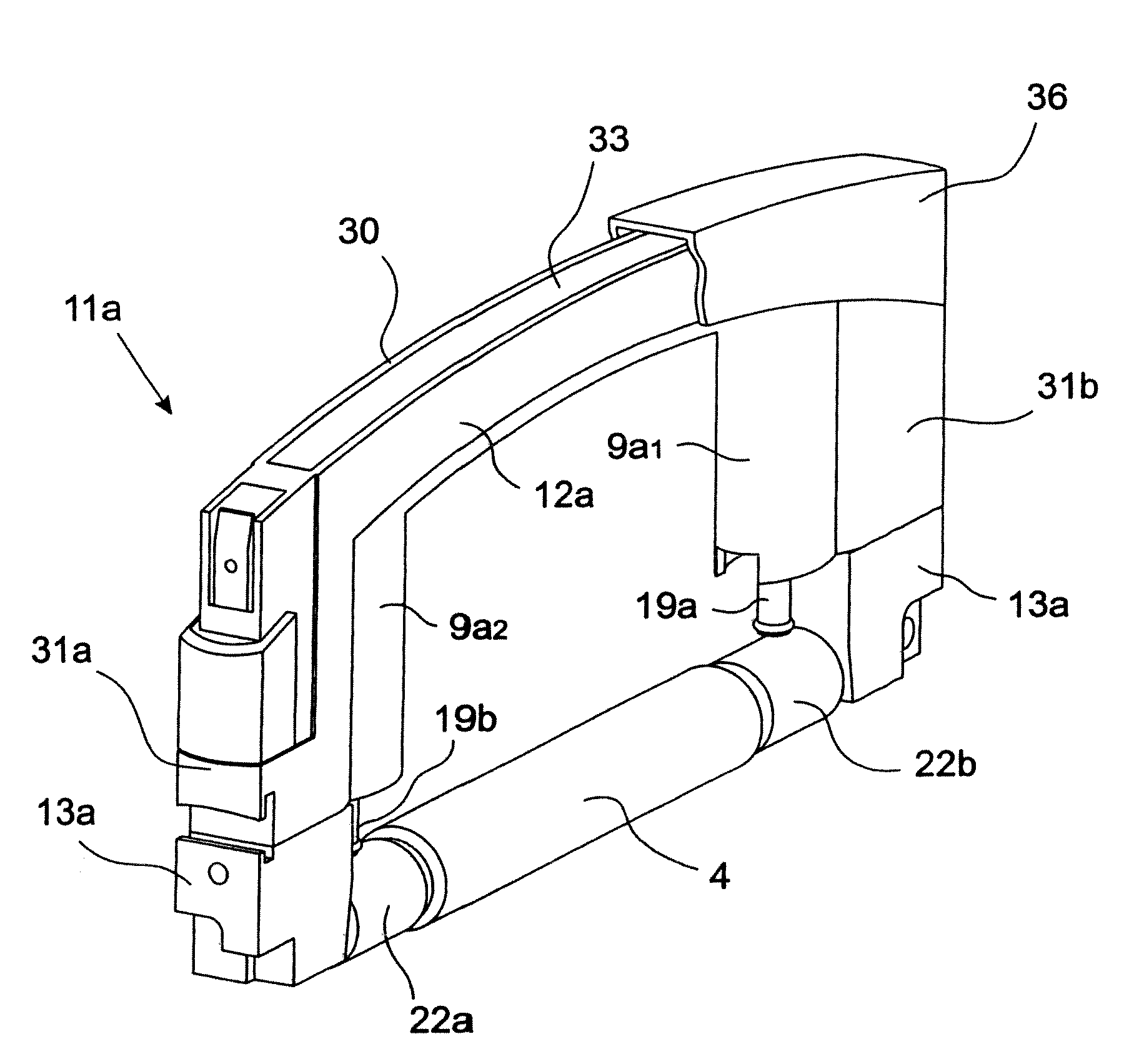

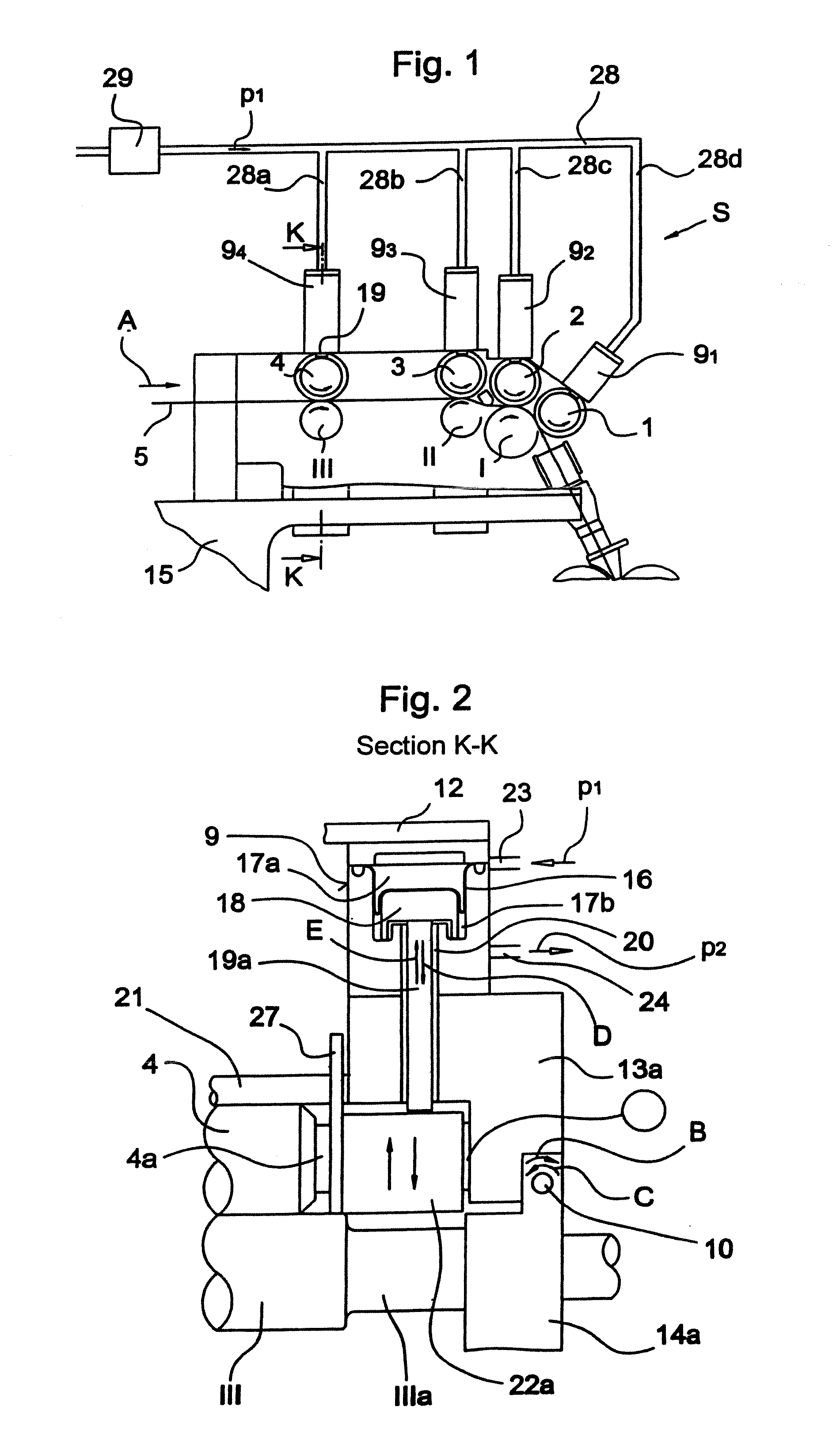

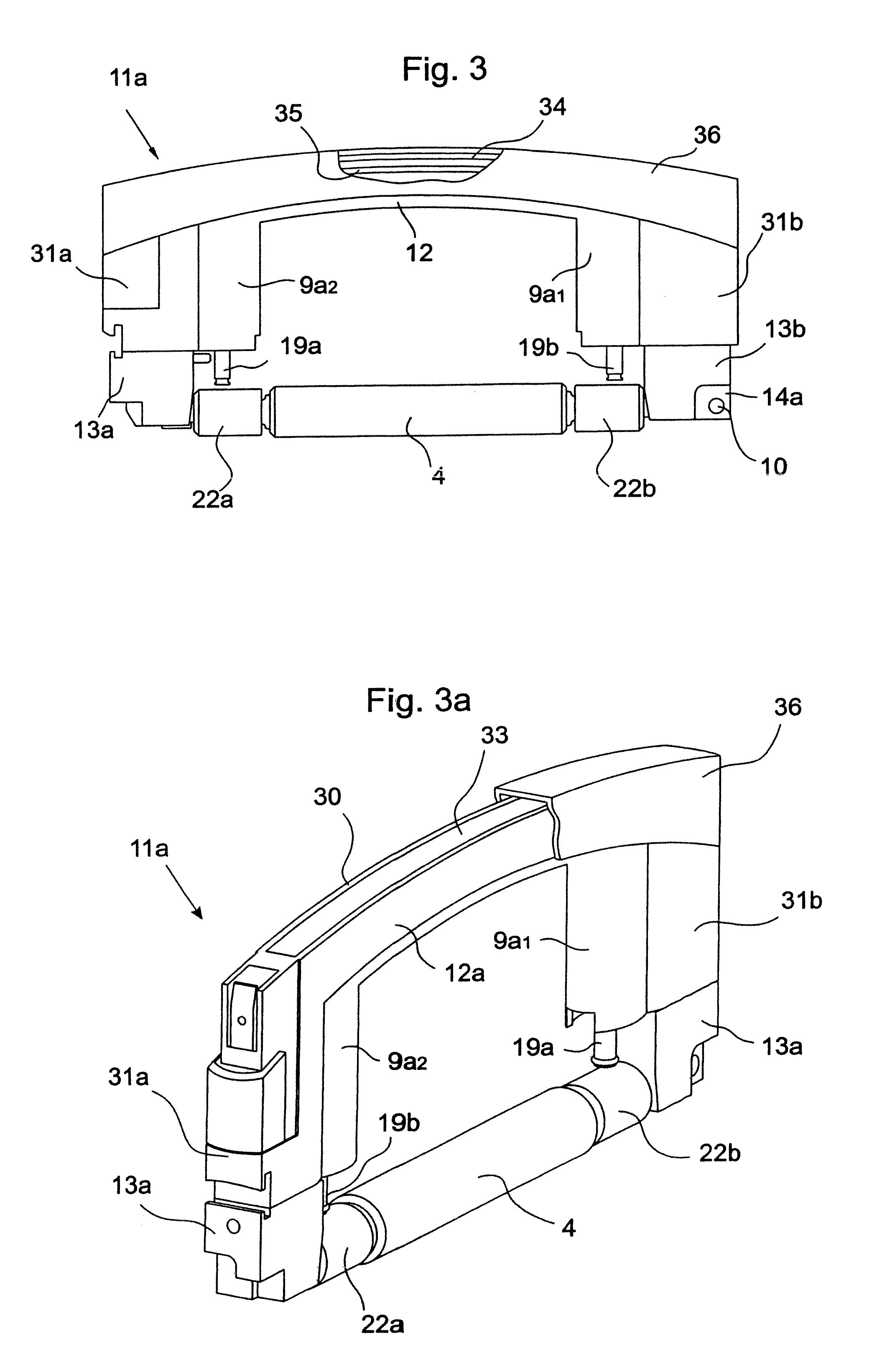

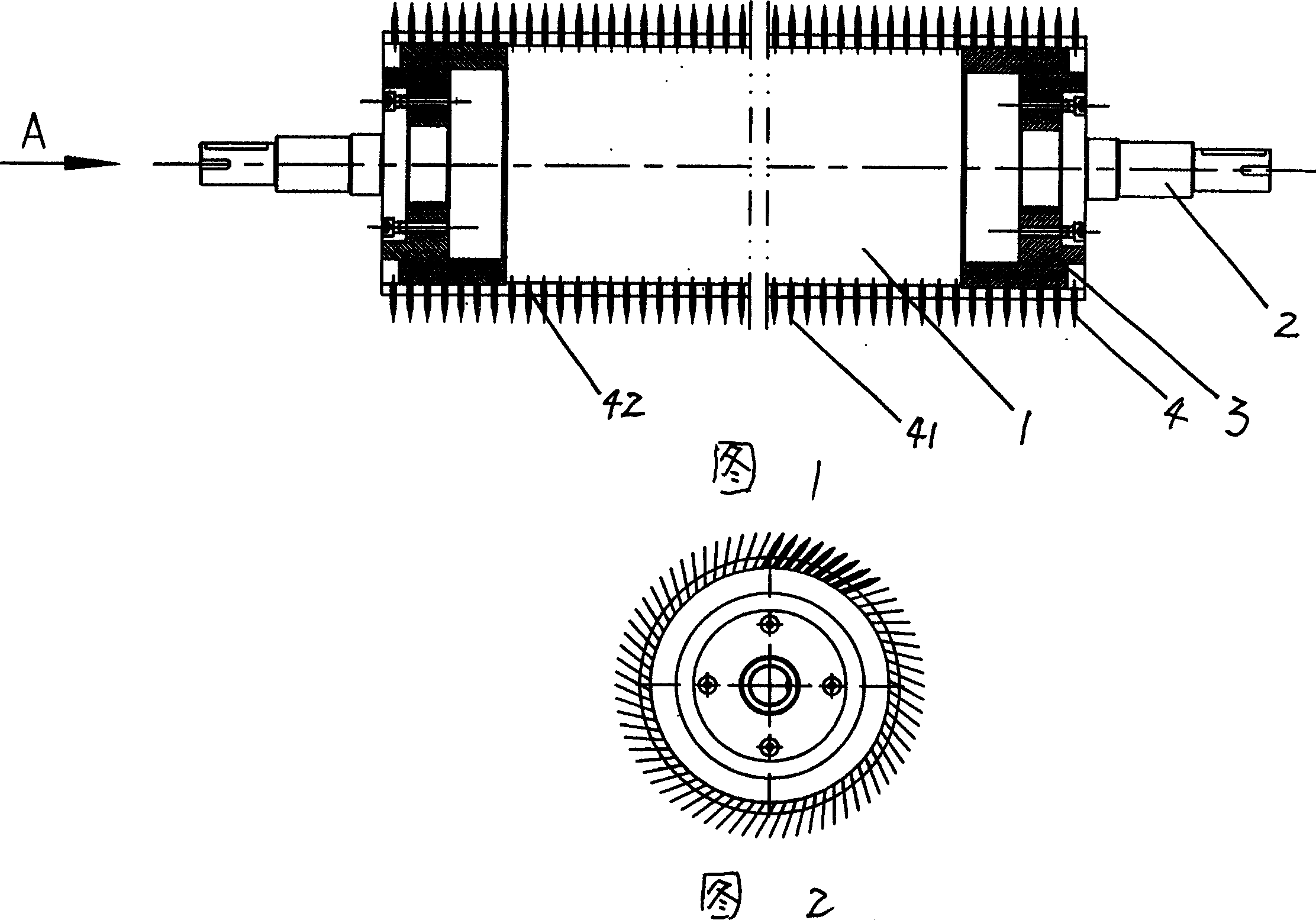

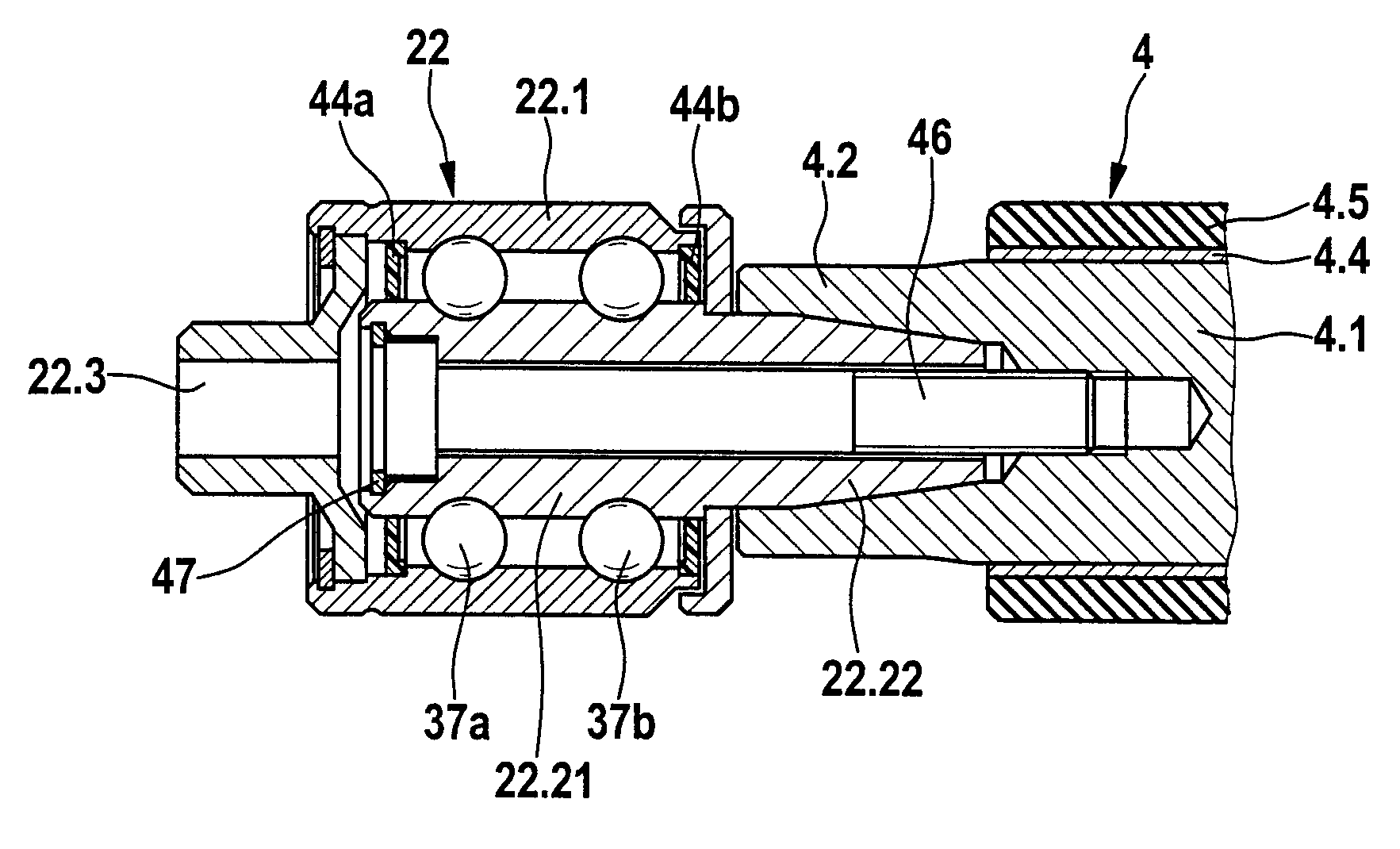

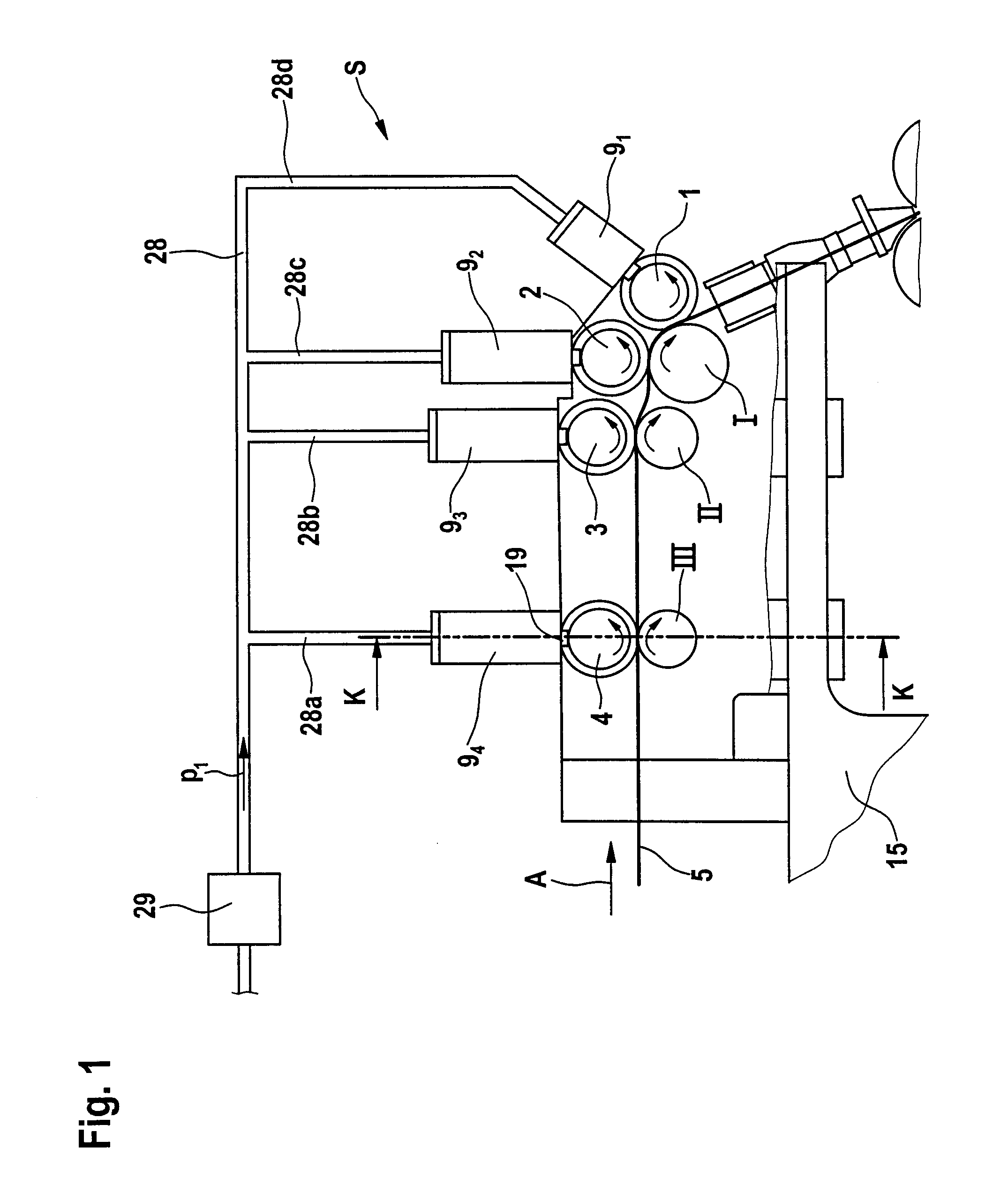

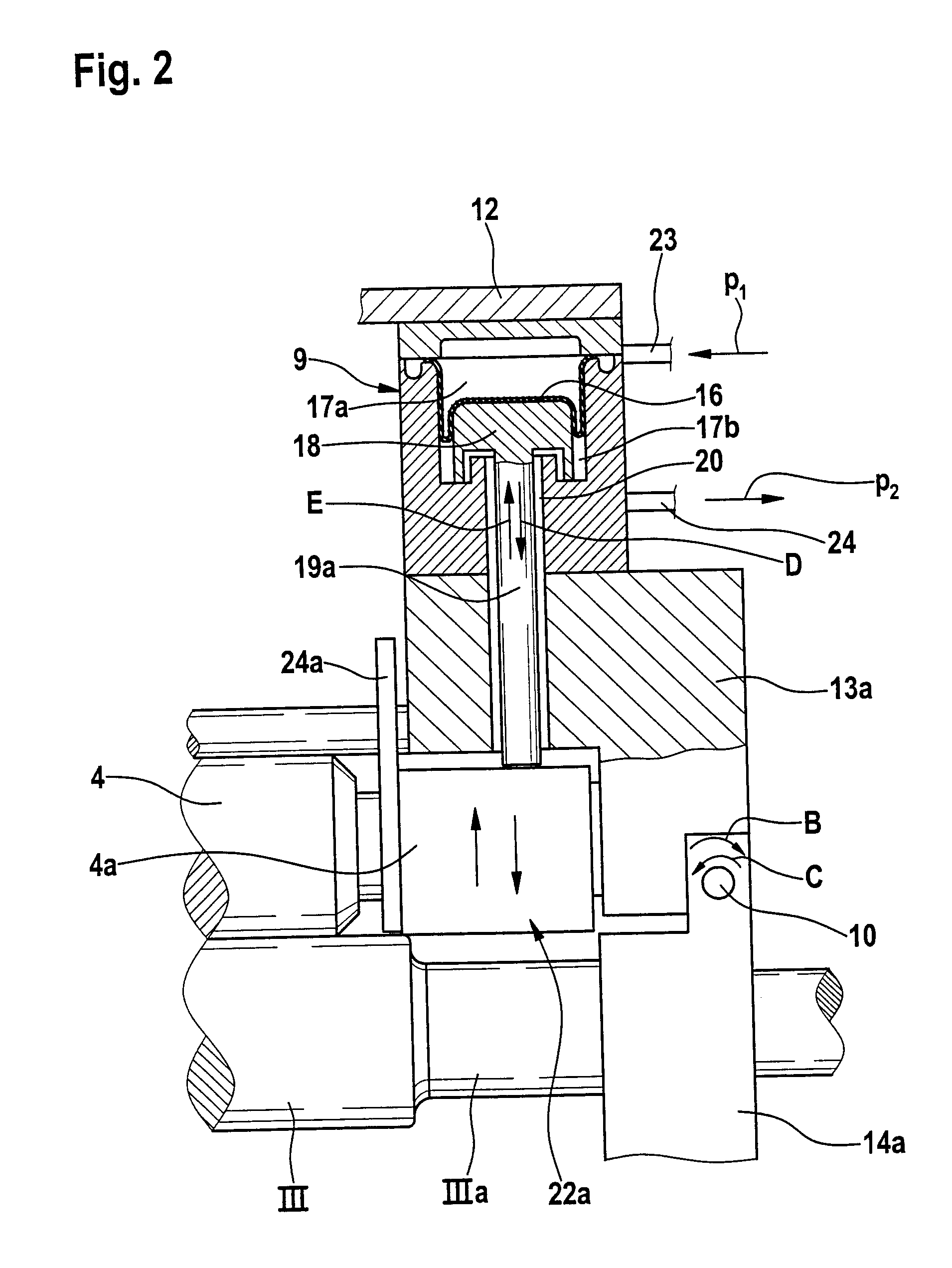

Device on a draw frame having a drafting system for textile fibre slivers

InactiveUS20090049652A1Simple and quick and reliableReliable force transmissionDrafting machinesBall bearingCoupling

In a device on a draw frame having a drafting system for textile fibre slivers with weighting of the upper rolls of the drafting system which comprises roll pairs arranged one behind the other, the pairs having lower and upper rolls, the rotating journals at the ends of the upper roll are mounted by means of bearing elements and the bearing elements each have at least one deep-groove ball bearing having an immovable outer housing (outer ring) and an internal rotational body (inner ring). In order to provide a structurally simple way in which the bearing housings can be mounted on or removed from the presser roll in a simple, quick and reliable manner, the bearing elements are in the form of deep-groove ball bearings and there is a coupling between the journal and the rotational body.

Owner:TRUETZSCHLER GMBH & CO KG

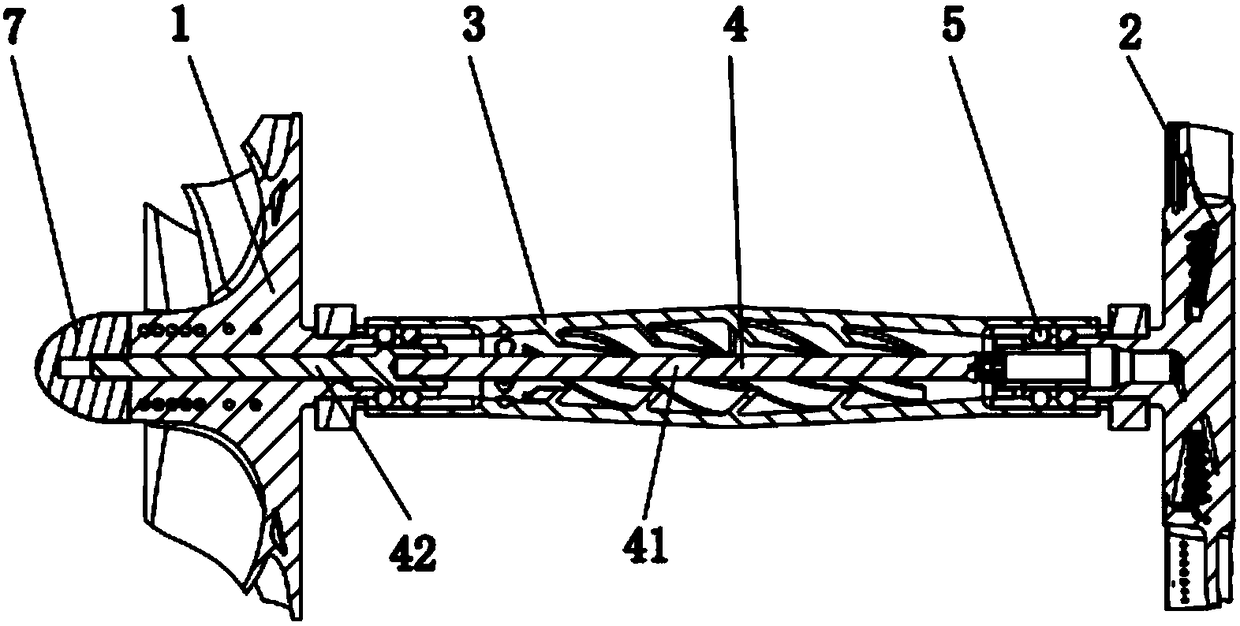

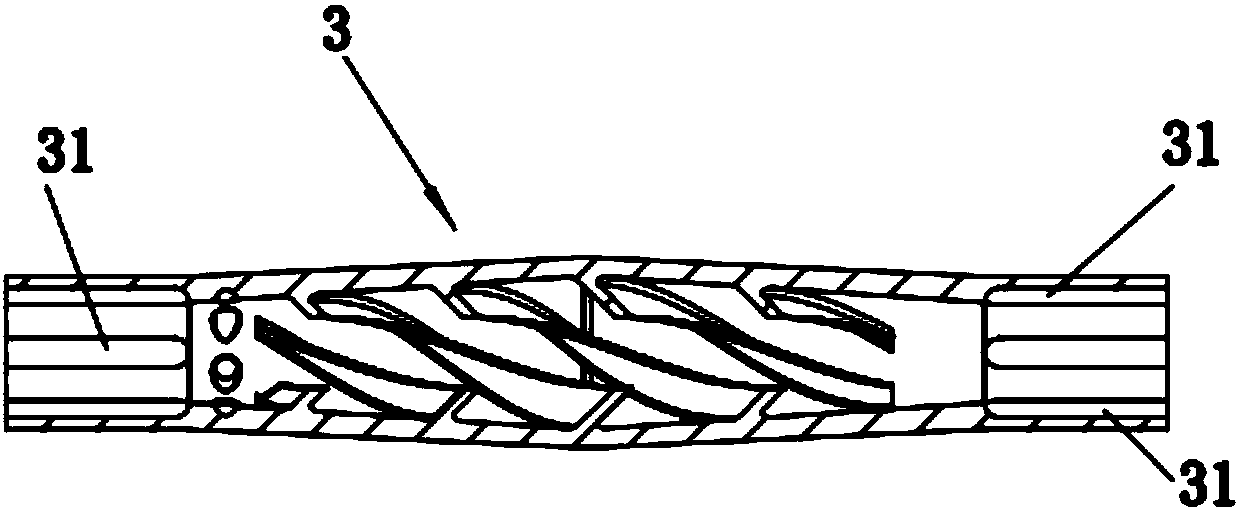

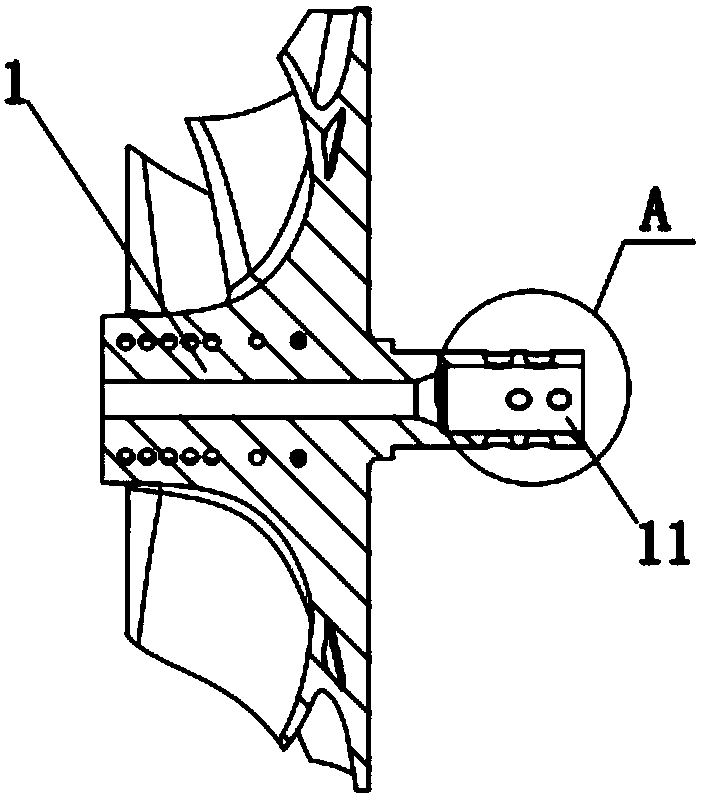

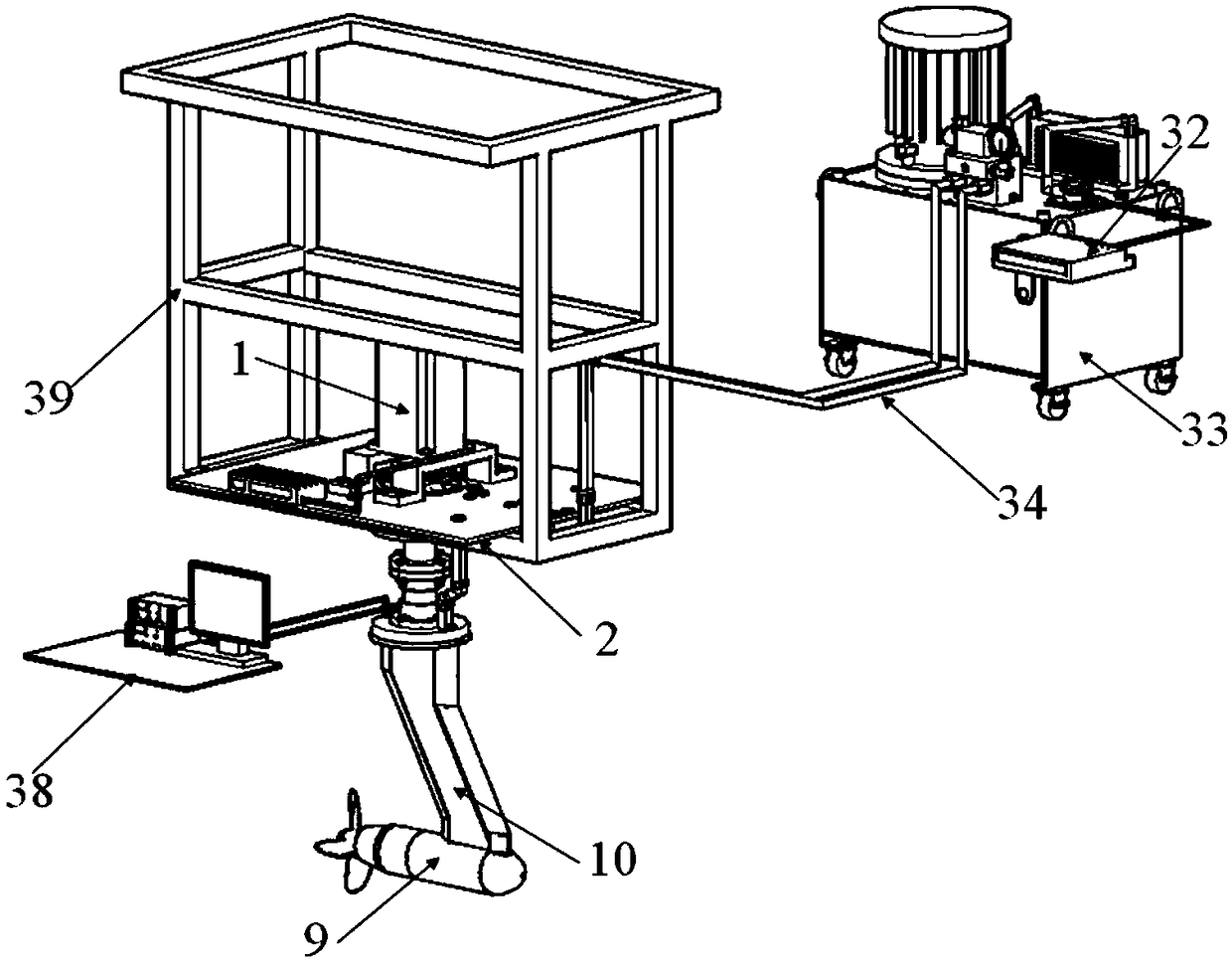

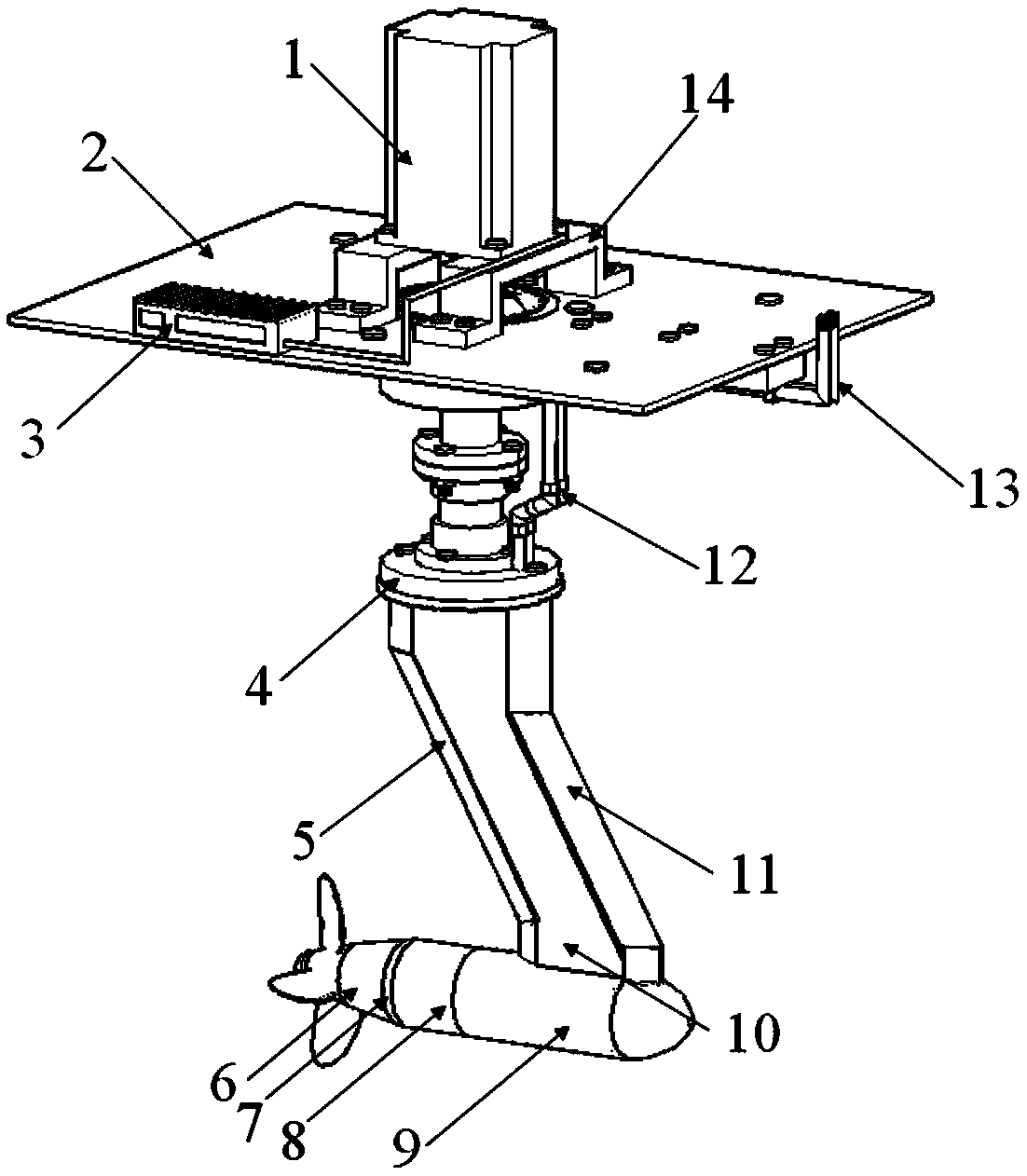

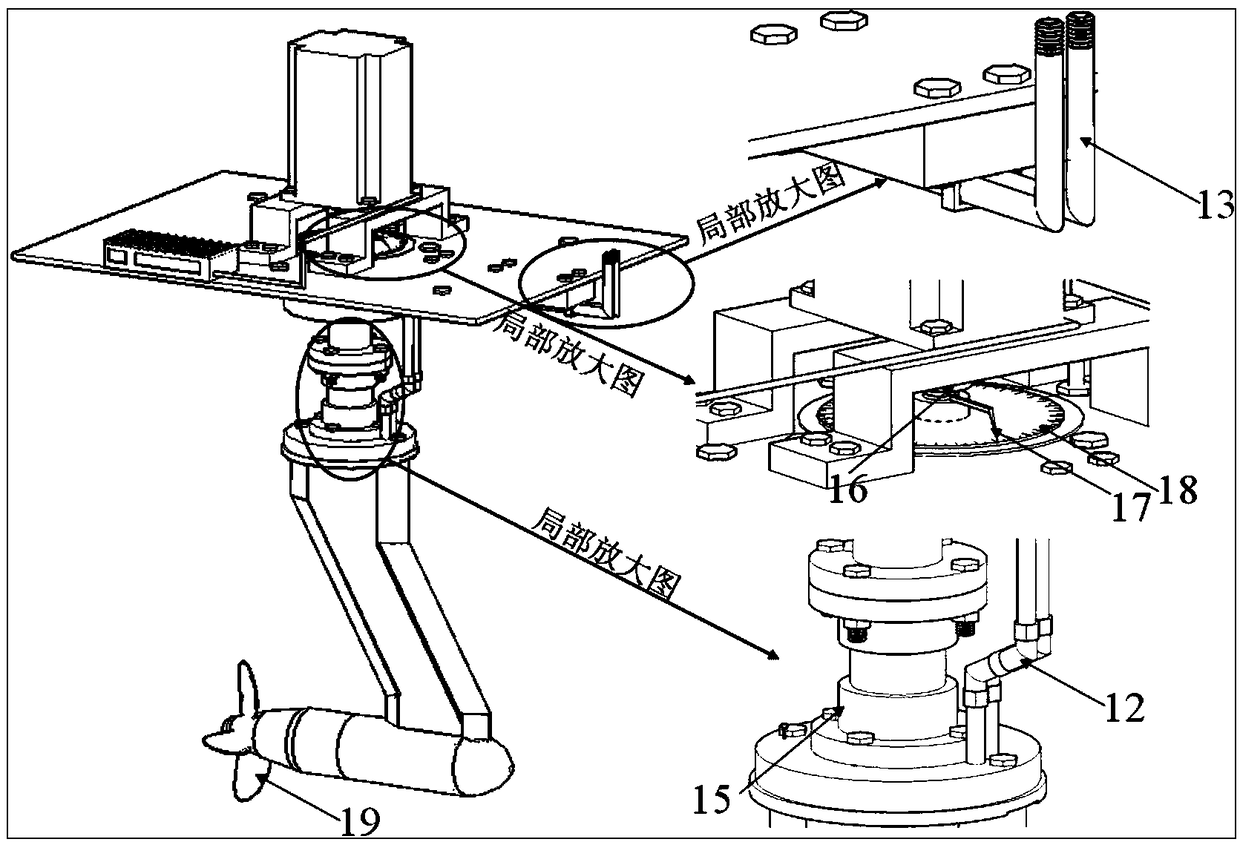

Hydraulicdrive type podded propulsor for testing

The invention provides a hydraulic drive type podded propulsor for testing. The hydraulic drive type podded propulsor for testing comprises a podded propulsor unit and further comprises a hydraulic control system; a propeller drive of the podded propulsor unit is a hydraulic motor; L-shaped rigid oil pipes are mounted on an oil inlet and an oil outlet of the hydraulic motor; the L-shaped rigid oilpipes are connected with a rigid oil pipe disposed along a pod supporting rod through a rigid oil pipe joint; the rigid oil pipe passes through a flange plate of the pod supporting rod; the rigid oilpipe on an upper end of the flange plate of the pod supporting rod is connected with a universal rotating joint; the universal rotating joint is then connected to one section of the rigid oil pipe; the hydraulic control system comprises a hydraulic pump station and a hydraulic motor controller; an oil outlet and an oil return port of the hydraulic pump station are connected with the last sectionof the rigid oil pipe through a flexible oil pipe. The hydraulic drive type podded propulsor for testing is suitable for development and research of the podded propulsor and has the advantages of small size, good stability, light weight and convenient assembly and disassembly.

Owner:HARBIN ENG UNIV

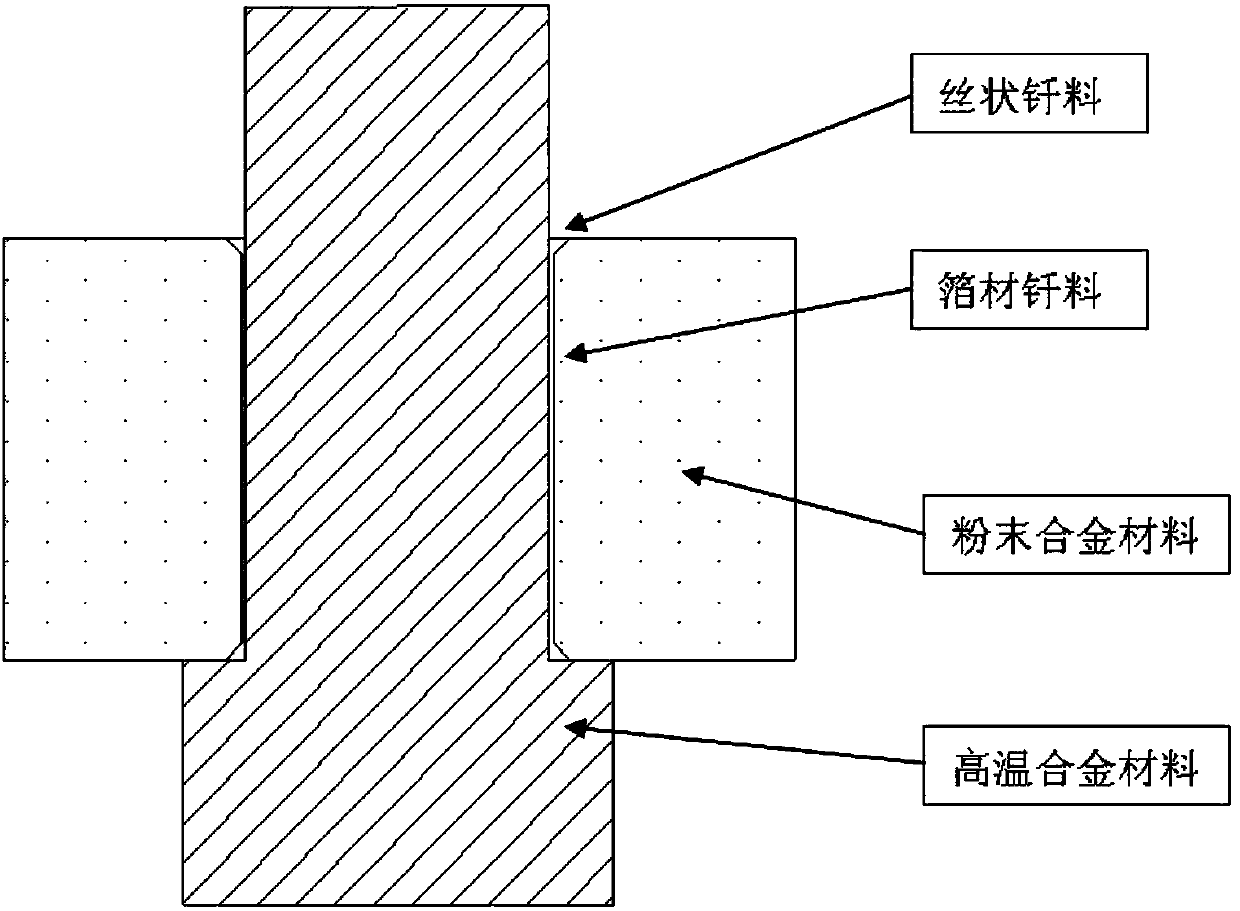

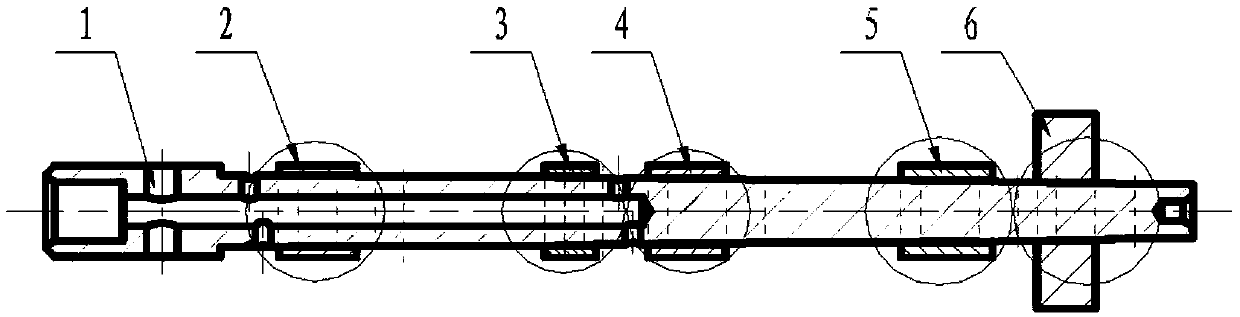

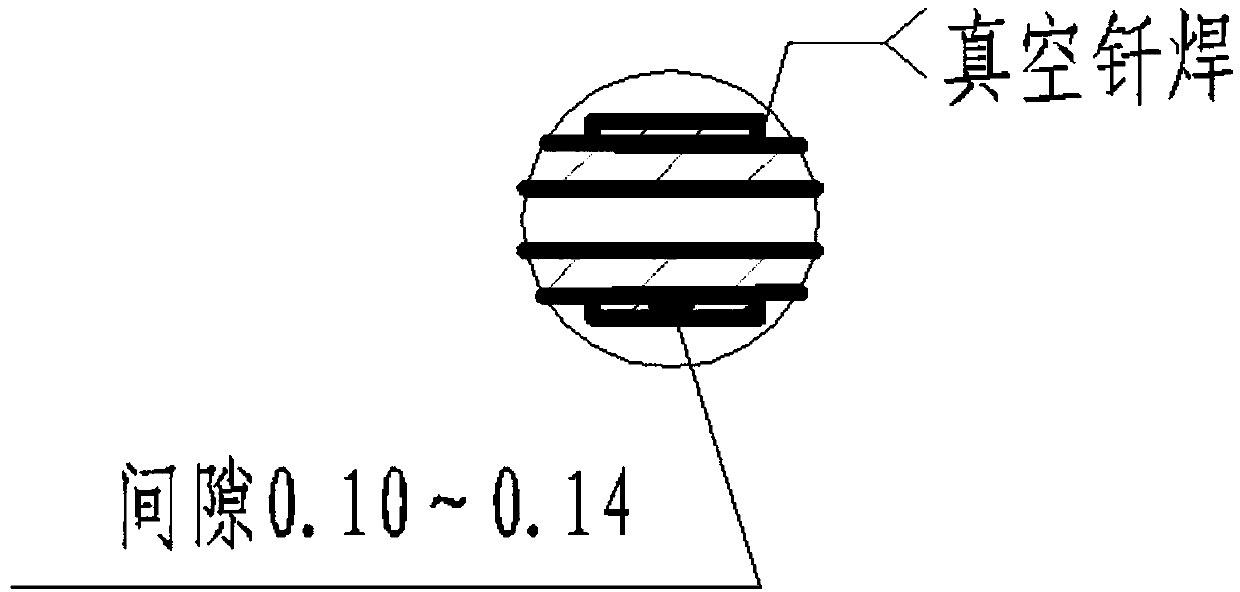

Vacuum brazing method of high-temperature alloy and cobalt-based powder metallurgy material

InactiveCN108031941AGood weld uniformityGuaranteed dimensional accuracy of coaxialitySoldering apparatusWelding/soldering/cutting articlesPowder metallurgySpare part

The invention discloses a vacuum brazing method of a high-temperature alloy and cobalt-based powder metallurgy material, which includes confirmation of a brazing gap; combined layout method of a gold-based brazing filler and a brazing technique. The invention realizes the preparation of a cobalt-based powder metallurgy wear-resisting material layer with excellent friction performance at the surface of a precise spare part. According to the precise spare part processed by the brazing technique, the brazing filler fills the weld joint completely, and the weld joint is good in uniformity; the coaxial dimension precision of the welding spare part is guaranteed, and the shear intensity of the weld joint is over 280 MPa.

Owner:GUIZHOU HONGLIN MACHINERY

Processing technology of rigid flexible wheels of robot speed reducer

The invention discloses a processing technology of rigid flexible wheels of a robot speed reducer. The processing technology includes the steps of manufacturing blanks of the rigid flexible wheels byprecise casting or forging casting, subjecting the blanks of the rigid flexible wheels to rough processing, subjecting the rough-processed blanks of the rigid flexible wheels to heat treatment, subjecting external gears and internal races of the rigid flexible wheels to super-finishing, and detecting various index of the super-finished rigid flexible wheels until reaching requirements of finishedproducts.

Owner:SHANDONG SHKE MACHINERY MFG +1

Radial magnetic bearing and sensor bracket split structure

InactiveCN106402158ASimplify control proceduresReduce control errorBearing assemblyShaft assemblySensor holderEngineering

Owner:NANJING CIGU TECH CORP LTD

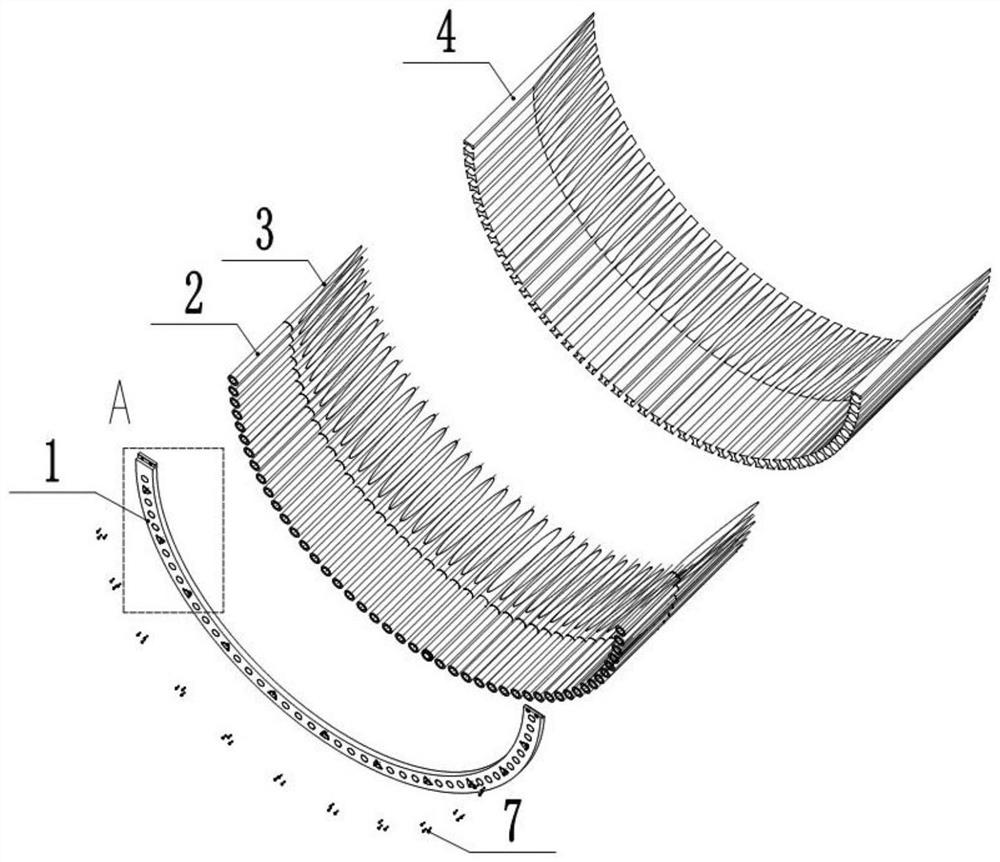

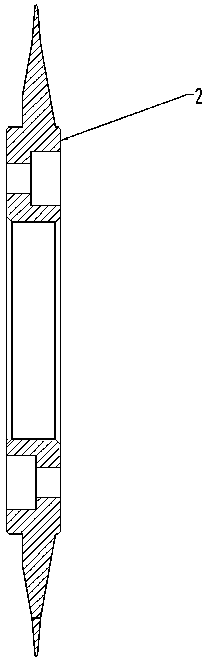

Needle roller for carding machine and preparation method thereof

A needle roller for carding machine belongs to a piece of equipment for carding machine in the cotton textile industry. The needle roller includes an aluminum pipe and a central axle; both ends of the aluminum pipe are sealed with flanges; the wall of the aluminum alloy pipe is opened with a aluminum hole; a steel needle is planted in the aluminum hole, which consists of a needle tip and a needle bar; the needle bar of the steel needle planted in the aluminum alloy pipe hole is adhered and integrated to the aluminum alloy pipe by super glue. The product quality is reliable; the needle roller and the needle tip have small coaxially and high co-straightness; the needle roller with the aluminum alloy as base structure is convenient in installation, has light weight, less energy consumption, high equipment manufacturing efficiency; in addition, the time for parking for maintenance is short, the carding quality is stable and unchanged, which is applicable to reconstruction of the current carding machines, and improves the performance and quality of the carding machines.

Owner:YIXING FANGZHOU ENVIRONMENT CONSERVATION

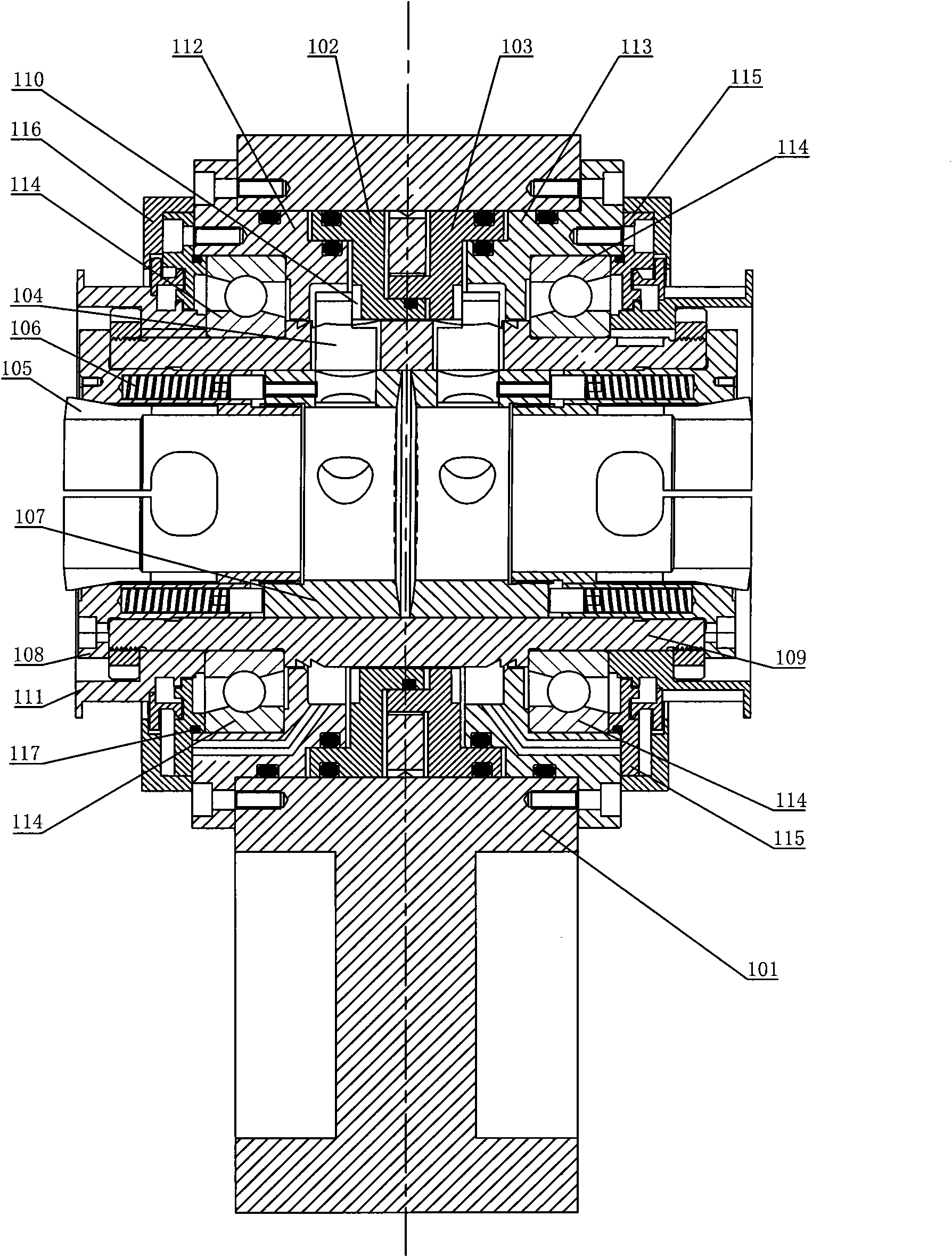

Moment rotary rigidity high-low temperature testing device

ActiveCN112254905AOvercoming Measurement Accuracy ProblemsReduce concentricityElasticity measurementDrive shaftEngineering

The invention relates to a moment rotary rigidity high-low temperature testing device, which comprises a foundation platform, a driving and testing integrated module, an overload protection module, anadjusting module and support modules. The overload protection module is a magnetic powder brake overload protection module; the overload protection module, the support modules, a high-low temperaturebox and the adjusting module are installed on the foundation platform, the high-low temperature box is located between the two support modules, the driving and testing integrated module is installedon the adjusting module, and a transmission shaft between a torsion driving module and the support module is provided with a dynamic torque sensor and an angle encoder. Box penetrating shafts connected with the output end of the torsion driving module and the output end of the overload protection module are supported by the support modules to rotate, the side walls of the high-low temperature boxare each provided with an annular elastic sealing gasket, and the annular elastic sealing gaskets are located in grooves of air sealing rings arranged on the box penetrating shafts in a sleeving modeand make friction contact with the bottom faces of the grooves. The air seal rings are circular rings formed by connecting two metal semi-rings in a butt joint mode. The device adapts to high and lowtemperature tests, and the test is flexible and convenient.

Owner:HARBIN INST OF TECH

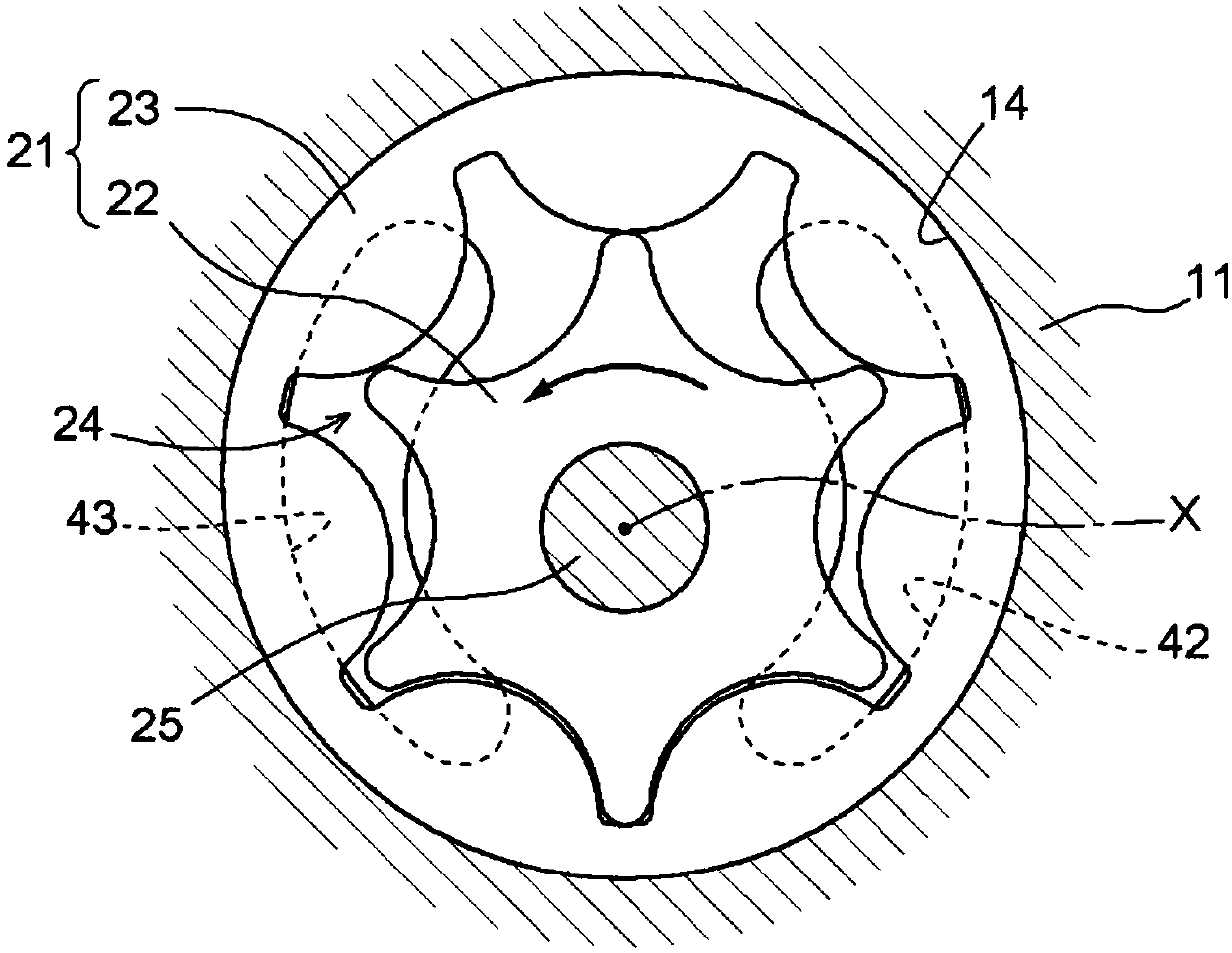

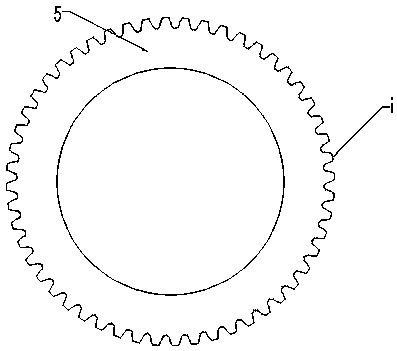

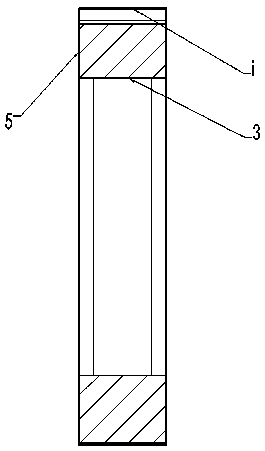

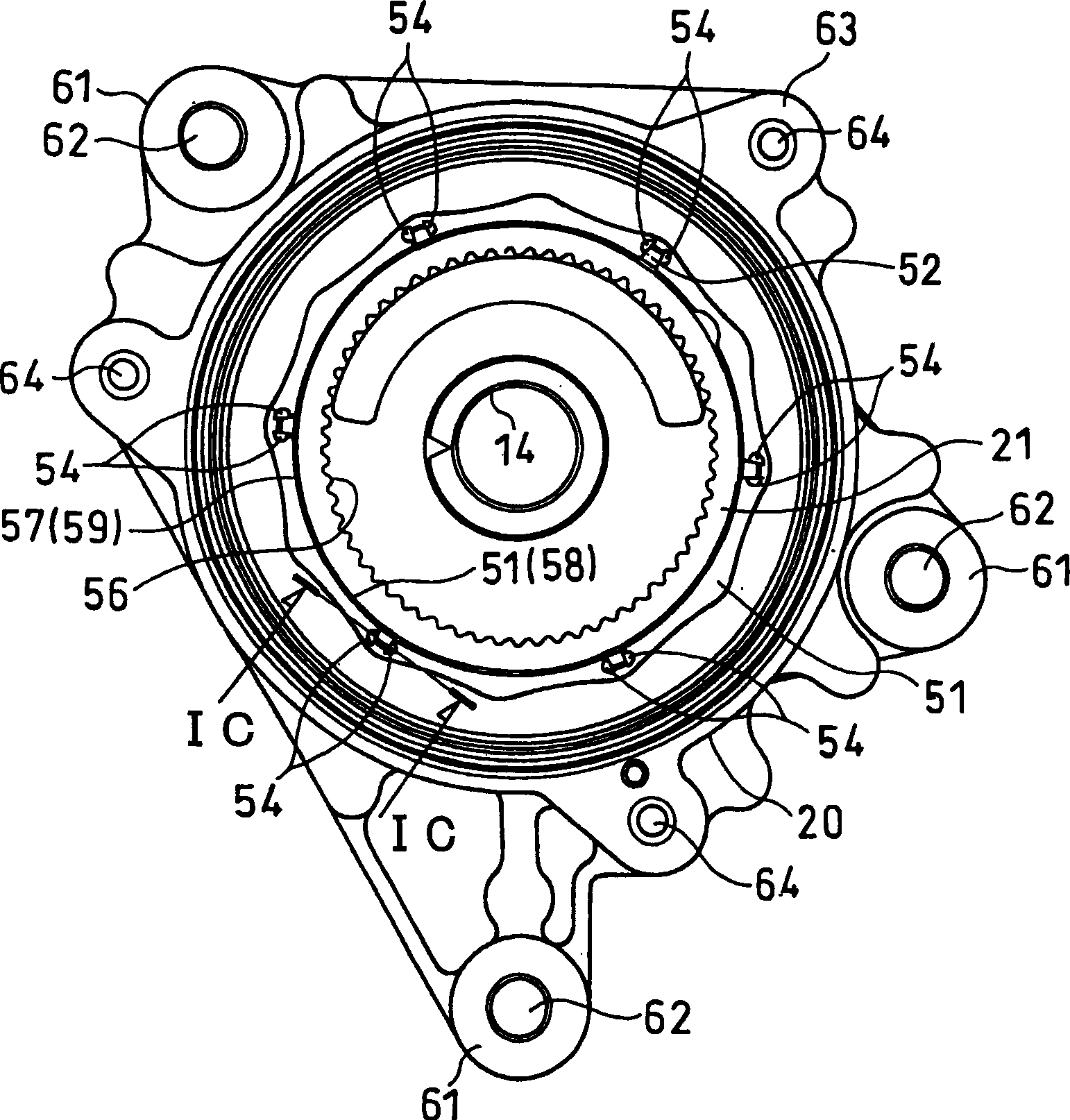

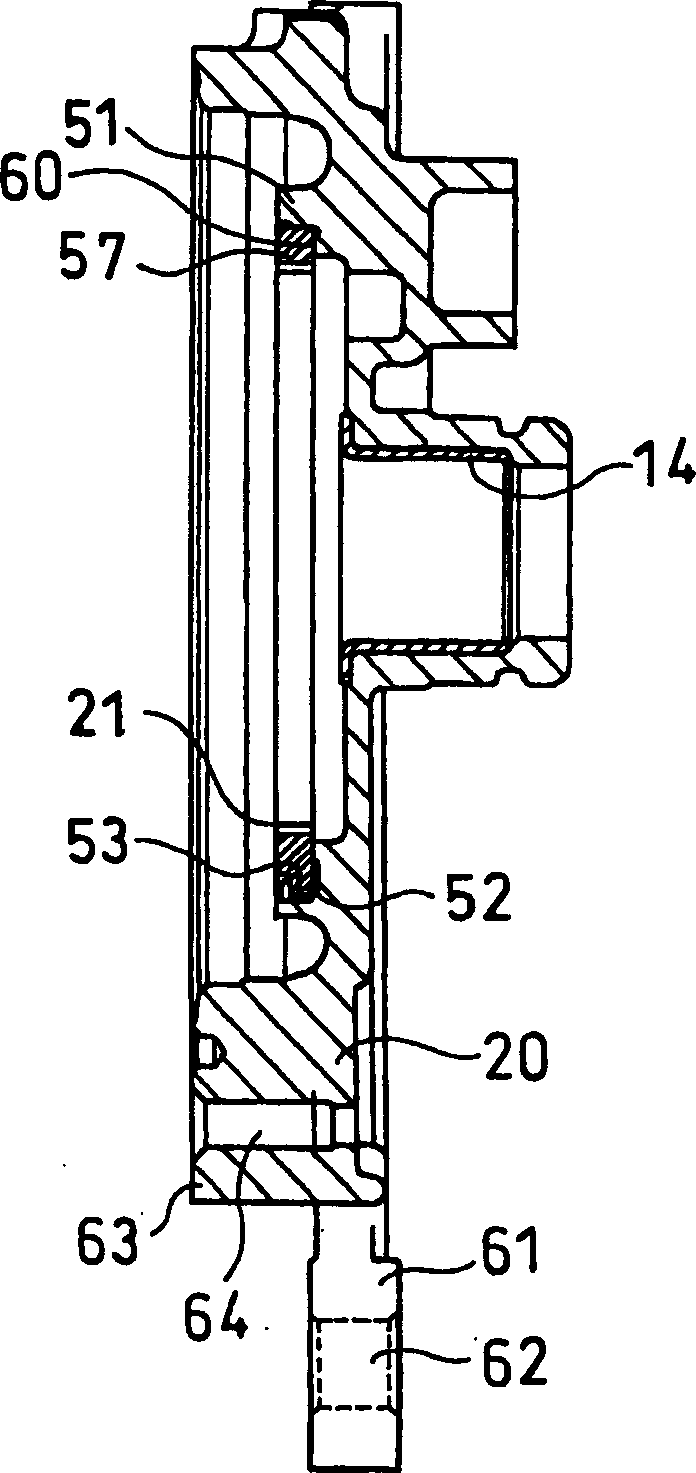

Gear device

ActiveCN1779298ALow roundnessReduce concentricityToothed gearingsPortable liftingGear wheelEngineering

The invention provides a toothed gearing, in which the peripheral part of internal gear circular part is press-inserted to the internal peripheral part of the front casing built-in wall. After a plurality of clamping catches are inserted in lots of clamping slots on the internal peripheral part of the front casing built-in wall, the two ends of clamping catches are applied the outside force to make them plastically deform, so as to form a plurality of riveted fixing part.

Owner:DENSO CORP +1

Device on a drafting system of a draw frame for textile fibre slivers

InactiveUS20090052824A1Simple and quick and reliableReliable force transmissionDrafting machinesBearing componentsTextile fiberRolling-element bearing

In a device on a drafting system for textile fibre slivers with weighting of the upper rolls of the drafting system which comprises roll pairs arranged one behind the other, the pairs having lower and upper rolls, the rotating journals at the ends of the upper roll are mounted by means of bearing elements and the bearing elements each have at least one rolling-element bearing having an immovable outer housing (outer ring) and an internal rotational body (inner ring). In order to provide a structurally simple way in which the bearing housings can be mounted on or removed from the presser roll in a simple, quick and reliable manner, the bearing elements are in the form of rolling-element bearings and there is a coupling between the journal and the rotational body.

Owner:TRUETZSCHLER GMBH & CO KG

Electric main shaft with mouse cage type motor stator cooling structure

InactiveCN101895170AEasy to disassembleQuick and easy disassemblyMechanical energy handlingCooling/ventillation arrangementCooling effectEngineering

The invention discloses an electric main shaft with a mouse cage type motor stator cooling structure, comprising a main shaft assembly, a motor stator, a motor rotor, a box body, a front bearing assembly and a rear bearing assembly, wherein the motor stator is sleeved in the box body; the motor rotor is sleeved on the main shaft assembly; the main shaft assembly is arranged in the motor stator and supported on the box body through the front bearing assembly and the rear bearing assembly; the box body is provided with a mouse cage type cooling passage used for cooling the motor stator; the front end of the box body is provided with a front bearing seat used for installing the front bearing assembly; the front bearing seat and the box body are cast into an integer; one end of the motor stator, which is close to the front bearing seat, is sleeved with a stator side ring, and the motor stator can act on the stator side ring from an inner hole of the front bearing seat through a cylinder tooling and be pushed out of the rear end of the box body. The electric main shaft with the mouse cage type motor stator cooling structure has compact structure, convenient disassembly and assembly and good cooling effect.

Owner:HUNAN UNIV

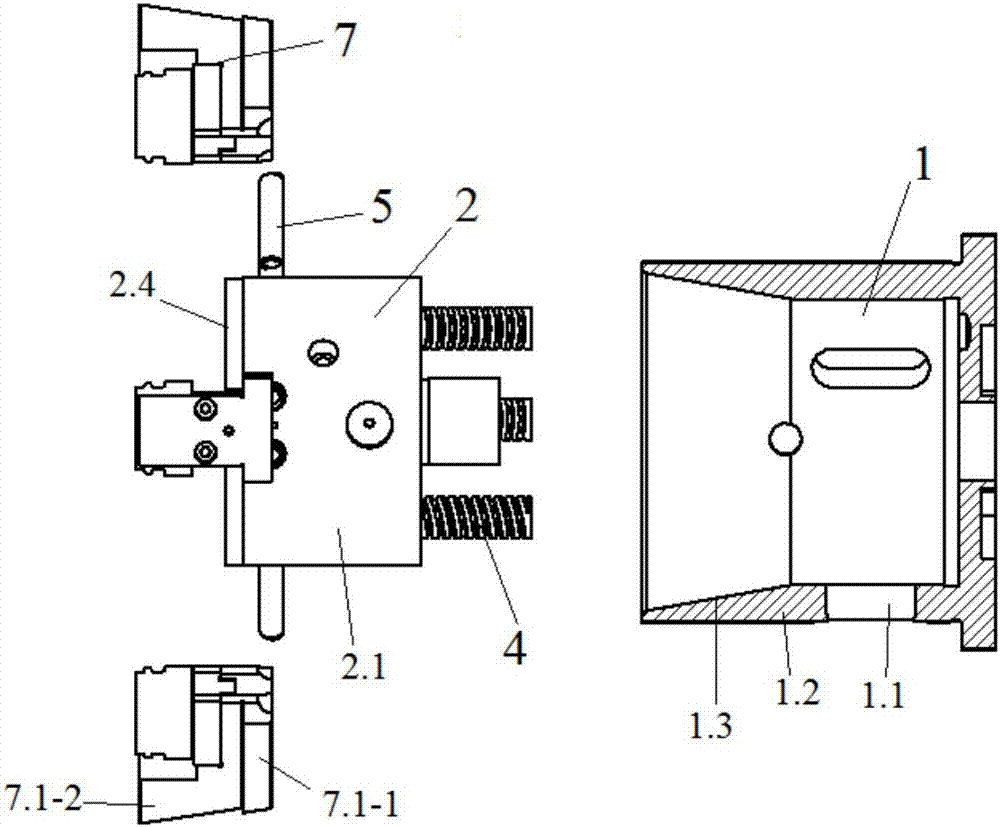

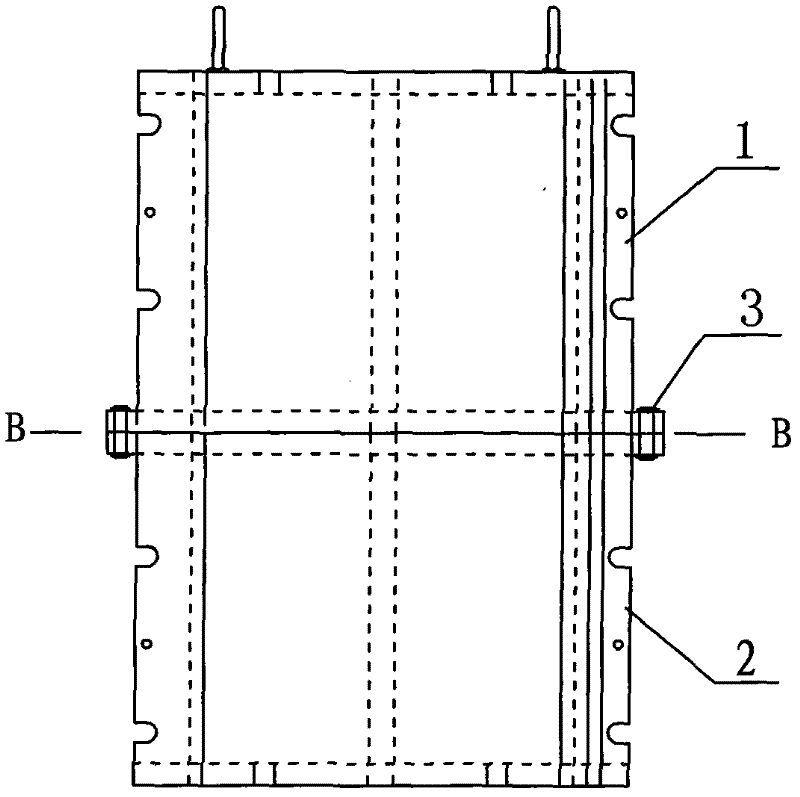

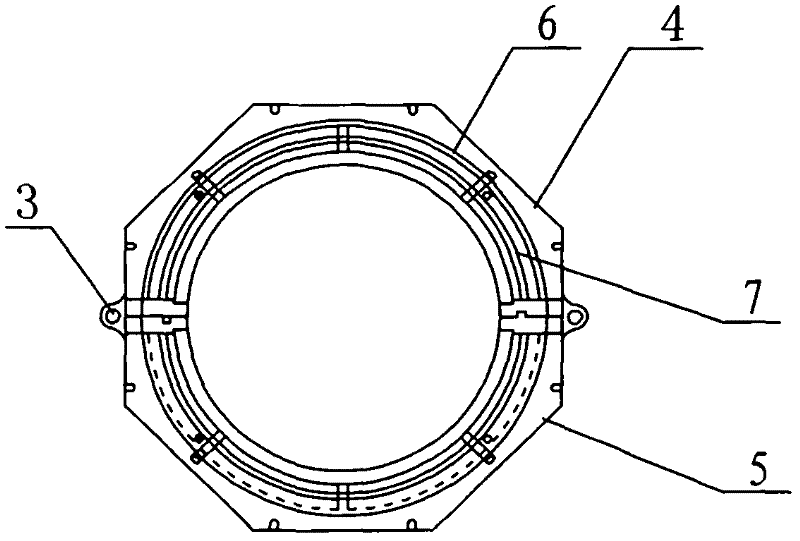

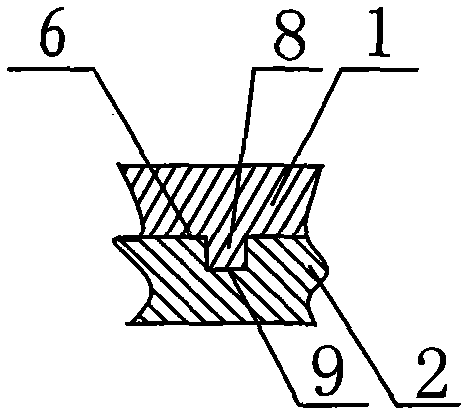

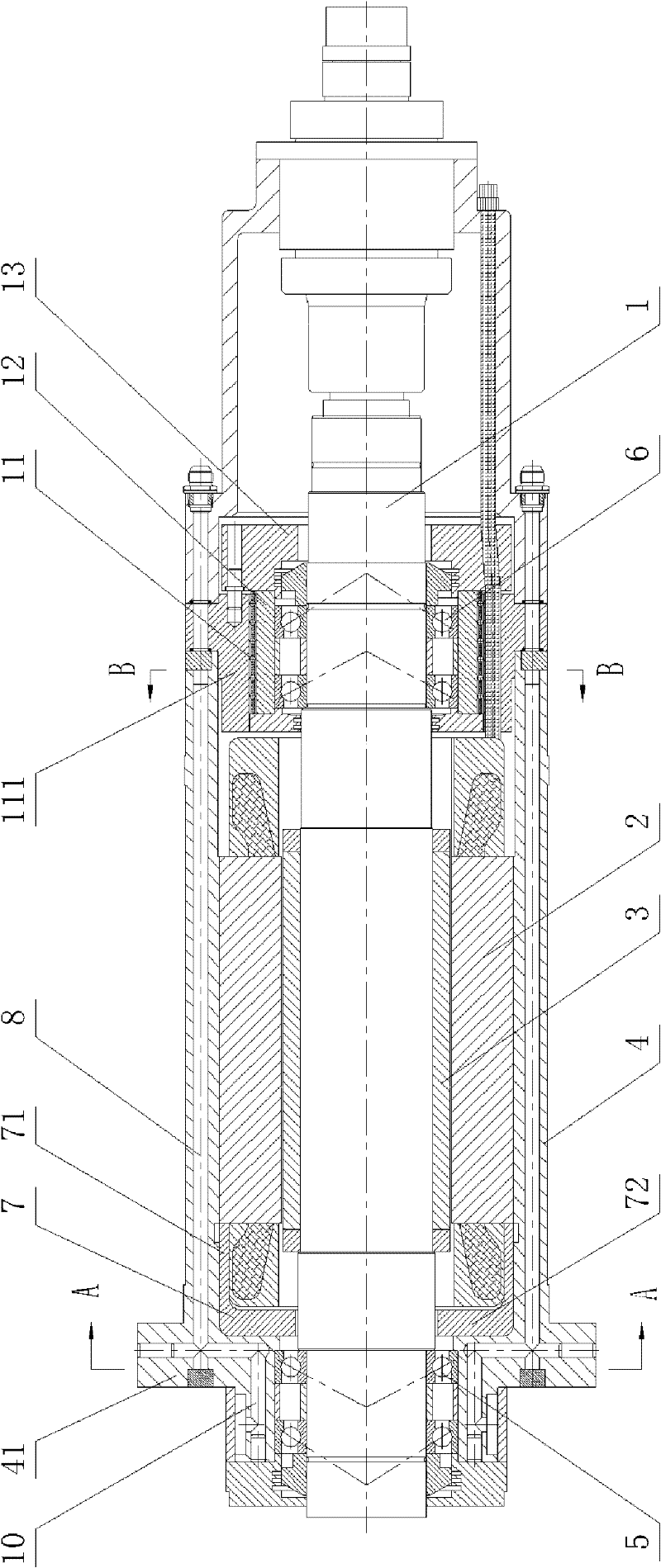

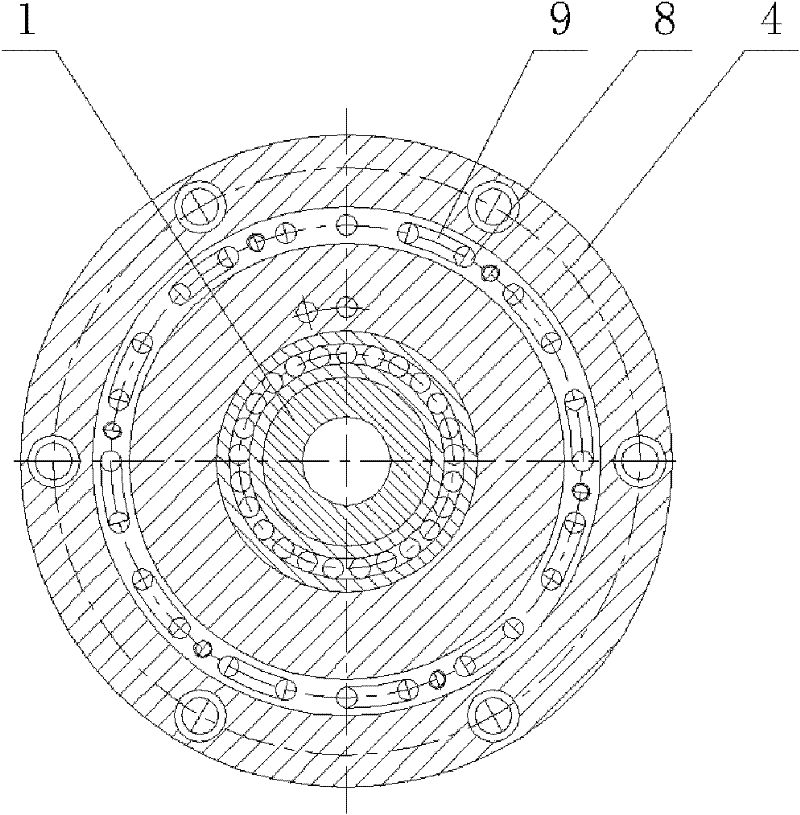

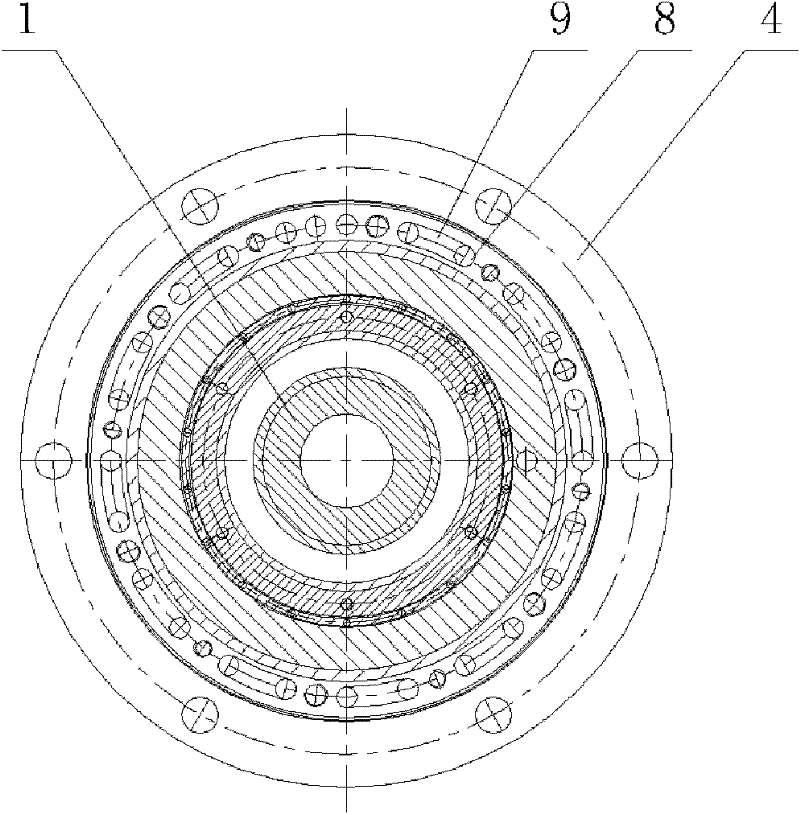

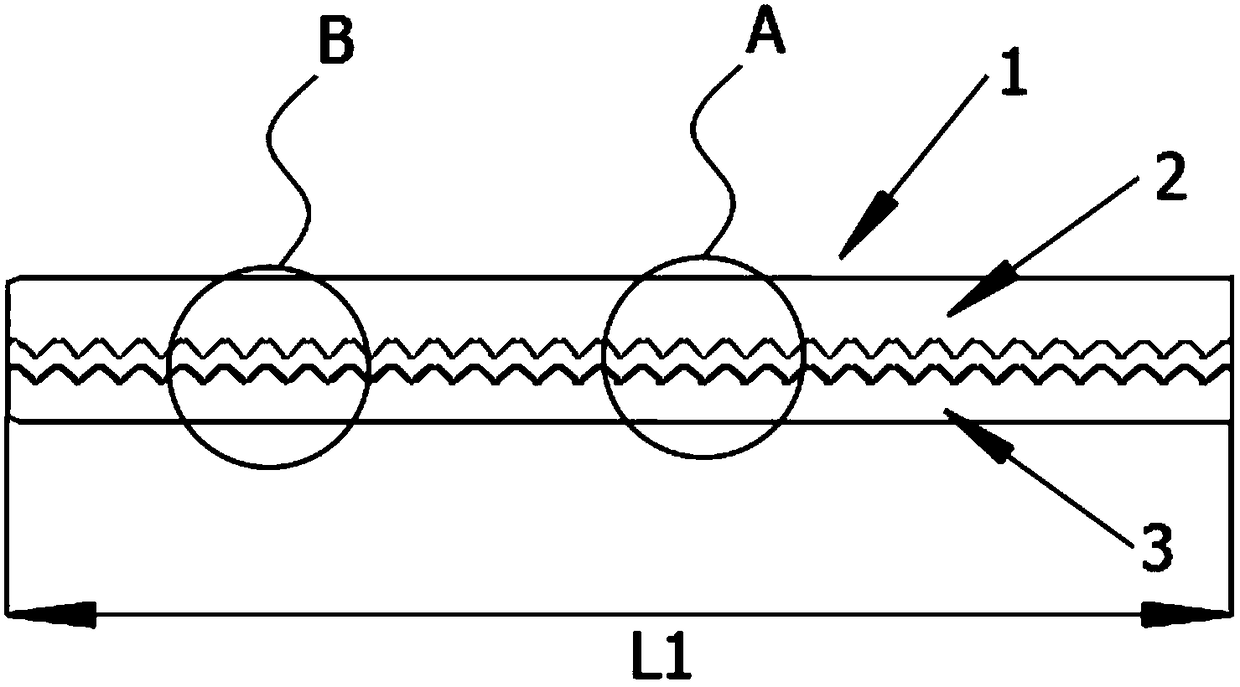

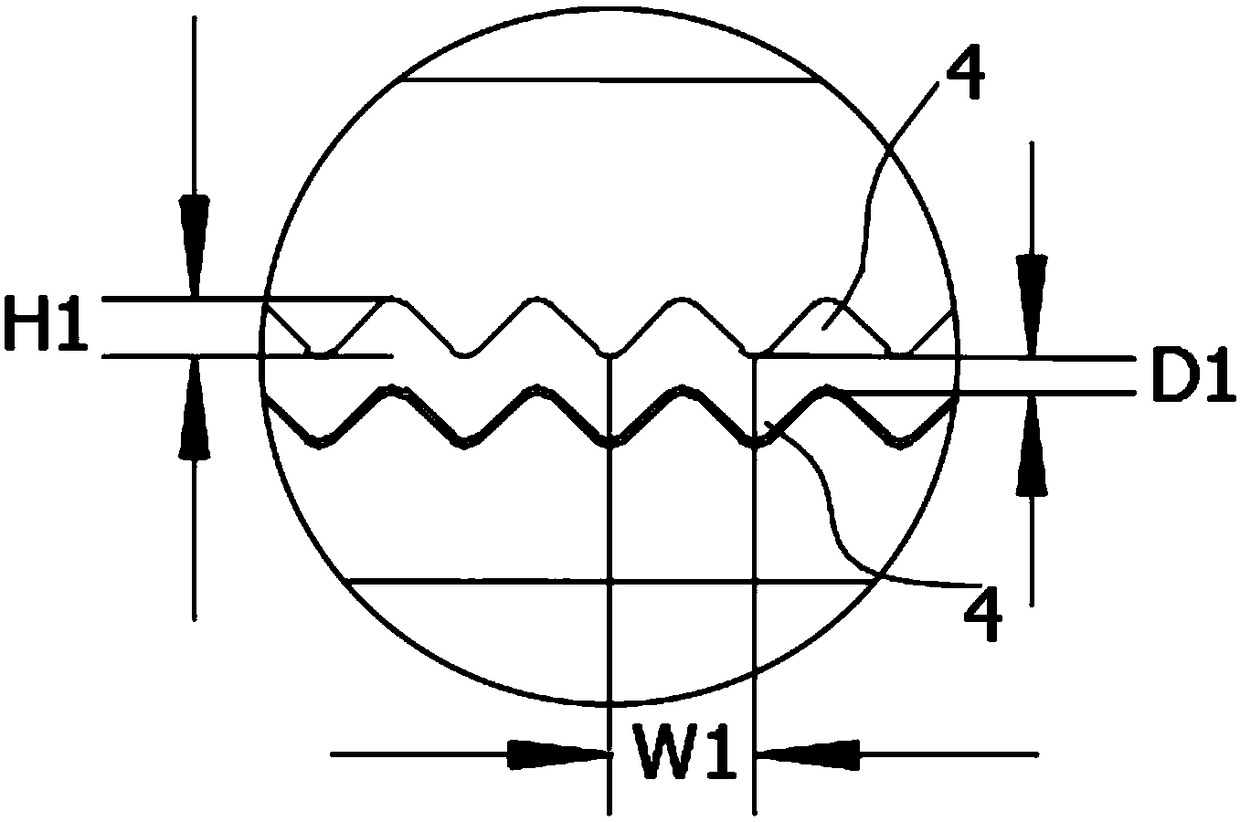

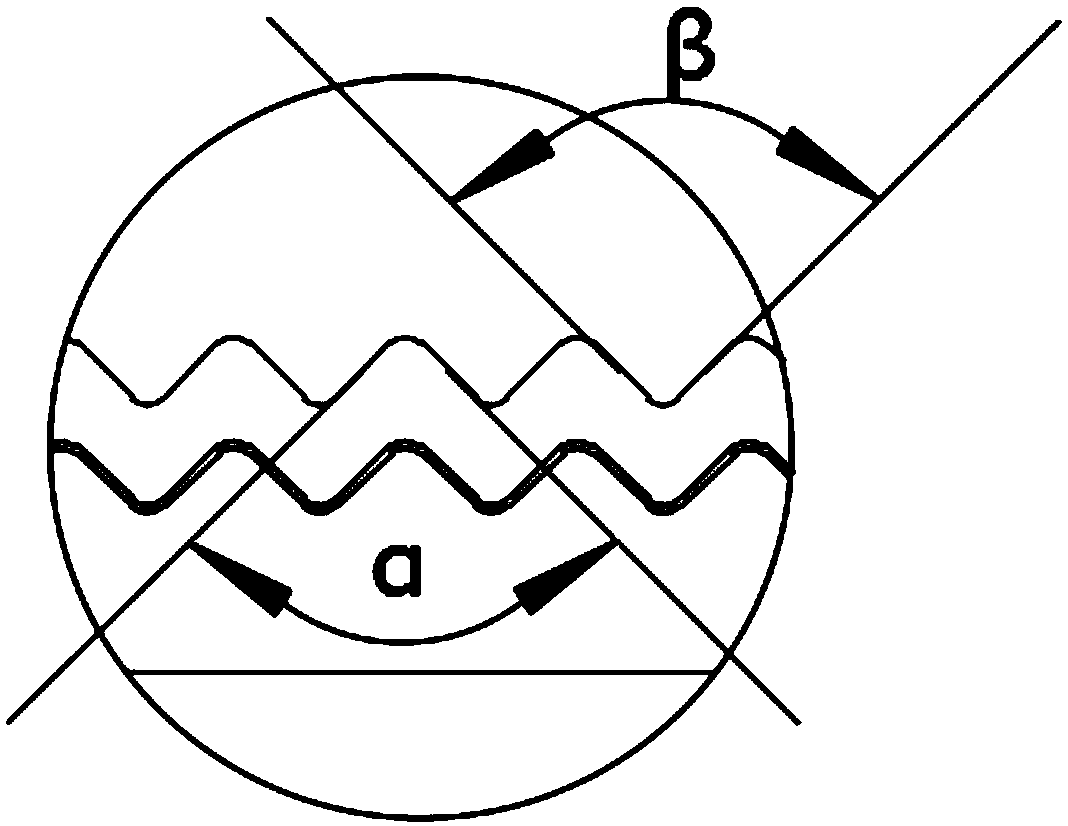

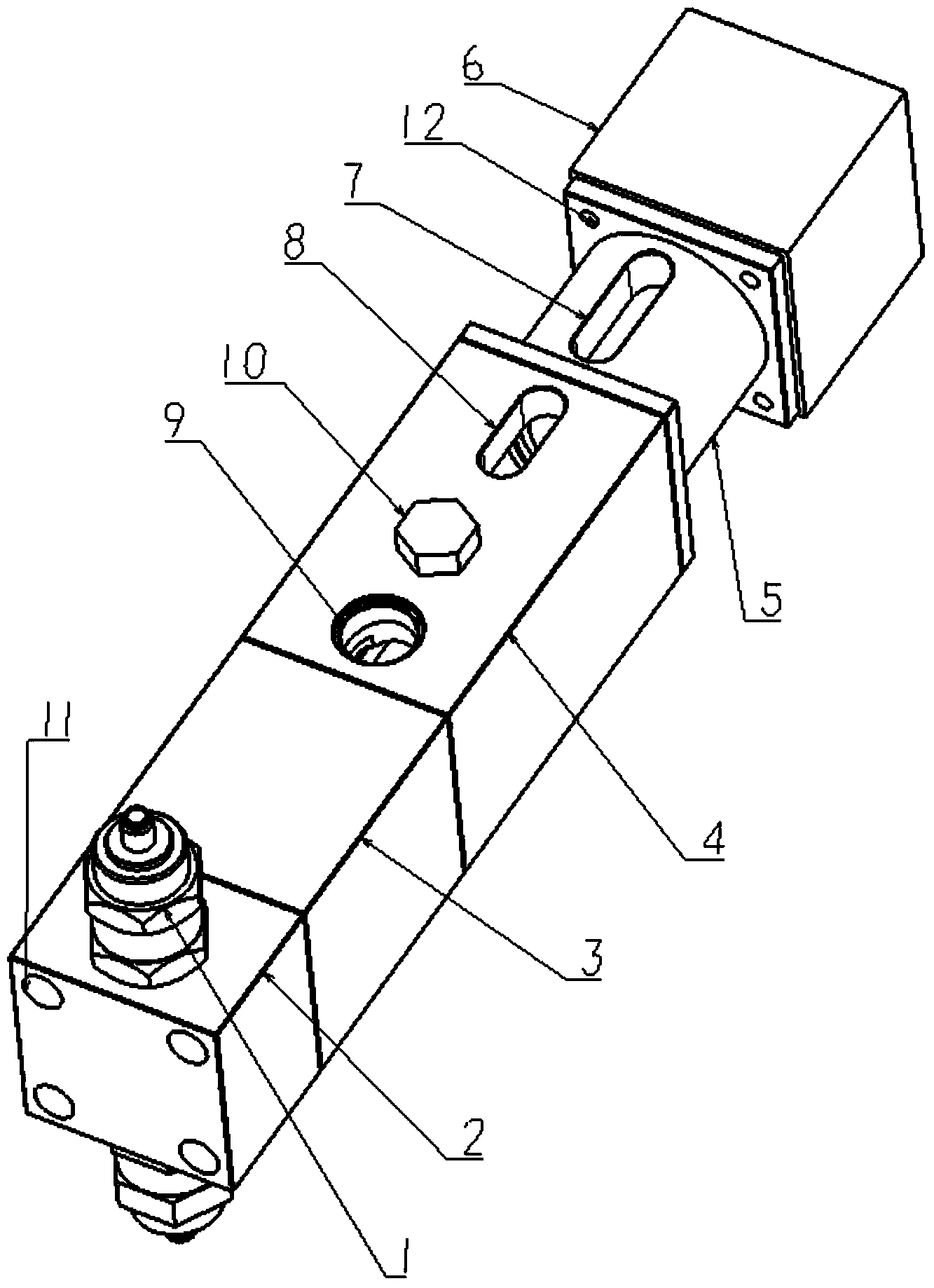

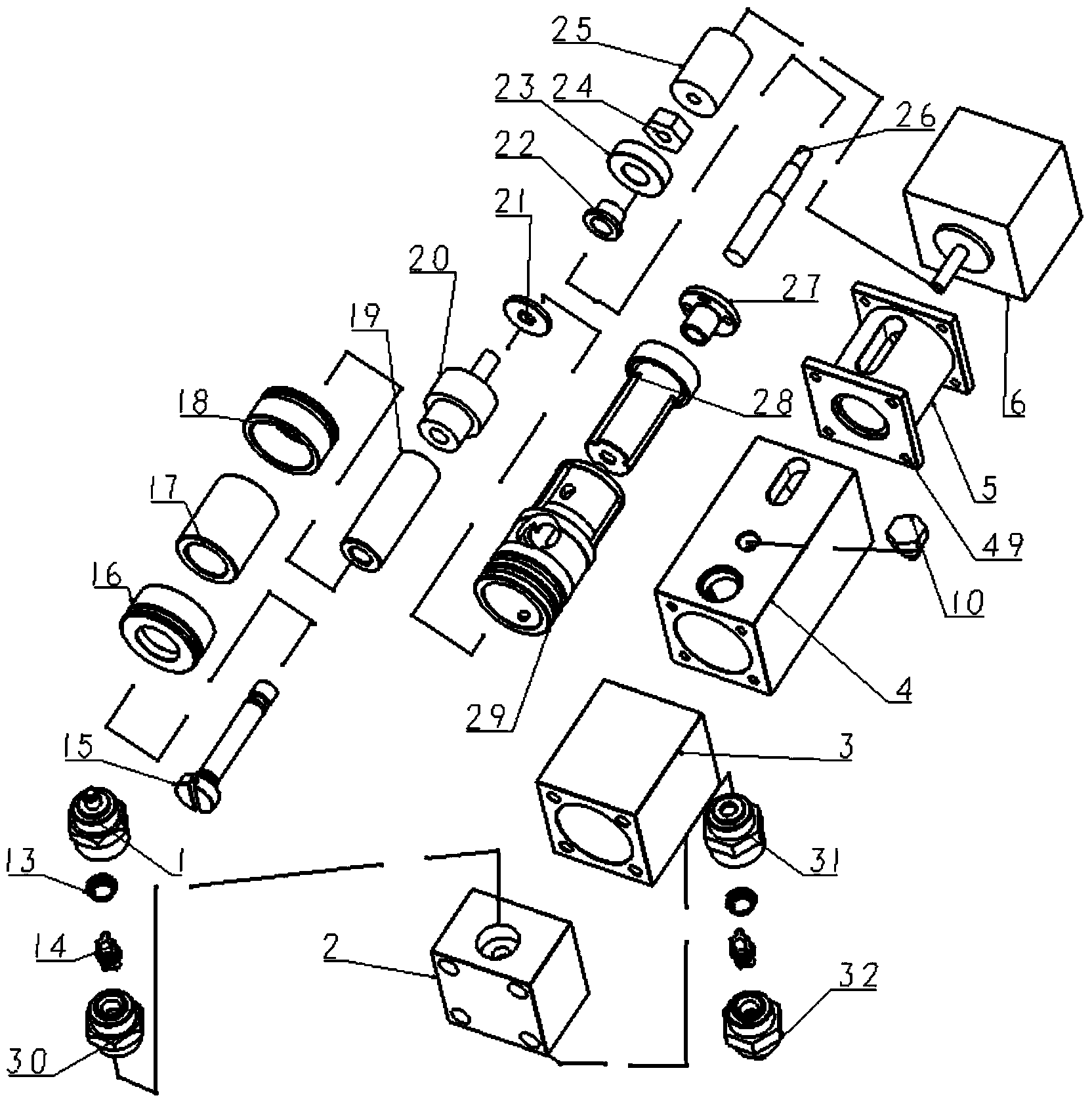

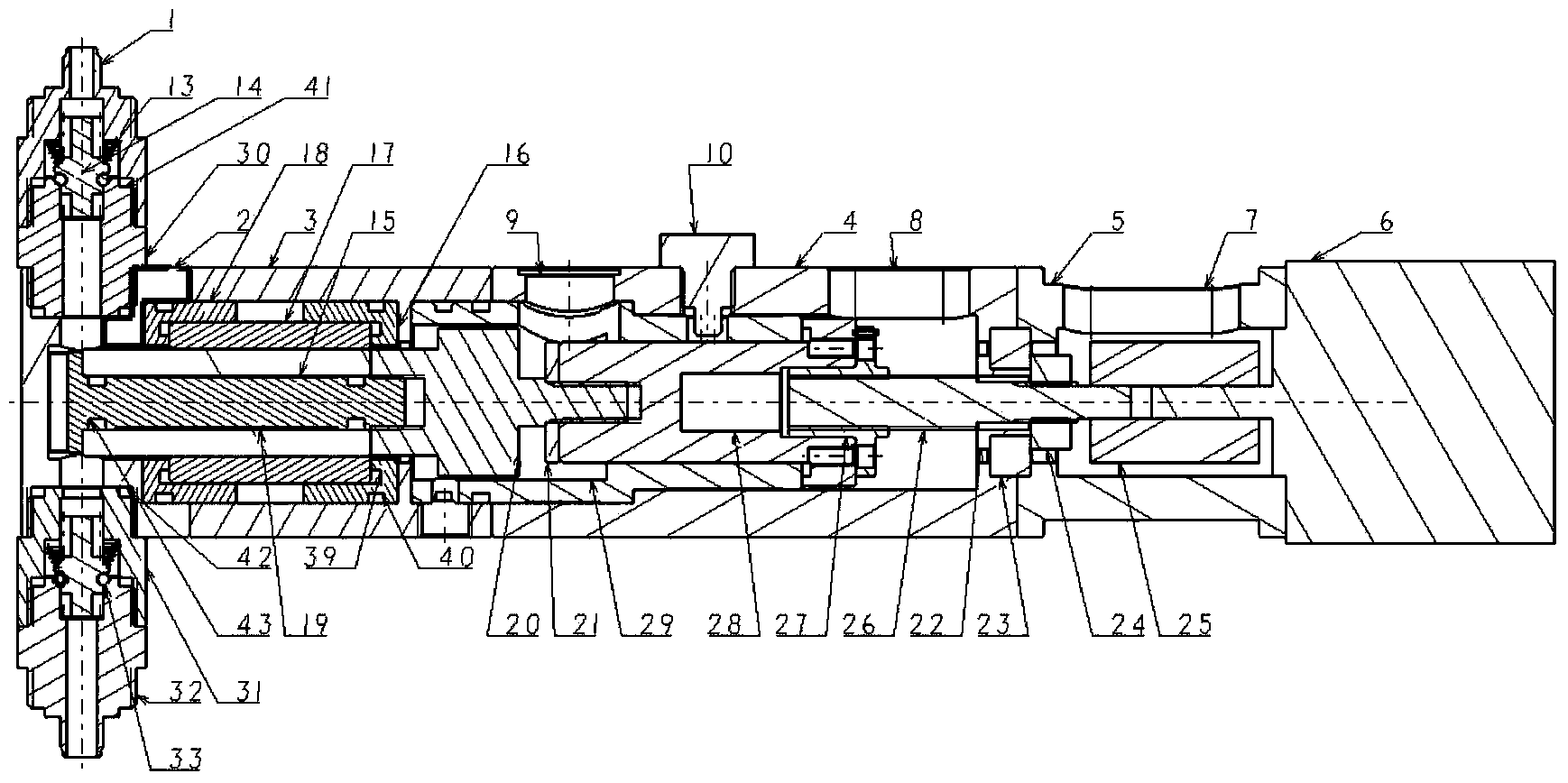

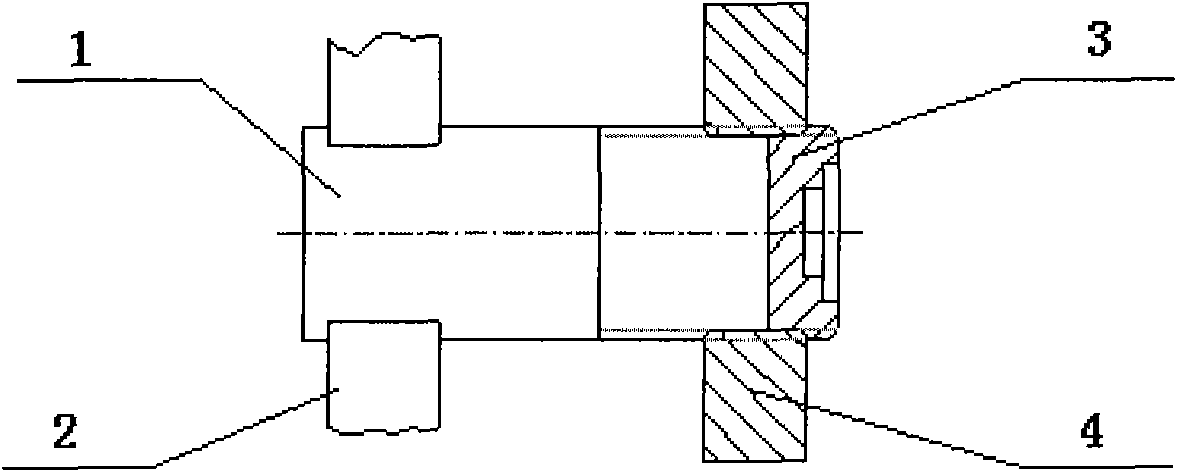

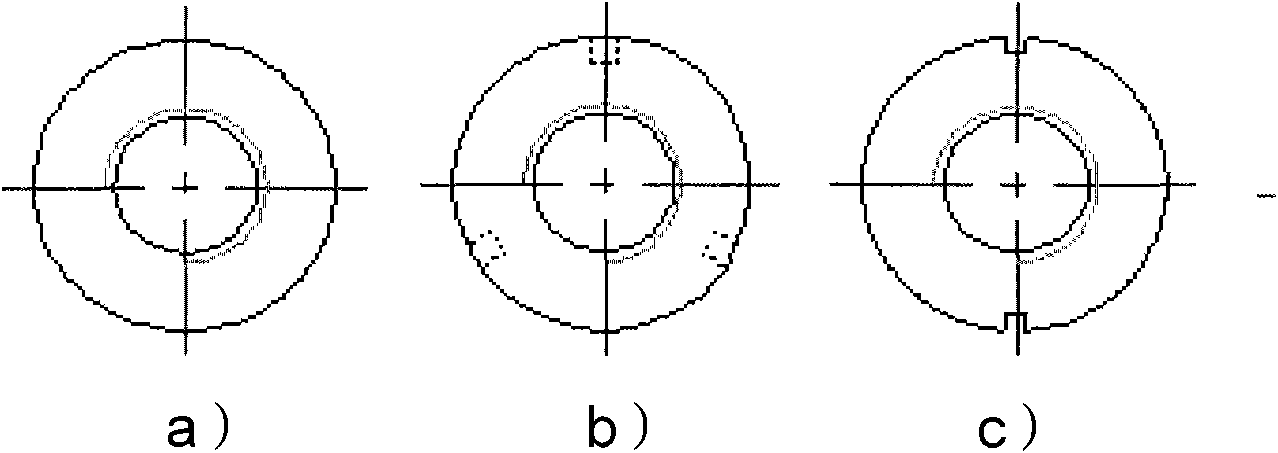

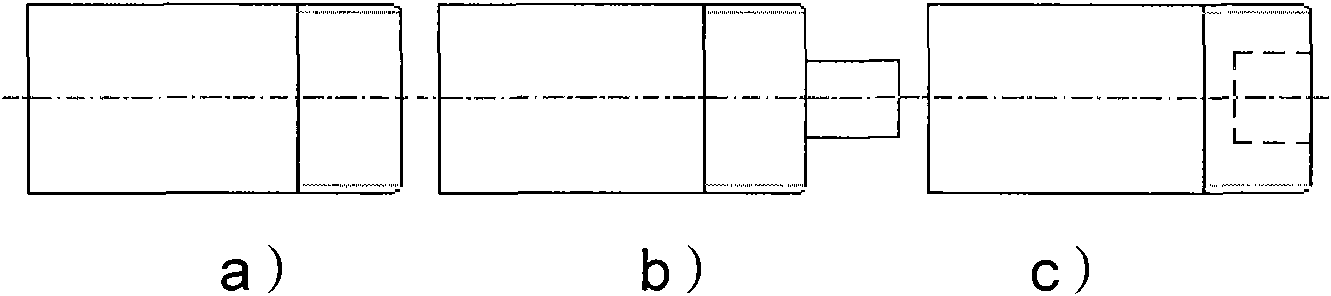

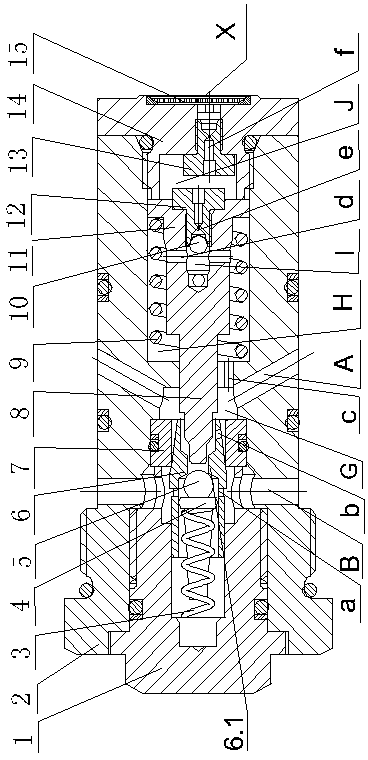

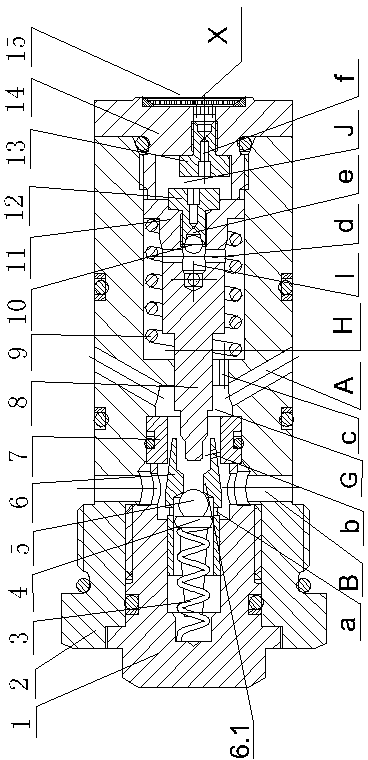

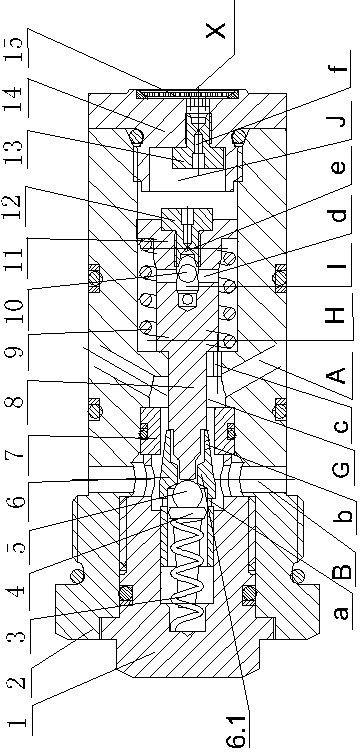

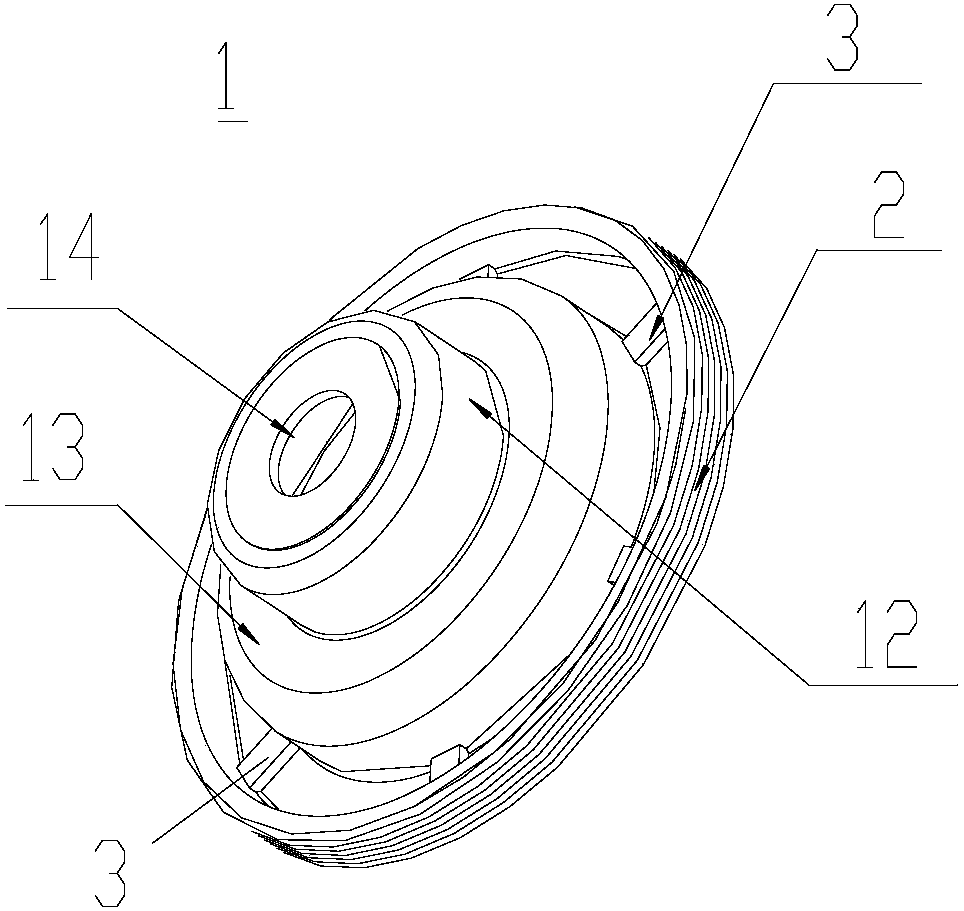

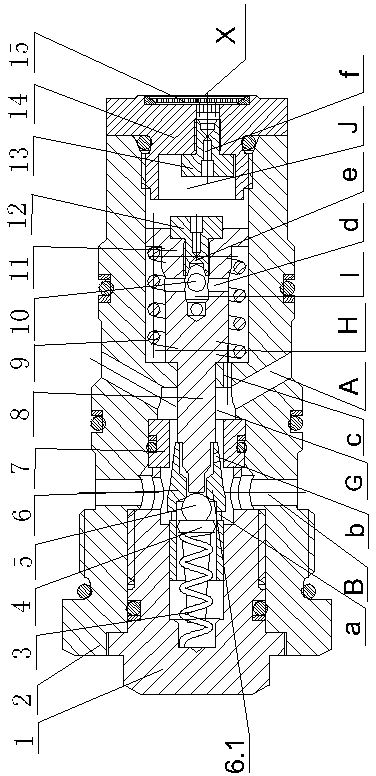

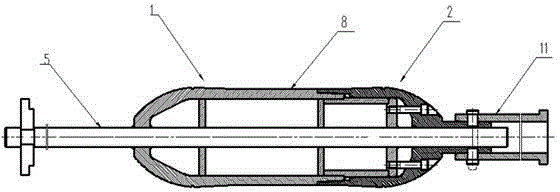

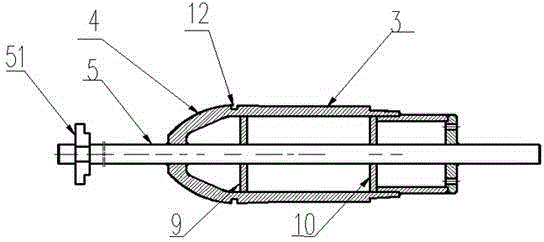

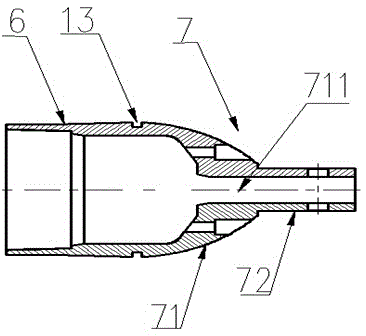

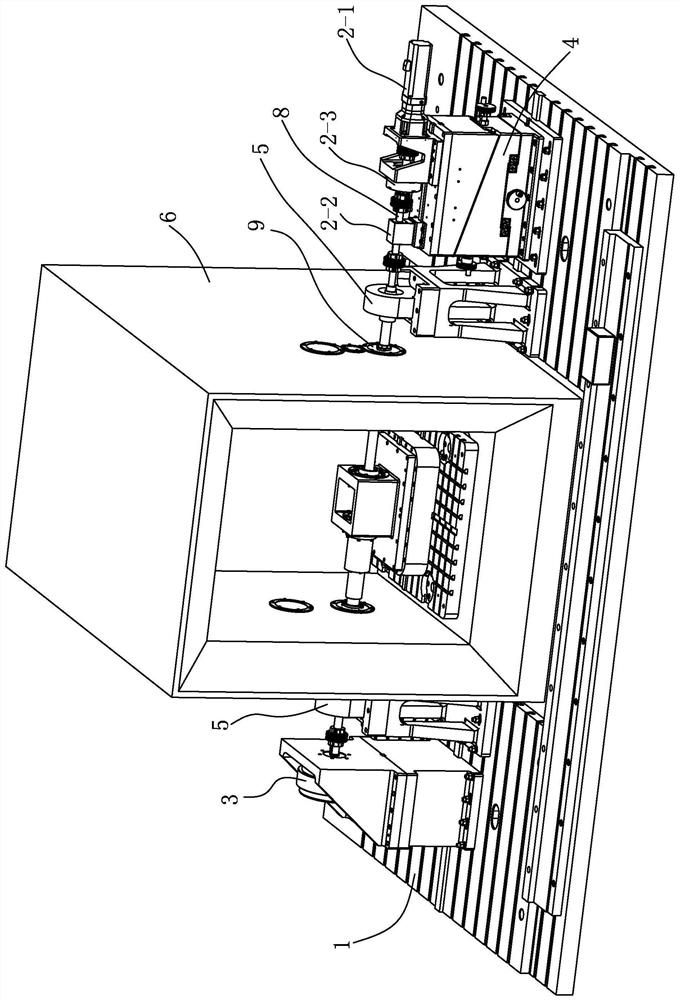

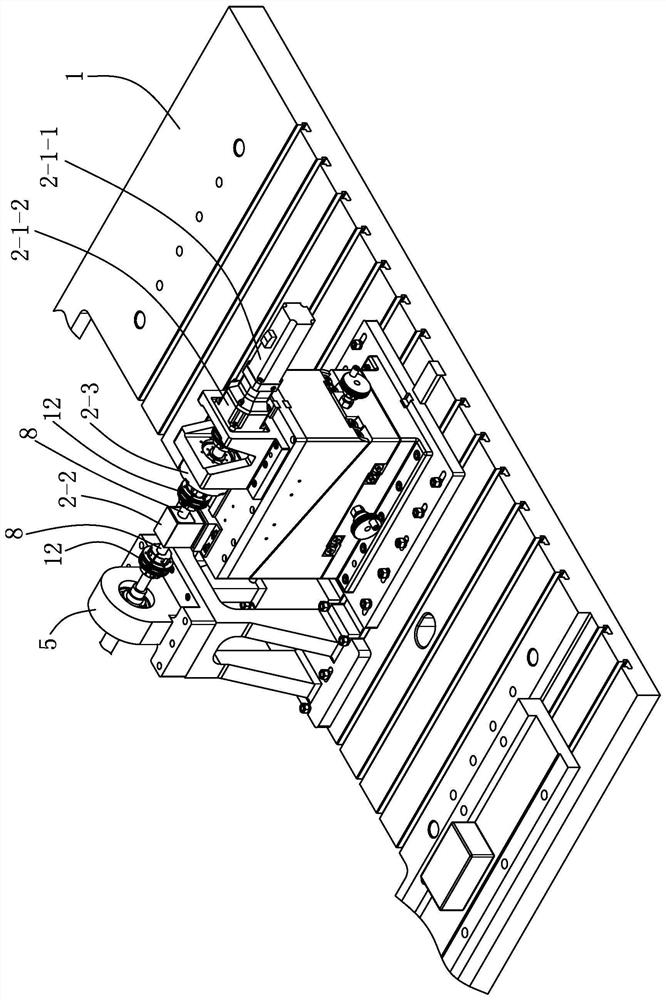

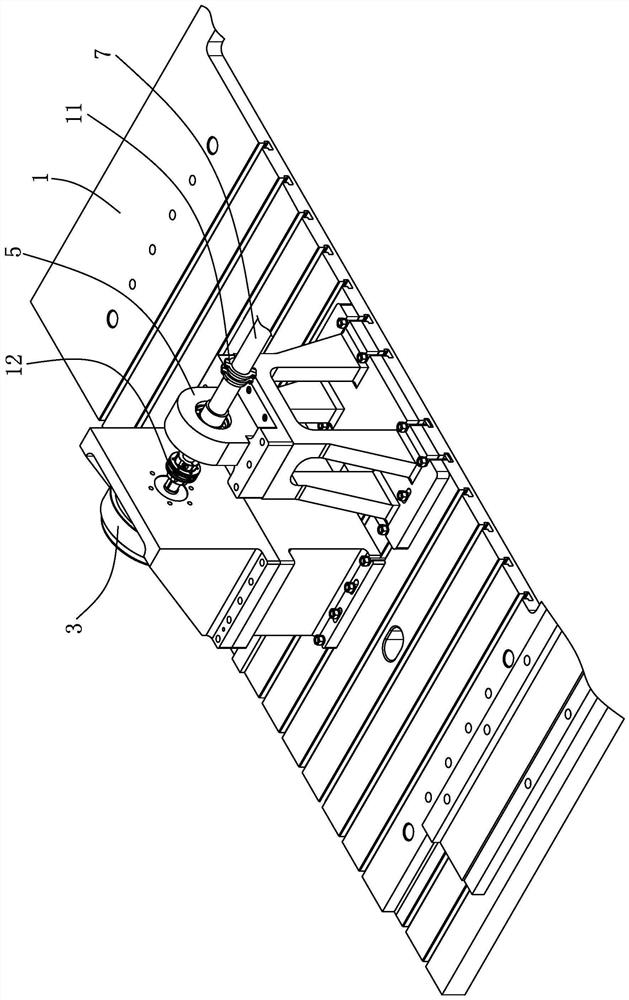

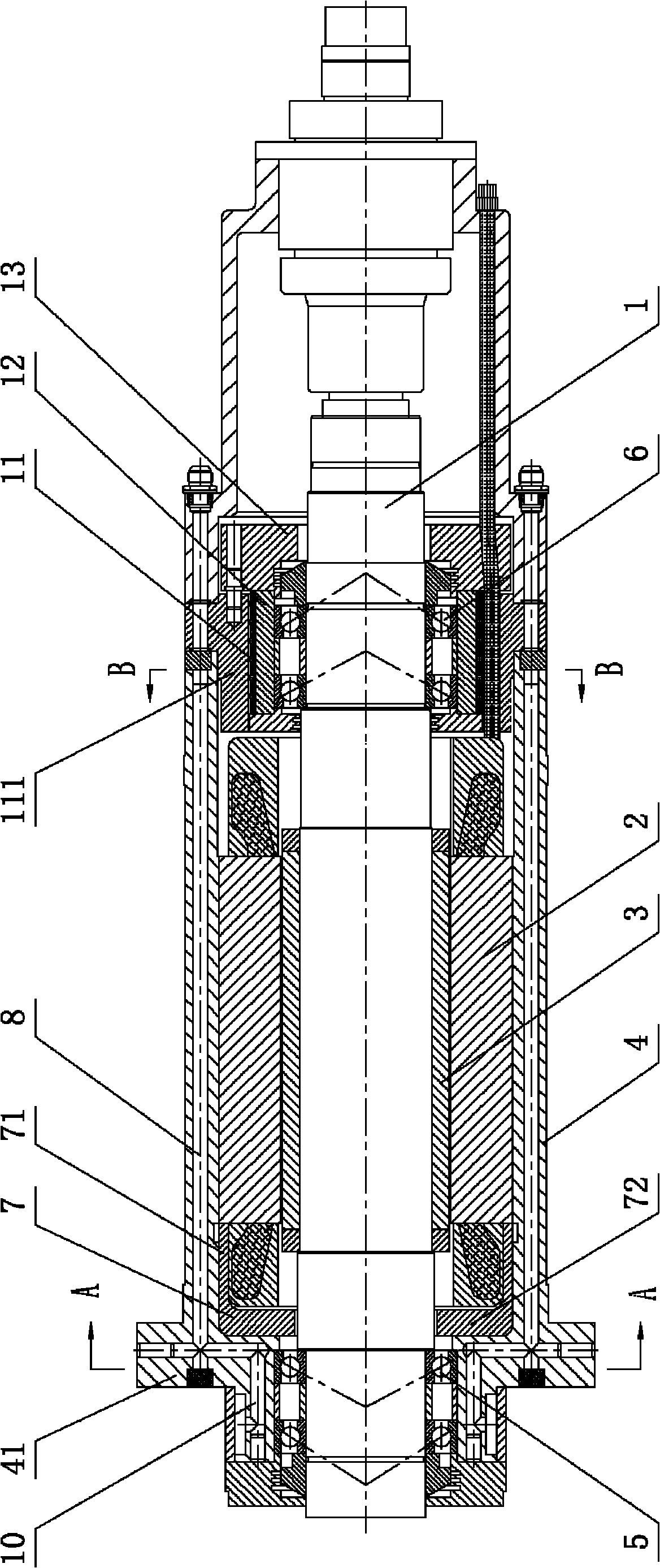

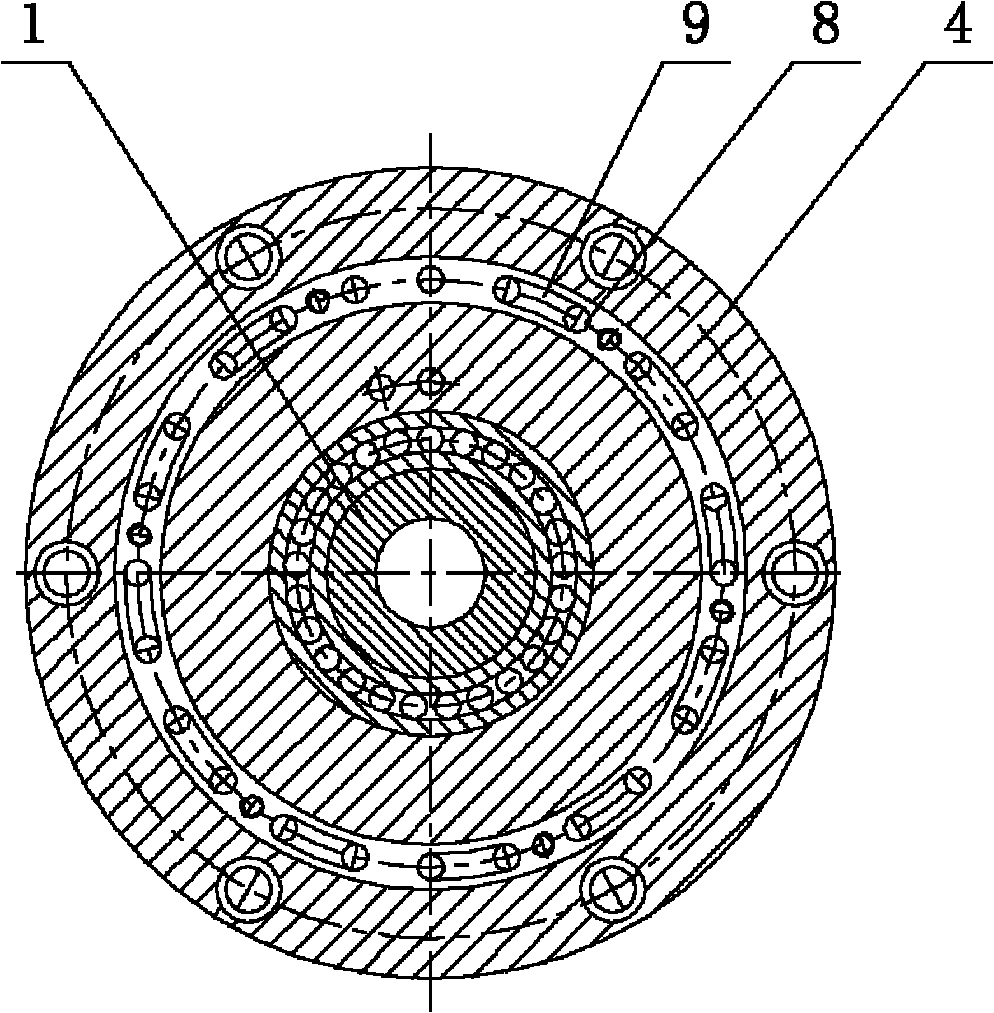

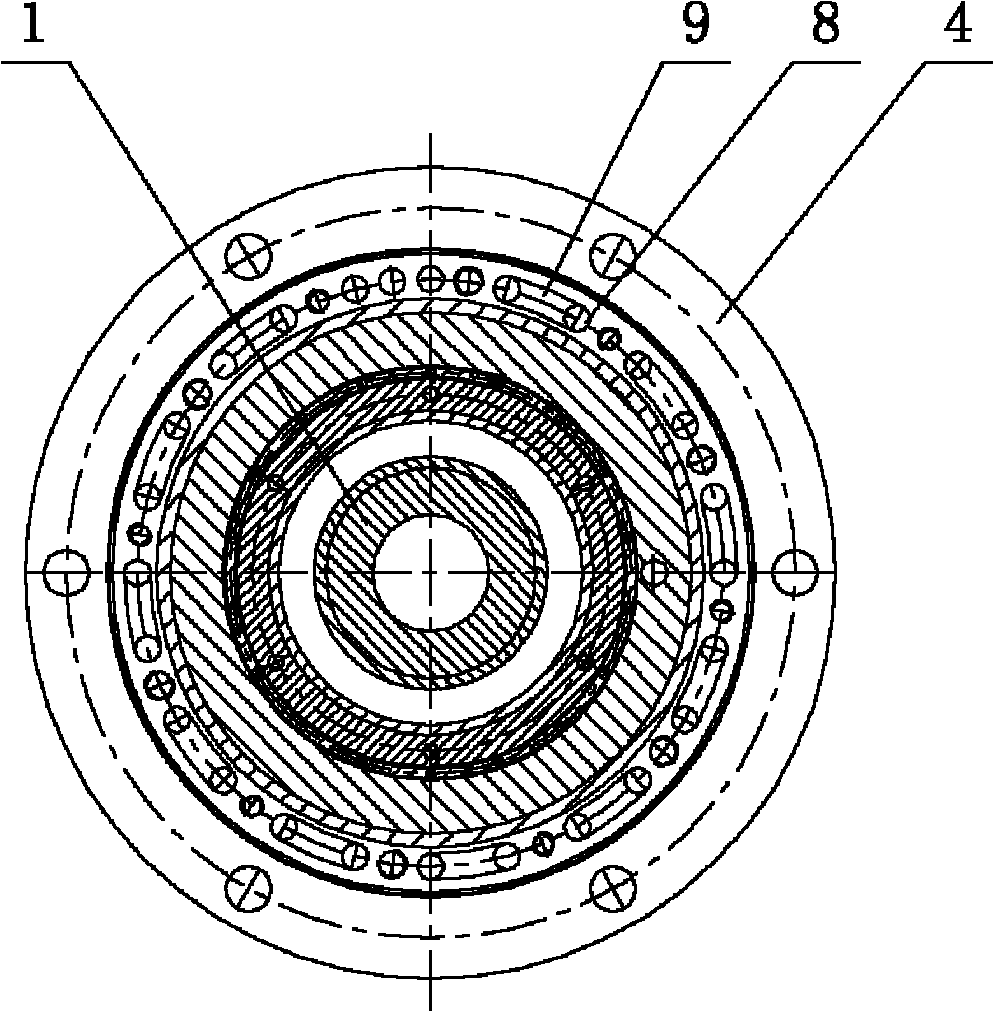

Manufacturing tool for [phi]25 mm tearing test piece

PendingCN112525650ASolve local dislocationAddress controllabilityPreparing sample for investigationUsing mechanical meansInsulation layerPilot hole

The invention discloses a manufacturing tool for a [phi]25 mm tearing test piece; an inner mold is placed in a shell, and an inner cavity of the shell is divided into a plurality of forming cavities through the inner mold. A top cover is placed on the upper end face of the shell, and the two ends of a positioning rod on the lower surface of the top cover are attached to the inner surfaces of the two sides of the shell so that the top cover can be positioned. Forming holes in the inner mold and the guide holes in the top cover are in one-to-one correspondence and are concentric. A pressure applying rod is arranged in each guide hole in the top cover. A vacuum bag sleeves the outer surface of the manufacturing tool. The method solves the problems of local dislocation and uncontrollable pressing pressure intensity of a test piece, is simple to operate, low in coaxiality of the tearing test piece and controllable in pressing pressure, improves the manufacturing quality of the tearing testpiece, has the bonding strength of 5.88 MPa and the ratio of the maximum and minimum difference values to the mean value of 0.08, and is stable in quality of the test piece; and the bonding performance of a shell and a heat insulation layer of a solid rocket engine can be expressed more accurately.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

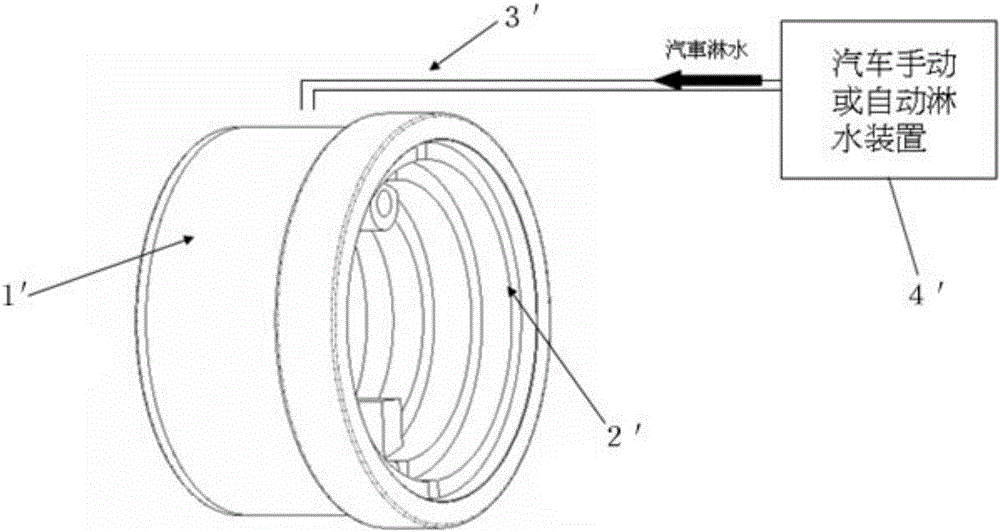

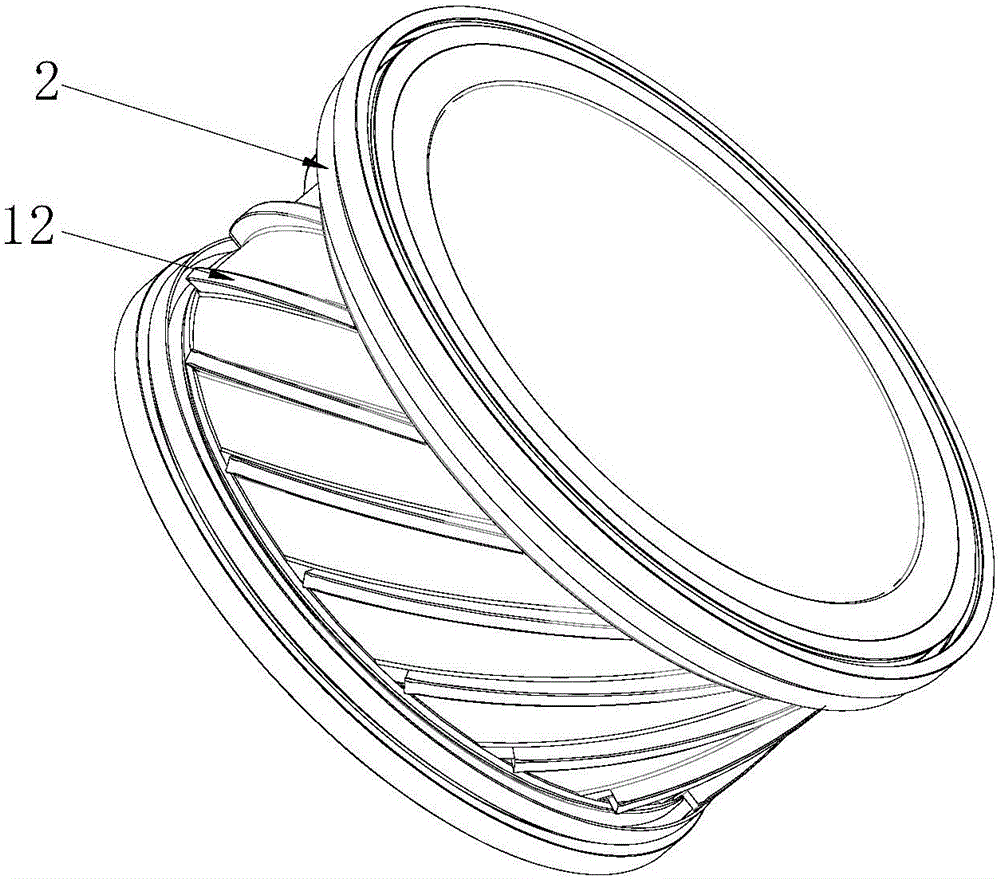

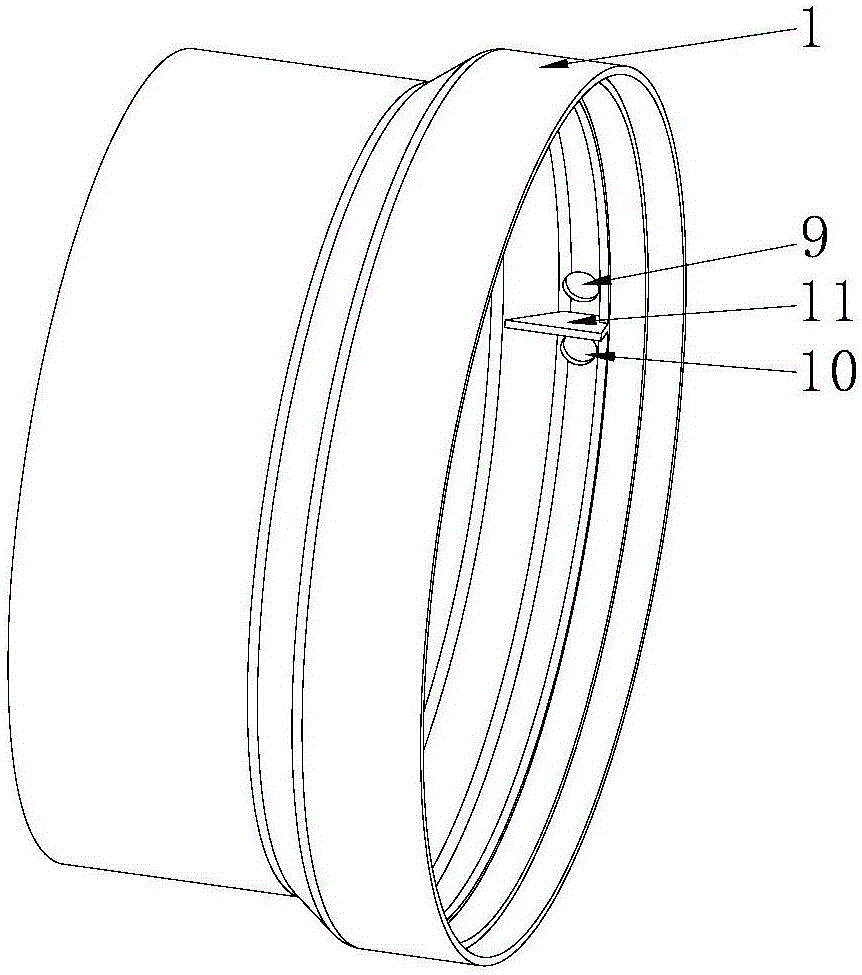

Water-cooled brake hub and waterway system thereof

Th invention discloses a water-cooled brake hub. The water-cooled brake hub comprises a water shade and a brake hub body; the water shade is installed outside the brake hub body, and a cooling liquid circulation space is formed between the water shade and the brake hub body; the water-cooled brake hub further comprises a first bearing component and a second bearing component which can rotate relative to the brake hub body, and the first bearing component and the second bearing component are located between the water shade and the brake hub body and connected with the water shade; a first sealing element and a second sealing element are arranged between the water shade and the brake hub body, the first sealing element and the second sealing element are located between the first bearing component and the second bearing component or outside the first bearing component and the second bearing component; the water shade is further provided with a water inlet and a water outlet which are located between the first sealing element and the second sealing element. The water-cooled brake hub is simple in structure, the bearings are adopted to fixedly connect the water shade with the brake hub, abrasion of a seal ring is greatly reduced, and the service life of the seal ring is prolonged. The invention further discloses a waterway system which is established by means of the water-cooled brake hub.

Owner:李涛 +1

Device on a drafting system of a draw frame for textile fibre slivers

InactiveUS7836558B2Simple and quick and reliableReliable force transmissionDrafting machinesBearing componentsTextile fiberRolling-element bearing

In a device on a drafting system for textile fiber slivers with weighting of the upper rolls of the drafting system which comprises roll pairs arranged one behind the other, the pairs having lower and upper rolls, the rotating journals at the ends of the upper roll are mounted by means of bearing elements and the bearing elements each have at least one rolling-element bearing having an immovable outer housing (outer ring) and an internal rotational body (inner ring). In order to provide a structurally simple way in which the bearing housings can be mounted on or removed from the presser roll in a simple, quick and reliable manner, the bearing elements are in the form of rolling-element bearings and there is a coupling between the journal and the rotational body.

Owner:TRUETZSCHLER GMBH & CO KG

Tool holder for piping end part machining

ActiveCN107159913AReduce runoutReduced round runoutTurning machine accessoriesPositioning apparatusEngineeringMachining

The invention discloses a fixture for piping end port forming. The fixture comprises a tool bit slide seat, wherein a hobbing cutter support seat is connected in the tool bit slide seat in a manner of coaxial slide fit, a rotating cutter assembly is arranged on the end part of the hobbing cutter support seat, and mutually-matched wedge surfaces are formed on the rotating cutter assembly and the tool bit slide seat; a slide sleeve sleeves outside the tool bit slide seat in a manner of coaxial slide; a waist-shaped guide hole formed in the axial direction of the tool bit slide seat is formed in the sidewall of the tool bit slide seat; the hobbing cutter support seat and the slide sleeve realize mutual connection through a pin shaft penetrating through the waist-shaped guide hole; and a location assembly used for ensuring the coaxiality of piping machining is arranged on the end part of the slide sleeve. The tool holder disclosed by the invention is convenient to use, high in machining accuracy, stable in control on the coaxiality of pipelines during machining, and higher in location accuracy, more convenient and faster relative to traditional machinery.

Owner:山东中宝金属材料有限公司

Rotor structure and engine

ActiveCN108487993AExtended service lifeReduce processing costsPump componentsBlade accessoriesAir compressorTurbine

The invention discloses a rotor structure and an engine, and belongs to the technical field of aero-engine equipment. The rotor structure comprises an air compressor, a turbine, a transmission torsionshaft sleeve and a locking pull rod. One end of the transmission torsion shaft sleeve is in transmission connection with the air compressor through a first transmission connection part, and the otherend of the transmission torsion shaft sleeve is in transmission connection with the turbine through a second transmission connection part. The locking pull rod penetrates through the transmission torsion shaft sleeve. The two ends of the locking pull rod are connected with the air compressor and the turbine separately. The first transmission connection part and / or the second transmission connection part are flexible transmission connection parts. According to the rod structure and the engine, under the combined effect of the transmission torsion shaft sleeve, the locking pull rod and the flexible transmission connection parts, flexible connection and transmission of the turbine and the air compressor are achieved; and automatic adjustment can be achieved to a certain extent in the high-speed rotating process of the engine so that the transmission torsion shaft sleeve, the locking pull rod and the flexible transmission connection parts can rotate separately around self axes, and accordingly, the requirements for the coaxiality, assembly precision and machining of all components of a rotor are lowered.

Owner:SHENZHEN YIDONG AVIATION TECH CO LTD

Die for casting dry type transformer coil

InactiveCN102360921AShorten processing lengthGuaranteed CircumferenceCoils manufactureTransformerEngineering

The invention relates to a die for casting a dry type transformer coil. The die consists of a left semi-shell and a right semi-shell which are connected into a whole through bolts, wherein sealing grooves are formed on contact surfaces of the left semi-shell and the right semi-shell; and a high-temperature-resistant silicon rubber strip is placed in each sealing groove for sealing. The invention is characterized in that: the die is equally divided into an upper part and a lower part which are connected into a whole through the bolts; corresponding sealing grooves are formed on the contact surfaces of the upper part and the lower part; the high-temperature-resistant silicon rubber strip is placed in each sealing groove for sealing; and a positioning connecting part is arranged on the outer side of each sealing groove. The circular degree, coaxiality and smoothness of the die can be guaranteed so that the range of equipment for processing the die is expanded, processing difficulty is reduced, processing period is shortened, processing cost is reduced and quality of the cast coil is guaranteed.

Owner:QINGDAO TRANSFORMER GRP CO LTD

Electric main shaft with mouse cage type motor stator cooling structure

InactiveCN101895170BEasy to disassembleQuick and easy disassemblyMechanical energy handlingCooling/ventillation arrangementCooling effectCooling channel

The invention discloses an electric main shaft with a mouse cage type motor stator cooling structure, comprising a main shaft assembly, a motor stator, a motor rotor, a box body, a front bearing assembly and a rear bearing assembly, wherein the motor stator is sleeved in the box body; the motor rotor is sleeved on the main shaft assembly; the main shaft assembly is arranged in the motor stator and supported on the box body through the front bearing assembly and the rear bearing assembly; the box body is provided with a mouse cage type cooling passage used for cooling the motor stator; the front end of the box body is provided with a front bearing seat used for installing the front bearing assembly; the front bearing seat and the box body are cast into an integer; one end of the motor stator, which is close to the front bearing seat, is sleeved with a stator side ring, and the motor stator can act on the stator side ring from an inner hole of the front bearing seat through a cylinder tooling and be pushed out of the rear end of the box body. The electric main shaft with the mouse cage type motor stator cooling structure has compact structure, convenient disassembly and assembly andgood cooling effect.

Owner:HUNAN UNIV

Compression-resistant type automobile hinge pin shaft and manufacturing technology thereof

ActiveCN108857295AElasticExtended service lifeBoltsPivotal connectionsManufacturing technologyEngineering

The invention discloses a compression-resistant type automobile hinge pin shaft and manufacturing technology thereof. The compression-resistant type automobile hinge pin shaft comprises a hollow hingepin, wherein an opening part is formed in the side wall of the hinge pin and along the axial direction of the hinge pin; the opening part is provided with a first side wall and a second side wall opposite to each other; a first tooth slot part is formed on the first side wall; a second tooth slot part is formed on the second side wall; the first tooth slot part and the second tooth slot part aremeshed with each other; the first tooth slot part and the second tooth slot part comprise a plurality of continuous tooth slots respectively; the opening width of the tooth crest of each tooth slot is1.4-1.6mm, the tooth depth is 0.6-0.7mm, and the tooth bottom of each tooth slot is of an arc shape; the junction surface of the tooth crests of adjacent tooth slots is of an arc shape. The hinge shaft provided by the invention has good overall compression resistance; with certain elasticity, the hinge shaft can counteract the impact force generated by a hinge part, thus the service life of the hinge pin is prolonged; moreover, the processing process is simple, the molding speed is high, and the production efficiency is improved.

Owner:昆山龙成鑫金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Manufacturing tool for [phi]25 mm tearing test piece Manufacturing tool for [phi]25 mm tearing test piece](https://images-eureka.patsnap.com/patent_img/27e5cc9f-e305-487b-b807-05ed4973b026/HDA0002881292390000011.png)

![Manufacturing tool for [phi]25 mm tearing test piece Manufacturing tool for [phi]25 mm tearing test piece](https://images-eureka.patsnap.com/patent_img/27e5cc9f-e305-487b-b807-05ed4973b026/HDA0002881292390000012.png)

![Manufacturing tool for [phi]25 mm tearing test piece Manufacturing tool for [phi]25 mm tearing test piece](https://images-eureka.patsnap.com/patent_img/27e5cc9f-e305-487b-b807-05ed4973b026/HDA0002881292390000013.png)