Electric pump and method for producing same

An electric pump and motor technology, applied in the direction of pumps, rotary piston type/swing piston type pump parts, pump components, etc., to achieve the effect of improving filling and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the present invention will be described in detail using the drawings.

[0031] 1. Structure and action of electric pump

[0032] [the whole frame]

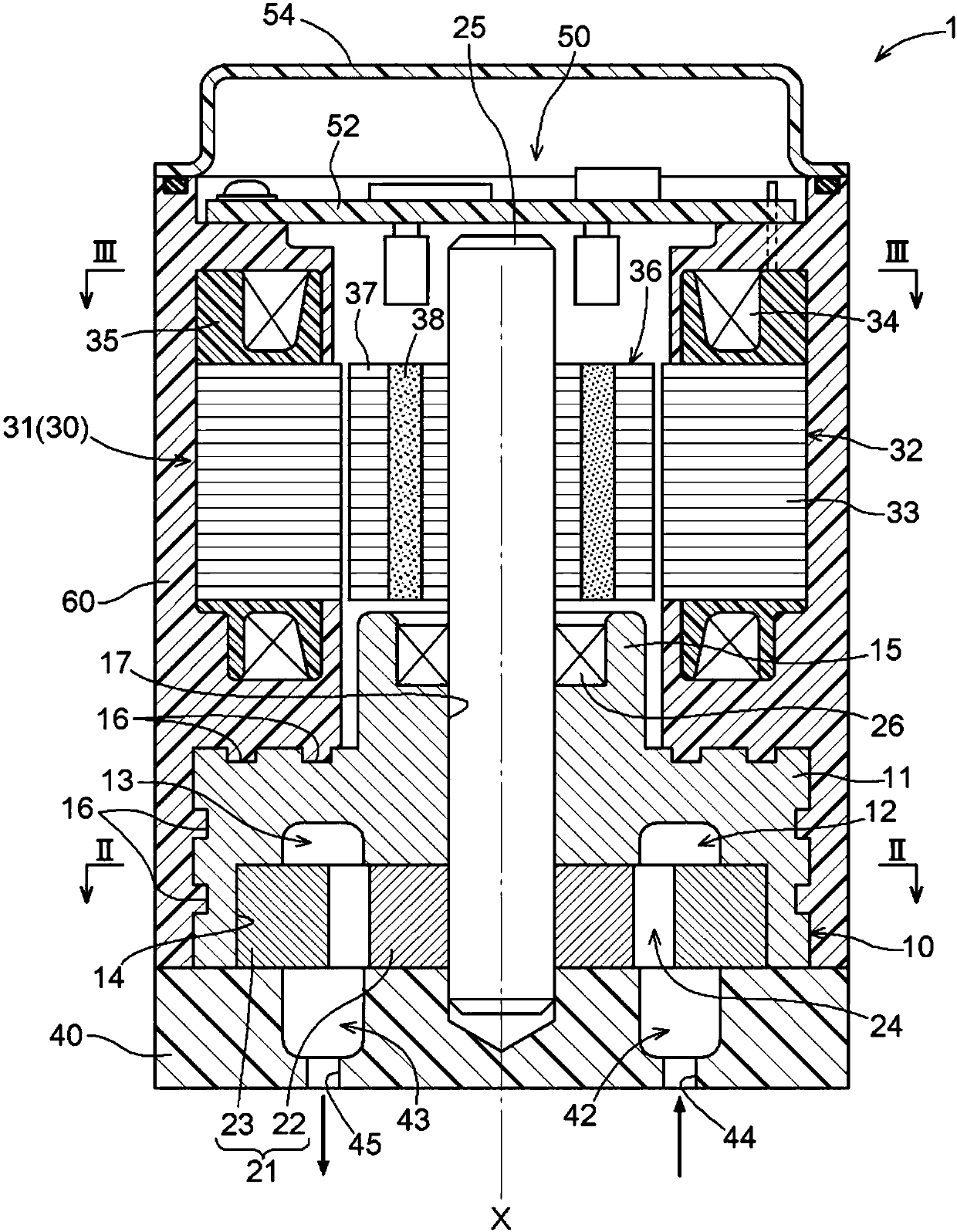

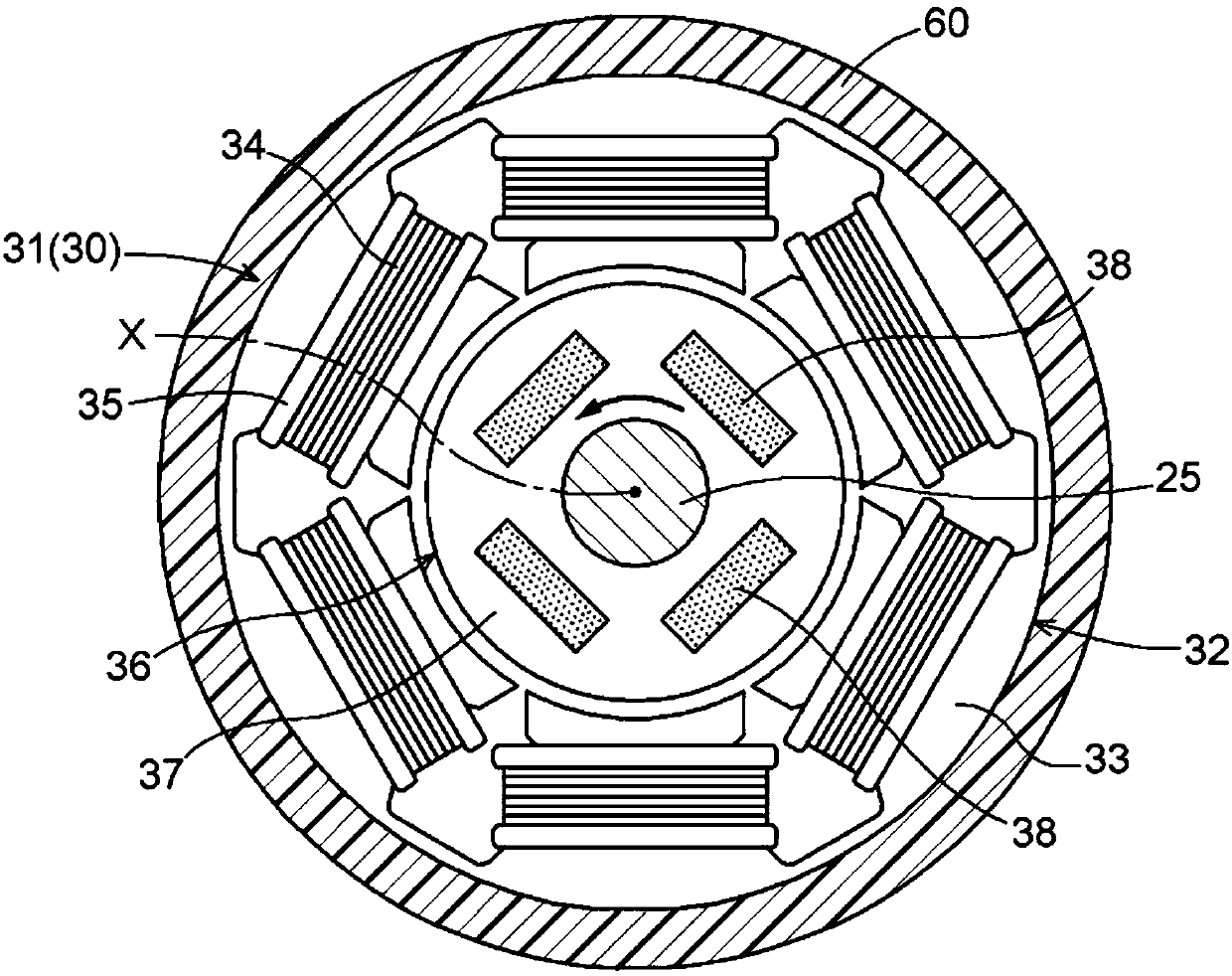

[0033] Such as Figure 1 ~ Figure 3 As shown, the electric pump 1 is composed of a motor part 30, a pump part 10, a control part 50, and a resin part 60. 30 across to the pump parts 10 and formed on their outer peripheries. Although the electric pump 1 is used to pressure-pump lubricating oil of an engine of a vehicle as working oil to a hydraulic machine, it can also be used in a hydraulic device other than a vehicle. In addition, liquid chemicals or chemical substances may be used as pressure pumping objects instead of working oil. It should be noted that working oil is an example of working fluid.

[0034] [Structure of pump part]

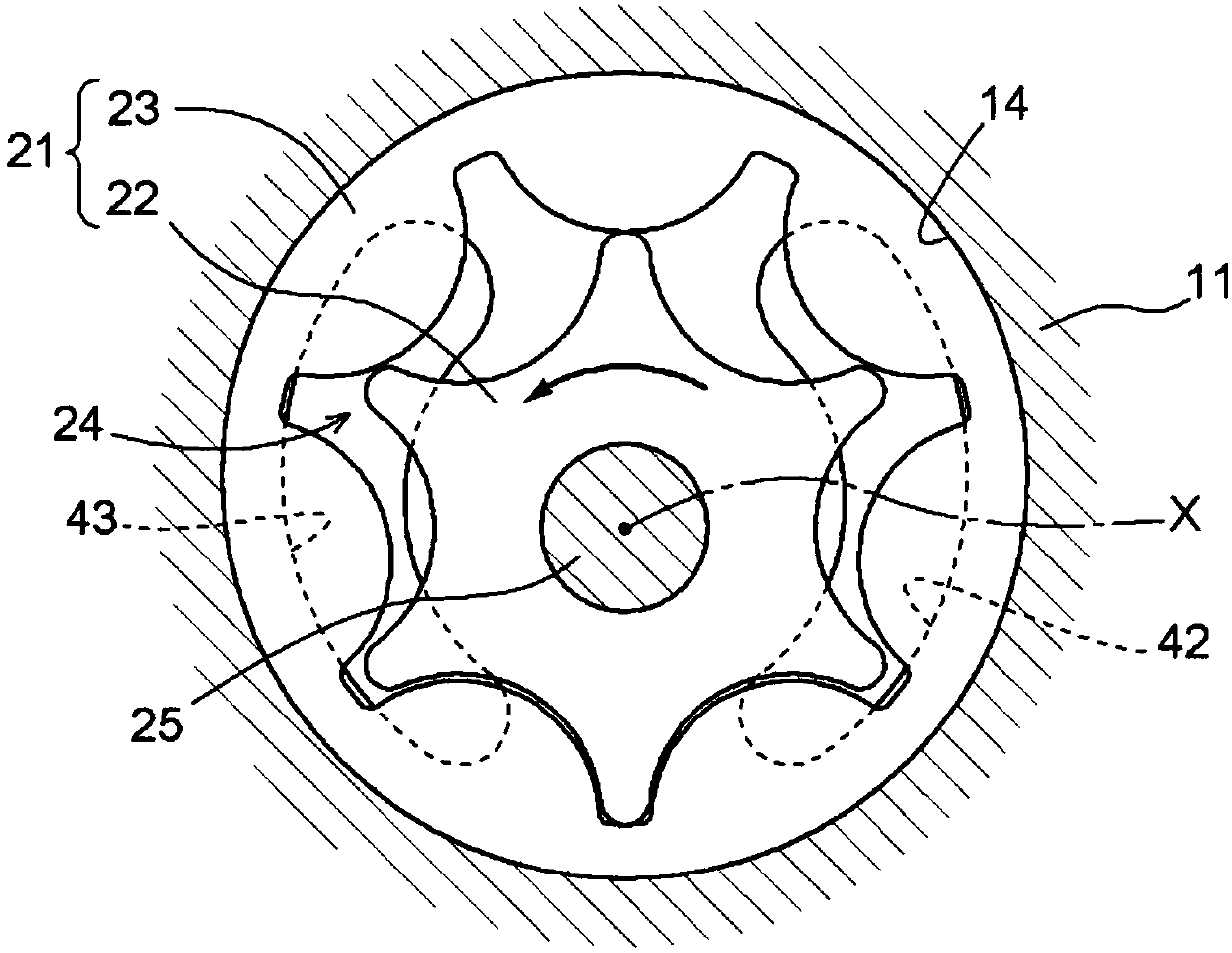

[0035] Such as figure 1 As shown, the pump unit 10 includes a pump casing 11 , an internal meshing gear pump 21 and a pump cover 40 . It should be noted th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com