Patents

Literature

38results about How to "Reliable force transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

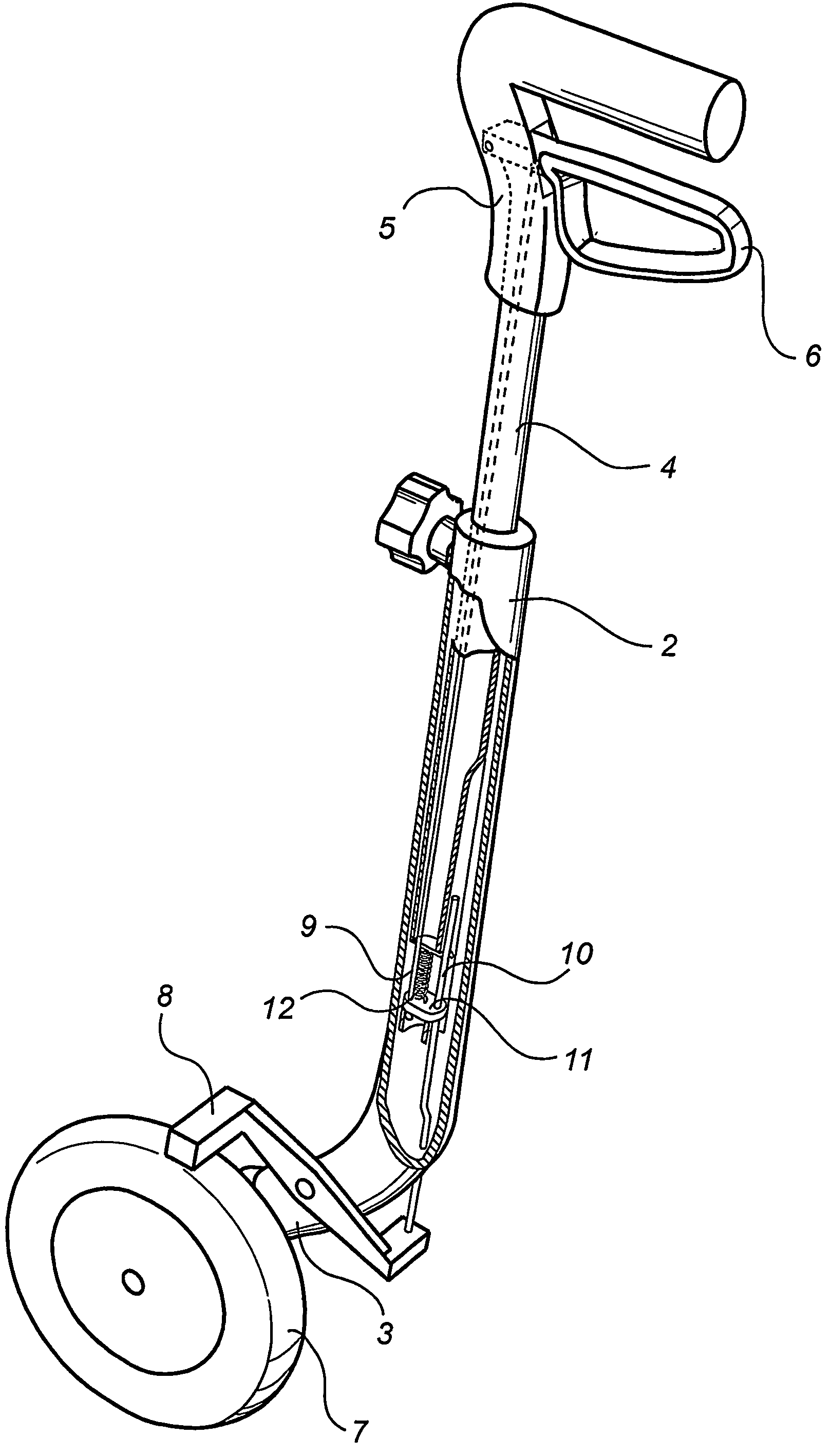

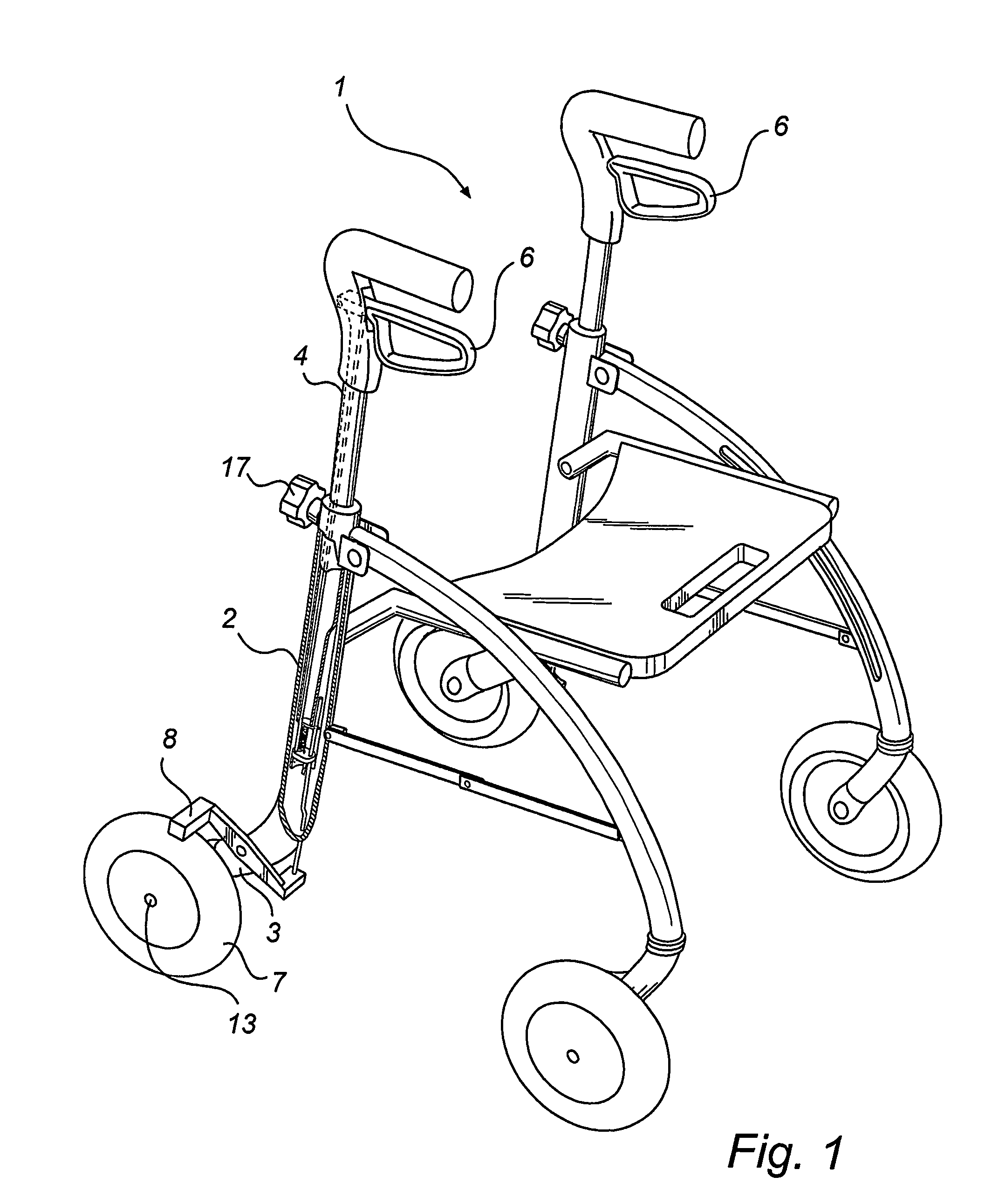

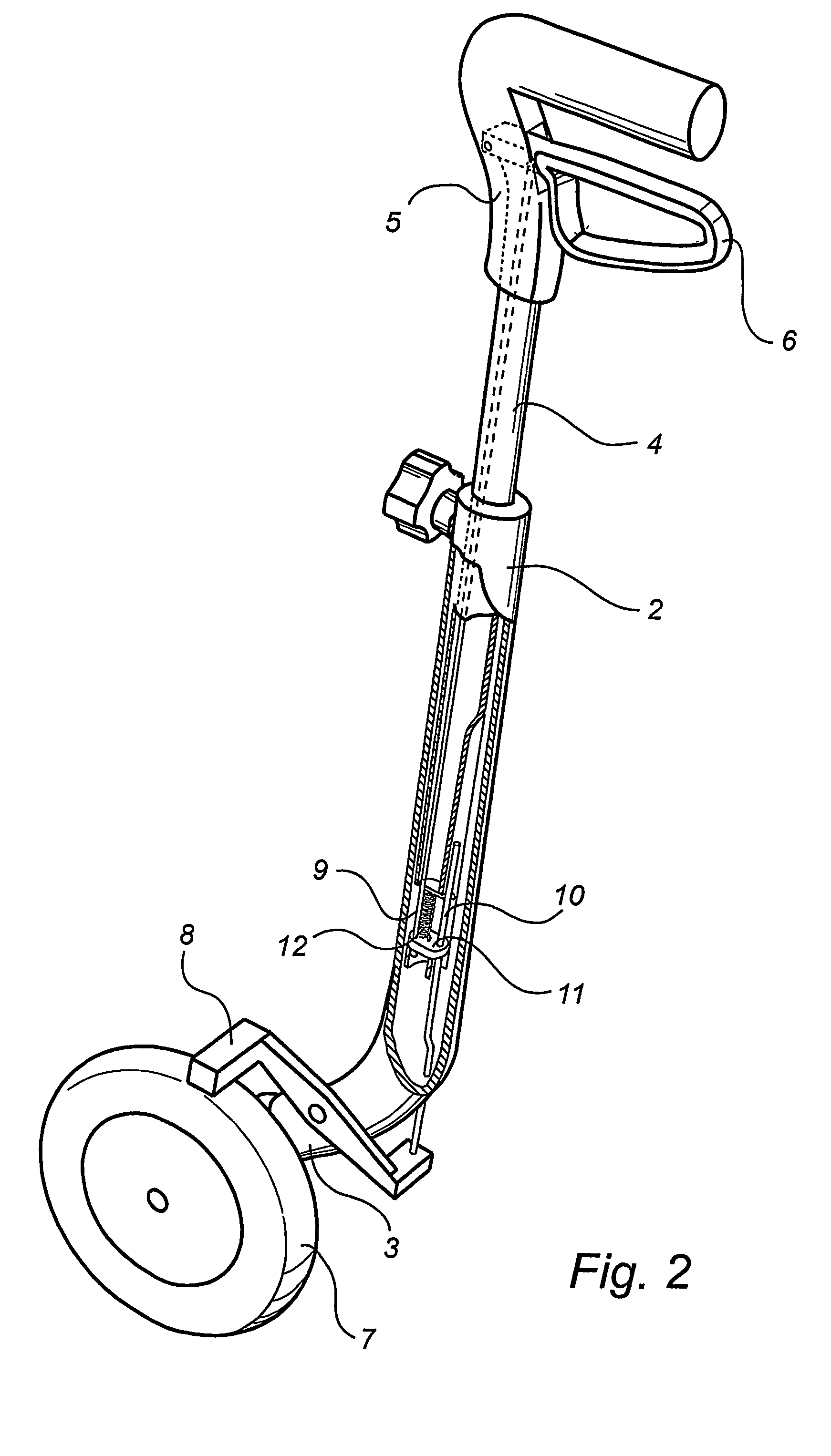

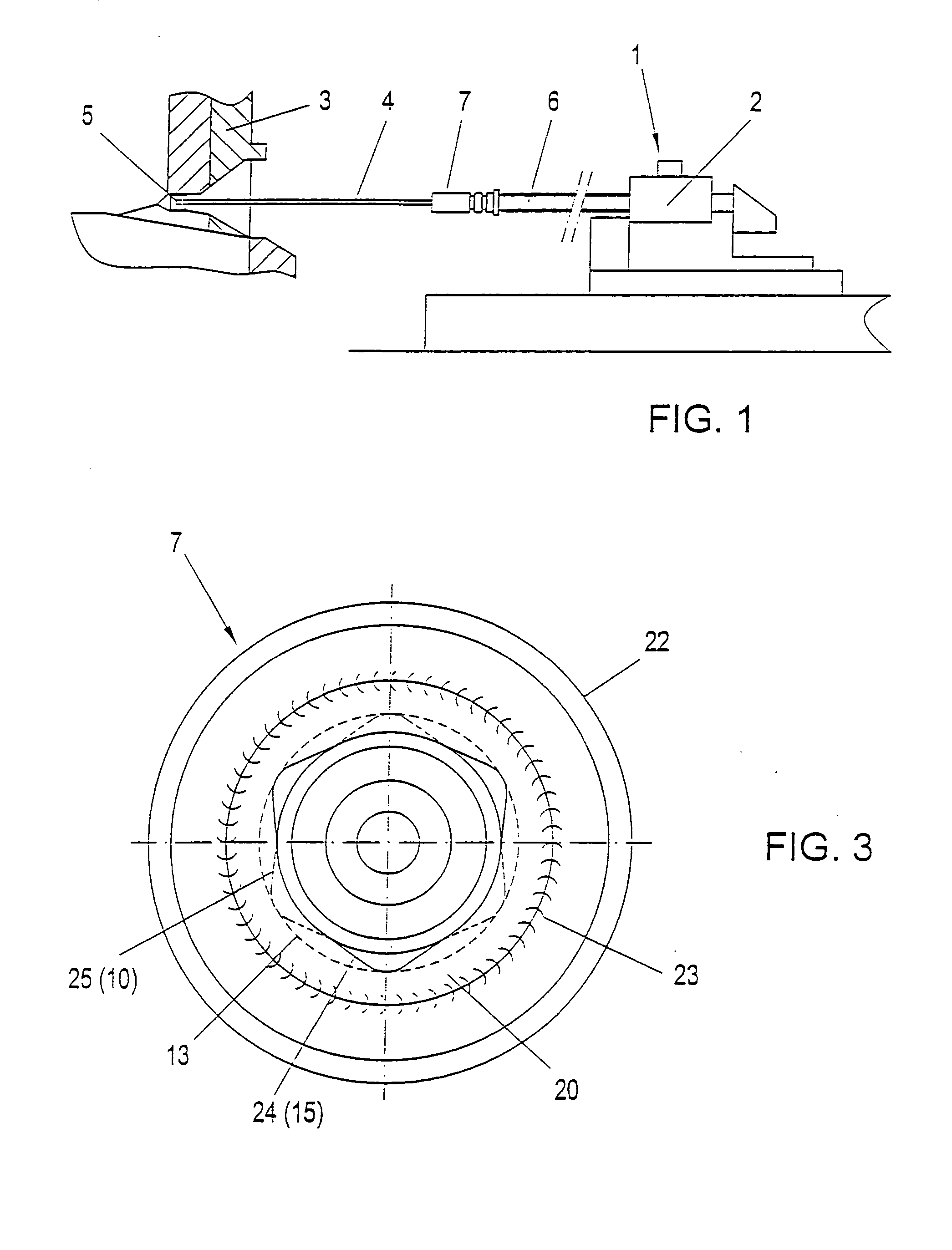

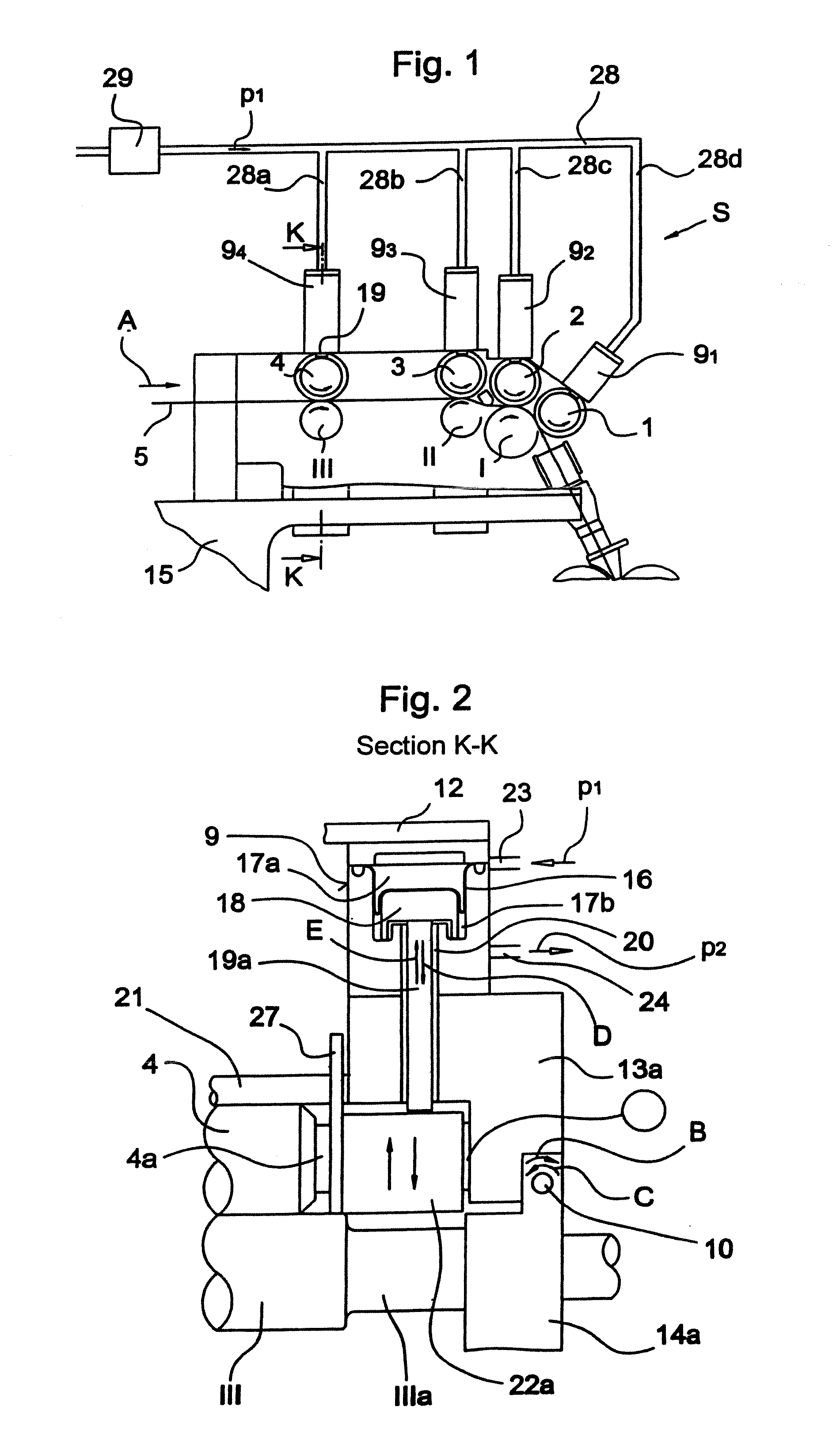

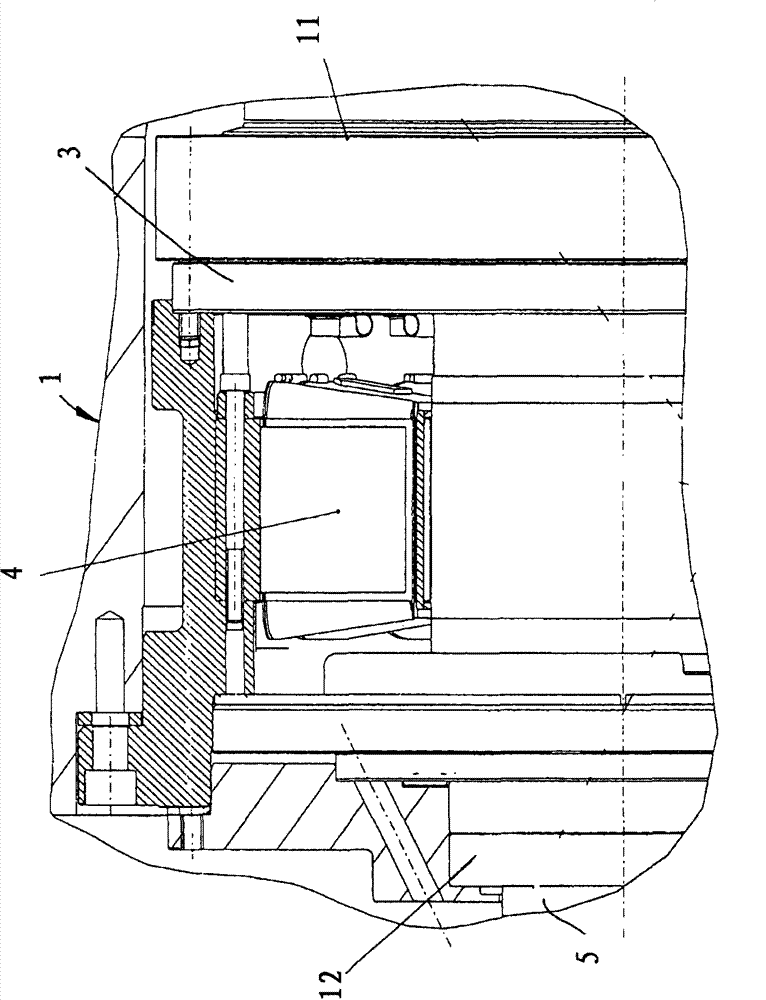

Walker device

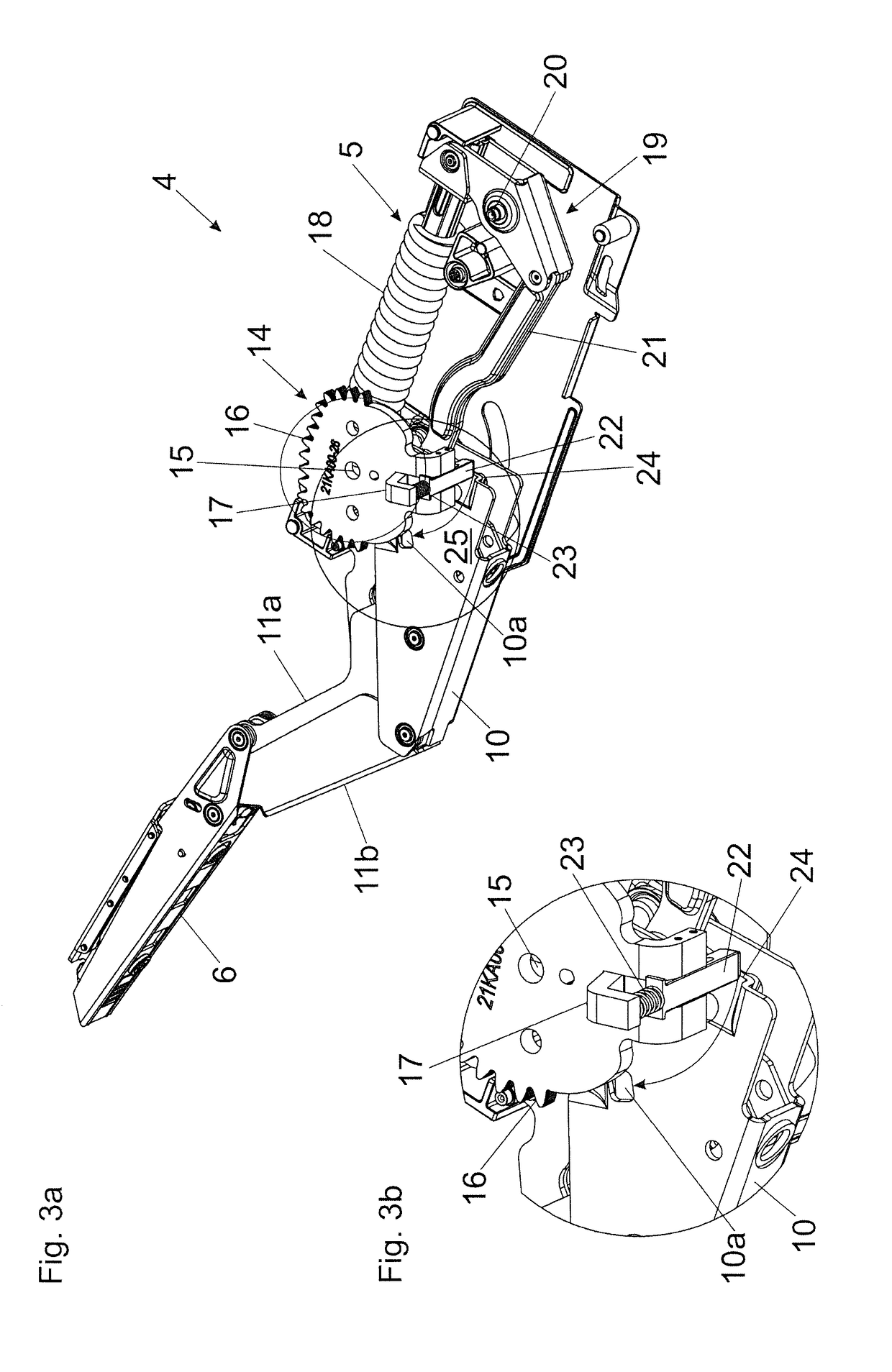

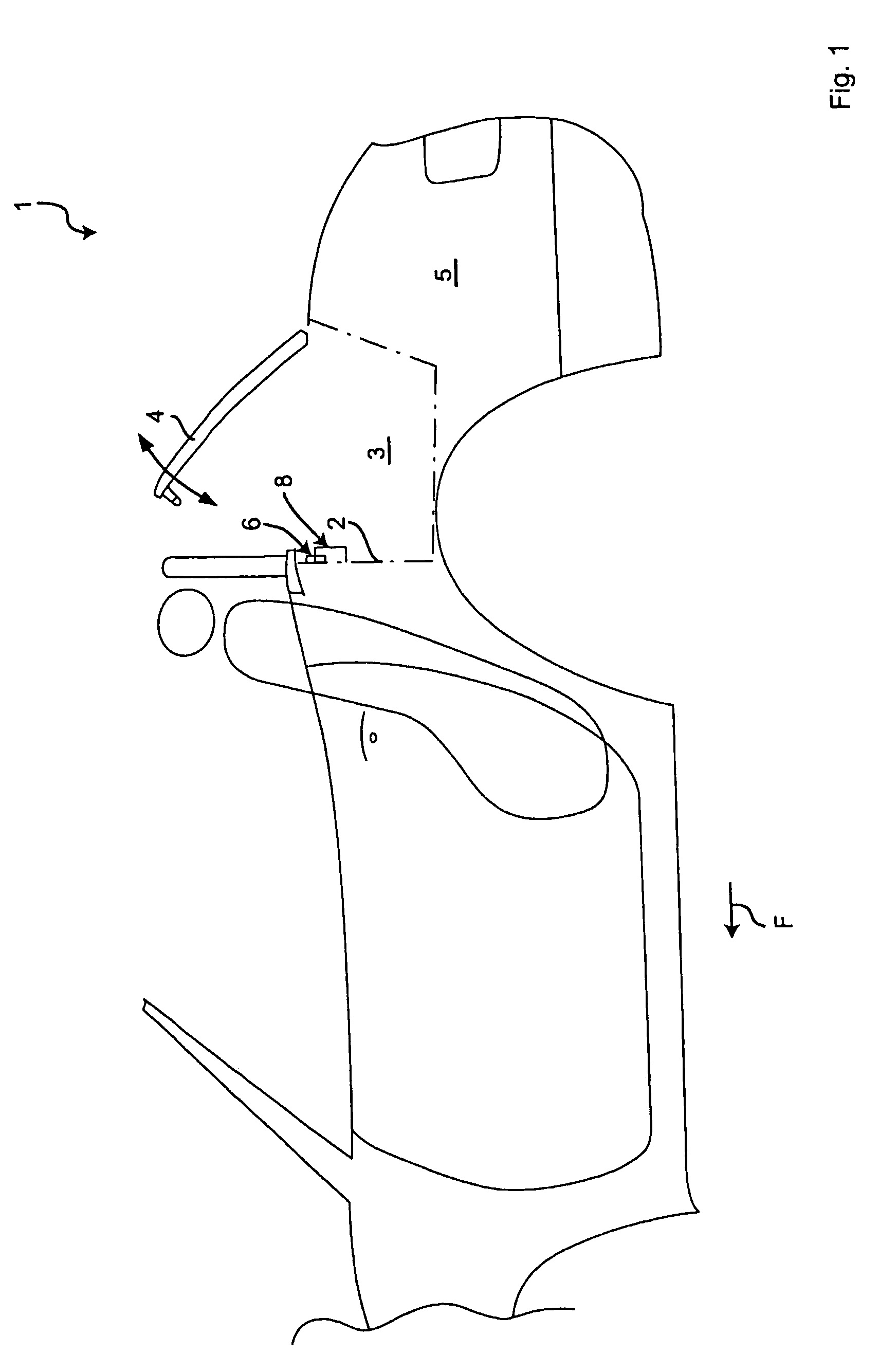

InactiveUS7410179B2Simple and safe processReduce manufacturing costCarriage/perambulator accessoriesConveyorsCouplingEngineering

The invention concerns a device in wheeled walker or rollator, comprising a frame member (2) having a lower end (3), a handle support rod (4) having an upper end (5), a brake-control means (6) arranged at the upper end (5) of the handle support rod, said brake-control means (6) being movable between a neutral position and a brake-application position. The rollator comprises a wheel (7) located at the lower end (3) of the frame member, the distance between said wheel (7) and the brake-control means (6) being changeable, a brake element (8) located adjacent the wheel (7), an upper force-transmission member (9) connected to said brake-control means (6), a lower force-transmission member (10) connected to said brake element (8), and a coupling means (11) for coupling-together said upper and said lower force-transmission members (9, 10). The upper force-transmission member (9) and the lower force-transmission member (10) are arranged to move freely relative to one another, when the brake-control means (6) assumes its neutral position and. The upper force-transmission member (9) and the lower force-transmission member (10) are arranged to be interconnected by means of said coupling means (11), when the brake-control means (6) leaves the neutral position, in response to which braking force is transferred to the brake element (8).

Owner:CARRERA OPTYL MARKETING +1

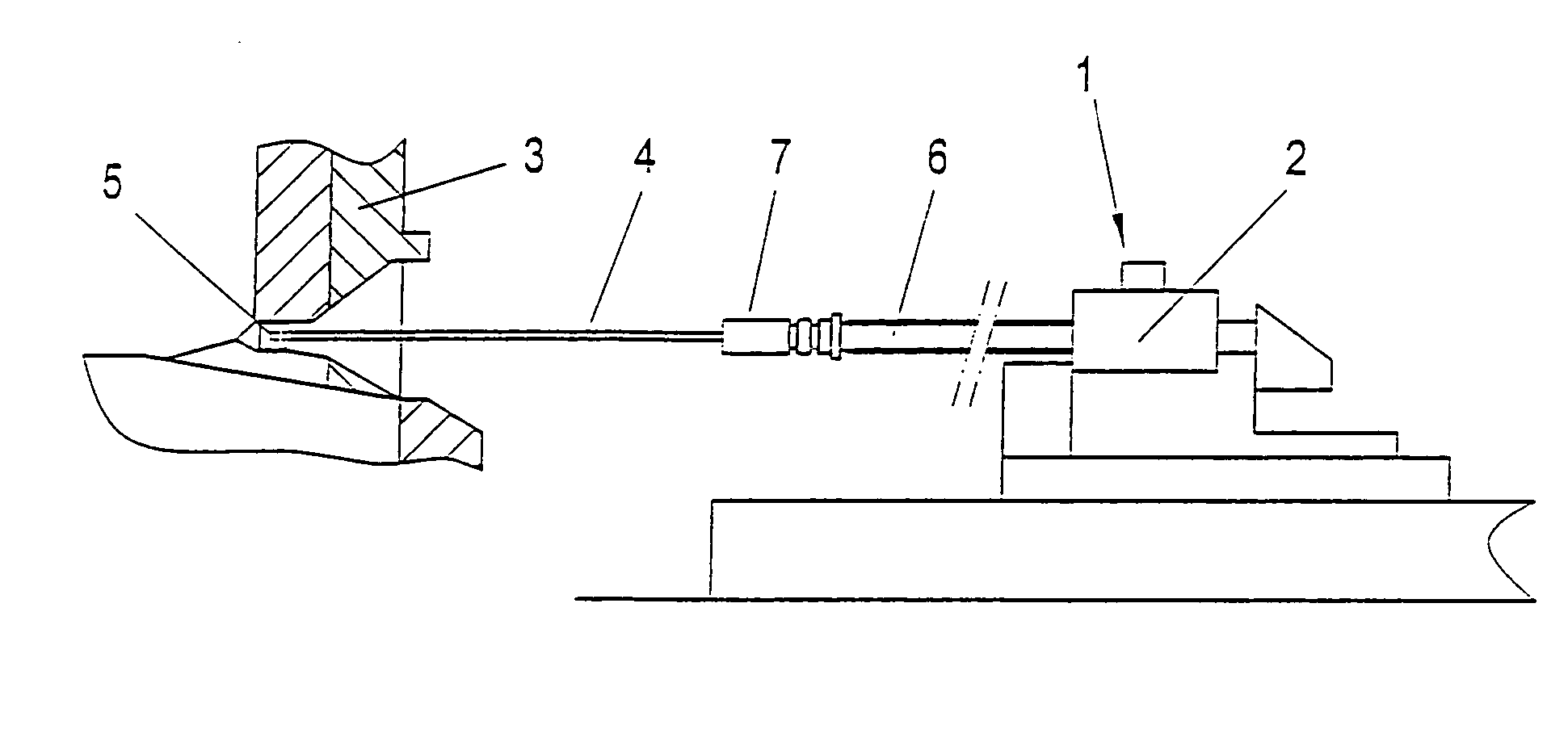

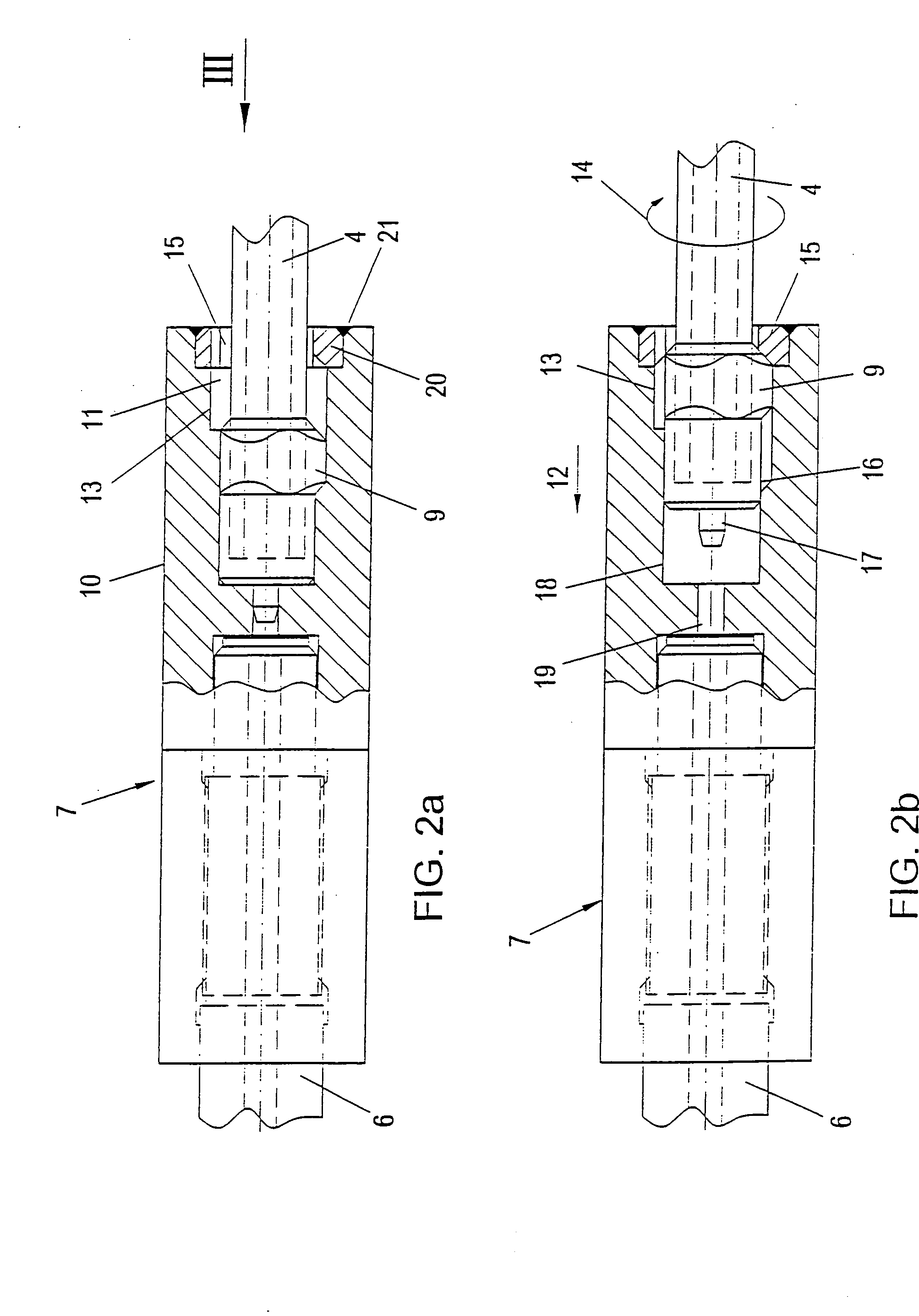

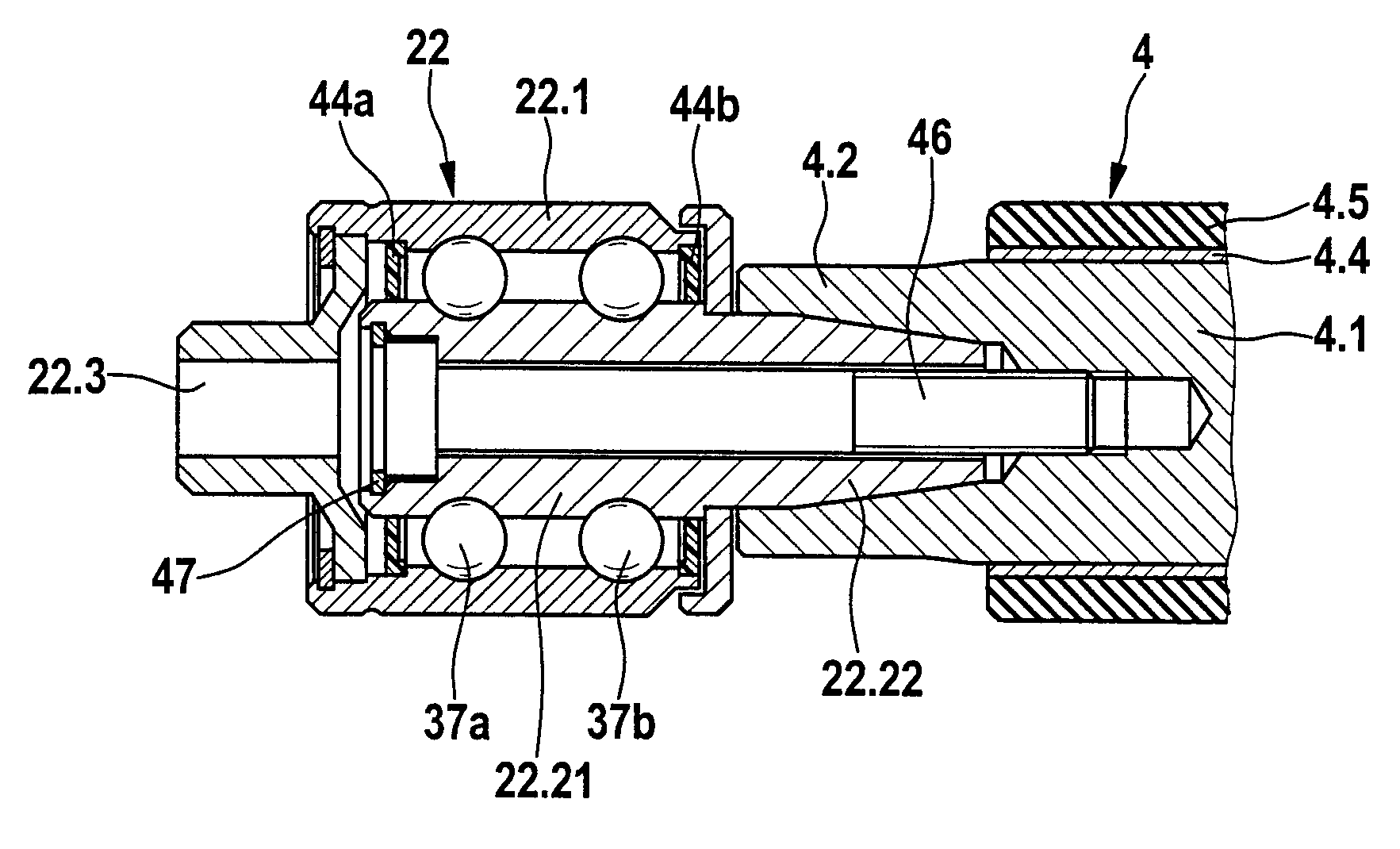

Method and arrangement for the rapid connection and detachment of connectable elements

InactiveUS20050042943A1Simple and reliable relative rotary movementShorten the lengthElectrically conductive connectionsDrilling rodsEngineeringMechanical engineering

In a method and an arrangement for the rapid connection and detachment of connectable elements (4, 6), particularly tubes or rods and / or driving elements and / or working elements capable of being fixed thereto such as, for instance, drill bits or the like, wherein an element (4) having a profiled end piece (9) is introduced into a respective reception opening (11) of the element (6) to be connected therewith and / or an intermediate or connection piece (7), particularly a bushing or sleeve, and connected with the second element (6) in a positive and force-transmitting manner, it is provided that, for the connection and detachment of the two elements (4, 6) to be connected, the profiled end piece (9) after a movement in the axial or connection direction (12) is rotated, by a partial region (15) of the reception opening (11) provided with a profile complementary to that of the end piece, relative to the reception opening (11) in a partial region (13) of the reception opening (11) having an enlarged clear cross section, and subsequently is again moved in the axial direction (12) into a further partial region (10) of the reception opening (11) provided with a profile complementary to that of the end piece (9), thus enabling rapid and simple connection and detachment at structurally simple expenses.

Owner:PAUL WURTH SA +1

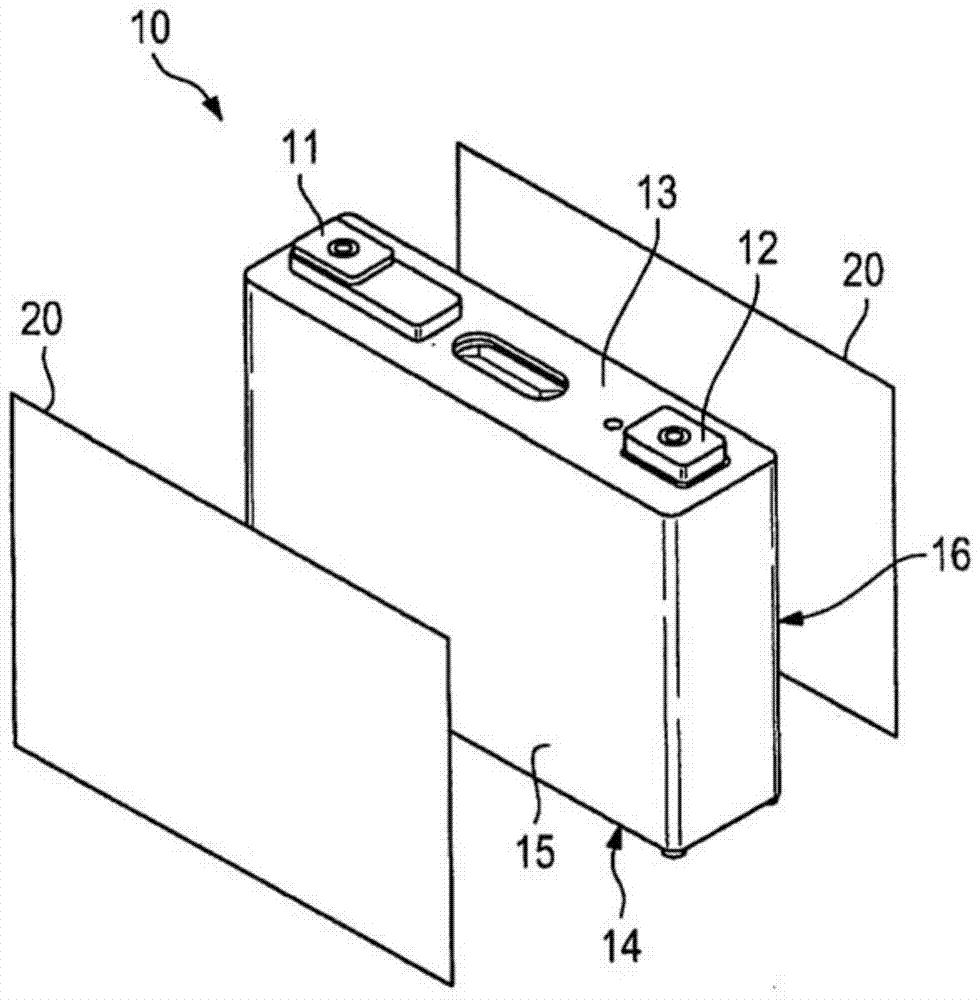

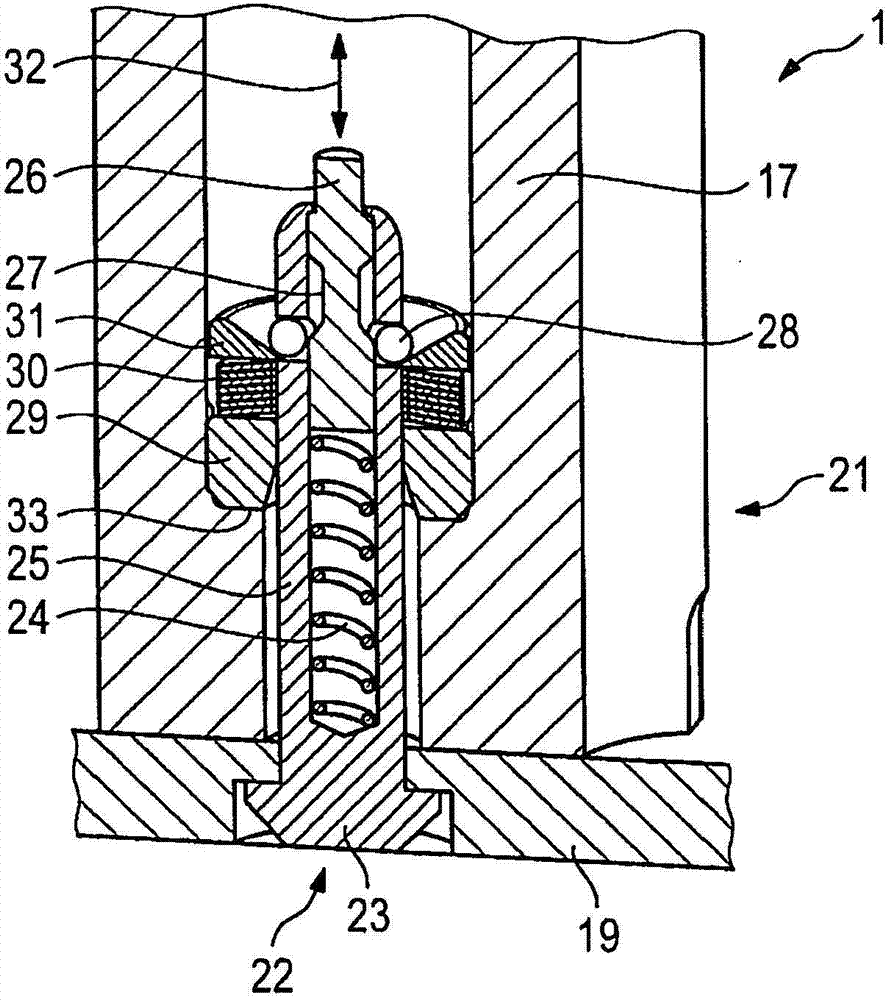

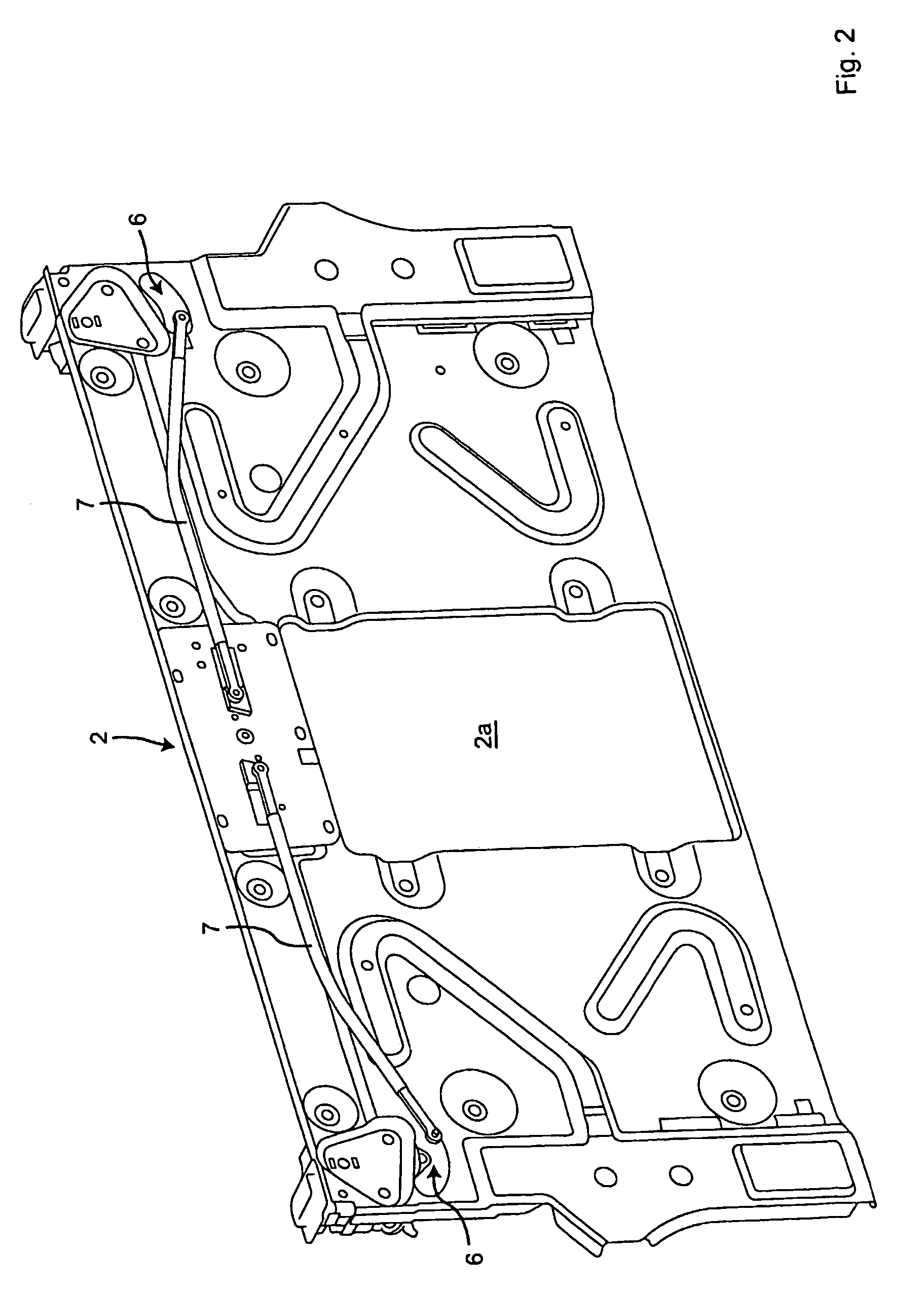

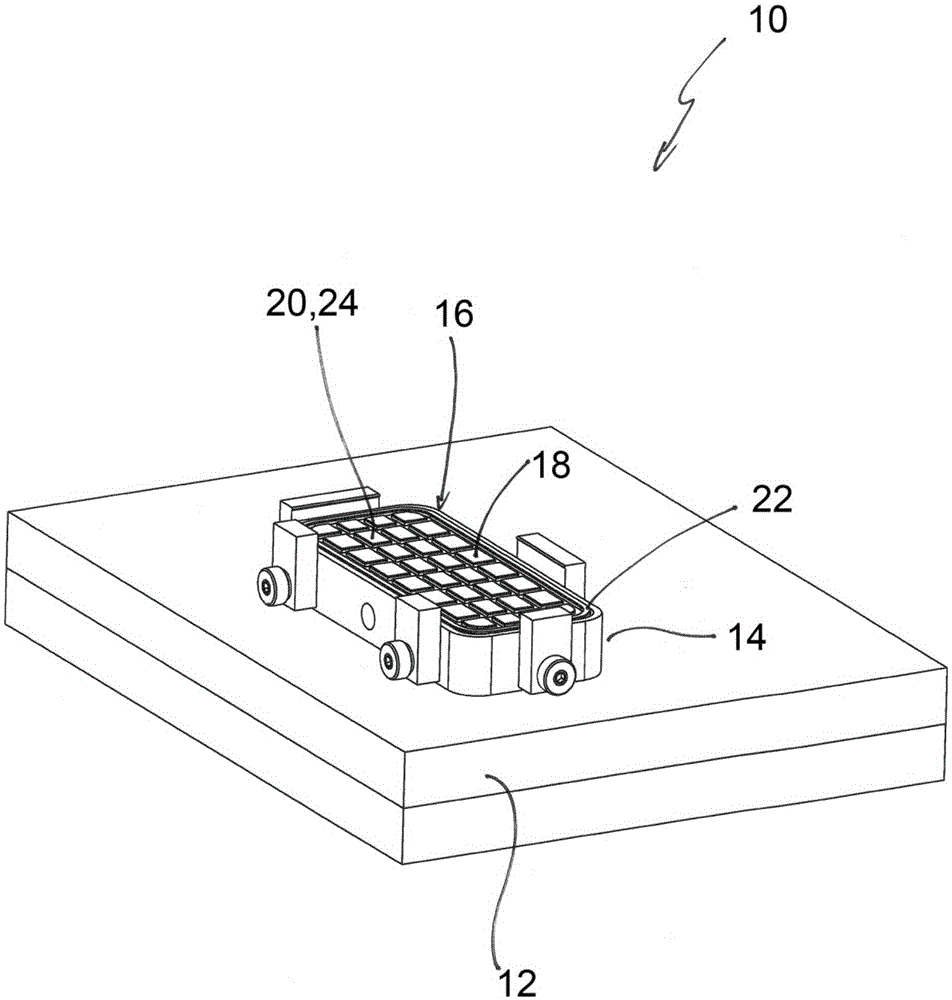

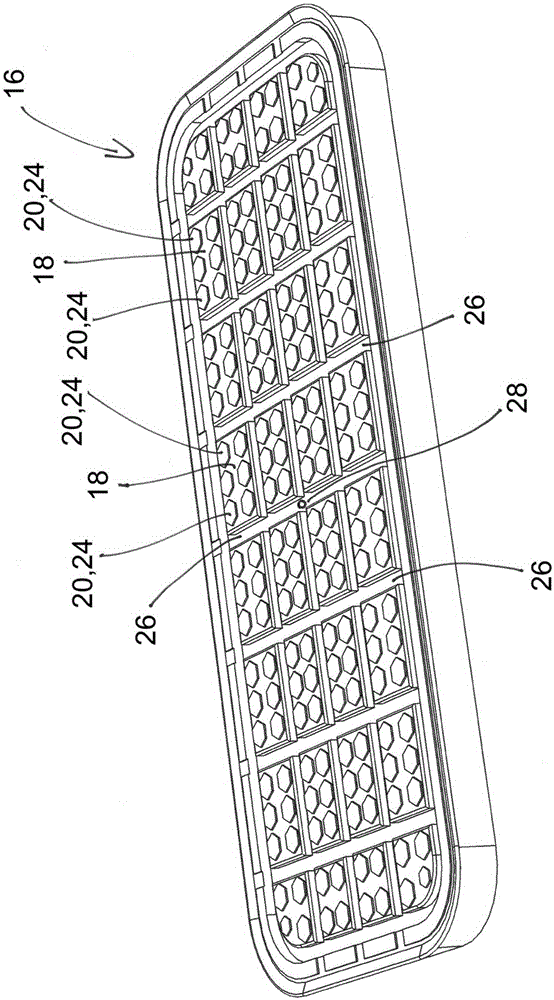

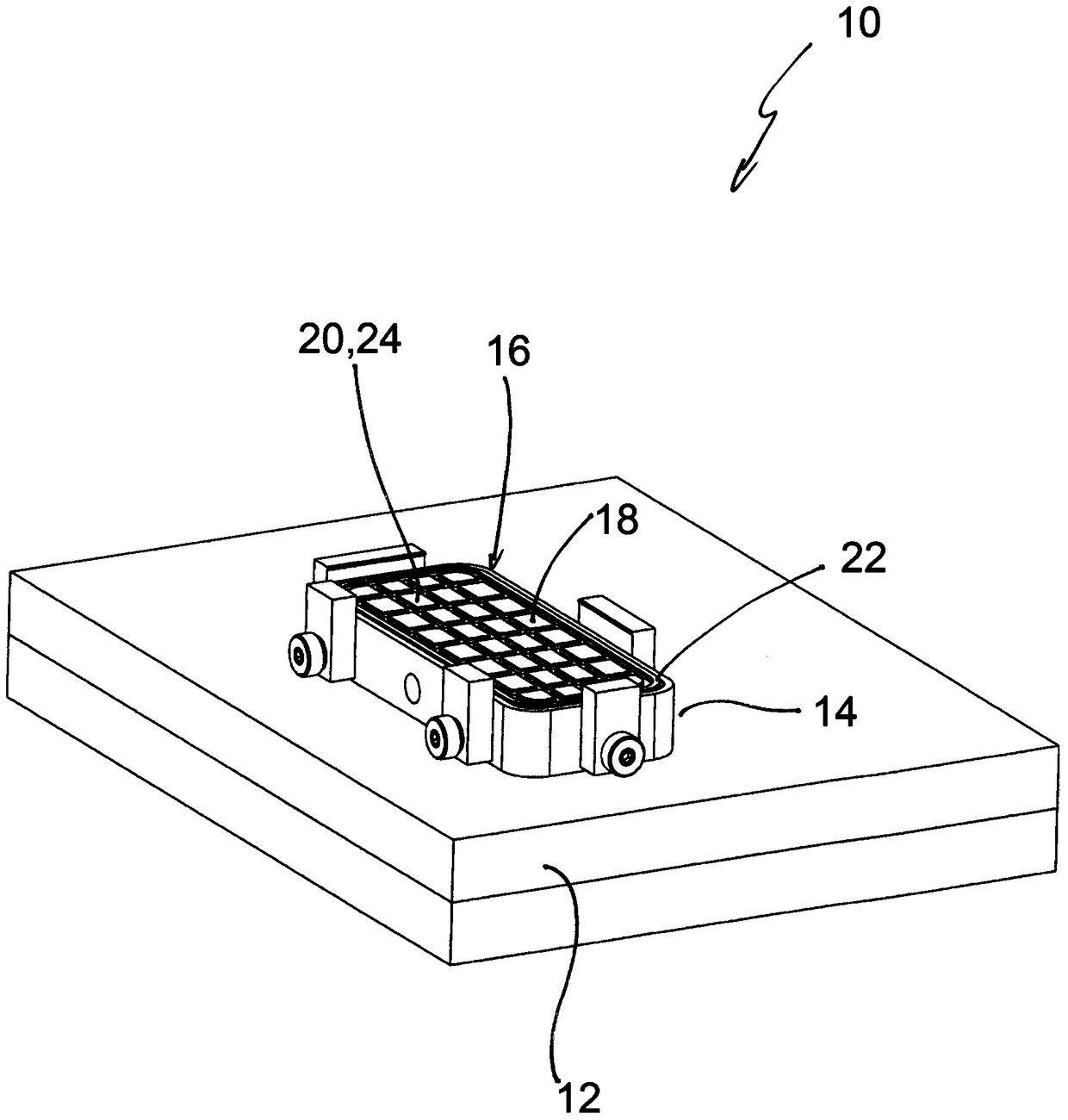

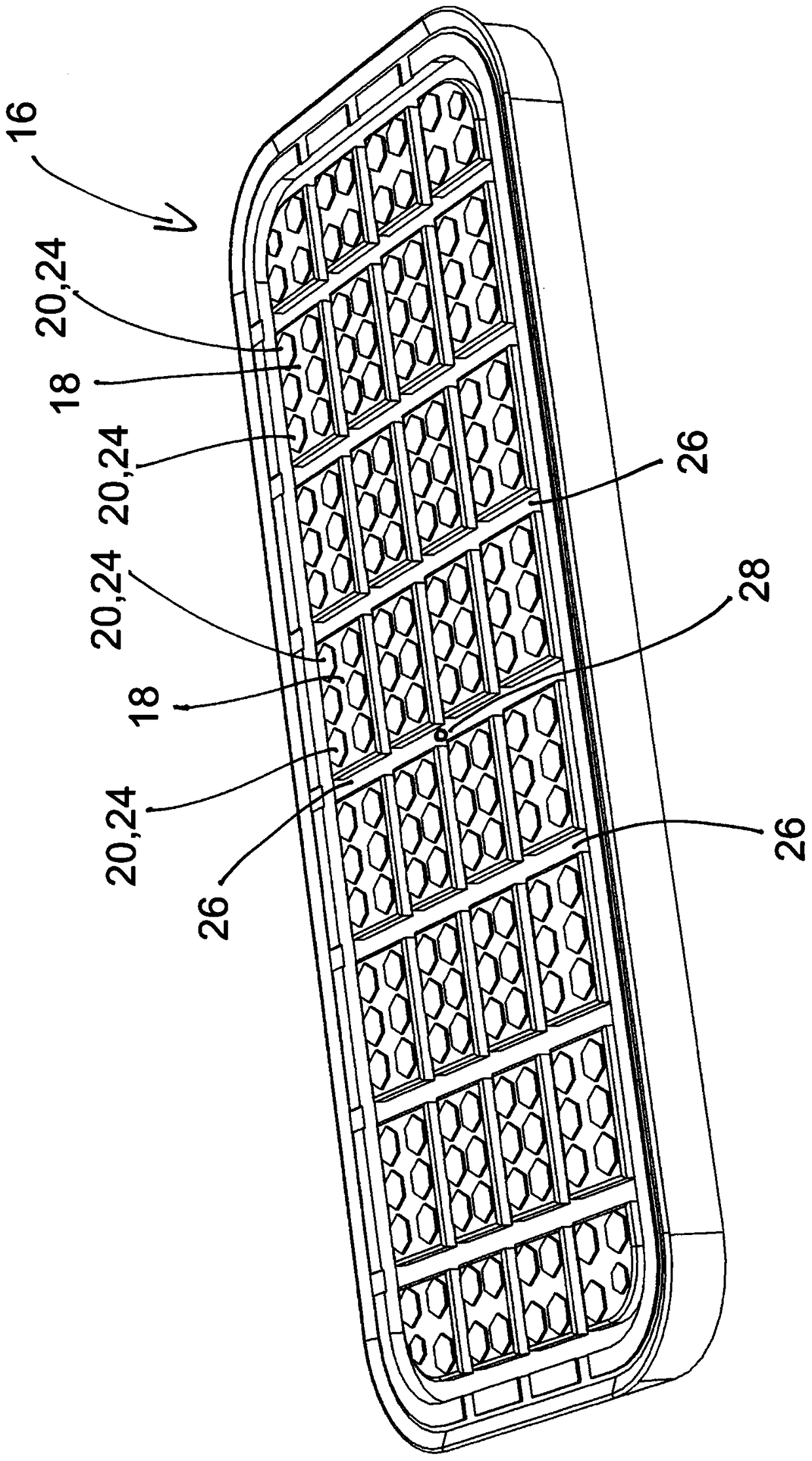

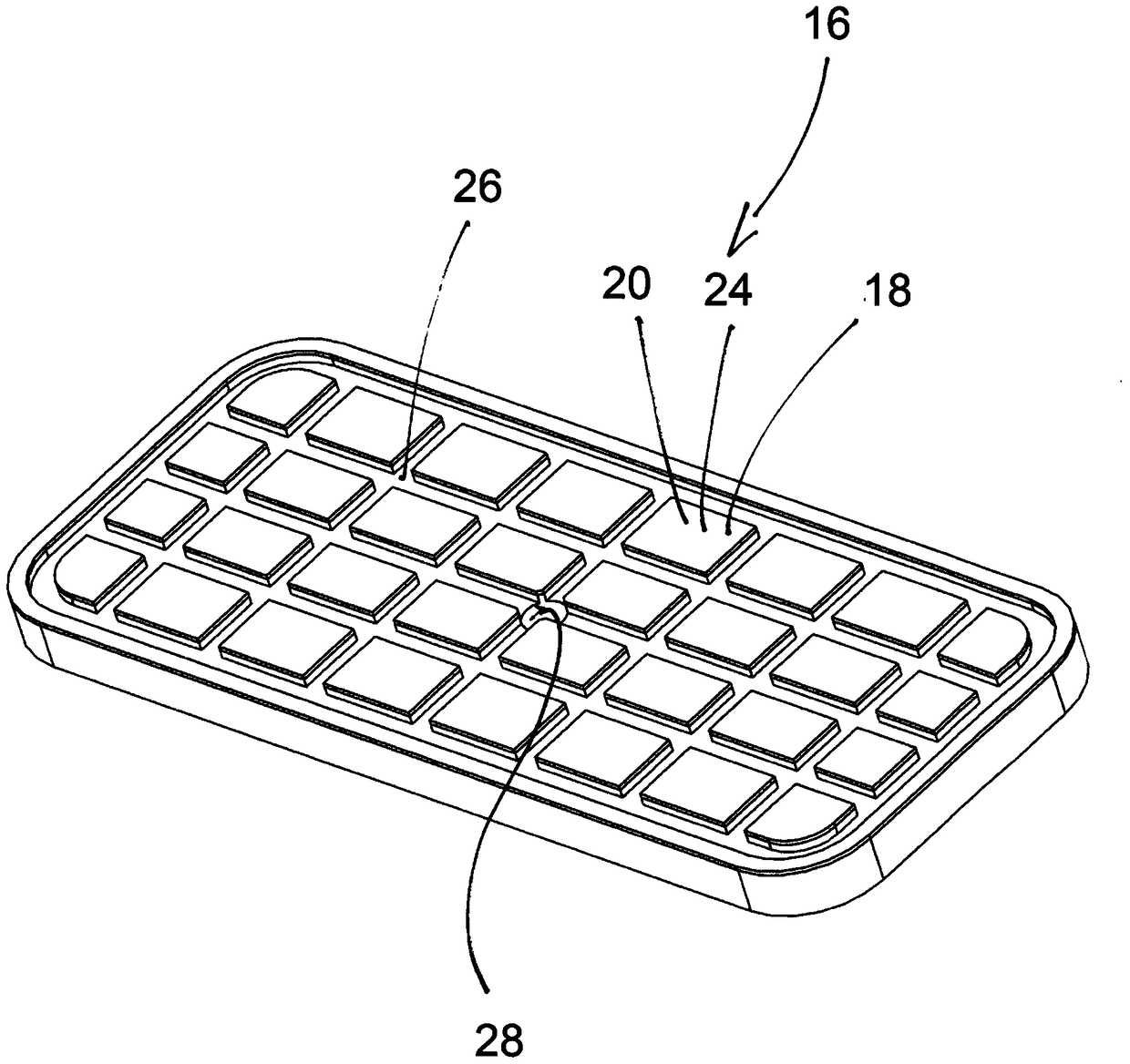

Arrangement for securing an energy storage module on a module support

ActiveCN103687738AReliable expansionReliable force transmissionFinal product manufactureElectric propulsion mountingComputer moduleEnergy storage

The invention relates to an arrangement (21) which comprises an energy storage module (1), a module support (19), in particular a vehicle body, and a ball lock pin (22) designed for securing the energy storage module (1) on the module support (19).

Owner:BAYERISCHE MOTOREN WERKE AG

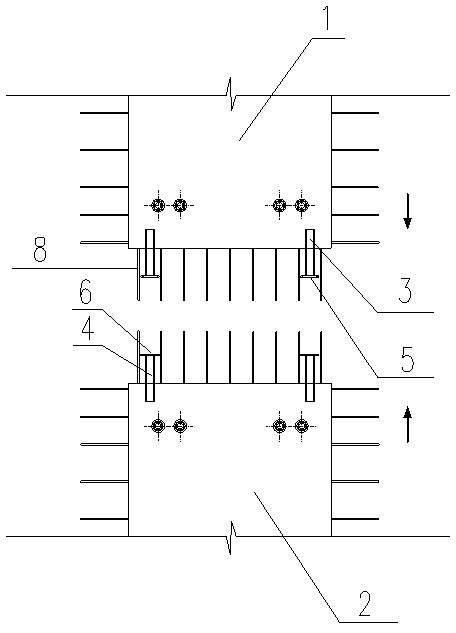

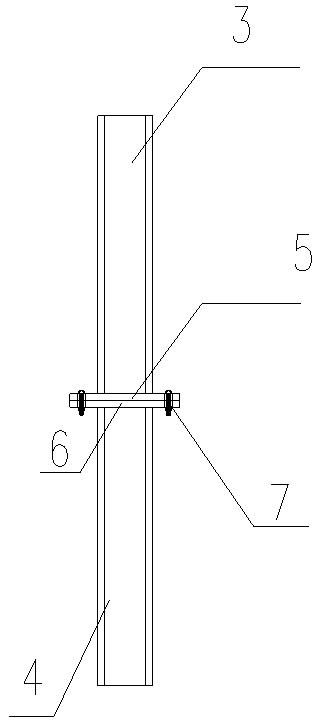

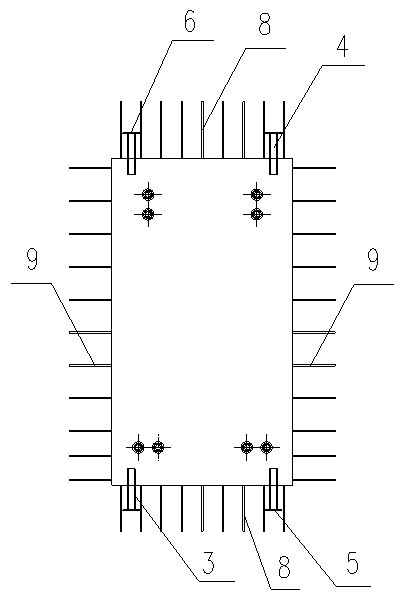

U-shaped thin-wall steel-prestress reinforced concrete combined bent cap and thin-wall steel tube concrete pier node structure and construction process

PendingCN110396915AReliable force transmissionAppearance has no effectBridge structural detailsBridge erection/assemblyReinforced concretePre stress

The invention discloses a U-shaped thin-wall steel-prestress reinforced concrete combined bent cap and thin-wall steel tube concrete pier node structure and a construction process. The structure comprises a U-shaped thin-wall steel-prestress reinforced concrete combined bent cap and a thin-wall steel tube concrete pier, when the thin-wall steel tube concrete pier and the U-shaped thin-wall steel-prestress reinforced concrete combined bent cap are connected, a connecting piece, an ear plate, a telescopic threaded steel tube, a platform beam, a telescopic steel rope and a hoop are arranged on the thin-wall steel tube concrete pier, the stability of the installation process is ensured, concrete is poured into a machined U-shaped thin-wall steel beam to form the the U-shaped thin-wall steel-prestress reinforced concrete combined bent cap, and when the concrete is solidified to the designed strength, the combined bent cap is formed by tensioning prestressed steel bars embedded in the concrete. According to the structure, the connection between the U-shaped thin-wall steel-prestress concrete combined bent cap and the steel tube concrete pier is reliable, installing is convenient, construction is simple, the seismic resistance and fire resistance are good, and the manufacturing cost is low.

Owner:CHONGQING UNIV

Electromagnetic regulator

InactiveUS20110210277A1Reduce wearReduce frictionOperating means/releasing devices for valvesMagnetsLinear motionPower flow

An electromagnetic regulator having an armature unit with a plunger unit (12) carrying out a linear movement when energized by a current flowing in a stationary coil unit (26, 38), wherein the plunger unit is designed to cooperate at the end thereof with a regulator partner (10). The plunger unit has a slide or ball bearing (36) at the end thereof which is fixed in a cage-like housing (38, 40) on the plunger unit such as to be able to rotate in reaction to a frictional force at right angles to the direction of the linear regulation movement.

Owner:ETO MAGNETIC GMBH

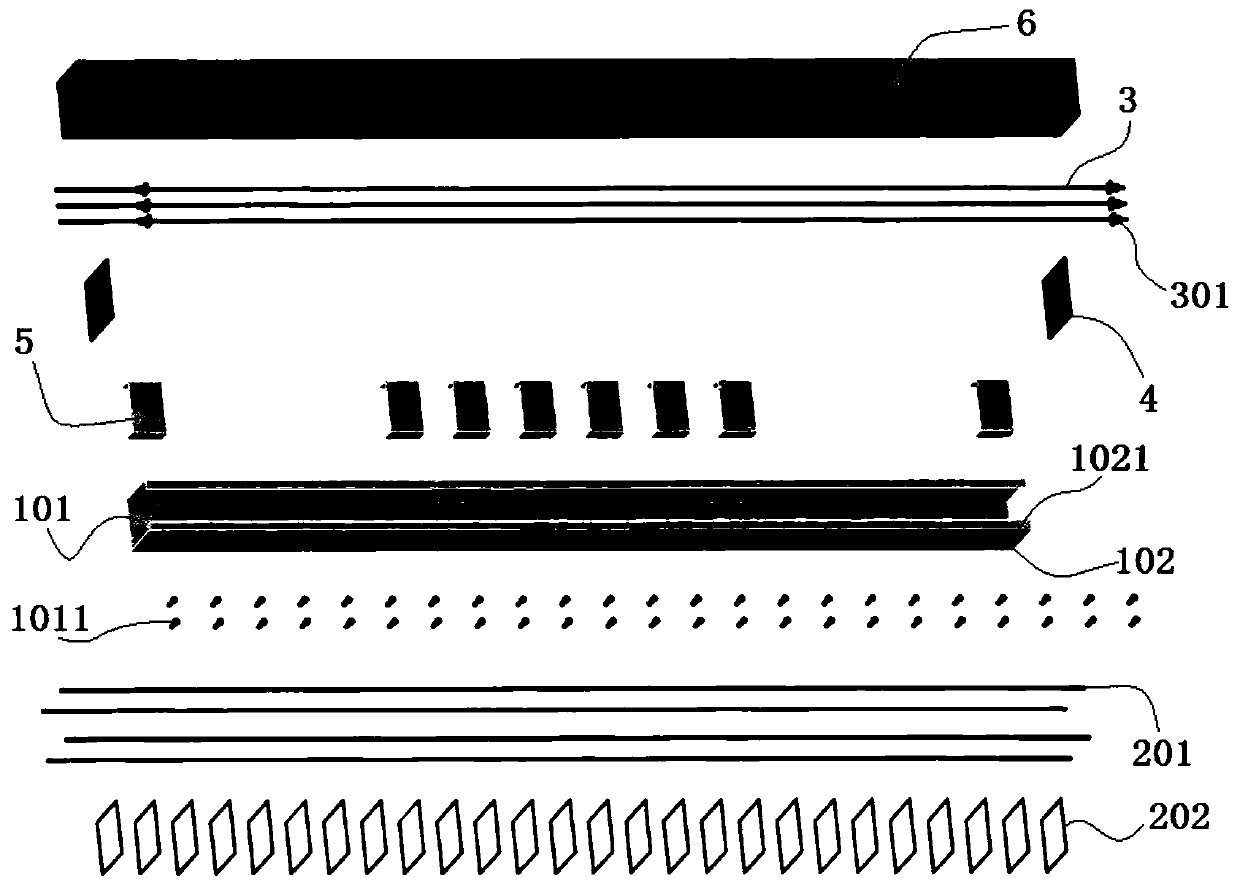

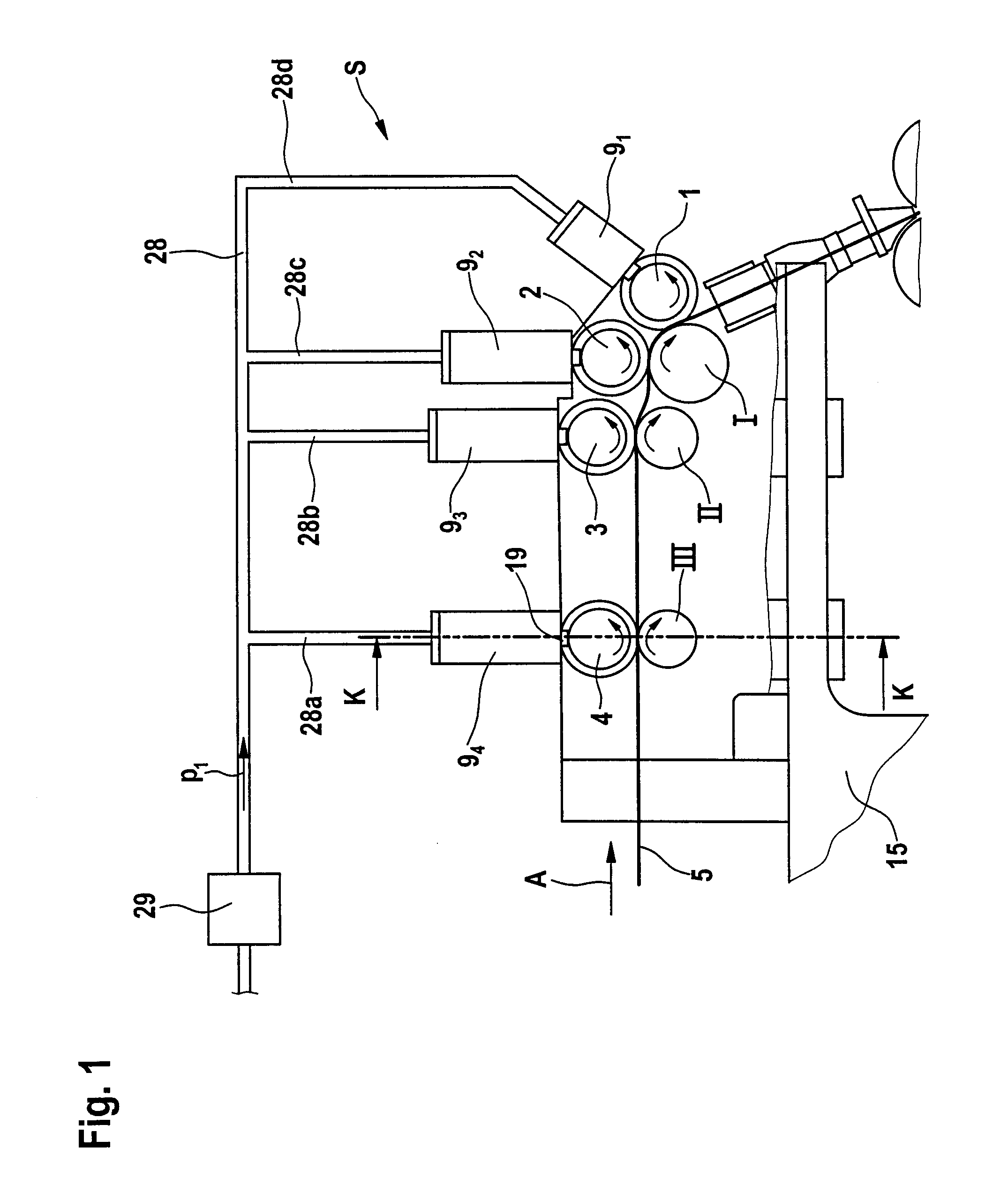

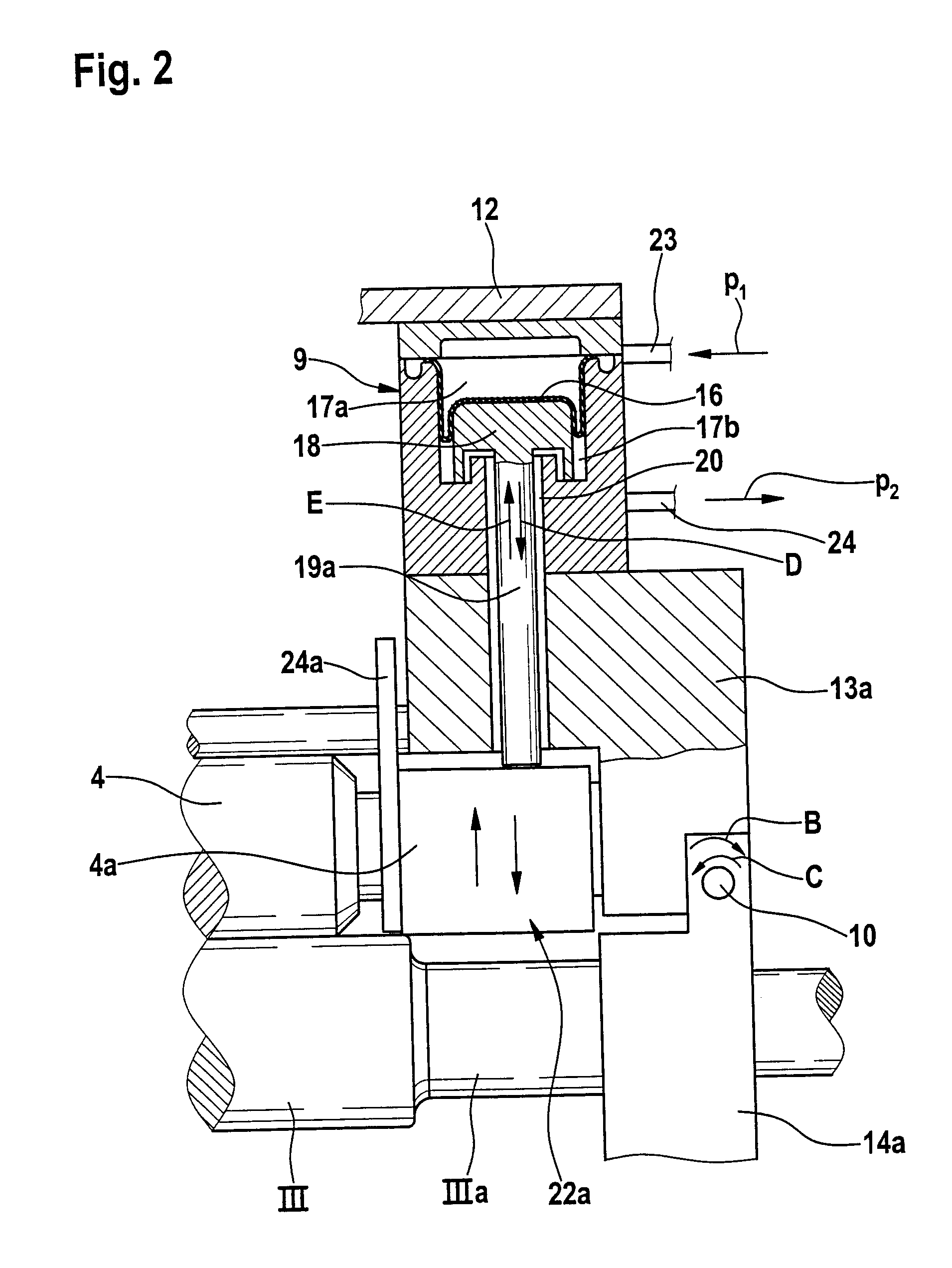

Device for combining several printed webs

InactiveCN1931695AGood effectReliable force transmissionFolding thin materialsArticle deliveryEngineeringMechanical engineering

Owner:M A N ROLAND DRUCKMASCHINEN AG

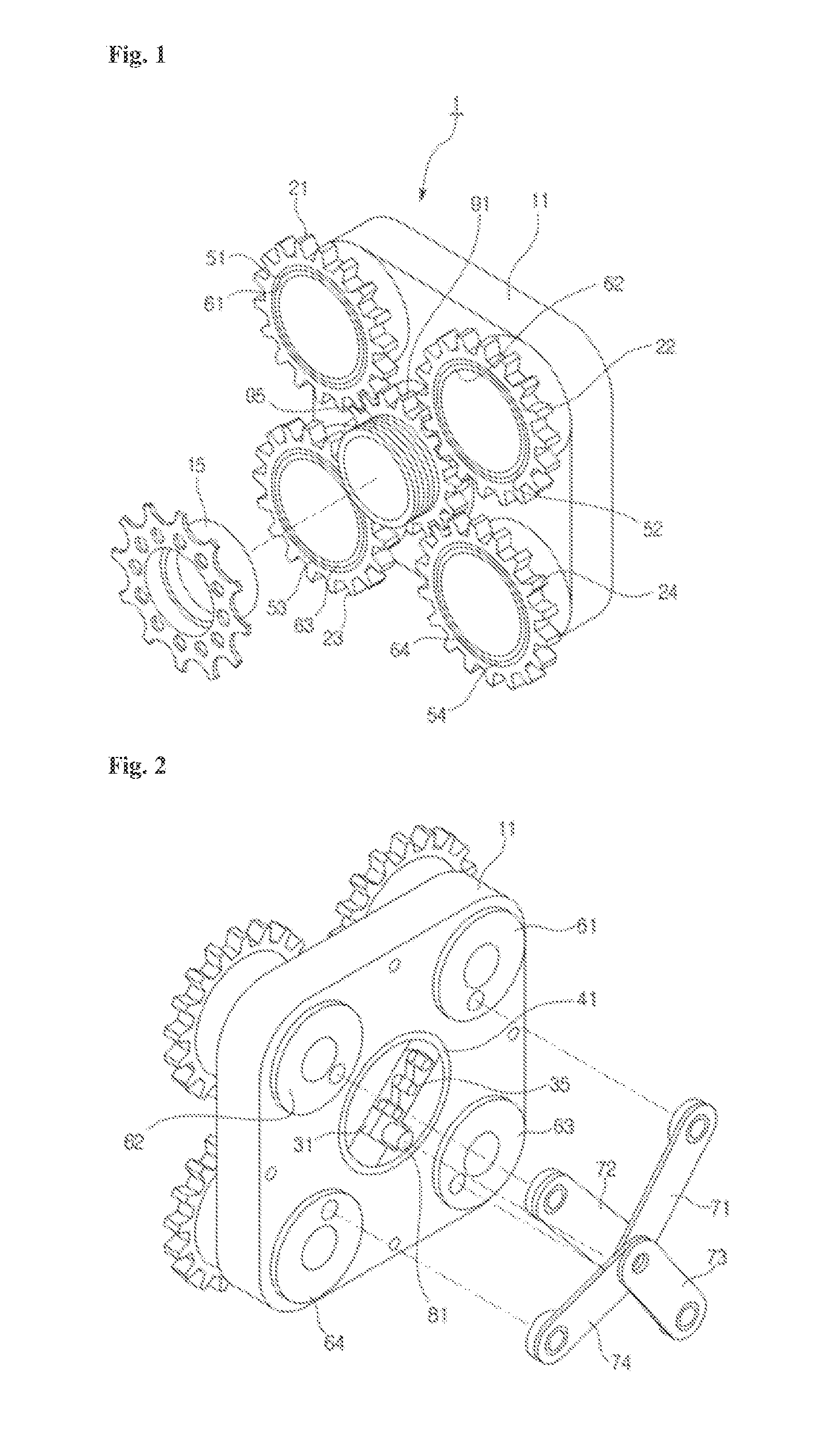

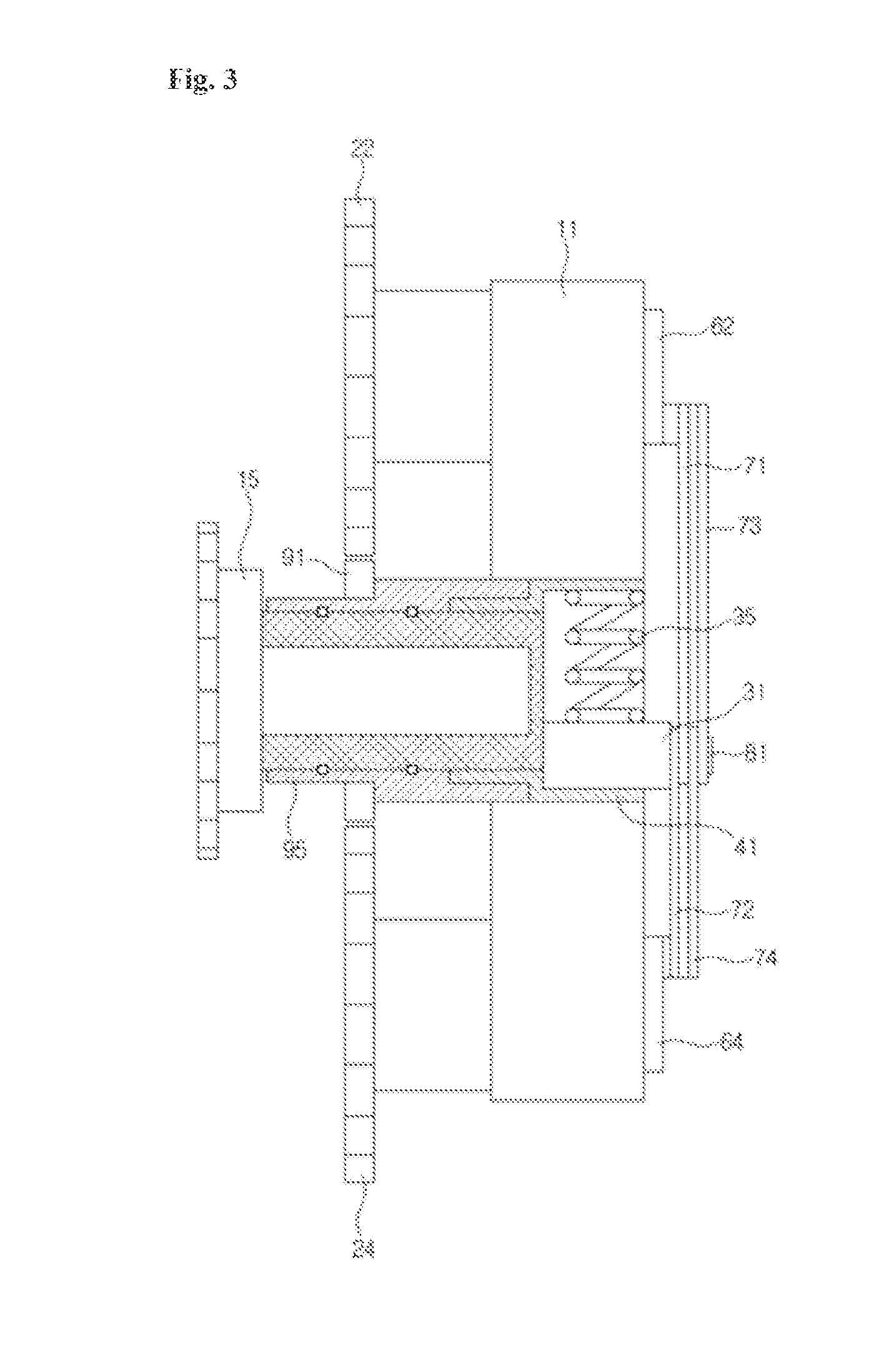

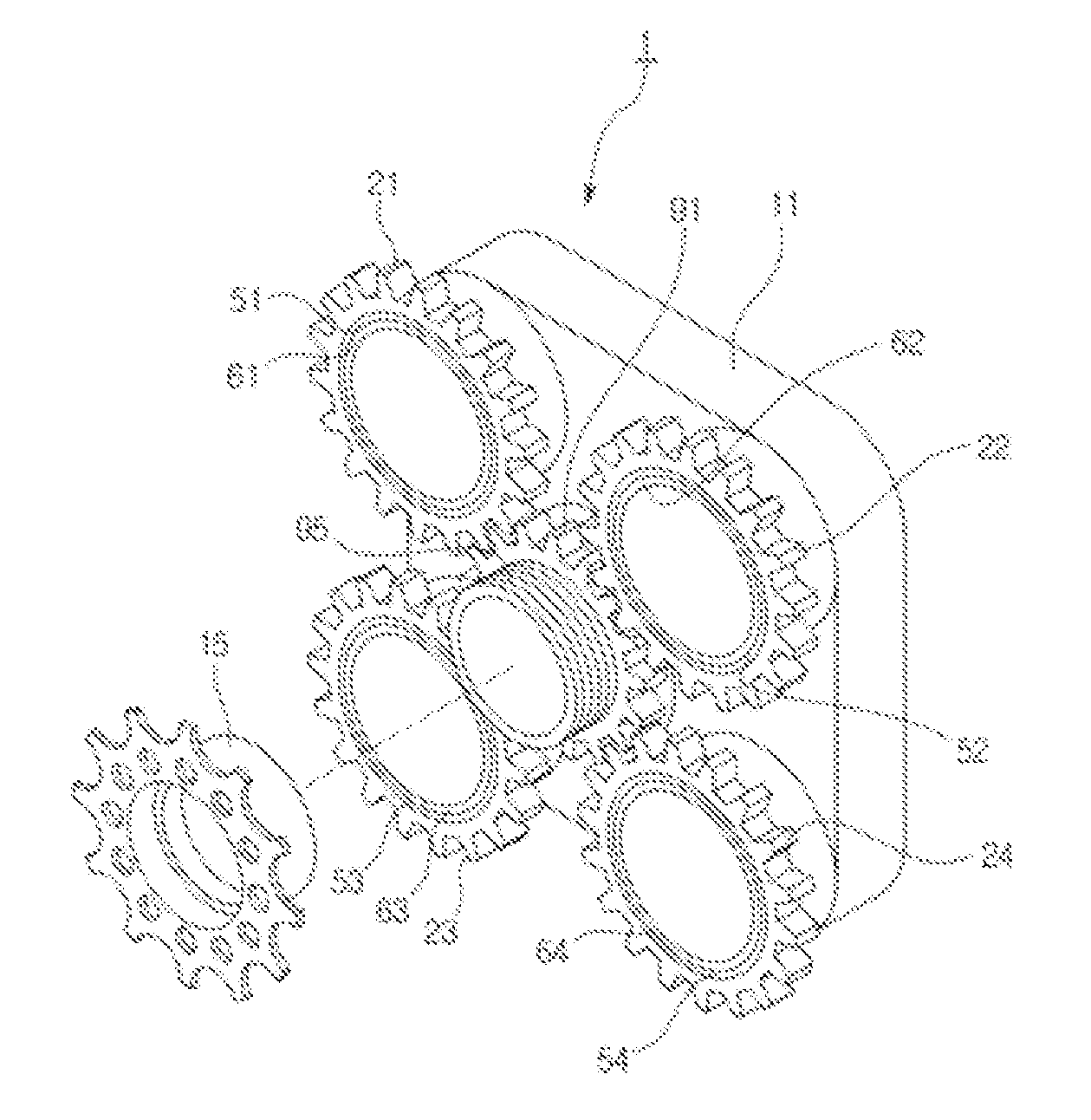

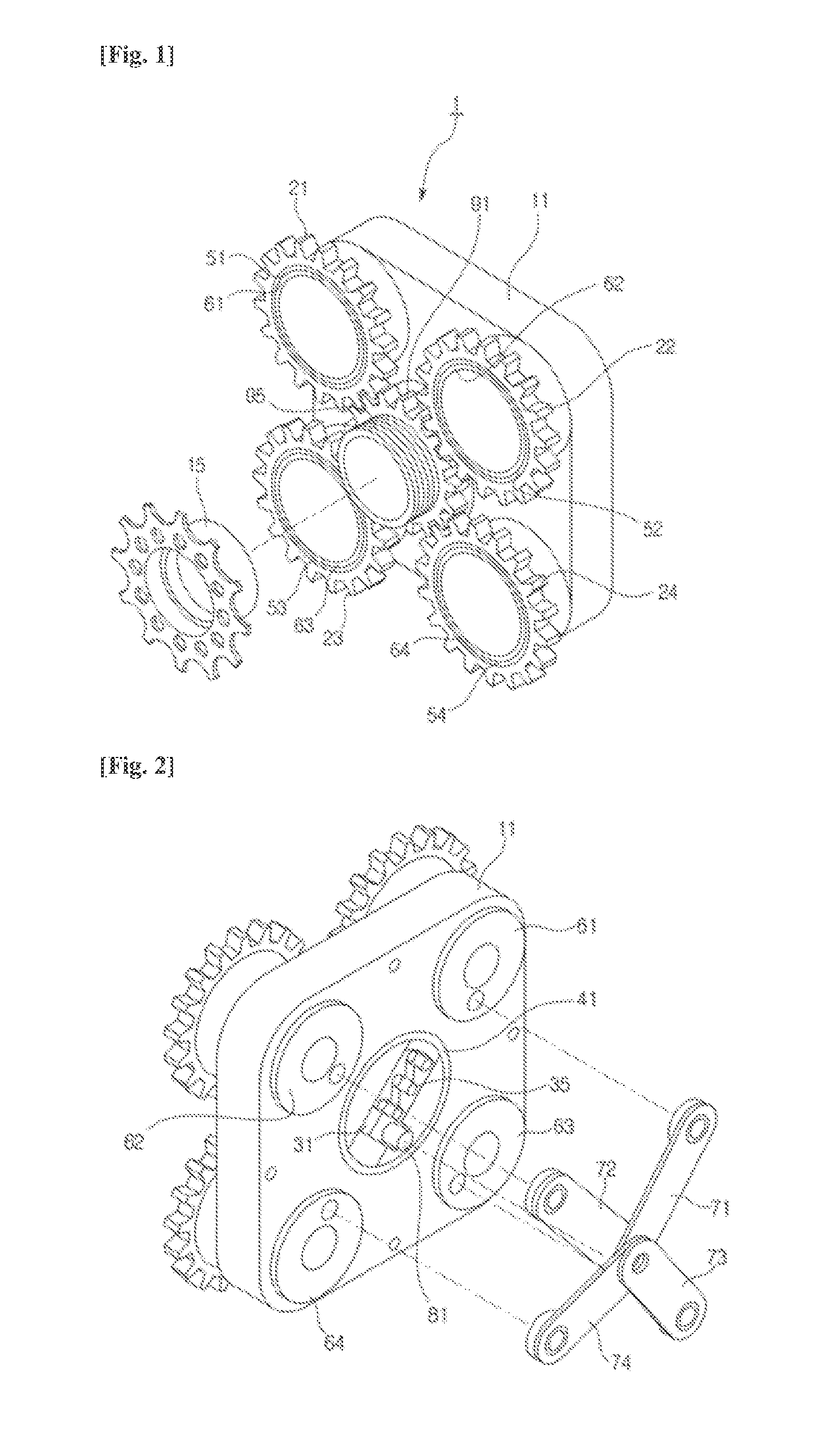

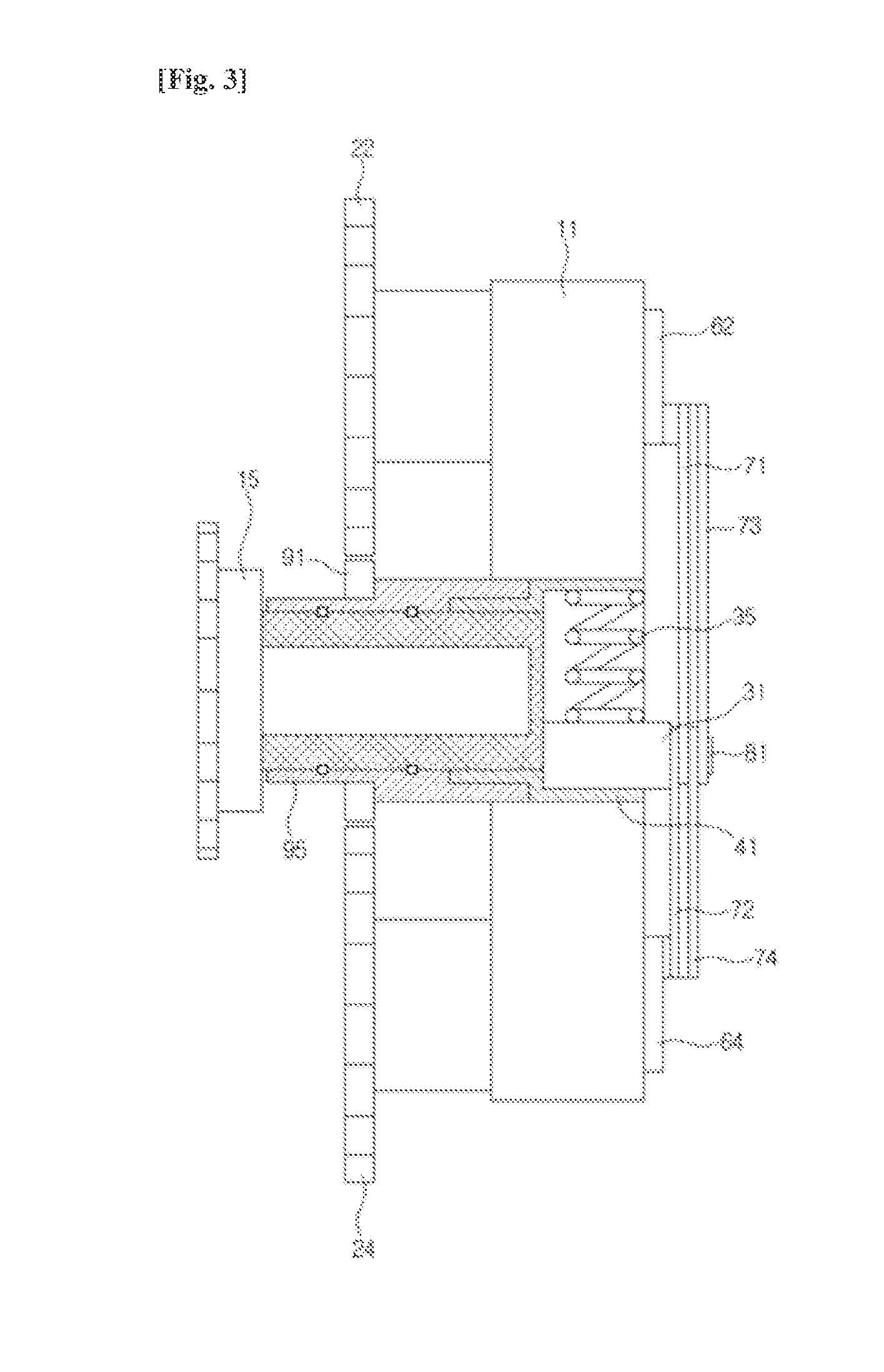

Continuously variable transmission apparatus

The present invention relates to a continuously variable transmission apparatus, which is characterized by comprising: an input shaft transferred with torque inputted from the outside; a plurality of driven gears which are arranged around the circumference of the input shaft as a certain phase difference and transferred with the power from the input shaft; a variable cam of which the turning radius can be varied by an external load; a variable input link which is coupled to and transferred with the torque of the input haft and allows the rotation thereof; a one-way clutch which is transferred undirectionally with the bidirectional torque to be transferred to the driven gears, respectively, and rotates the driven gears in one direction; a plurality of cam shafts which contact the one-way direction clutch internally or externally; and a plurality of output links, each of which one end revolves together with the variable cam around the center of rotation of the variable input link and the other ends of which are coupled to the cam shafts respectively and allow swiveling thereof.

Owner:SHIN HYUN WOO +1

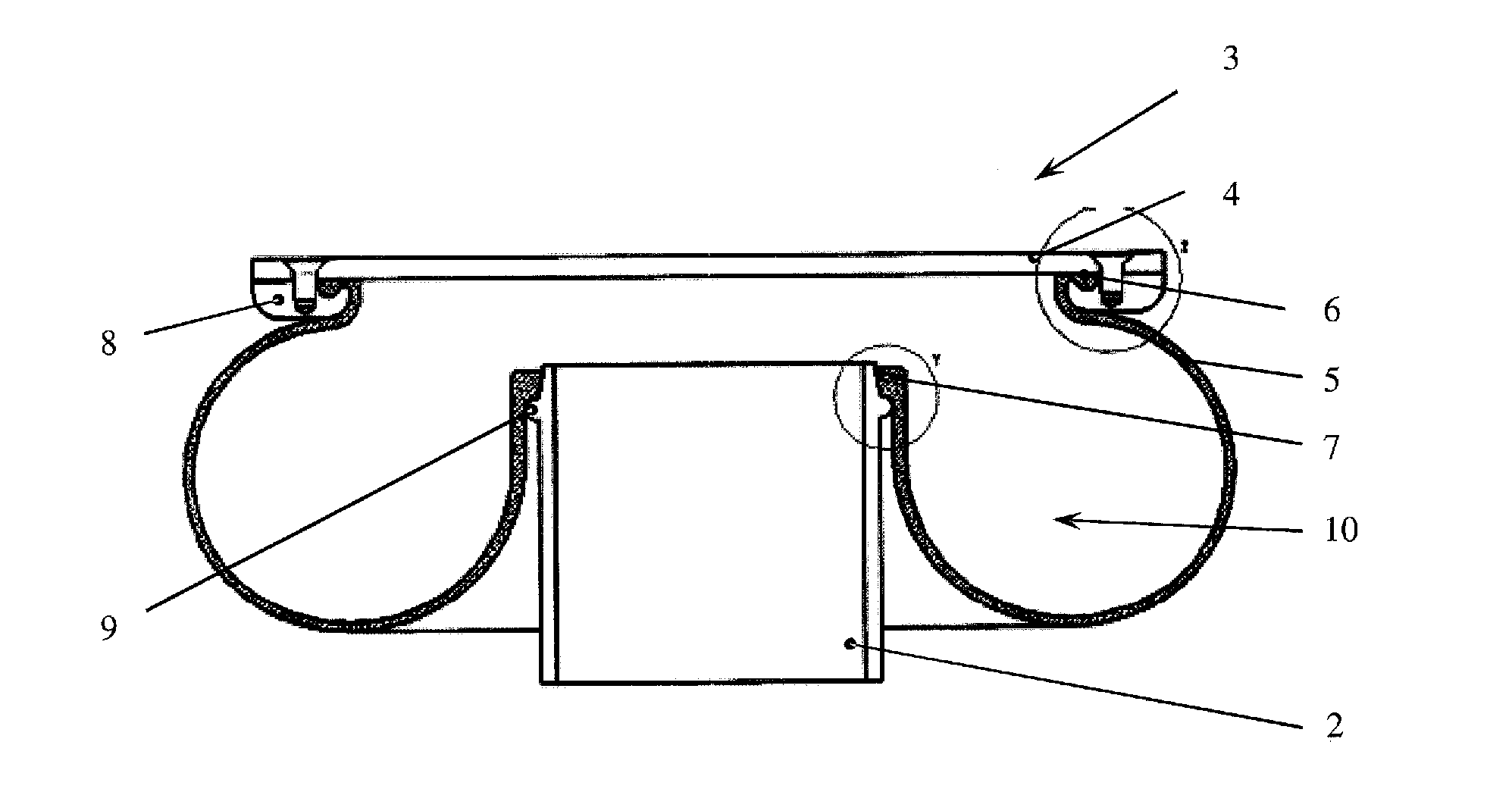

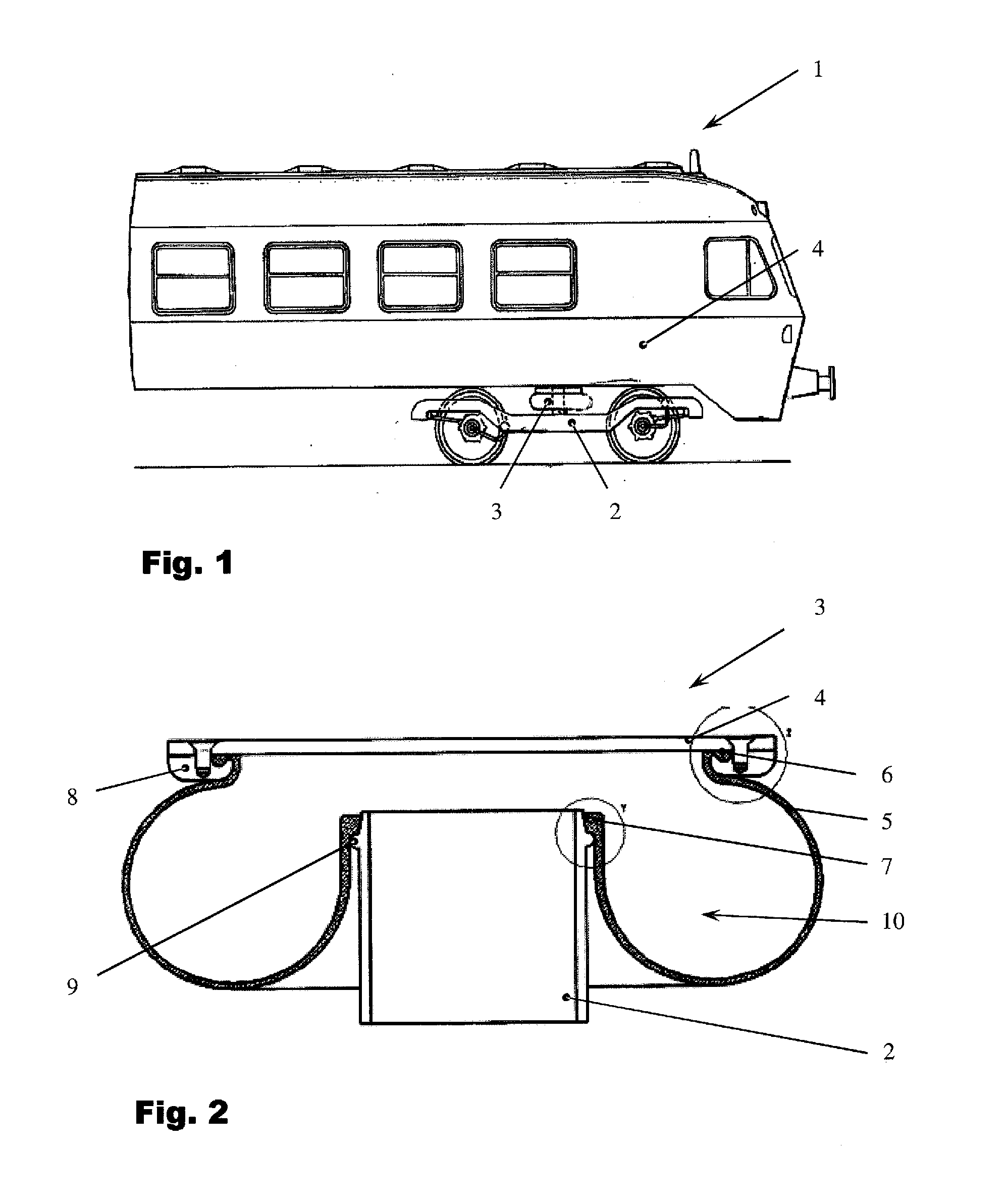

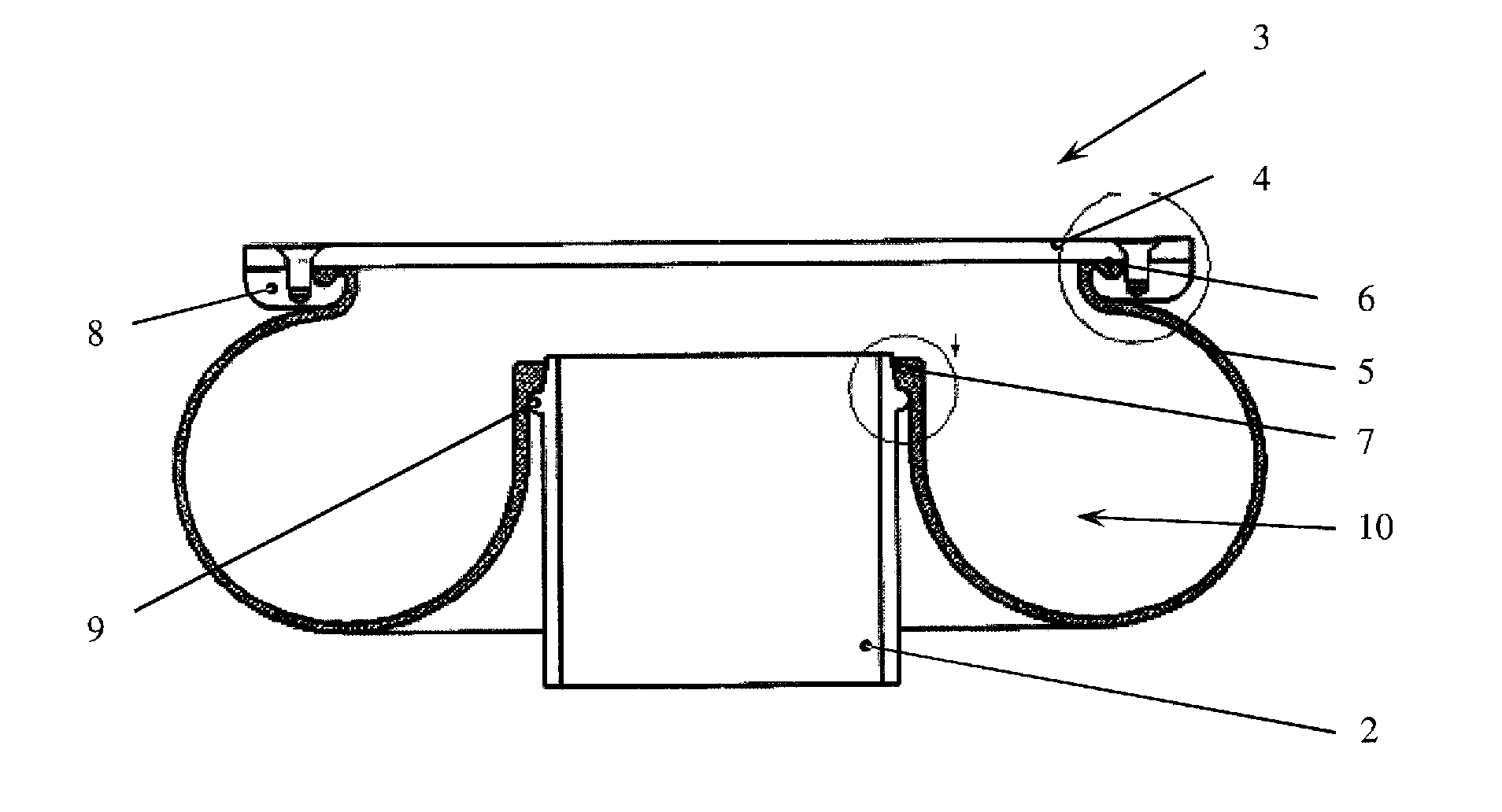

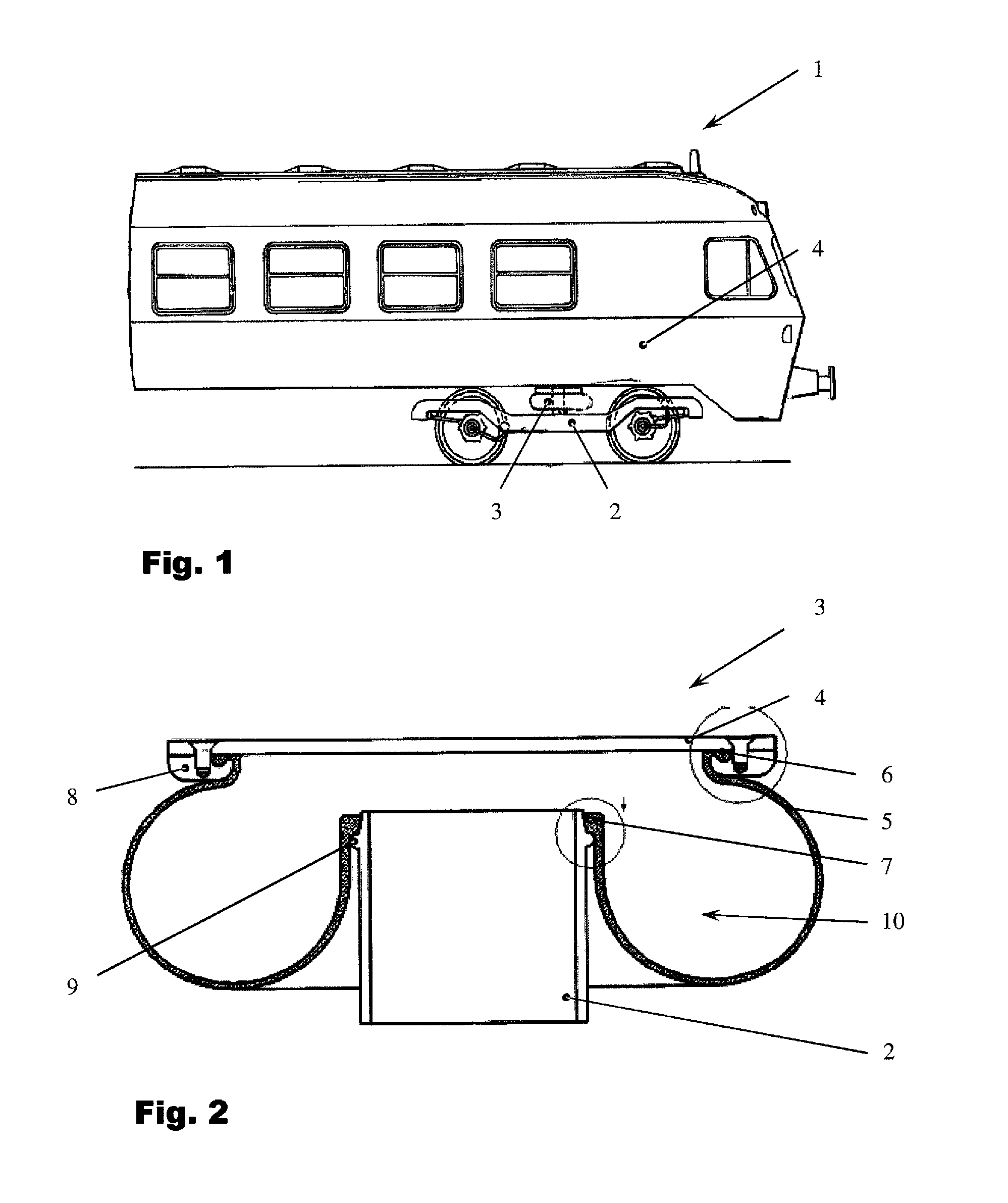

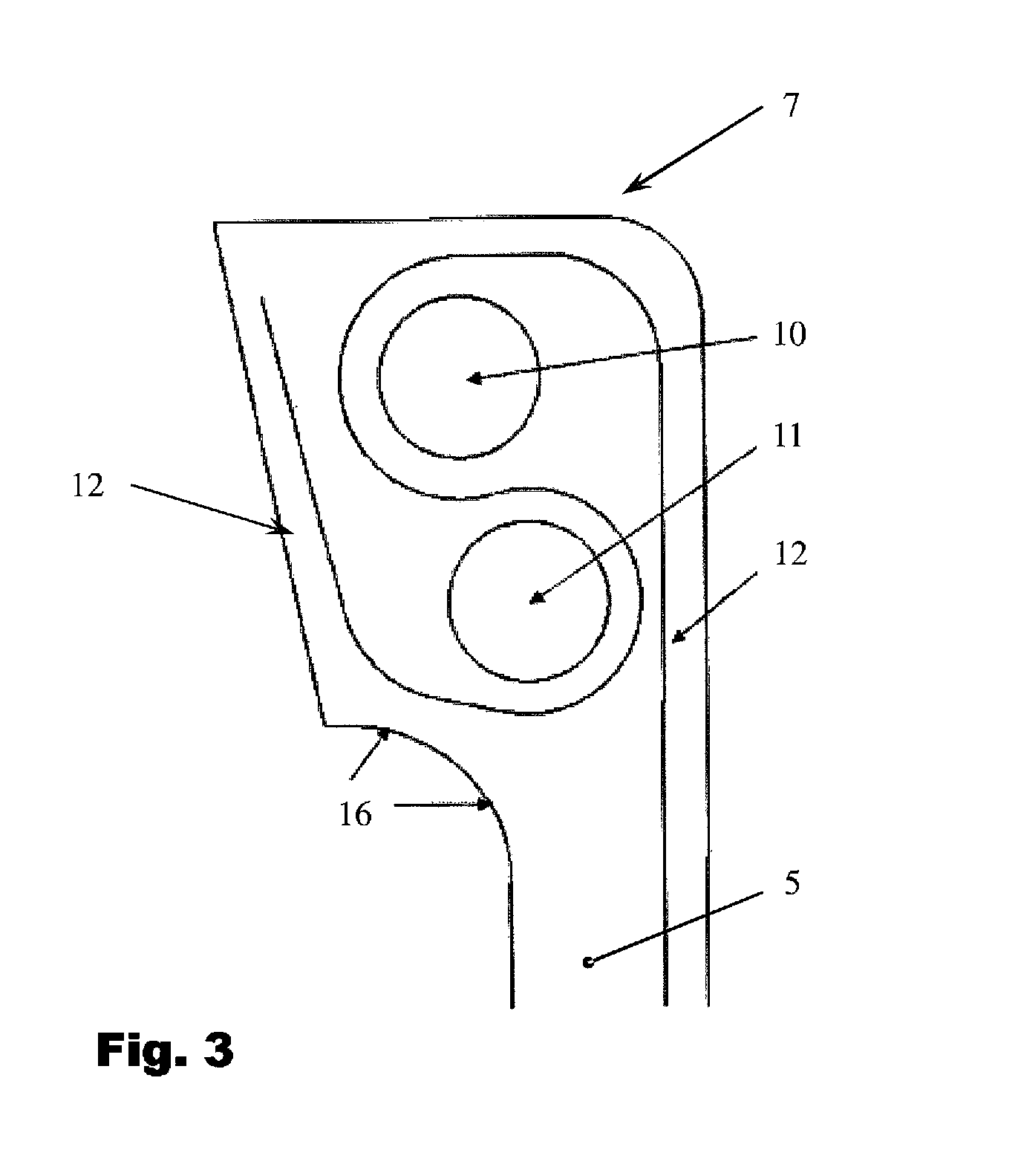

Pneumatic Spring Device for a Rail Vehicle

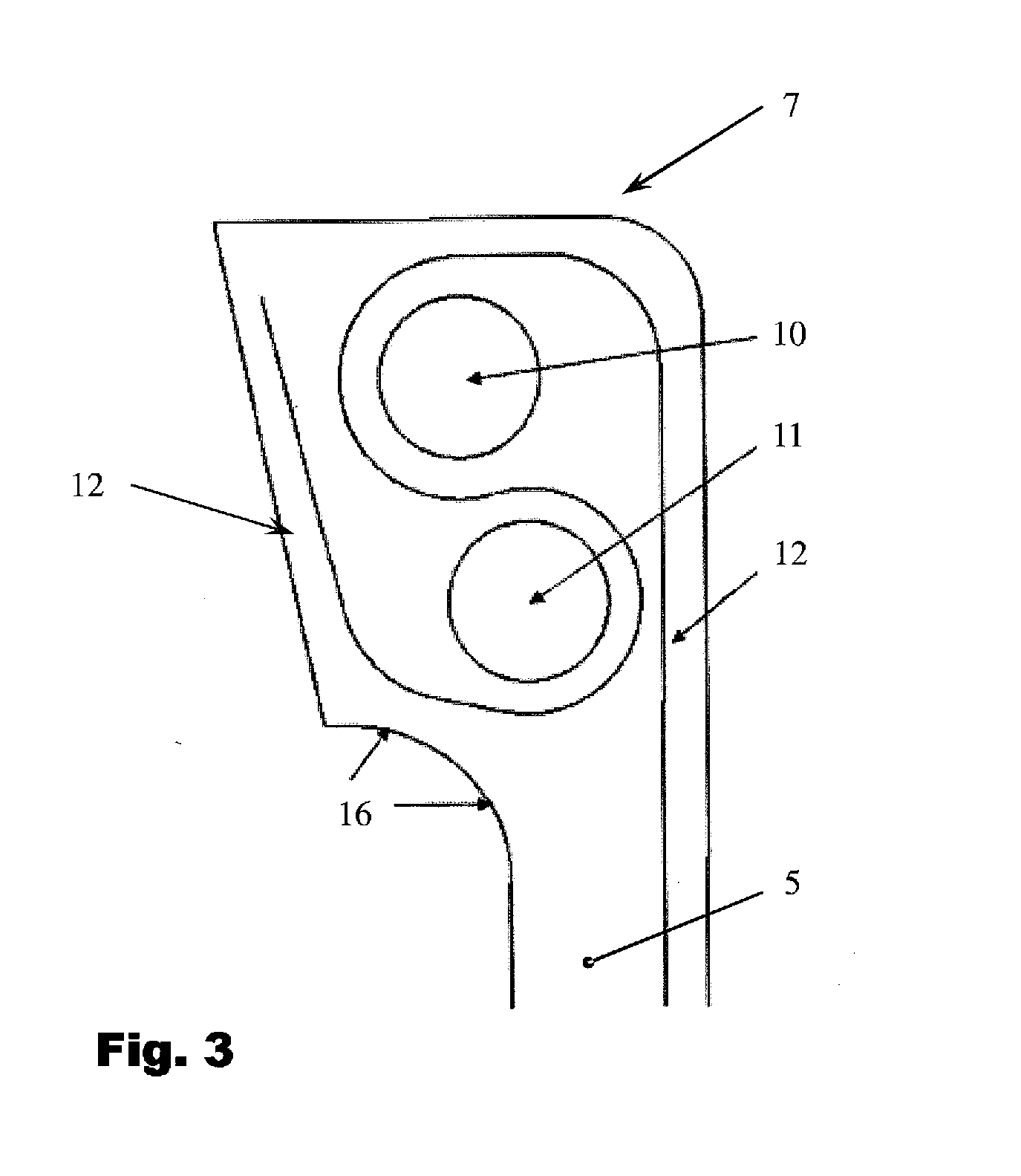

The invention is directed to a pneumatic spring device (3) of a rail vehicle (1). The device includes a pneumatic spring bellows (5), which is provided on both ends with a bead ring (6, 7), wherein the bead ring (6, 7) has a core made of two core rings (10, 11, 13, 14) positioned separately in the bead ring and the reinforcement elements (12) are guided in an S shape between the core rings and loop around the latter.

Owner:CONTITECH LUFTFEDERSYST

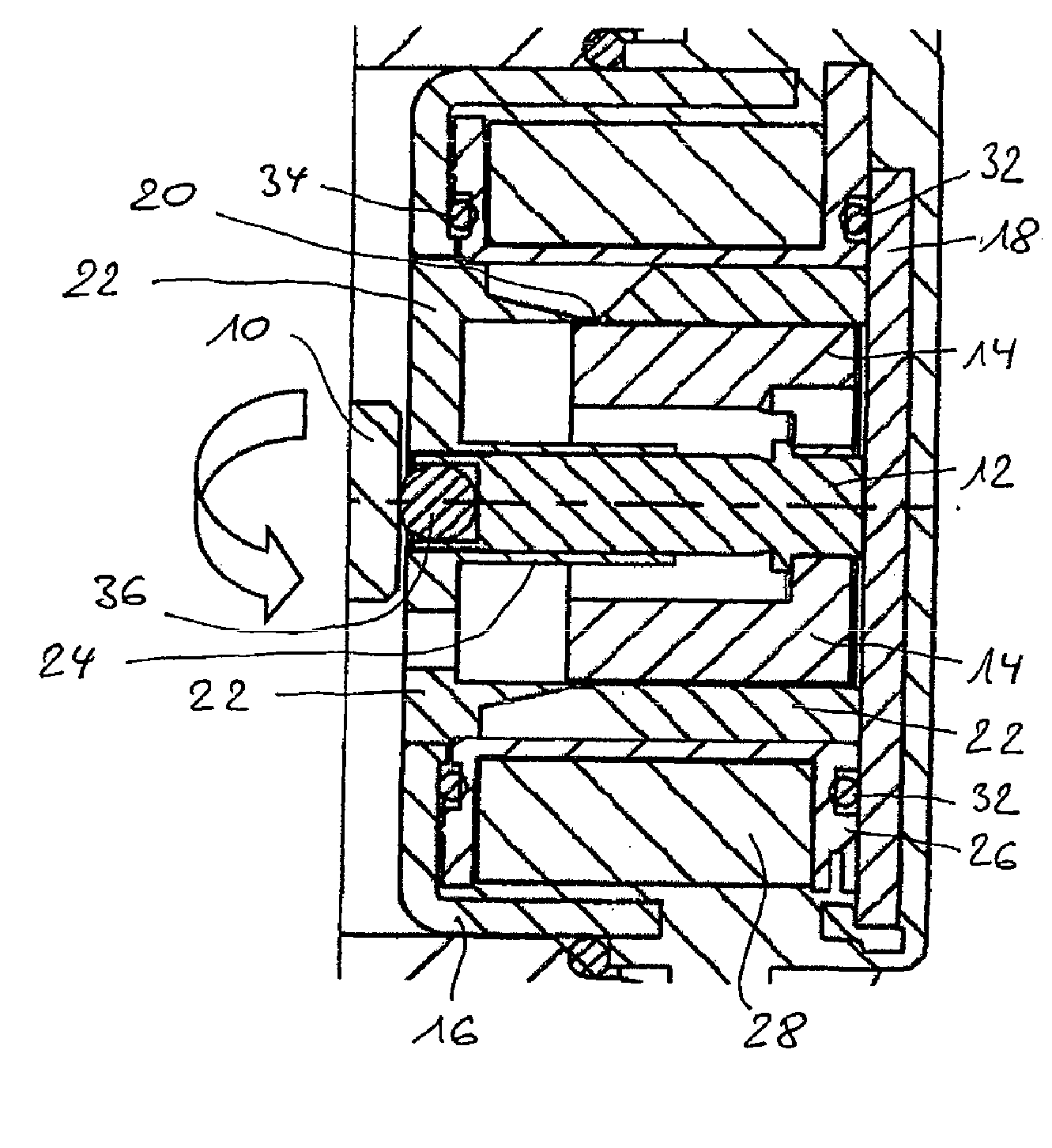

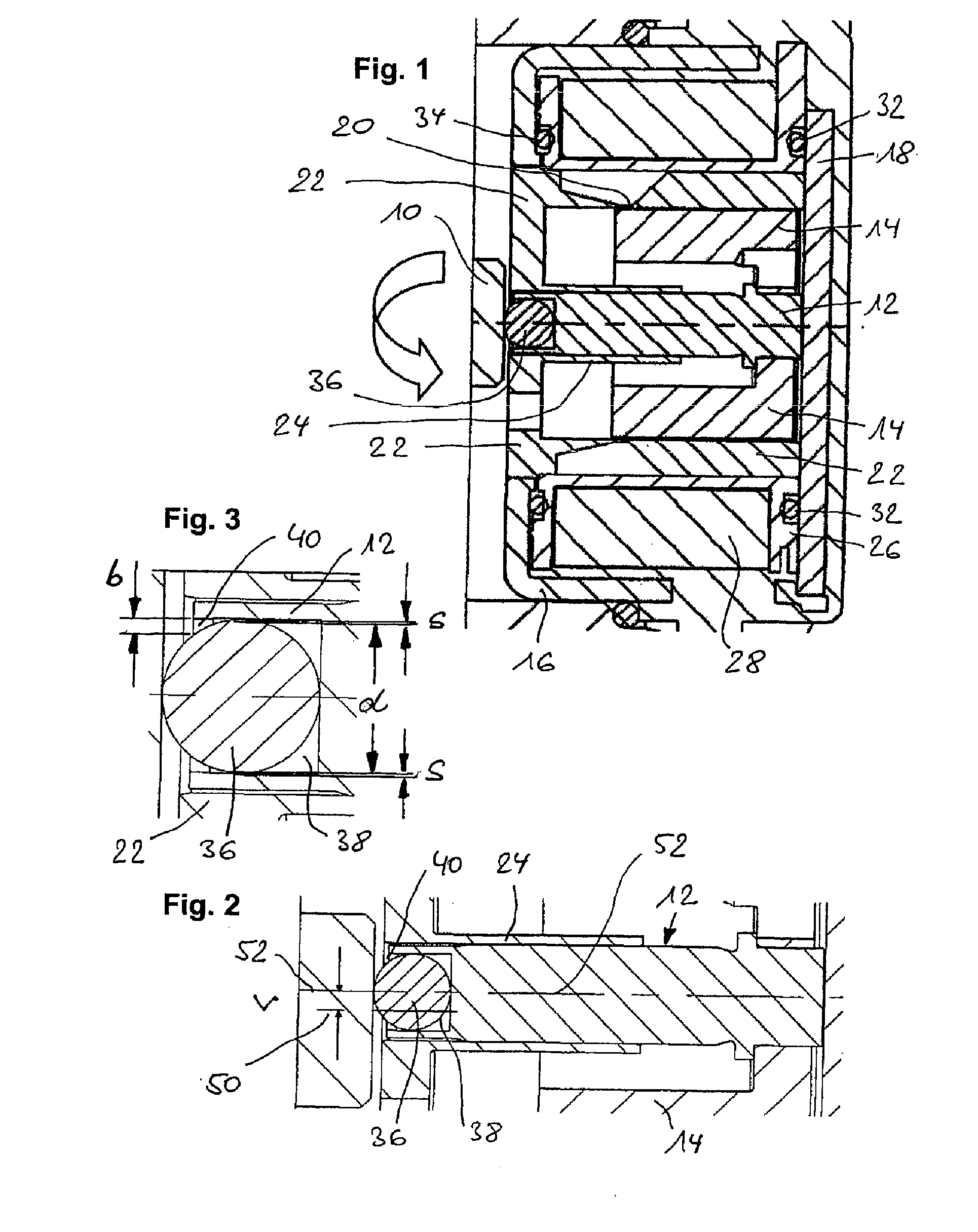

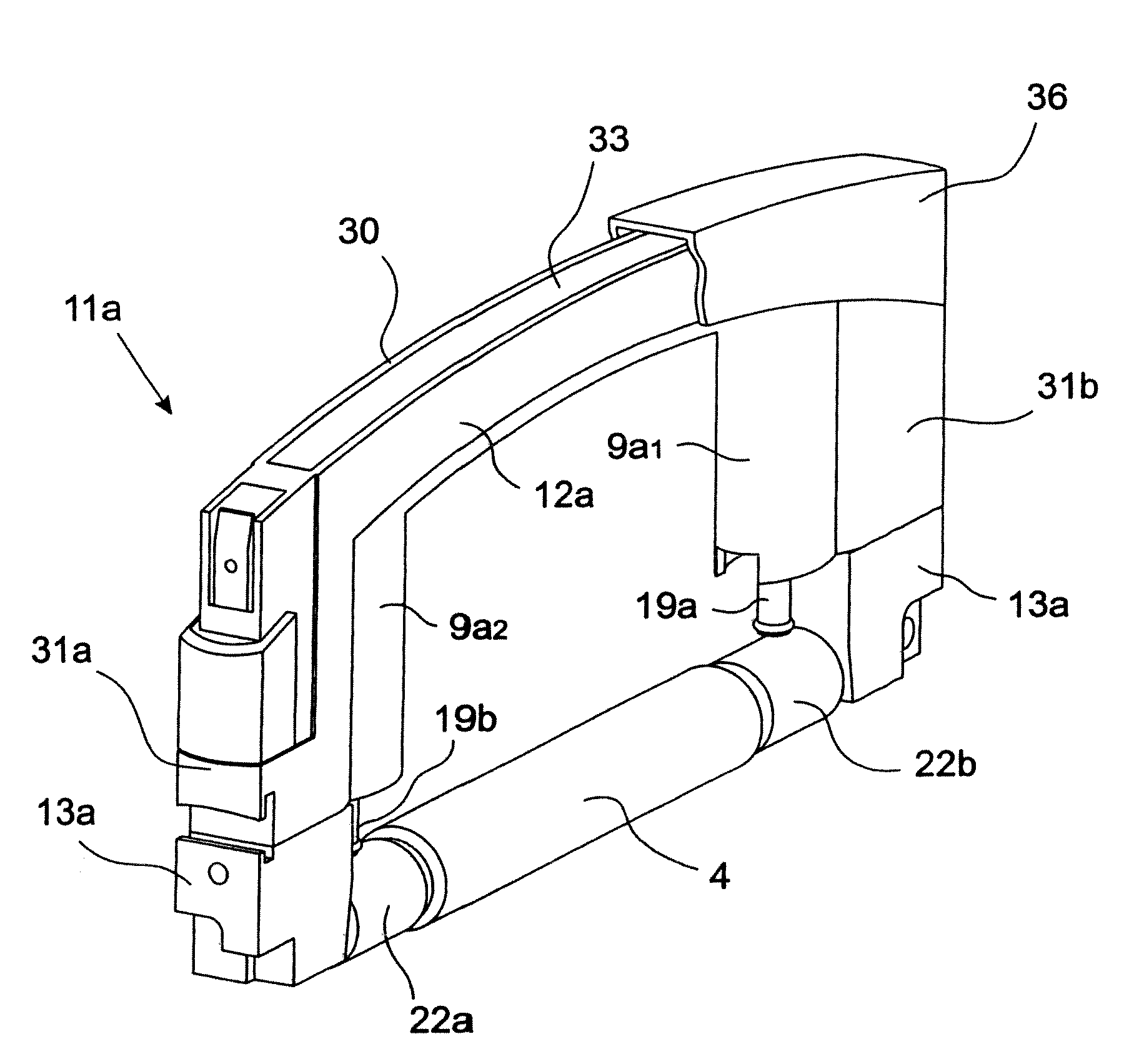

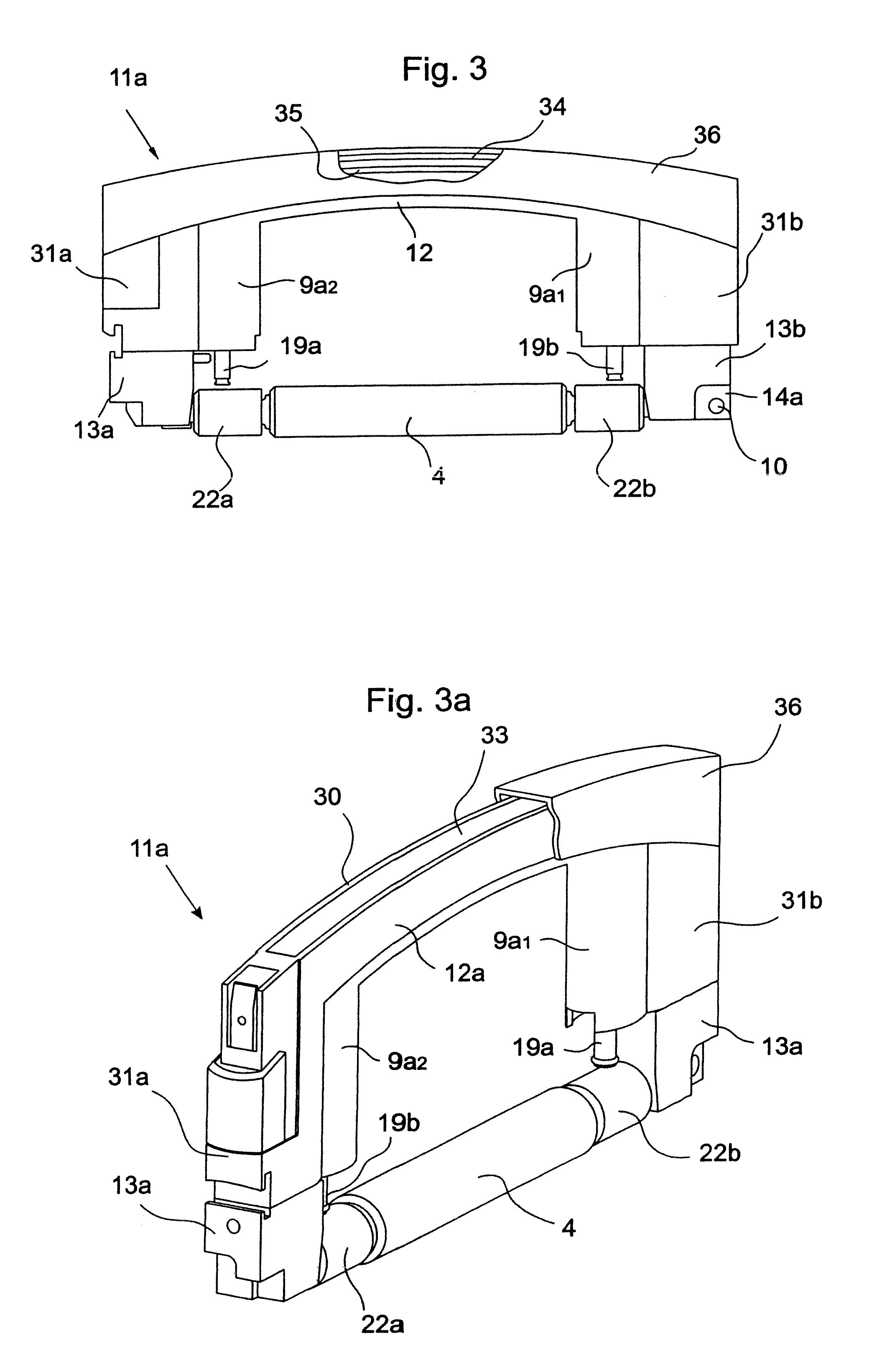

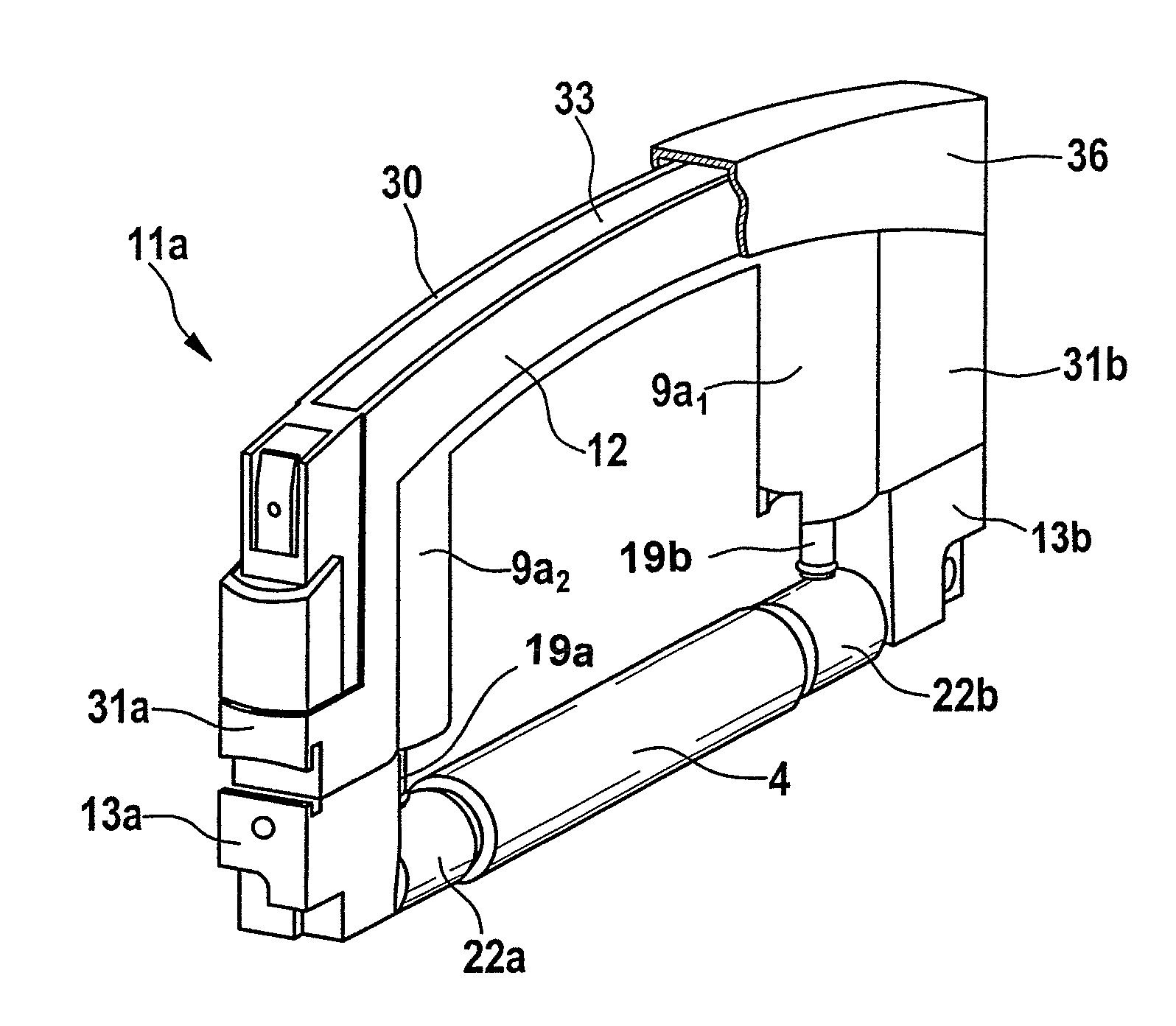

Device on a draw frame having a drafting system for textile fibre slivers

InactiveUS20090049652A1Simple and quick and reliableReliable force transmissionDrafting machinesBall bearingCoupling

In a device on a draw frame having a drafting system for textile fibre slivers with weighting of the upper rolls of the drafting system which comprises roll pairs arranged one behind the other, the pairs having lower and upper rolls, the rotating journals at the ends of the upper roll are mounted by means of bearing elements and the bearing elements each have at least one deep-groove ball bearing having an immovable outer housing (outer ring) and an internal rotational body (inner ring). In order to provide a structurally simple way in which the bearing housings can be mounted on or removed from the presser roll in a simple, quick and reliable manner, the bearing elements are in the form of deep-groove ball bearings and there is a coupling between the journal and the rotational body.

Owner:TRUETZSCHLER GMBH & CO KG

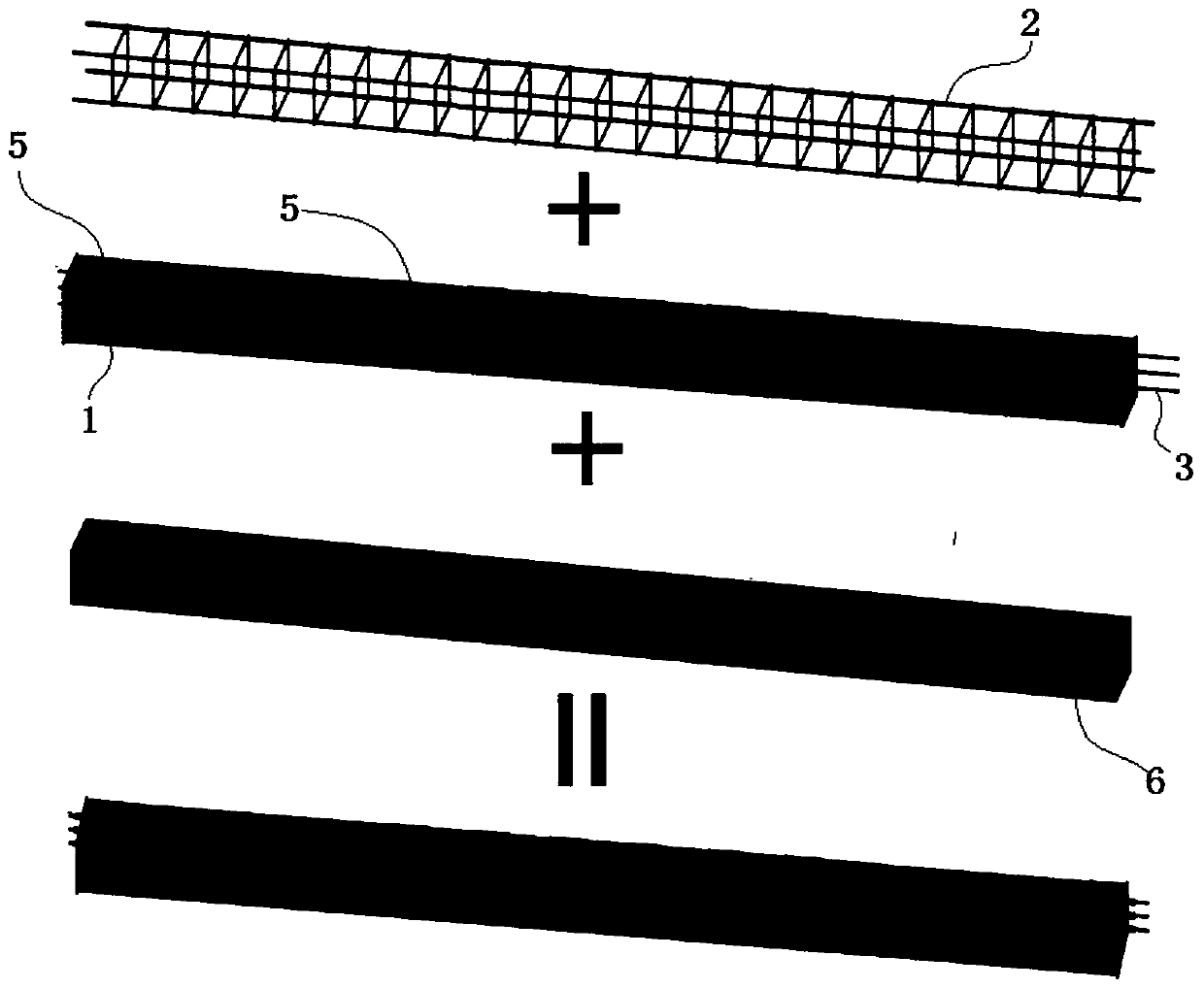

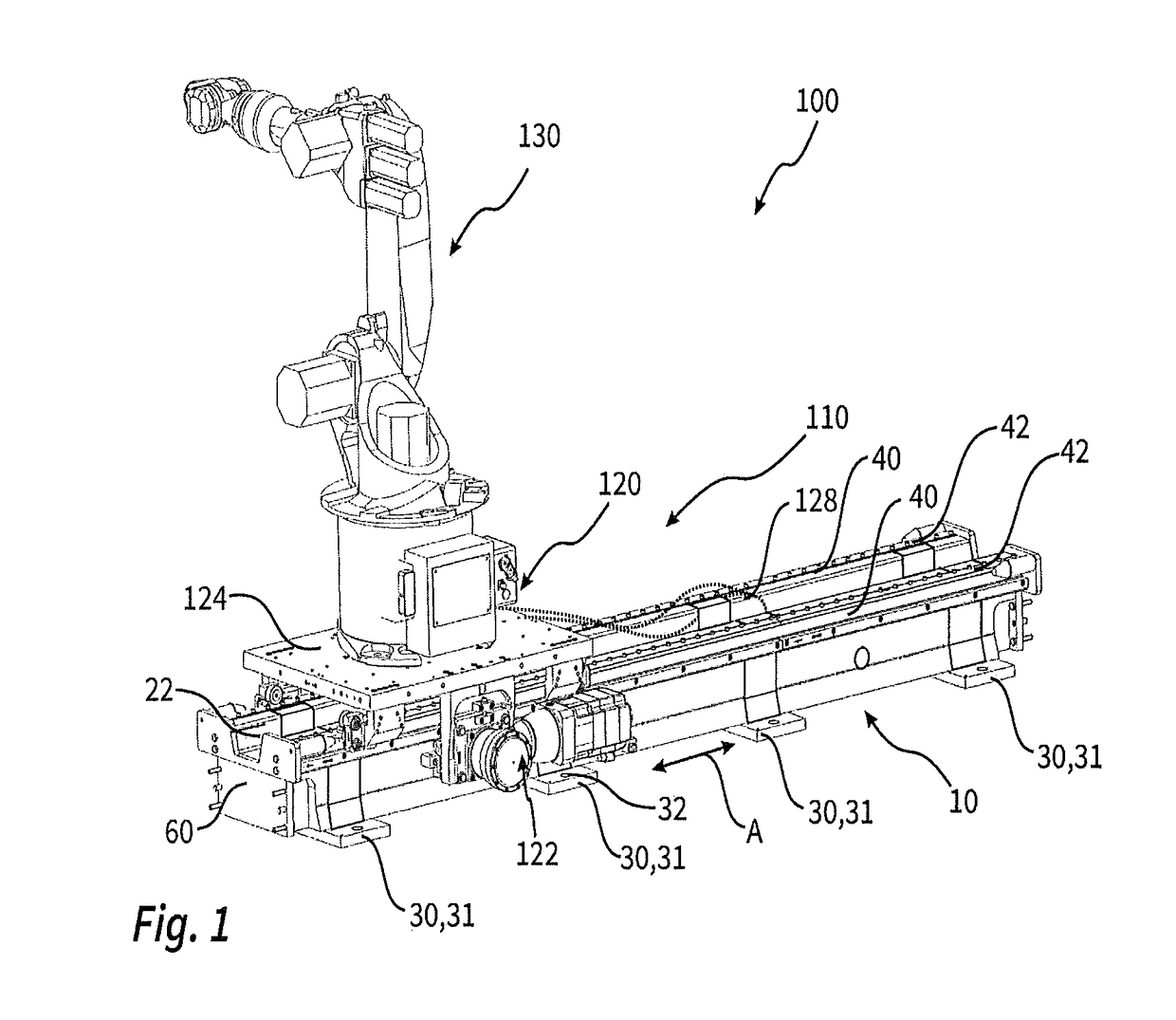

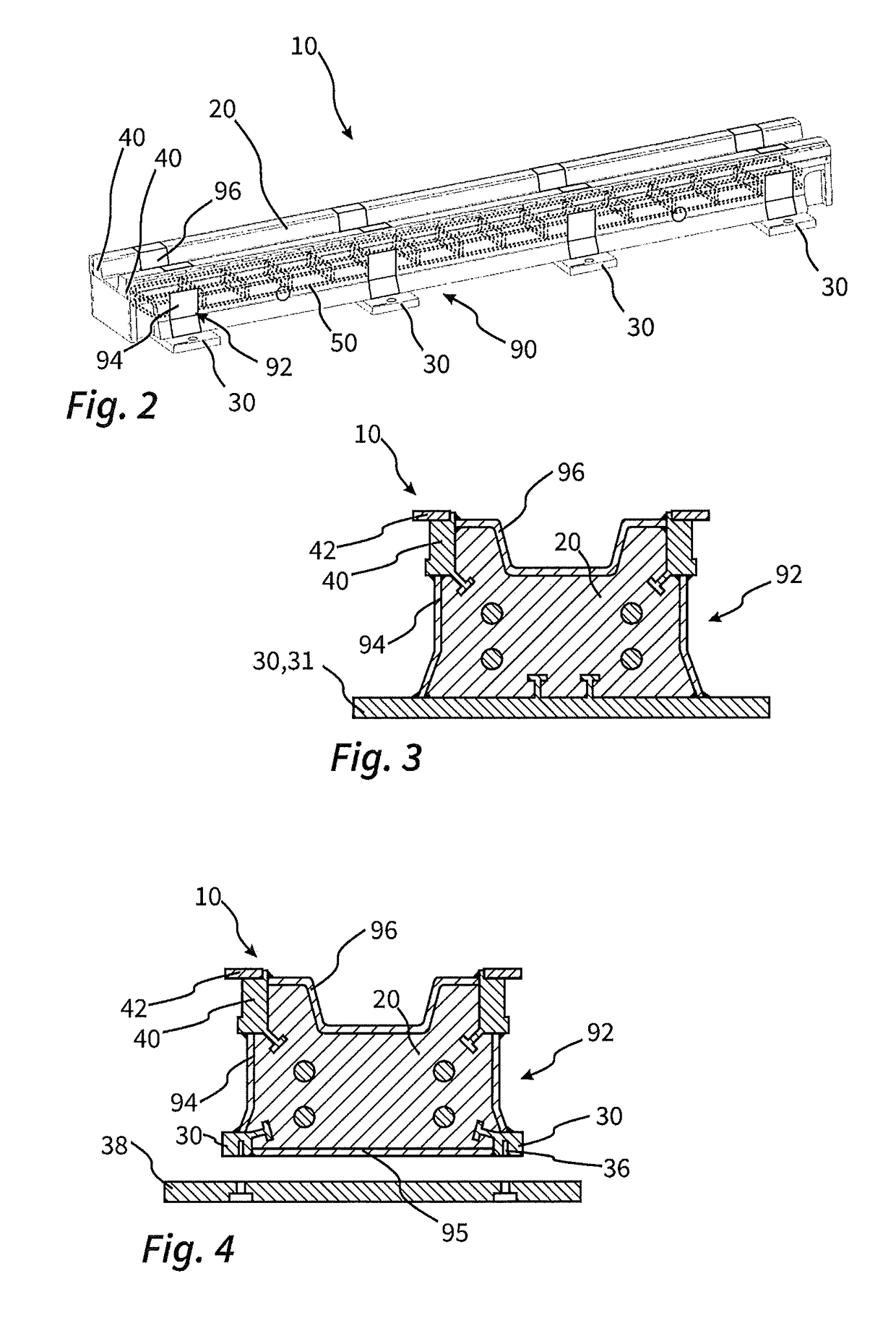

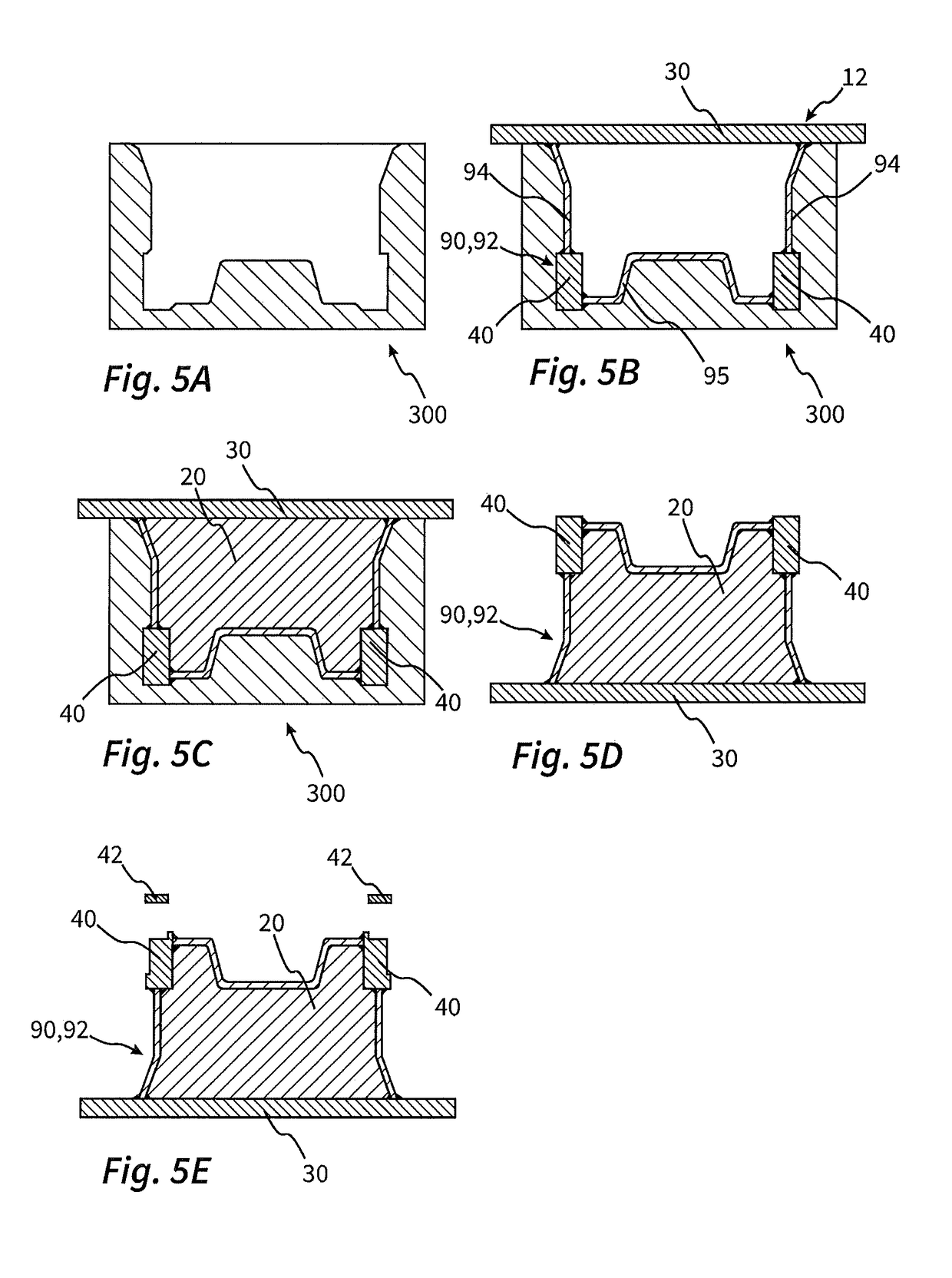

Support rail for a robot platform that is displaceable in a translatory manner, and displacement system and robot system having such a support rail

InactiveUS20190047138A1Cost advantageFlexibility advantageProgramme-controlled manipulatorRailsRobotic systemsExoskeleton structure

A support rail for a robotic platform having a support structure of concrete, a lower metallic connection flange and an upper connection flange or a guide rail disposed on an external side of the support structure. The lower connection flange, on the one hand, and the upper connection flange or the guide rail, respectively, on the other hand, are connected by a rigid metallic exoskeleton structure provided on the external side of the support structure and surrounding at least partially or completely the support structure.

Owner:IPR - INTELLIGENTE PERIPHERIEN FUR ROBOTER

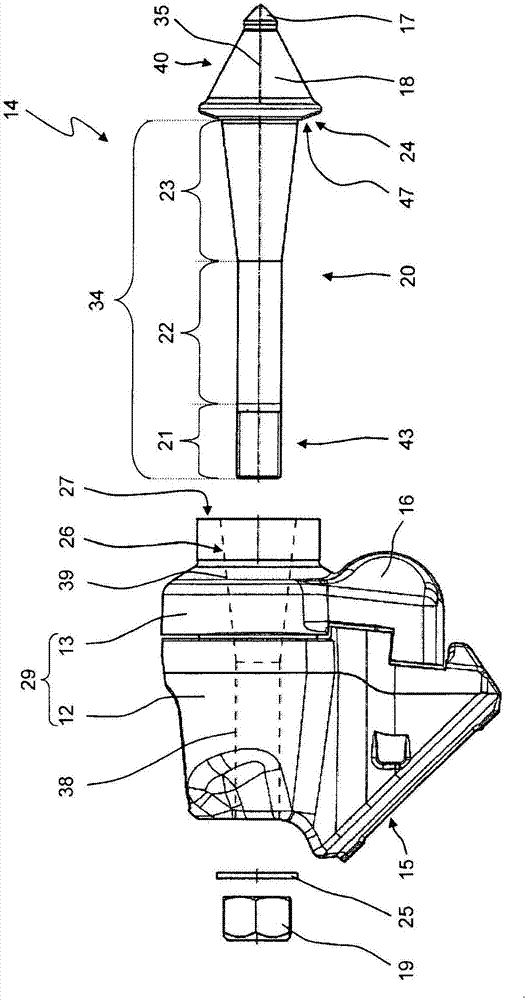

Chisel holder

ActiveUS9719348B2Reliable force transmissionReduce insertion loadDrill bitsSlitting machinesChiselRoad surface

Owner:WIRTGEN GMBH

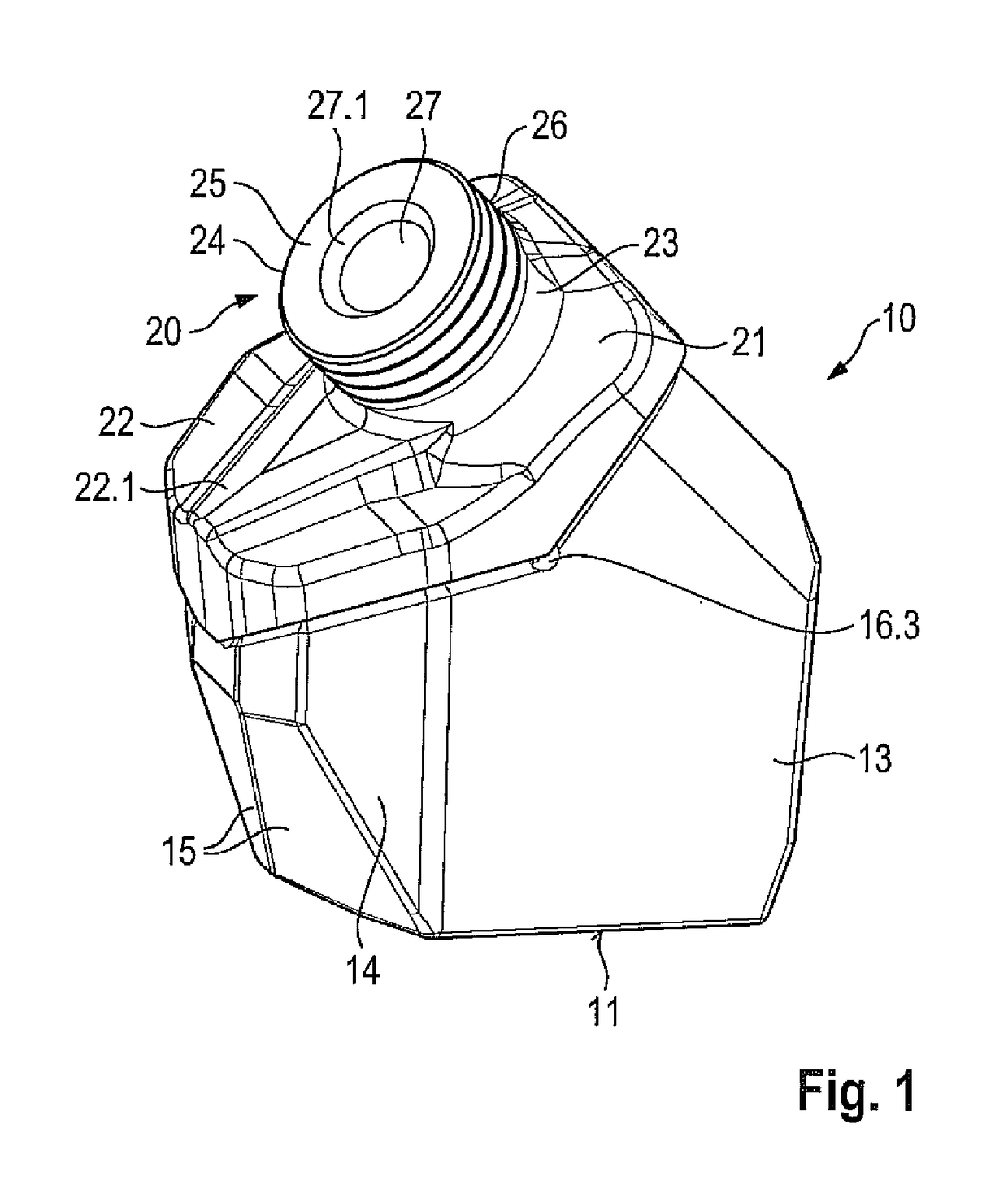

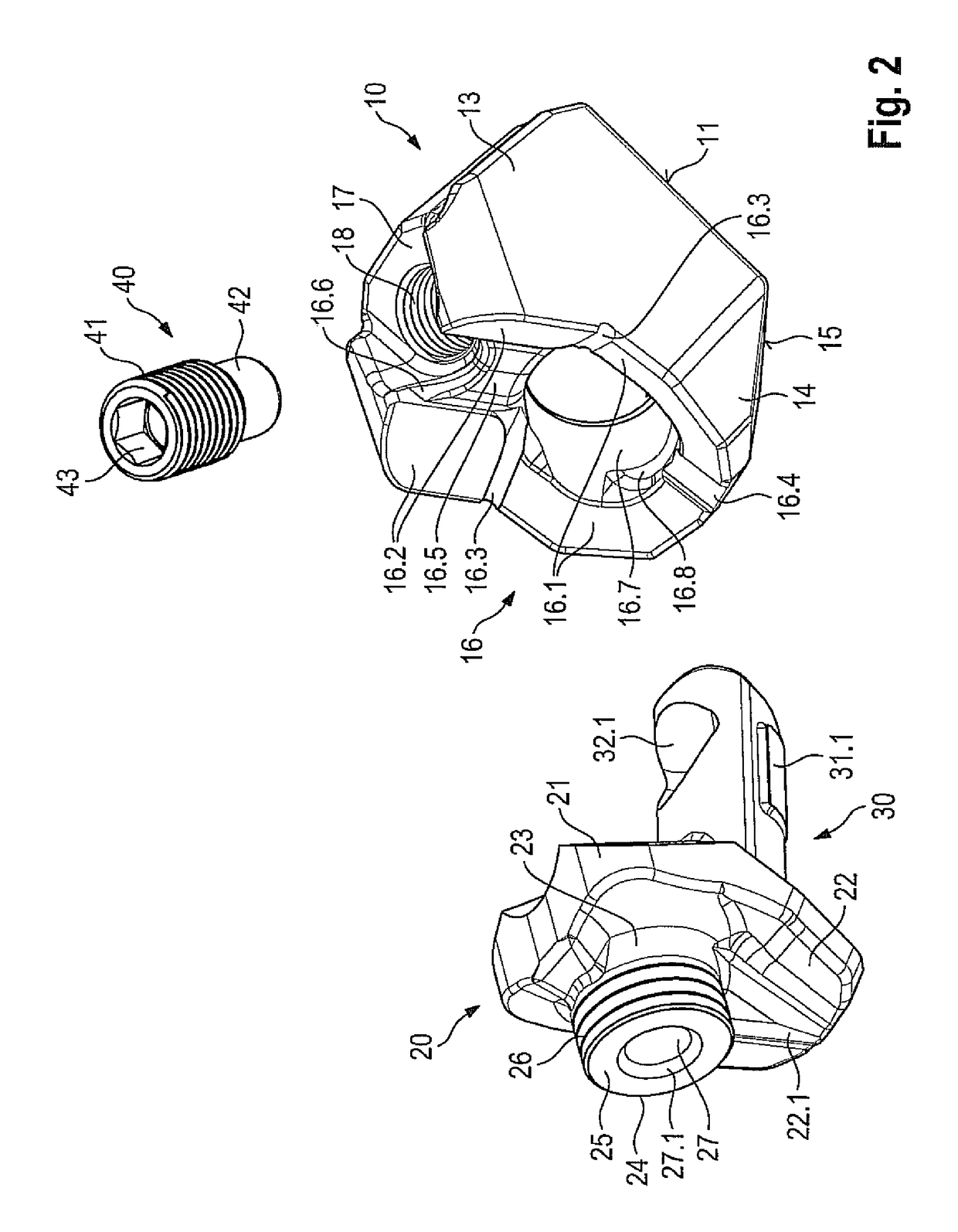

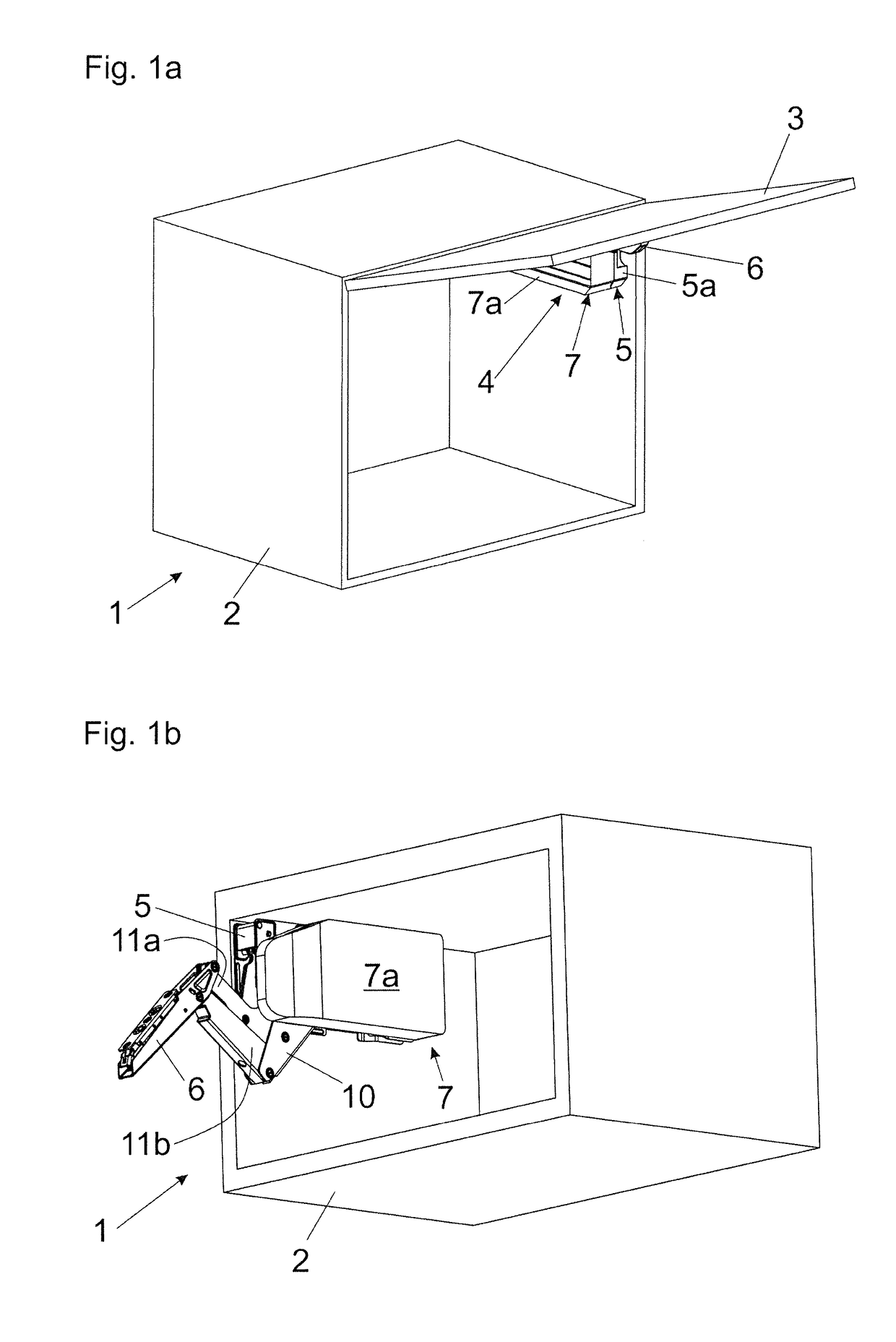

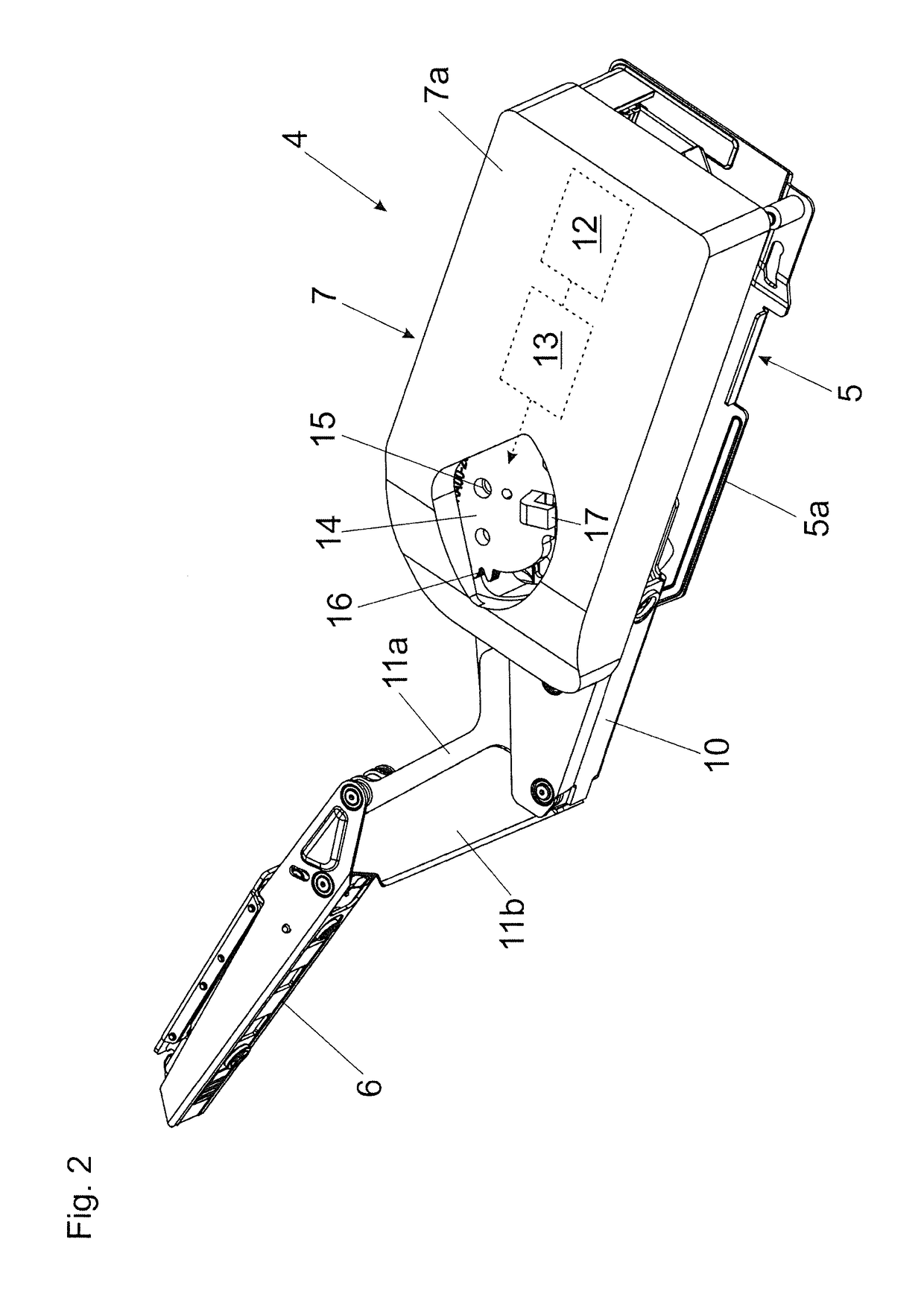

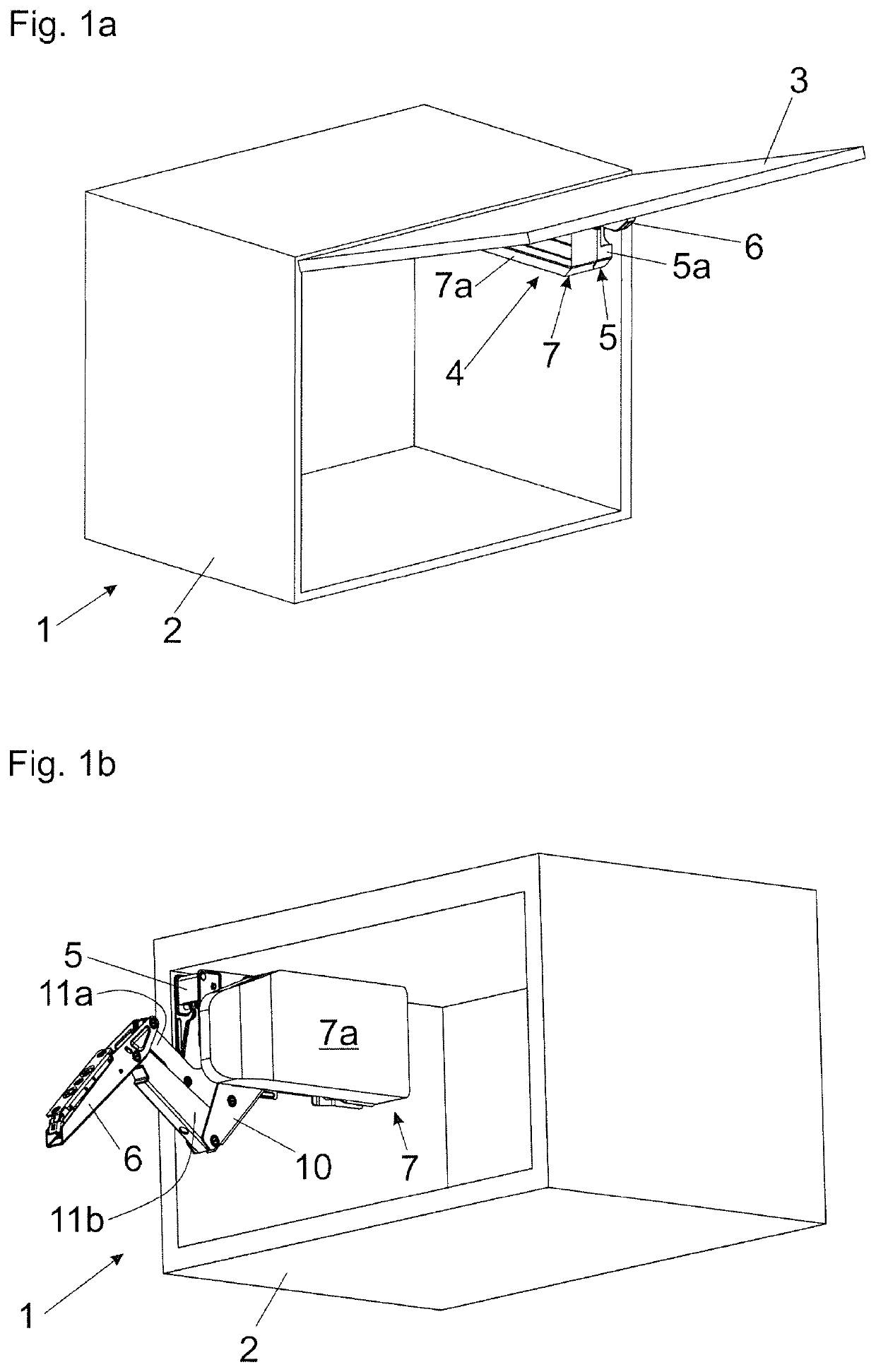

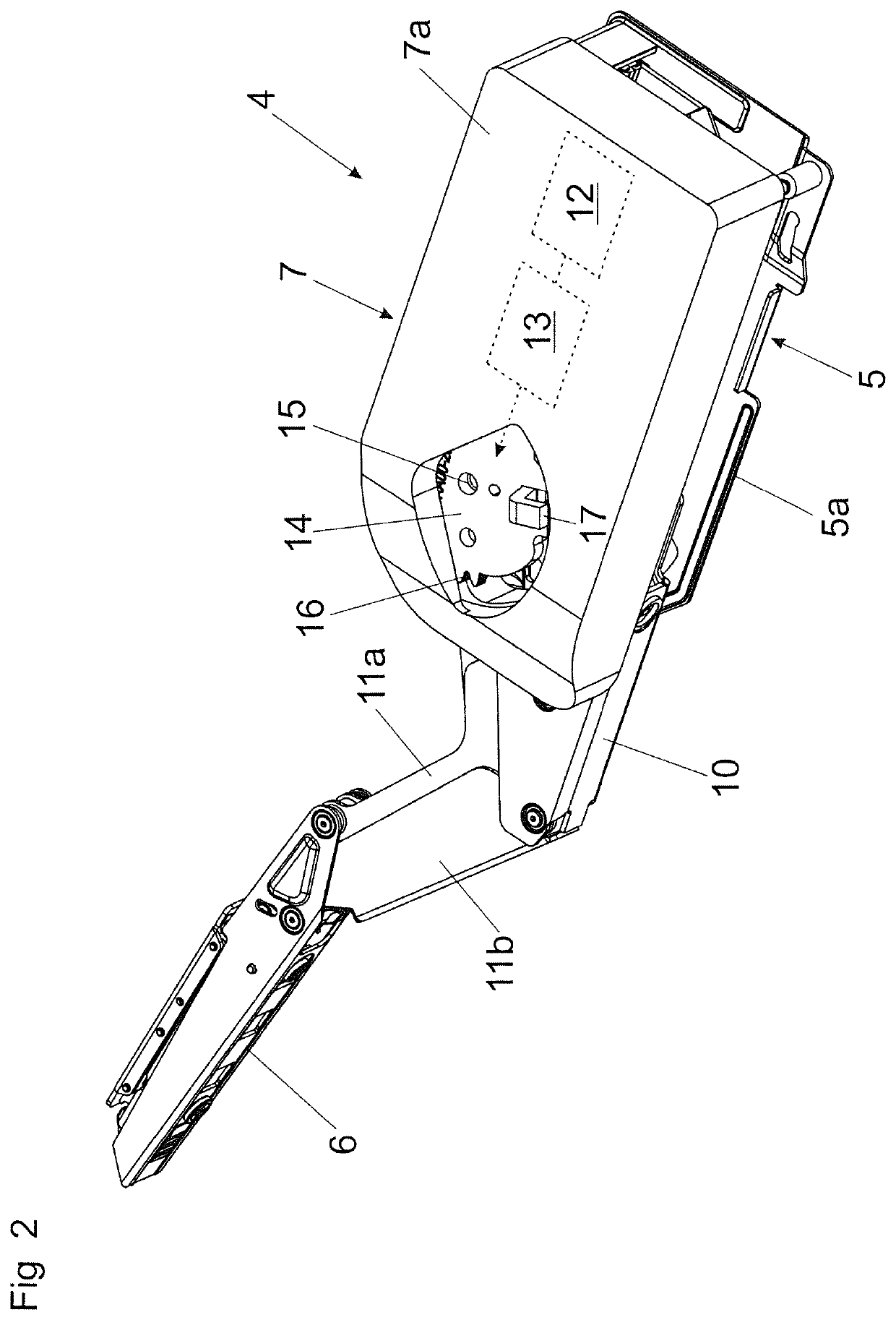

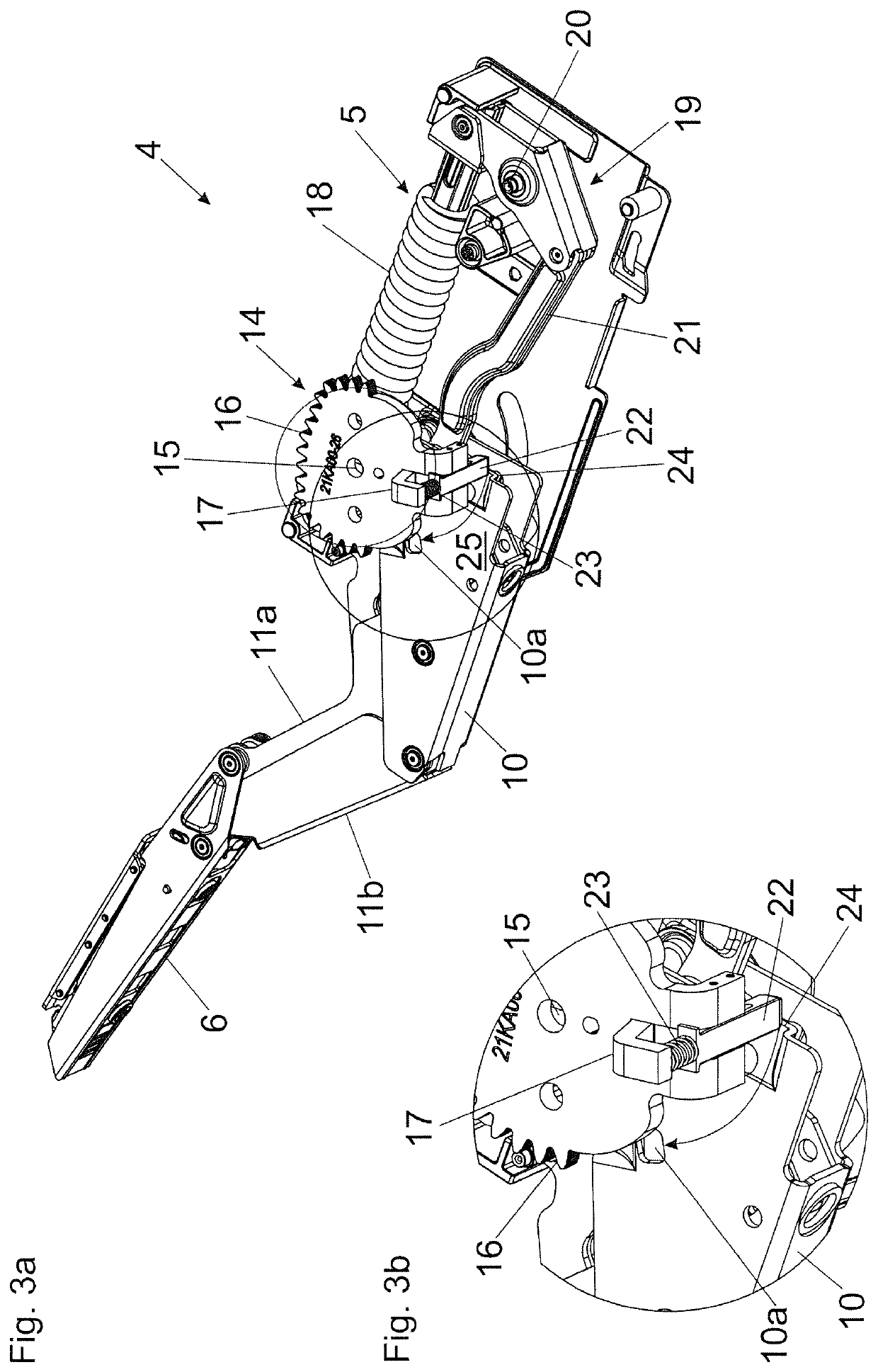

Furniture drive system

ActiveUS20190010747A1Reliable force transmissionPower-operated mechanismWing openersControl armEngineering

A furniture drive system includes a mechanical control unit having a pivotably mounted control arm for moving a movable furniture part, a spring device for applying force to the control arm, and a movably mounted control part having a transmission opening for transmitting a force from the spring device to the control arm. An electrical drive unit has an electric motor for moving the movable furniture part, and a driver to be driven by the electric motor for transmitting a torque of the electric motor to the mechanical control unit. The driver can be inserted into the transmission opening, and the electrical drive unit and the mechanical control unit are designed as separate assemblies and can be fastened to each other. A contact surface for the driver is arranged laterally adjacent to the transmission opening and the driver is preloaded toward the contact surface by a force store.

Owner:JULIUS BLUM GMBH

Continuously variable transmission apparatus

The present invention relates to a continuously variable transmission apparatus, which is characterized by comprising: an input shaft transferred with torque inputted from the outside; a plurality of driven gears which are arranged around the circumference of the input shaft as a certain phase difference and transferred with the power from the input shaft; a variable cam of which the turning radius can be varied by an external load; a variable input link which is coupled to and transferred with the torque of the input haft and allows the rotation thereof; a one-way clutch which is transferred undirectionally with the bidirectional torque to be transferred to the driven gears, respectively, and rotates the driven gears in one direction; a plurality of cam shafts which contact the one-way direction clutch internally or externally; and a plurality of output links, each of which one end revolves together with the variable cam around the center of rotation of the variable input link and the other ends of which are coupled to the cam shafts respectively and allow swiveling thereof.

Owner:SHIN HYUN WOO +1

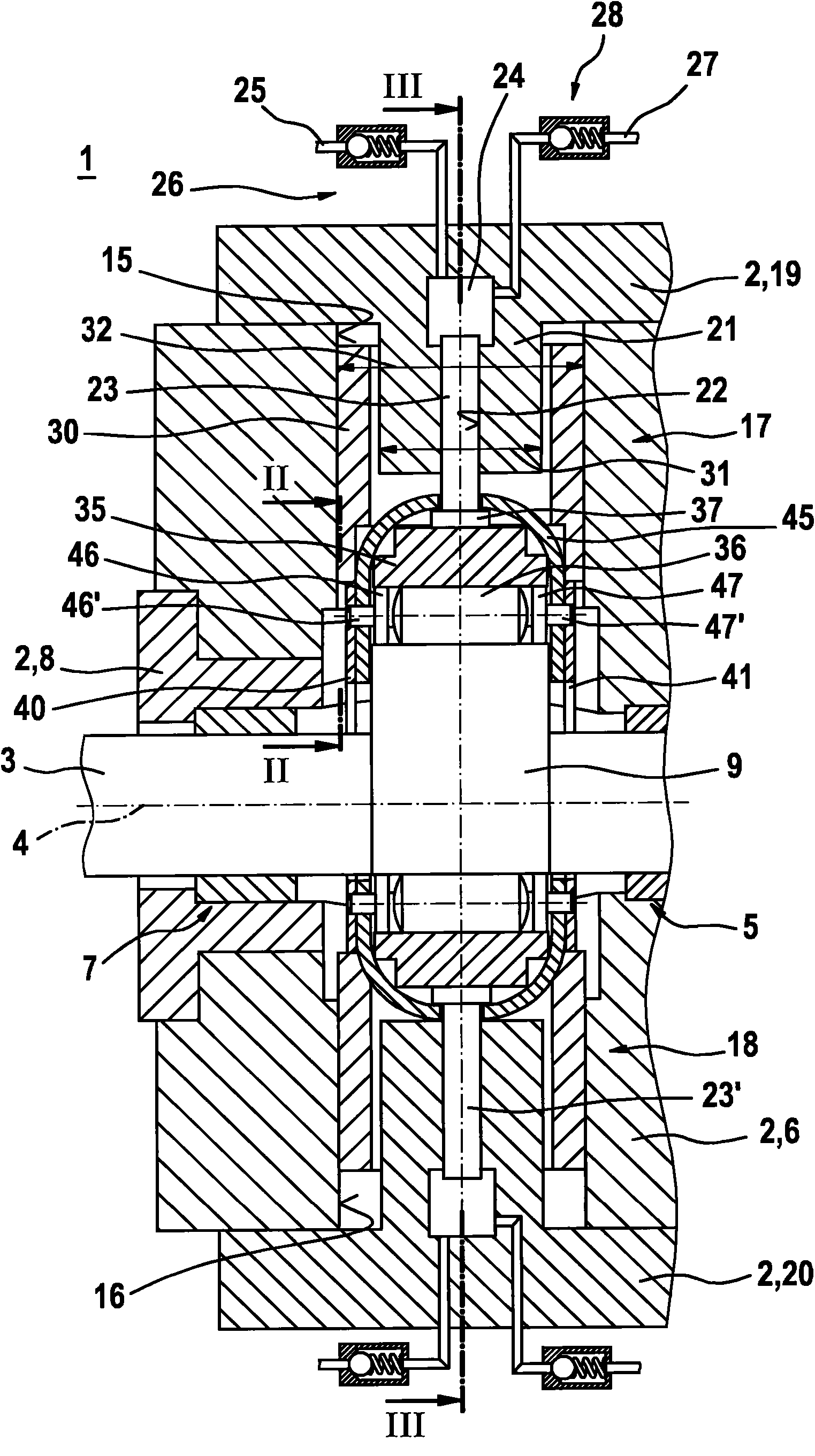

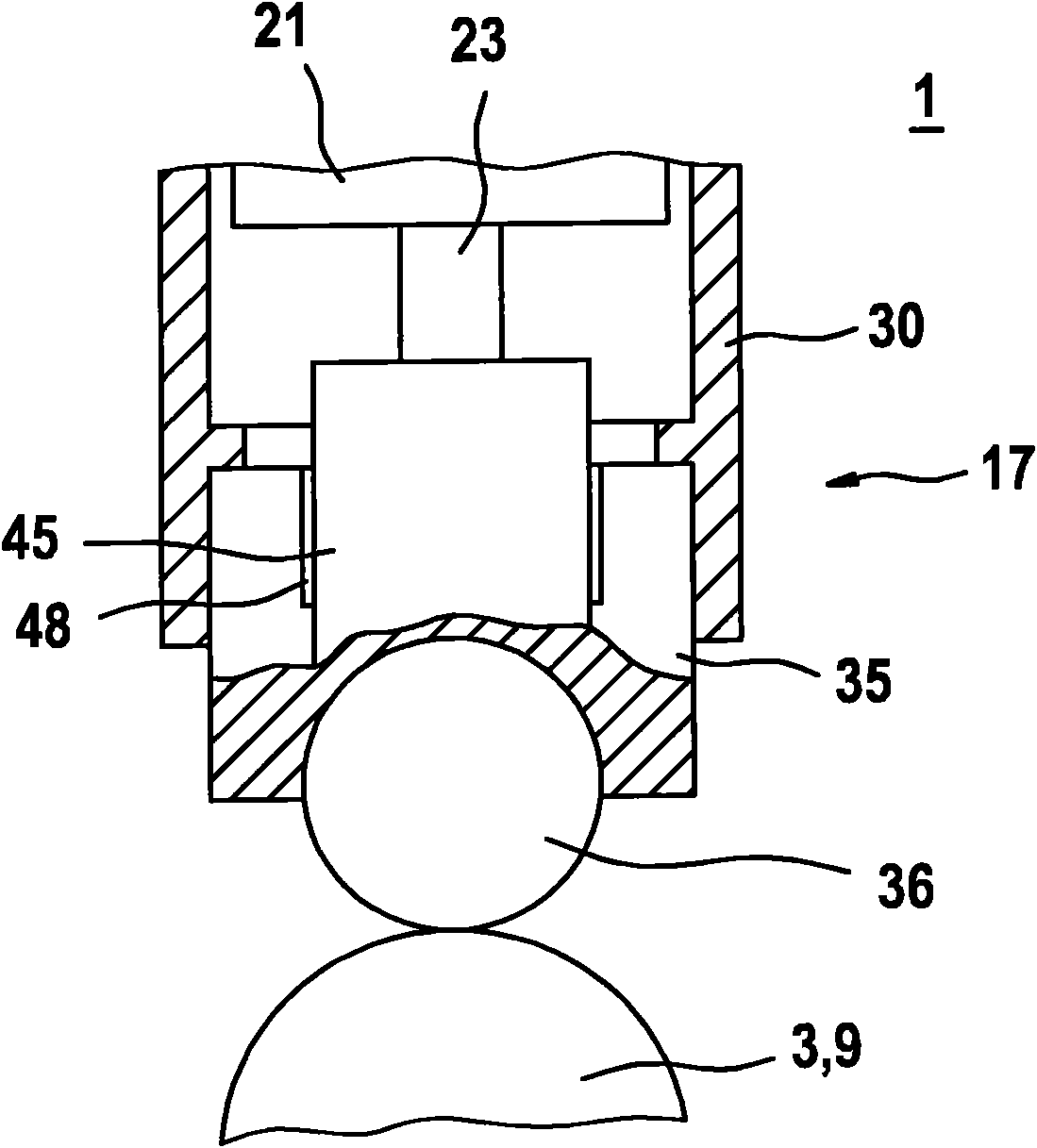

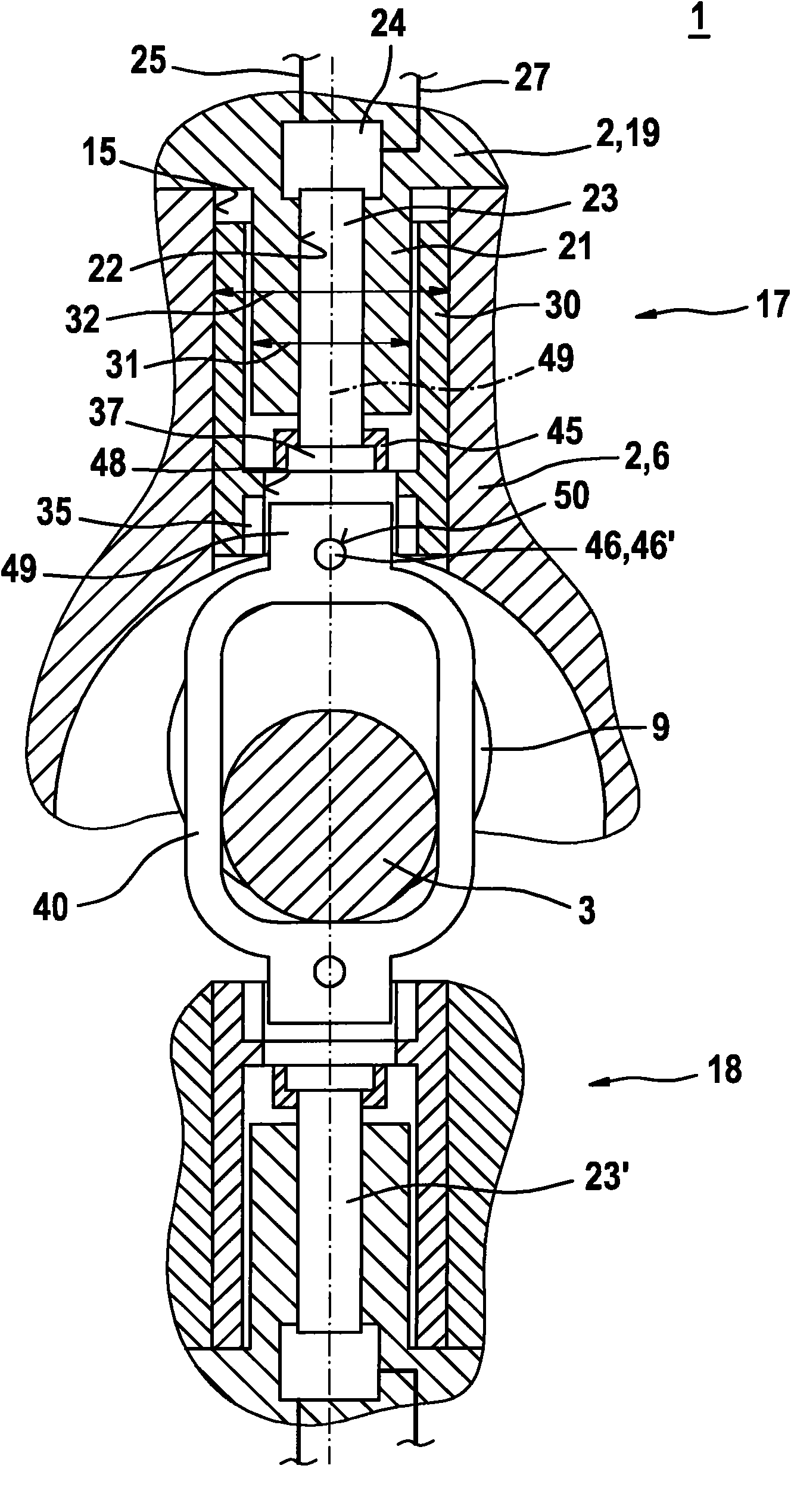

High-pressure pump

InactiveCN101978158ASimple designFavorable configurationFuel injecting pumpsPositive-displacement liquid enginesCombustionDrive shaft

A high-pressure pump (1) is used especially as a fuel pump for fuel injection systems in air-compressing, self-igniting internal combustion engines. Said high-pressure pump (1) comprises a first pump subassembly (17), a second pump subassembly (18), and a drive shaft (3). The first pump subassembly (17) is located at least approximately across from the second pump subassembly (18) in relation to the drive shaft (3). At least one cam (9) for driving both the first pump subassembly (17) and the second pump subassembly (18) is provided on the drive shaft (3). Furthermore, spring elements (40, 41) are provided which are connected to a piston (23) of the first pump subassembly (17) by means of a retaining brace (45) and are connected to a piston (23) of the second pump subassembly (18). The spring elements (40, 41) are mounted in a biased manner such that the two pistons (23, 23) return without separate return springs or retracting springs during operation of the high-pressure pump (1).

Owner:ROBERT BOSCH GMBH

Device on a drafting system of a draw frame for textile fibre slivers

InactiveUS20090052824A1Simple and quick and reliableReliable force transmissionDrafting machinesBearing componentsTextile fiberRolling-element bearing

In a device on a drafting system for textile fibre slivers with weighting of the upper rolls of the drafting system which comprises roll pairs arranged one behind the other, the pairs having lower and upper rolls, the rotating journals at the ends of the upper roll are mounted by means of bearing elements and the bearing elements each have at least one rolling-element bearing having an immovable outer housing (outer ring) and an internal rotational body (inner ring). In order to provide a structurally simple way in which the bearing housings can be mounted on or removed from the presser roll in a simple, quick and reliable manner, the bearing elements are in the form of rolling-element bearings and there is a coupling between the journal and the rotational body.

Owner:TRUETZSCHLER GMBH & CO KG

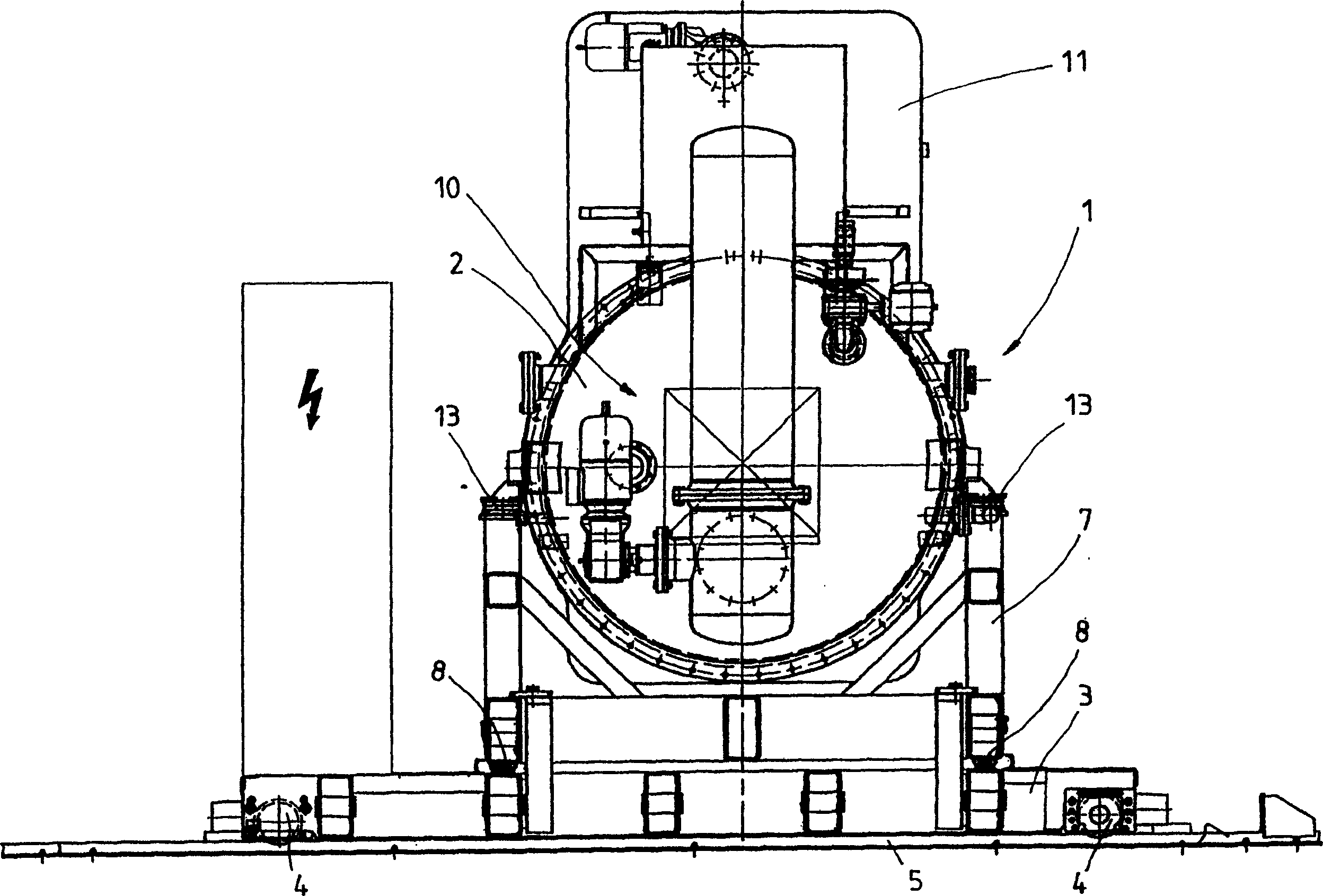

Appartus for transporting metal working piece

InactiveCN1536310AHigh vertical forceReliable force transmissionCharge manipulationFurnace typesEngineeringMetal working

Owner:IPSEN INT INC

Furniture drive system

ActiveUS10590692B2Reliable force transmissionPower-operated mechanismWing openersControl armTorque transmission

A furniture drive system includes a mechanical control unit having a pivotably mounted control arm for moving a movable furniture part, a spring device for applying force to the control arm, and a movably mounted control part having a transmission opening for transmitting a force from the spring device to the control arm. An electrical drive unit has an electric motor for moving the movable furniture part, and a driver to be driven by the electric motor for transmitting a torque of the electric motor to the mechanical control unit. The driver can be inserted into the transmission opening, and the electrical drive unit and the mechanical control unit are designed as separate assemblies and can be fastened to each other. A contact surface for the driver is arranged laterally adjacent to the transmission opening and the driver is preloaded toward the contact surface by a force store.

Owner:JULIUS BLUM GMBH

Device on a drafting system of a draw frame for textile fibre slivers

InactiveUS7836558B2Simple and quick and reliableReliable force transmissionDrafting machinesBearing componentsTextile fiberRolling-element bearing

In a device on a drafting system for textile fiber slivers with weighting of the upper rolls of the drafting system which comprises roll pairs arranged one behind the other, the pairs having lower and upper rolls, the rotating journals at the ends of the upper roll are mounted by means of bearing elements and the bearing elements each have at least one rolling-element bearing having an immovable outer housing (outer ring) and an internal rotational body (inner ring). In order to provide a structurally simple way in which the bearing housings can be mounted on or removed from the presser roll in a simple, quick and reliable manner, the bearing elements are in the form of rolling-element bearings and there is a coupling between the journal and the rotational body.

Owner:TRUETZSCHLER GMBH & CO KG

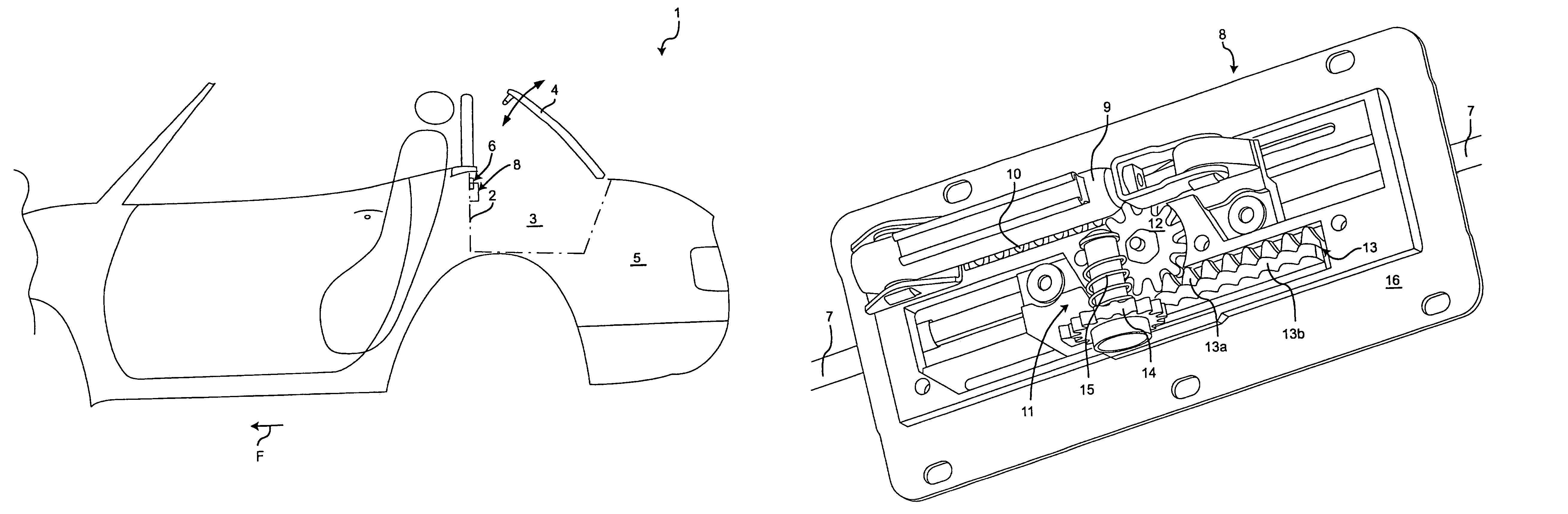

Convertible vehicle

InactiveUS7681938B2Reliable force transmissionSimple designEngine sealsConstruction fastening devicesConvertibleCoupling

The invention relates to a cabriolet vehicle having a roof that can be stored underneath a cover part in an open position, at least two displaceable engagement organs and an associated drive being provided to secure a closed cover part. The drive interacts with the engagement organs to transmit a driving force through a force transmission element having a component that extends in the transverse direction of the vehicle. A driven organ can lie in a transverse direction of the vehicle and generally on the same plane as the force transmission elements. In addition, a gear mechanism can be displaced by a rectilinear coupling organ that is connected to the force transmission element and runs parallel to the drive organ.

Owner:VALMET AUTOMOTIVE

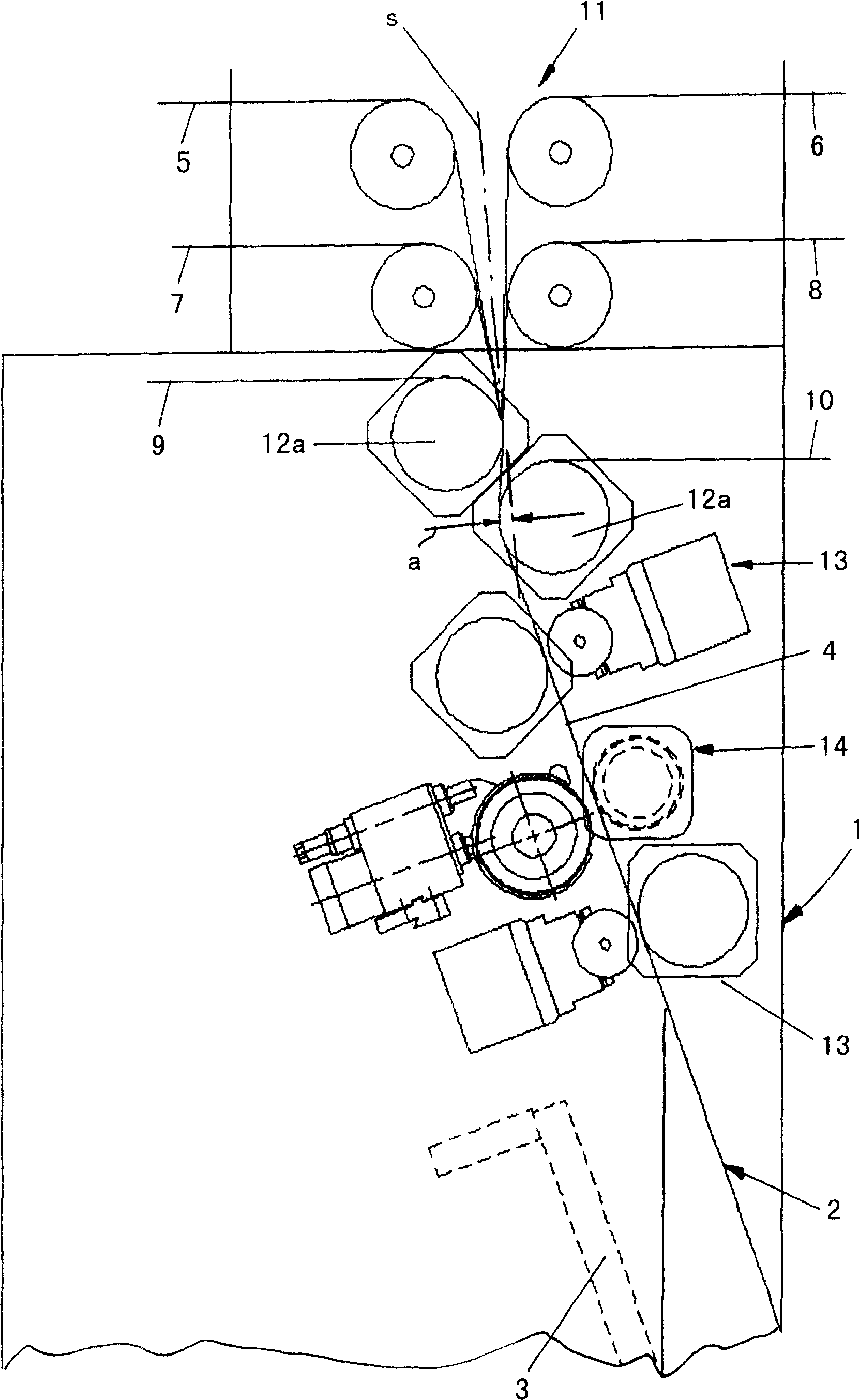

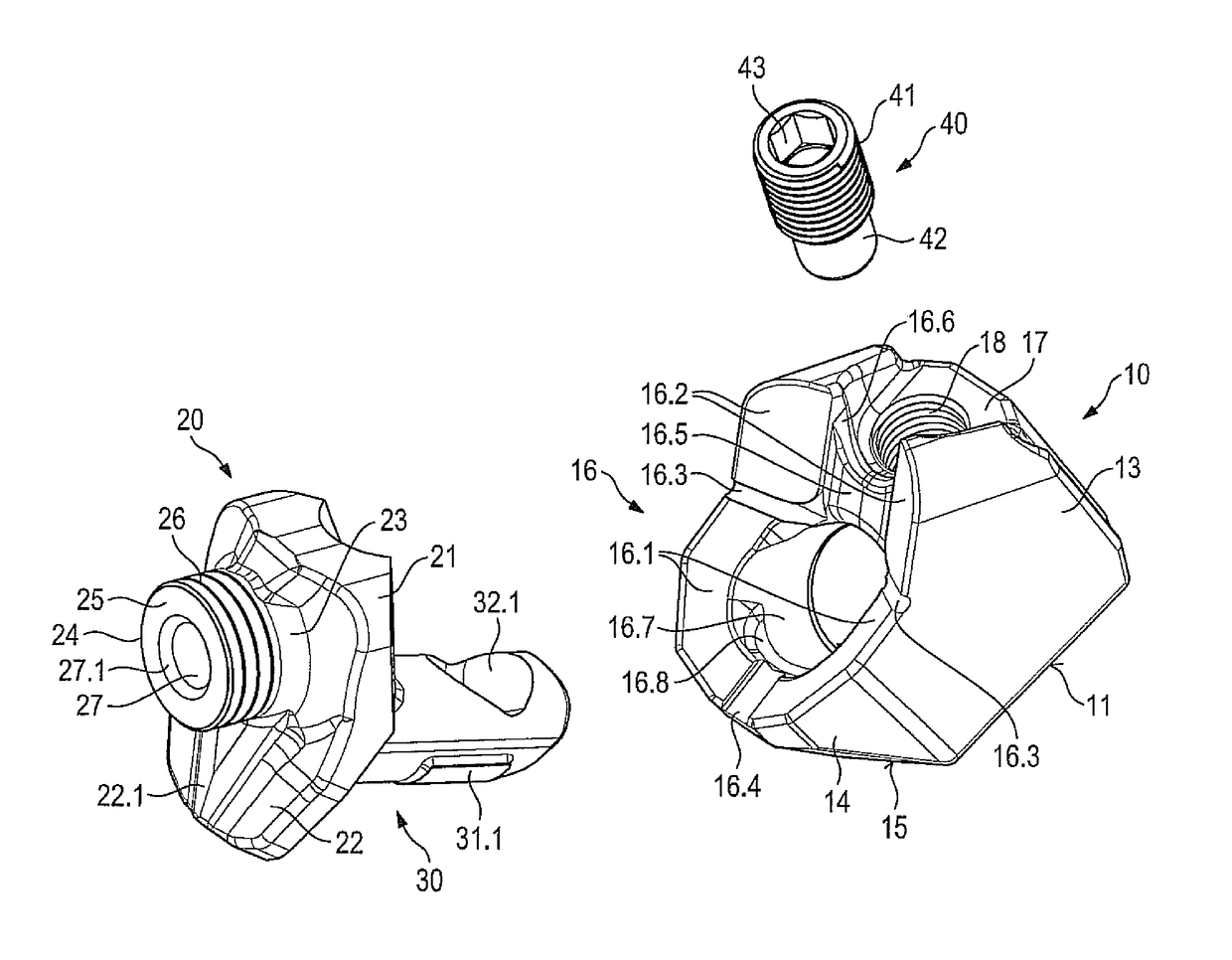

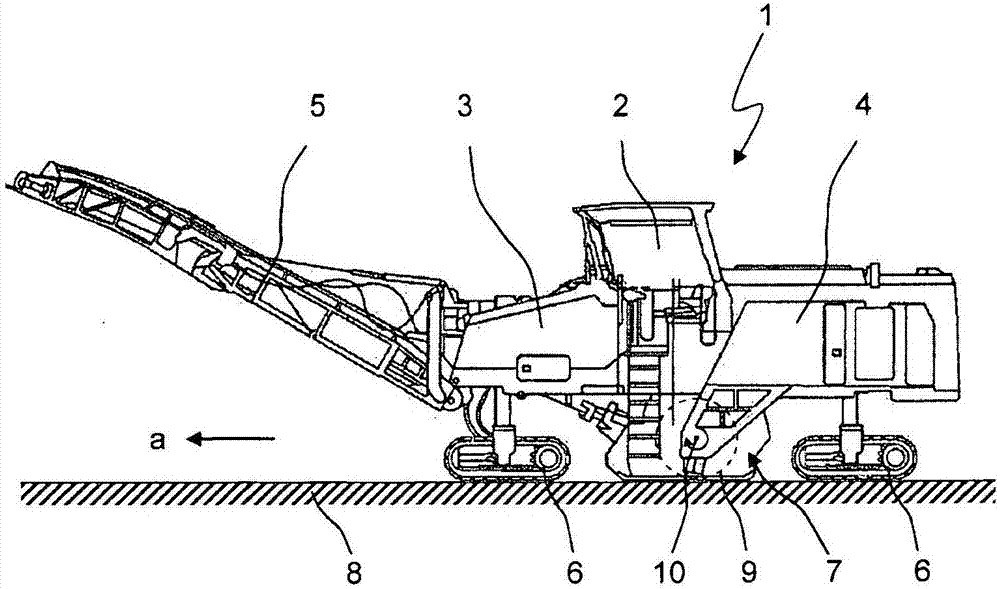

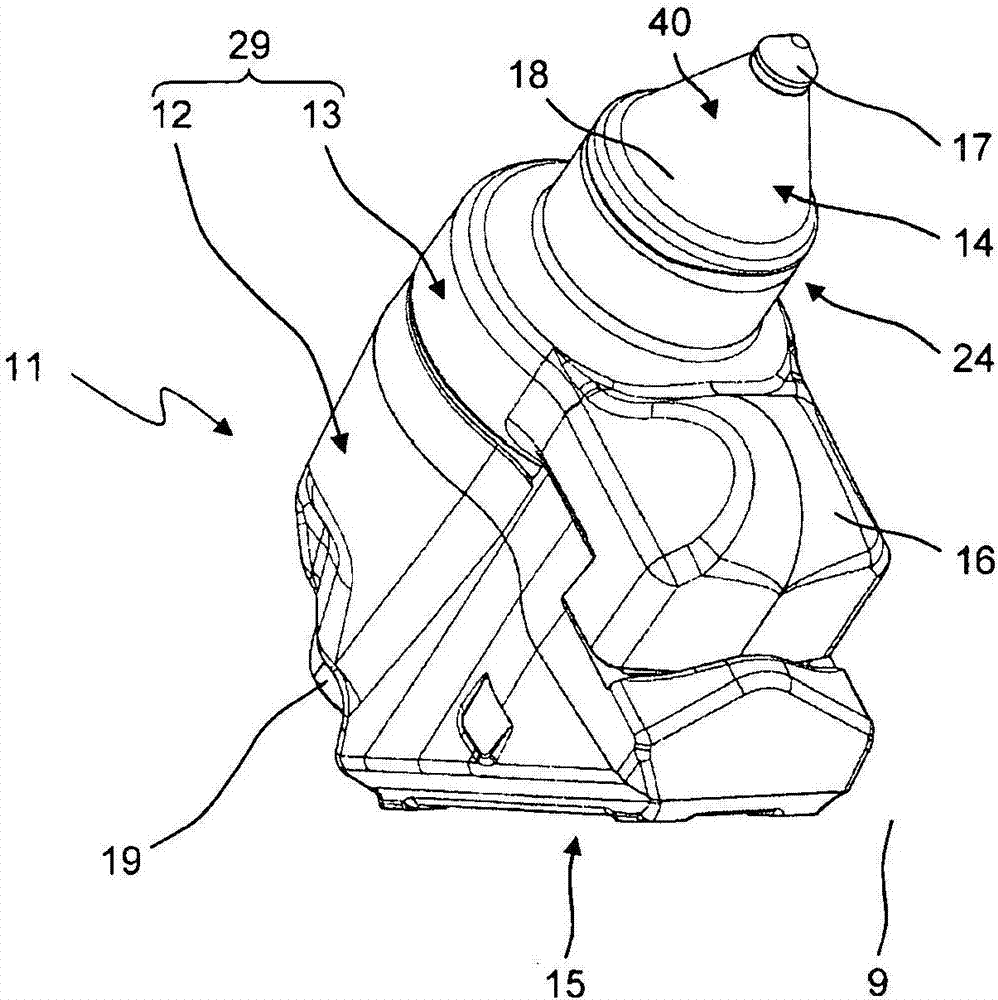

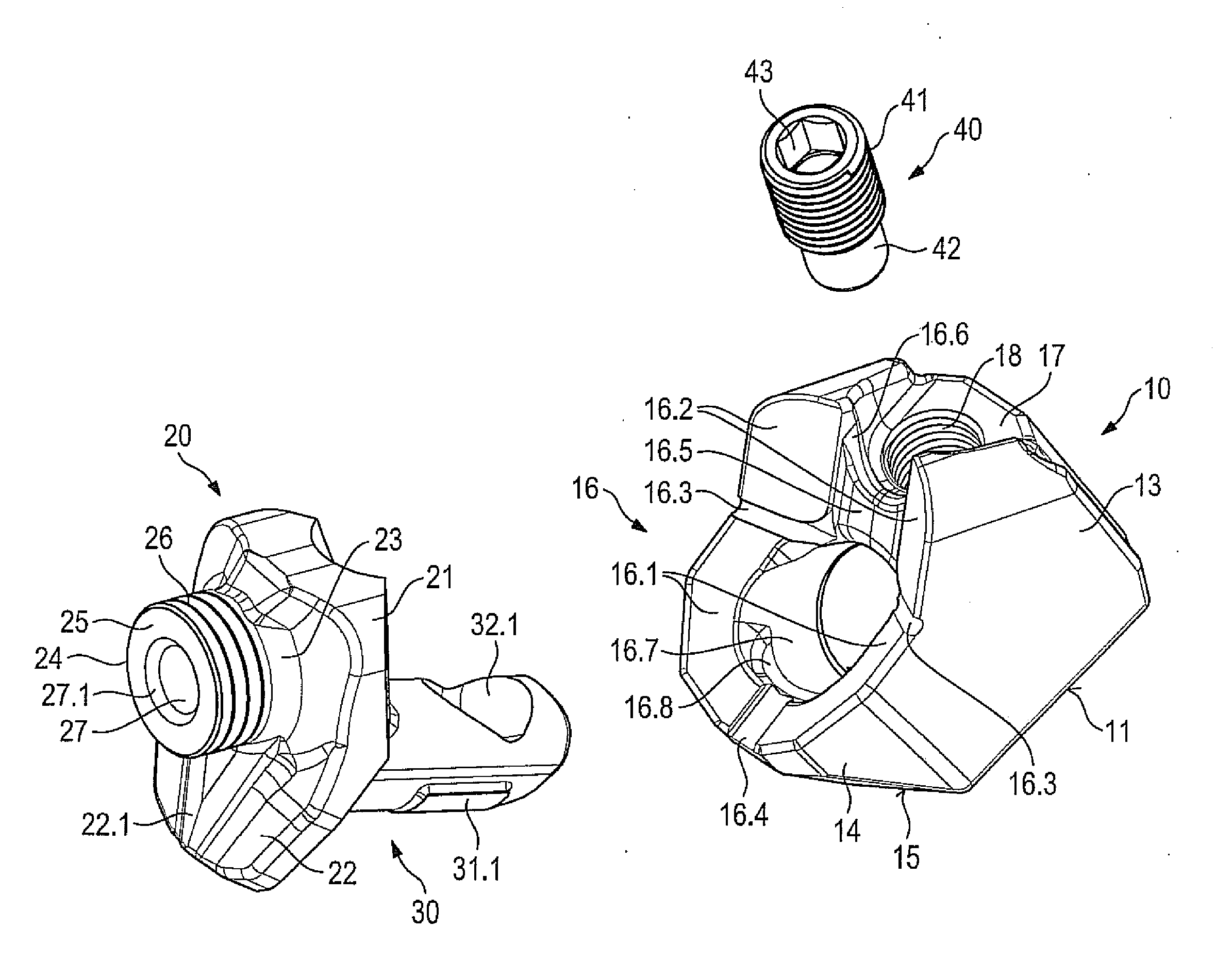

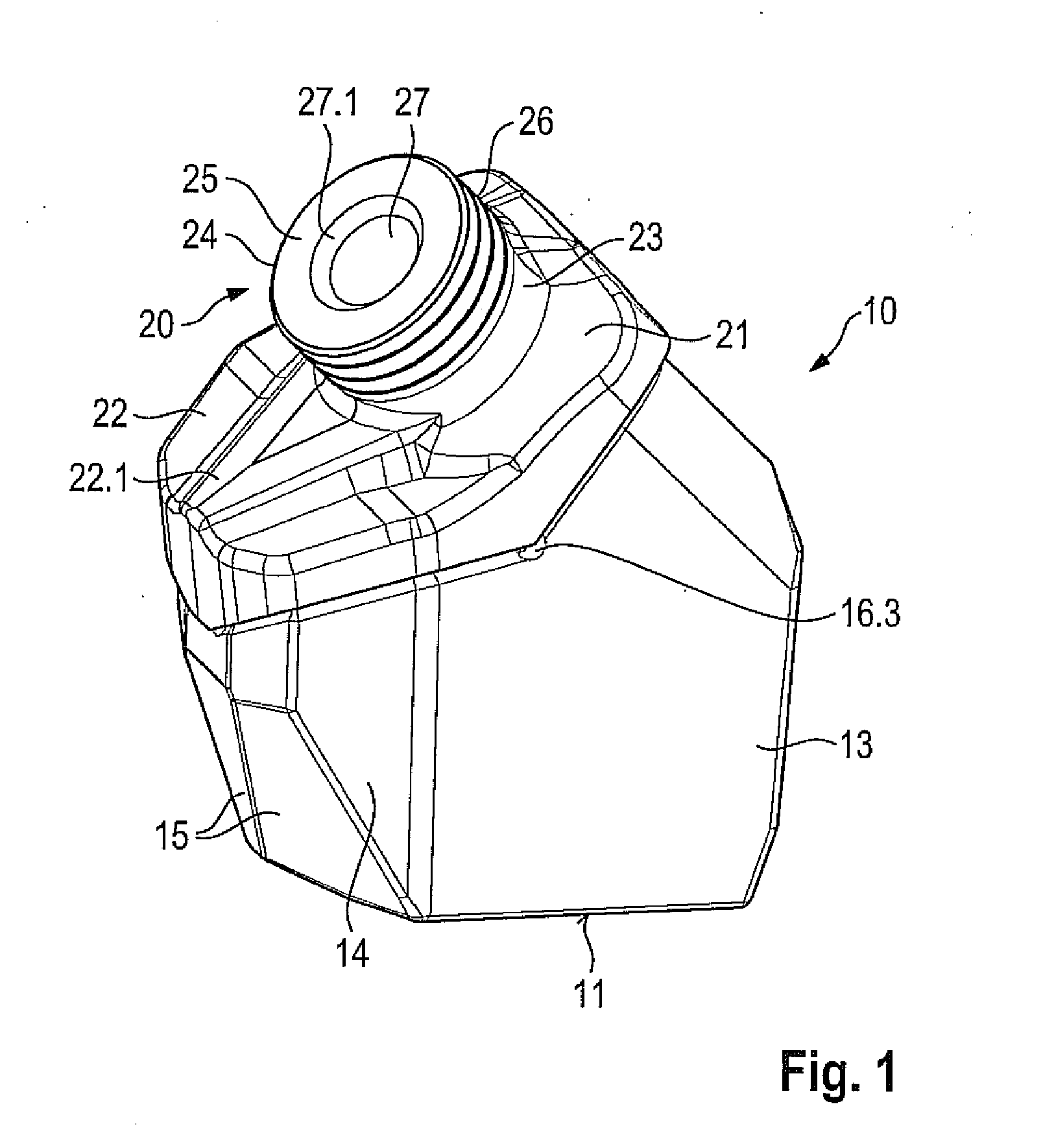

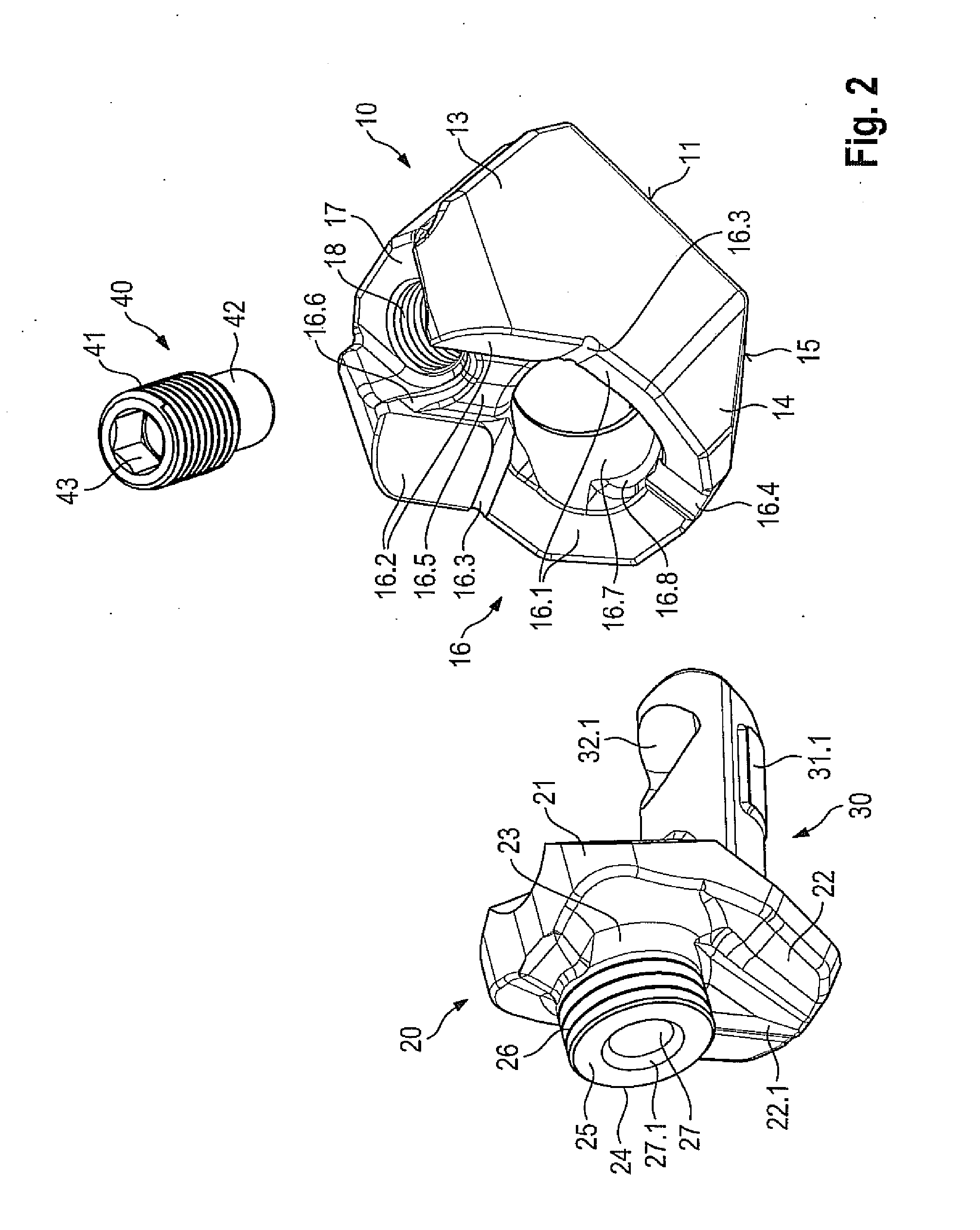

Tool system for ground milling machine and the ground milling machine comprising the tool system

ActiveCN107002373ASlow down wear progressionQuick installationSlitting machinesRoads maintainenceWear resistantEngineering

The invention relates to a tool system (11) for a ground milling machine (1), in particular a road miller, a road recycler, a road stabilizer or a surface miner. The tool system (11) comprises: a milling bit (14) with a highly wear-resistant bit tip (17), in particular comprising PCD material, and a bit shaft (20) extending along a longitudinal axis (35); and a bit holder (29) with a shaft-receiving socket (26), wherein the bit shaft (20) of the milling bit (14) has at least one tapered section (23) that narrows in a direction running away from the bit tip (17). A securing device (19) is also provided, and is designed to draw the milling bit (14) along the longitudinal axis (35) of the latter away from the bit tip (17) into the shaft-receiving socket (26). The shaft-receiving socket (26) of the bit holder (29) are designed to be complementary to the bit shaft (20) of the milling bit (14) such that the tapered section (23), when interlocked with the securing device (19), lies in the shaft-receiving socket (26) against the bit holder (29) in a friction-locked manner. In addition, the bit holder (29) comprises a base holder (12) and an interchangeable holder (13). The base holder (12) comprises a holder-receiving socket (37) for receiving the interchangeable holder (13) and the interchangeable holder (13) comprises the shaft-receiving socket (26). The securing device (19) is designed such that it draws the milling bit (14) along the longitudinal axis (35) of the latter in a direction away from the bit tip (17) into the shaft-receiving socket (26) and also draws the interchangeable holder (13) into the holder-receiving socket (37) in the base holder (12). The invention also relates to a milling bit and to an interchangeable holder for the tool system and to a ground milling machine comprising the tool system.

Owner:BOMAG

U-shaped thin-wall steel-prestress concrete combined bent cap and thin-wall steel tube concrete pier node structure and construction process

PendingCN110396916AReliable force transmissionAppearance has no effectBridge structural detailsBridge erection/assemblyPre stressRebar

The invention discloses a U-shaped thin-wall steel-prestress concrete combined bent cap and thin-wall steel tube concrete pier node structure and a construction process. The structure comprises a U-shaped thin-wall steel-prestress concrete combined bent cap and a thin-wall steel tube concrete pier, when the thin-wall steel tube concrete pier and the U-shaped thin-wall steel-prestress concrete combined bent cap are connected, a connecting piece, an ear plate, a telescopic threaded steel tube, a platform beam and a telescopic steel rope are arranged on the thin-wall steel tube concrete pier, thestability of the installation process is ensured, concrete is poured into a machined U-shaped thin-wall steel beam to form the the U-shaped thin-wall steel-prestress concrete combined bent cap, and when the concrete is solidified to the designed strength, the combined bent cap is formed by tensioning prestressed steel bars embedded in the concrete. According to the structure, the connection between the U-shaped thin-wall steel-prestress concrete combined bent cap and the steel tube concrete pier is reliable, installing is convenient, construction is simple, the seismic resistance and fire resistance are good, and the manufacturing cost is low.

Owner:CHONGQING UNIV

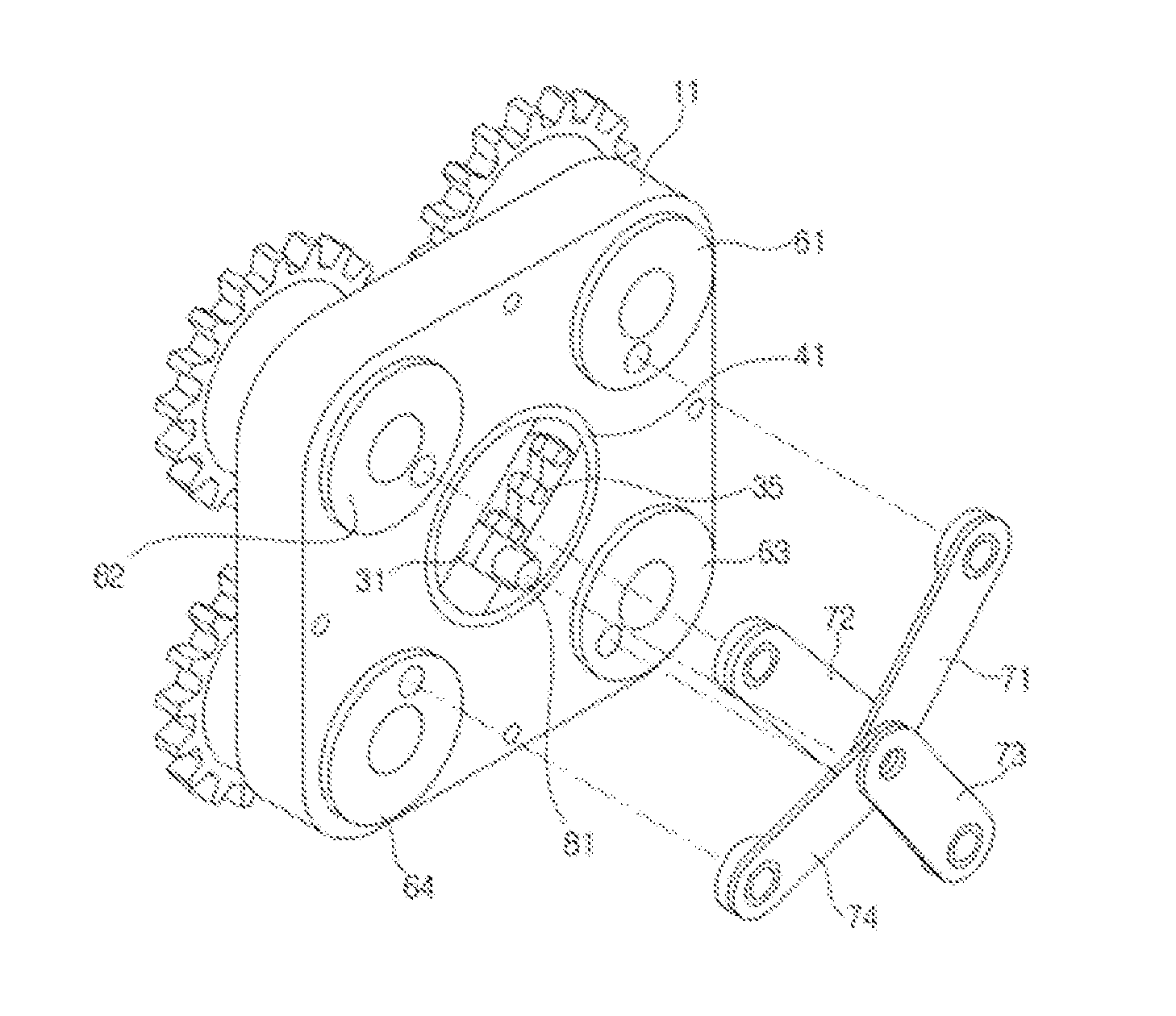

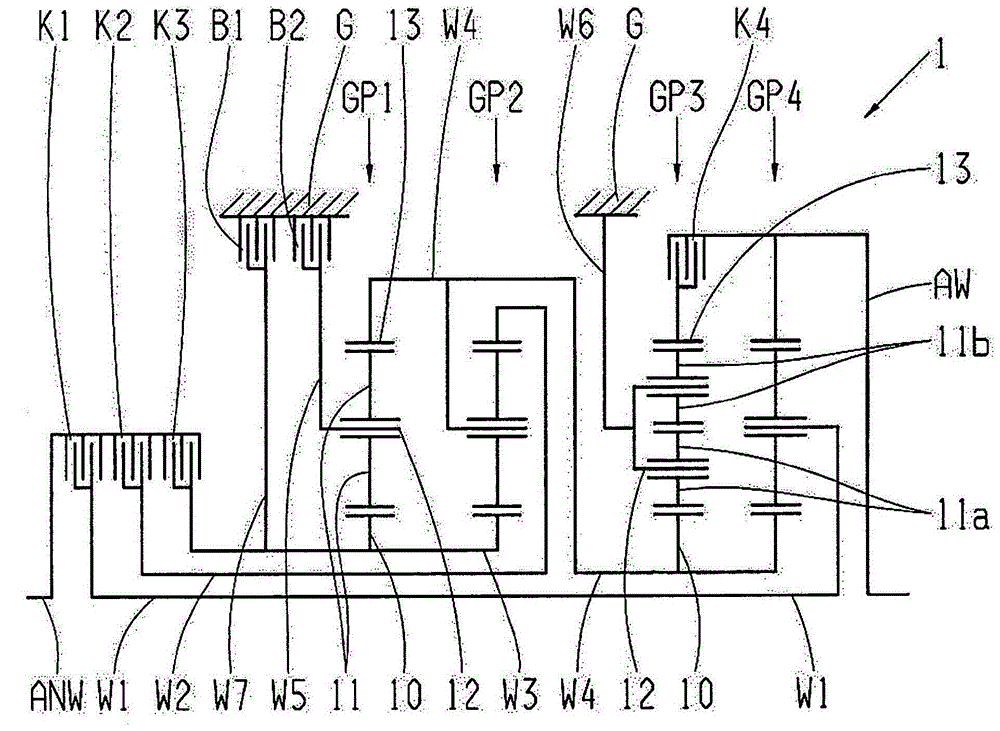

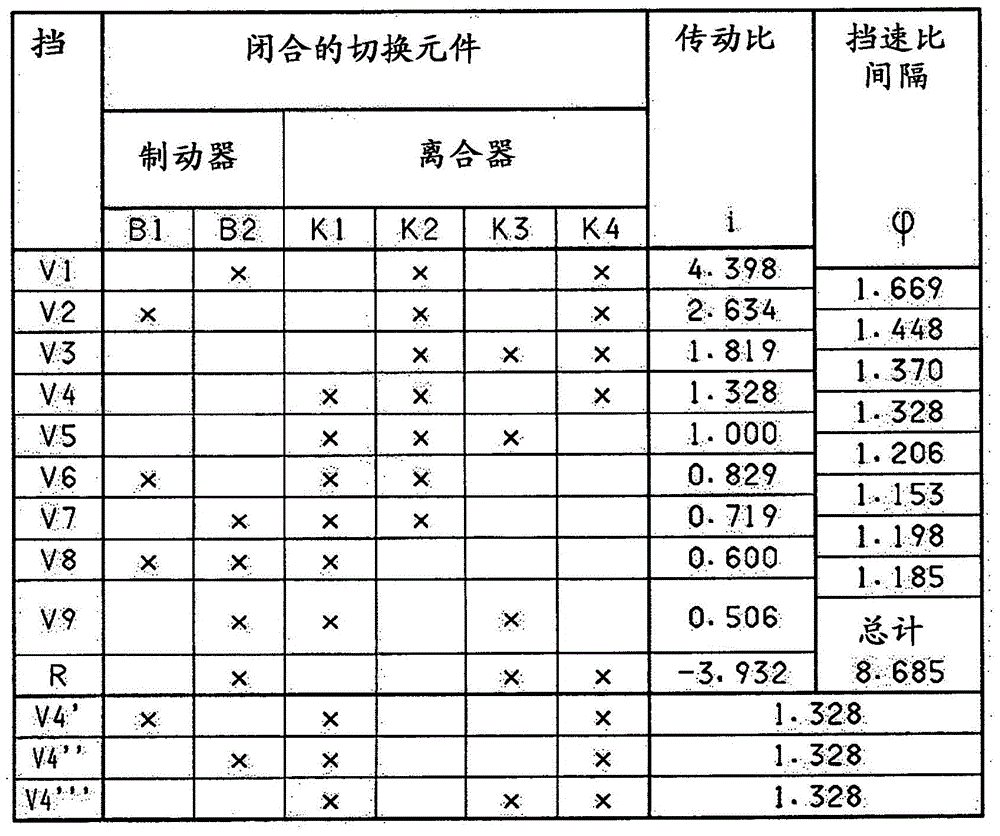

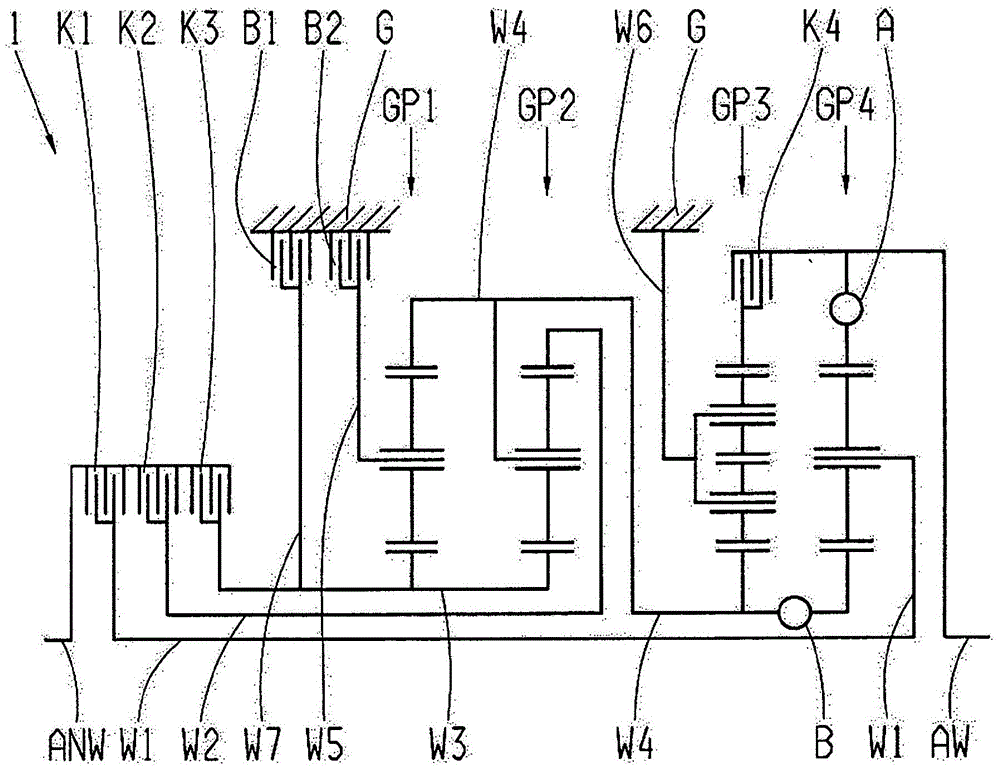

Transmission for a motor vehicle

The invention relates to a transmission, in particular multi-clutch transmission, for a motor vehicle, comprising the elements of a driveshaft, a plurality of planetary gear sets, wherein one planetary gear set comprises the planetary elements of a sun gear, one or more planetary gears, a web and a ring gear, N shifting elements, comprising a plurality of clutches, wherein N is an integer greater than four, and an output shaft, wherein the driveshaft can be connected to the output shaft by means of at least one of the N shifting elements in order to form a plurality of gear stages by means of at least one of the planetary gear mechanisms, wherein the N shifting elements comprise at least M brakes and N‑M clutches, wherein M is an integer greater than or equal to one, and wherein at least (N‑M) / 2 clutches interact with the driveshaft and / or the output shaft.

Owner:ZF FRIEDRICHSHAFEN AG

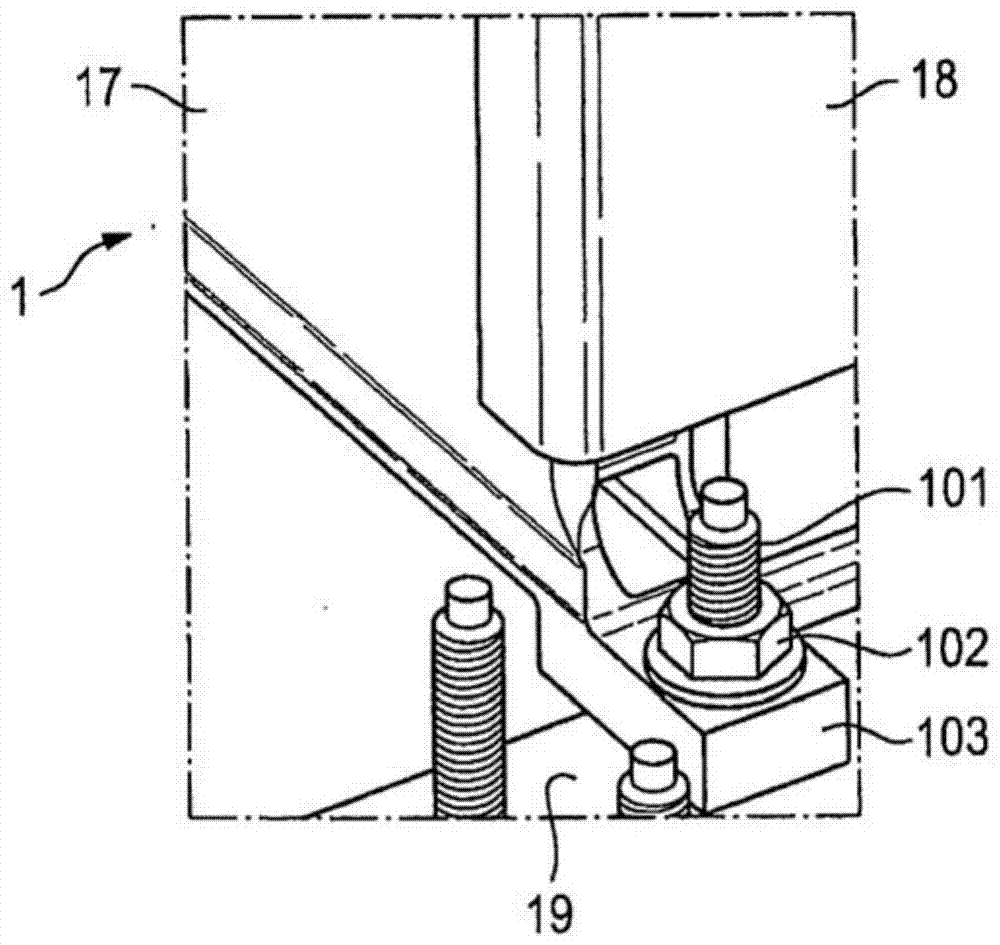

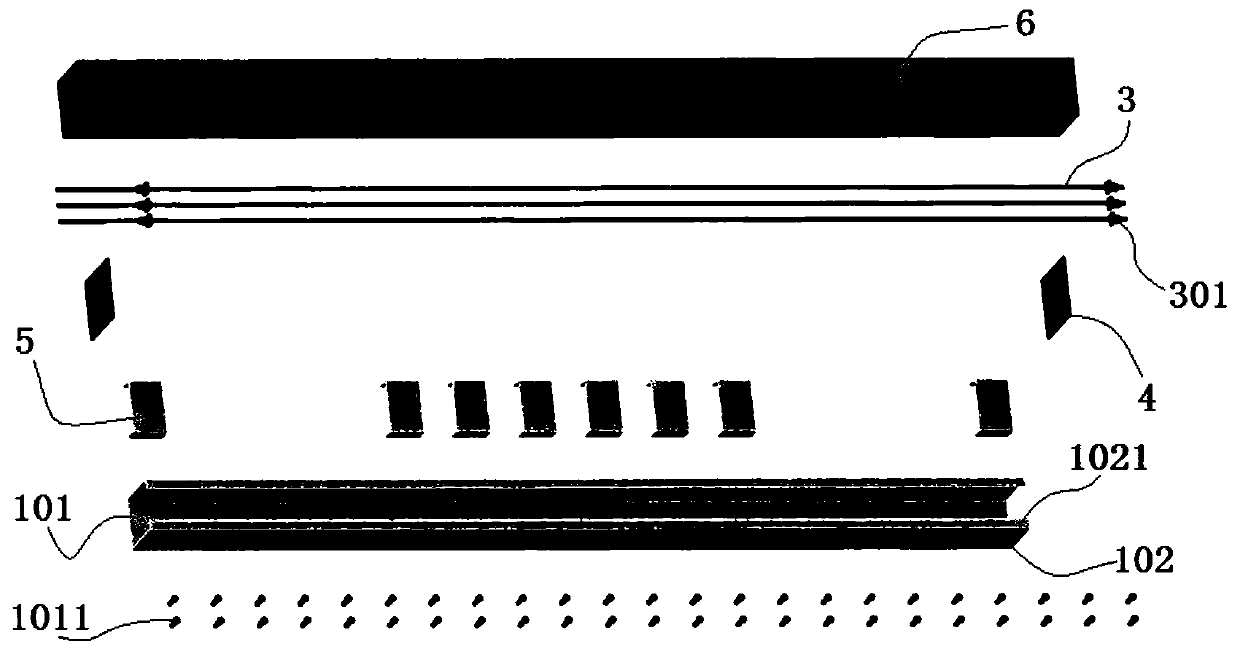

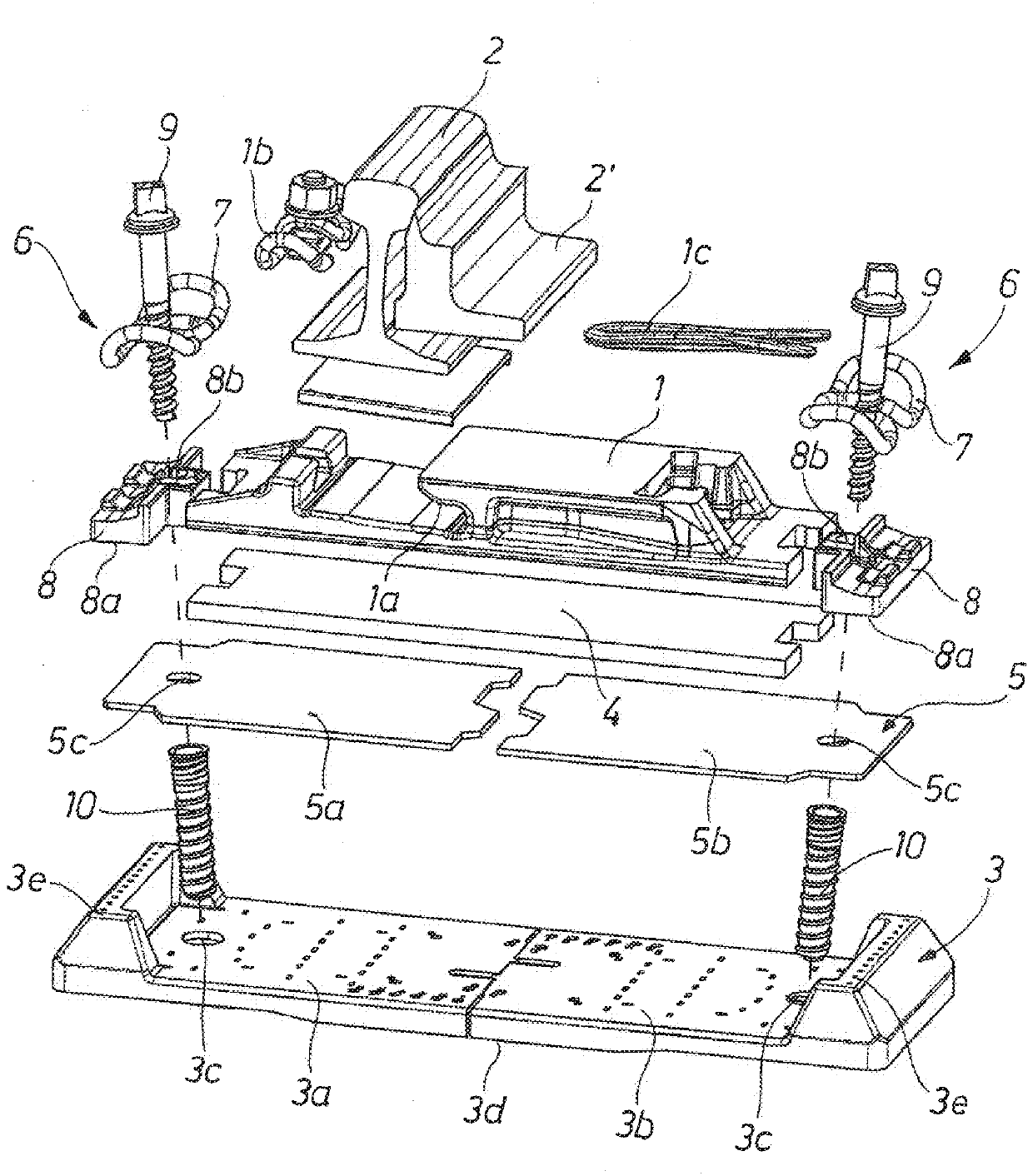

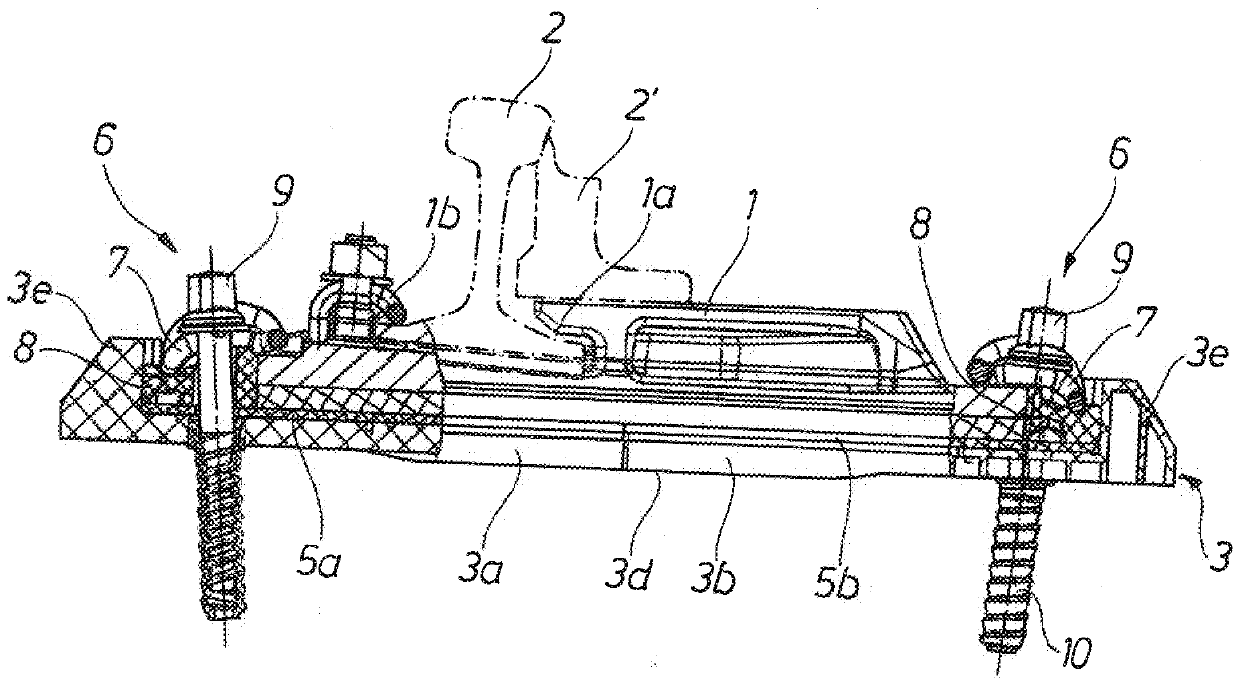

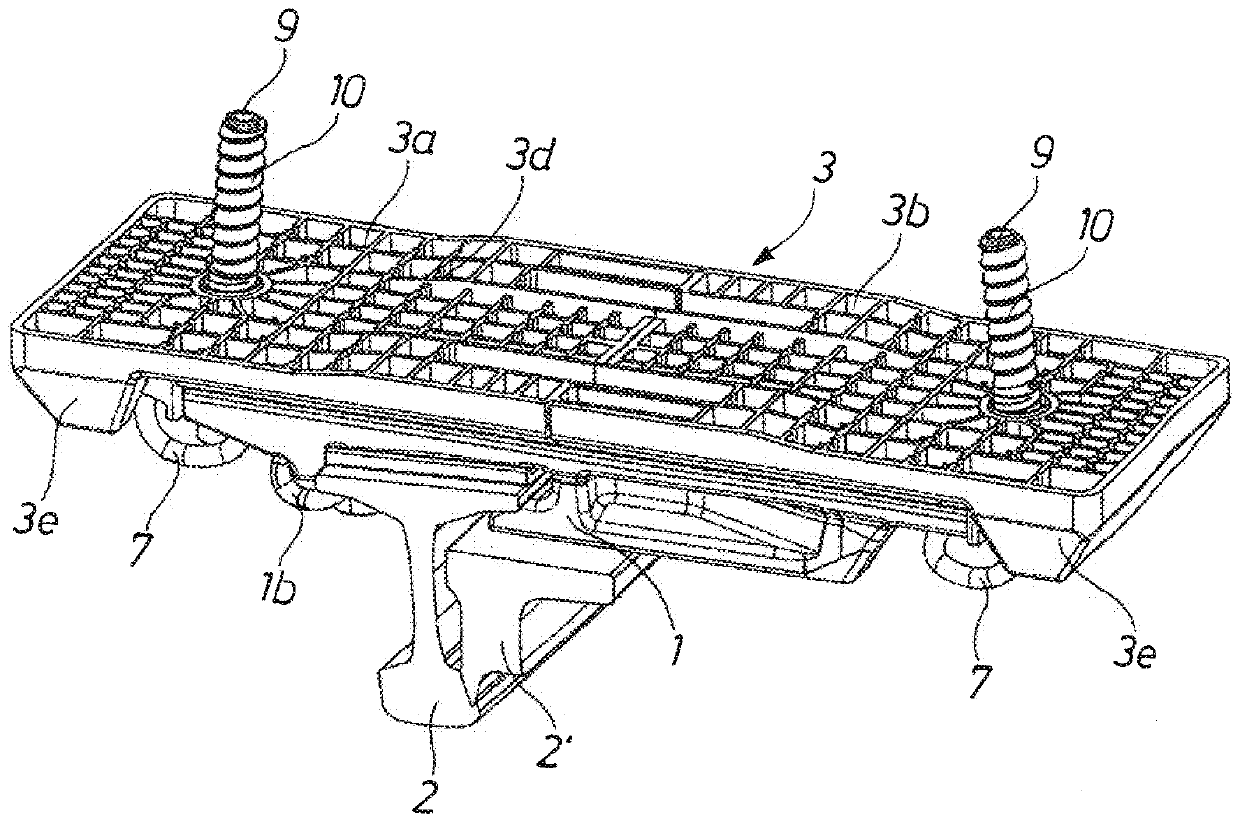

Rail fastening system

PendingCN110735364AFirmly connectedEasy to adjustRail switchesRail fastenersClassical mechanicsStructural engineering

The invention provides a rail fastening system for fastening at least one rail (2) to a rail substrate, preferably a solid travel path, which comprises: a rail support plate (1) arranged for holding the rail (2), wherein the rail (2) in the mounted state is in contact with the rail support plate and is fastened thereto by means of a rail mount (1a, 1b, 1c); a base plate (3) arranged for fasteningthe rail support plate (1) on the rail substrate, wherein the rail support plate (1) in the mounted state is fastened on the base plate (3) by way of one or more, preferably two, retaining elements (6) and the base plate (3) is in contact with the rail substrate; wherein the base plate (3) is of multi-part, preferably two-part, construction so that this is adjustable to different dimensions of therail support plate (1).

Owner:SCHWIHAG

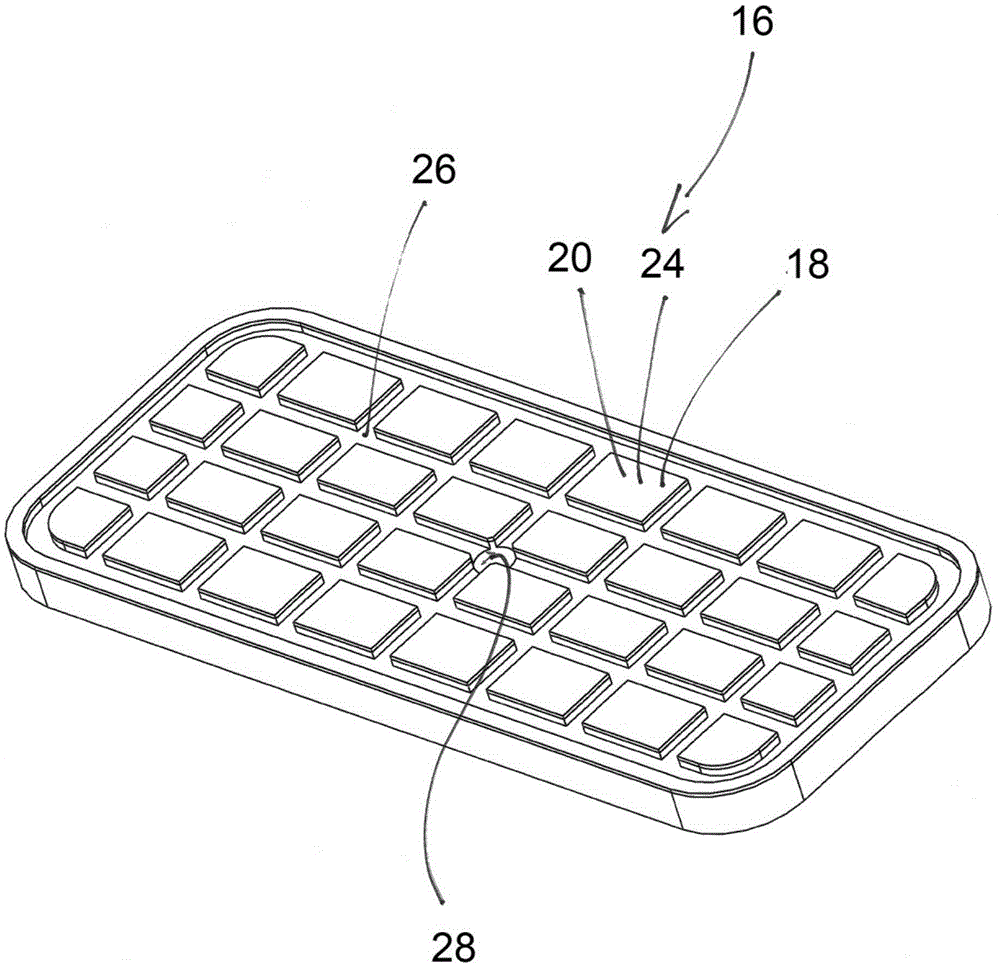

Vacuum Chuck Or Gripping Device

ActiveCN105583665ASimple and reliable productionStable frictionConveyorsPositioning apparatusMechanical engineeringElastomer

The invention relates to a vacuum chuck or gripping device, with a suction surface to which a held workpiece can be sucked, the suction surface has at least one bearing region, which rests while holding the workpiece at this. For positionally stable, friendly and slip-proof suction and holding of the workpiece, the contact region has a coating with an elastomer.

Owner:J SCHMALZ GMBH

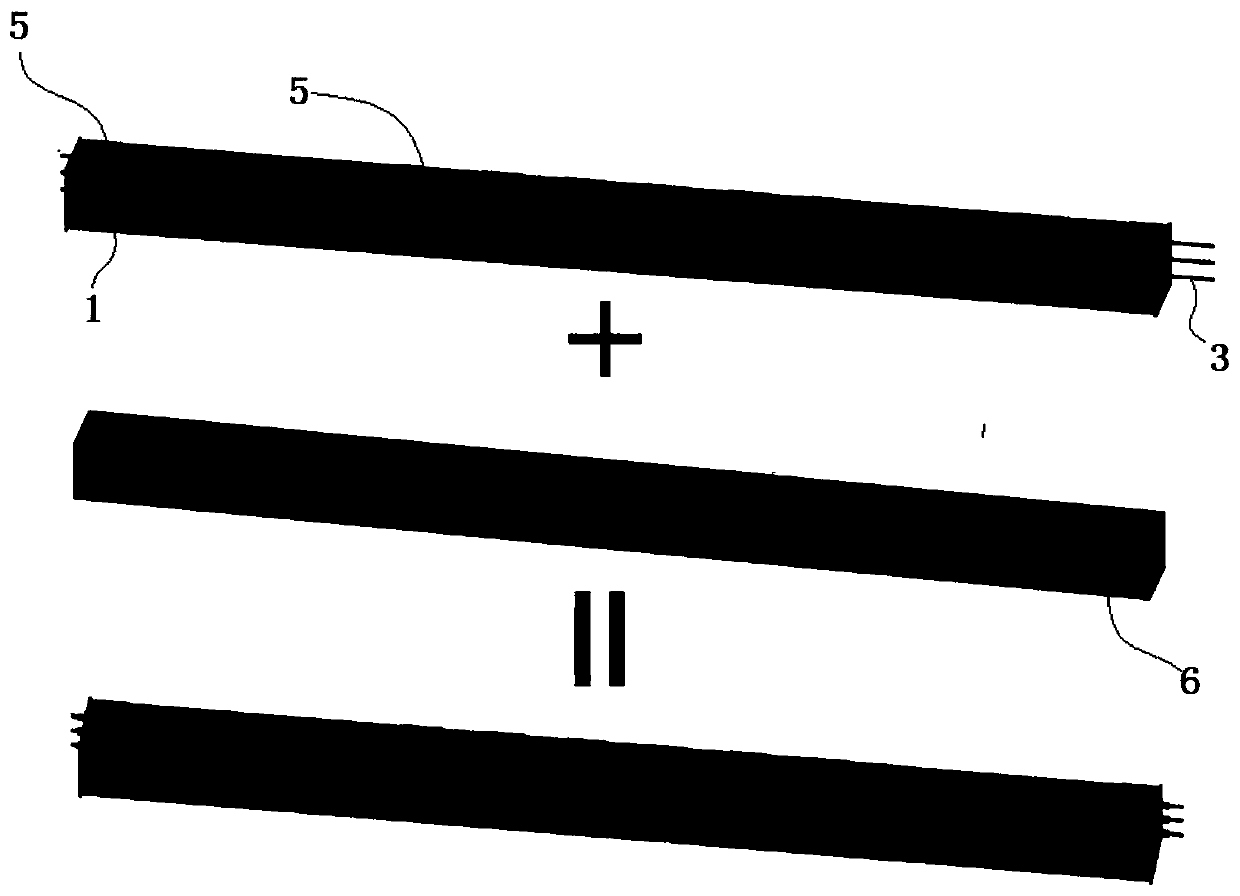

Splicing type prefabricated wall body and upper and lower connecting structure thereof

InactiveCN110685375AAvoid Uncertain Factors of Incomplete GroutingReliable force transmissionWallsBuilding reinforcementsLap jointRebar

The invention belongs to the field of building engineering, and relates to a splicing type prefabricated wall body and an upper and lower connecting structure thereof. According to the technical scheme, a first prefabricated wall body and a second prefabricated wall body are spliced up and down, wherein a first steel pipe is pre-buried at the bottom of the first prefabricated wall body, the upperpart of the first steel pipe is buried in the first prefabricated wall body, and the lower part of the first steel pipe is exposed out of the first prefabricated wall body; a second steel pipe is pre-buried at the bottom of the second prefabricated wall body, the lower part of the second steel pipe is buried in the second prefabricated wall body, and the upper part of the second steel pipe is exposed out of the second prefabricated wall body; the first steel pipe and the second steel pipe are vertically aligned and connected in position; and longitudinally distributed reinforcing steel bars exposed out of the first prefabricated wall body and the second prefabricated wall body are in staggered lap joint anchoring with one another. According to the splicing type prefabricated wall body andthe upper and lower connecting structure thereof, a grouting sleeve is omitted, the upper and lower prefabricated wall bodies are connected with each other through adopting the additionally-arranged upper and lower steel pipes, so that a temporary support is formed, in this way, construction of upper and lower splicing of the prefabricated wall body is facilitated, and meanwhile the cost of the grouting sleeve is saved, and therefore the method is economical and reliable.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

Chisel Holder

ActiveUS20160076370A1Reliable transmissionRelieve pressureDrill bitsSlitting machinesChiselRoad surface

The invention relates to a bit holder for an earth working machine, in particular a road milling machine, having a support member onto which an insertion projection is indirectly or directly attached on an insertion projection side, the support member comprising two first and / or two second stripping surfaces that are at an angle to one another, and the support member having a working side that comprises a bit receptacle. In order to achieve a stable and long-lived configuration for such a bit holder, provision is made according to the present invention that the first and / or second stripping surfaces diverge from the insertion projection side toward the working side.

Owner:WIRTGEN GMBH

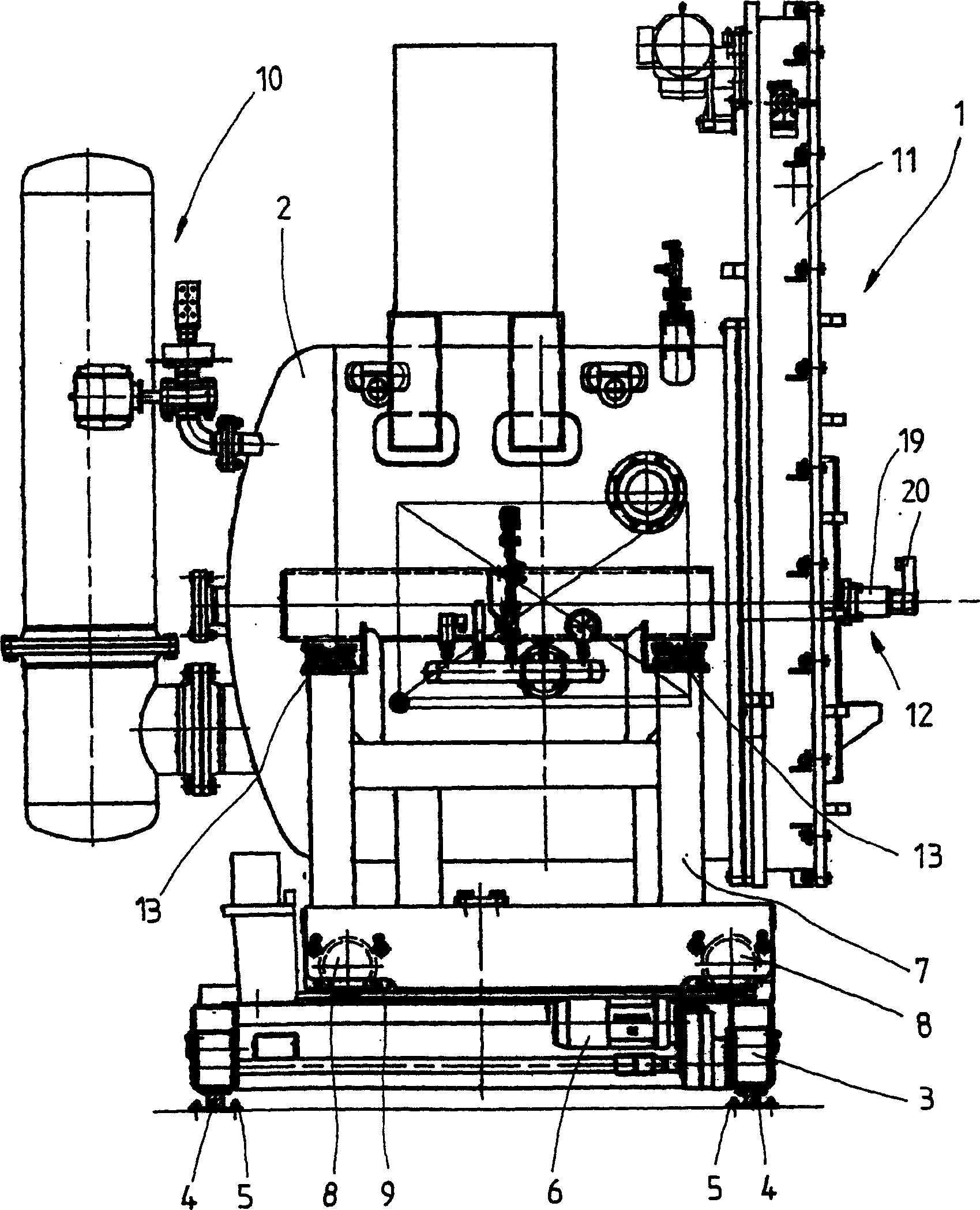

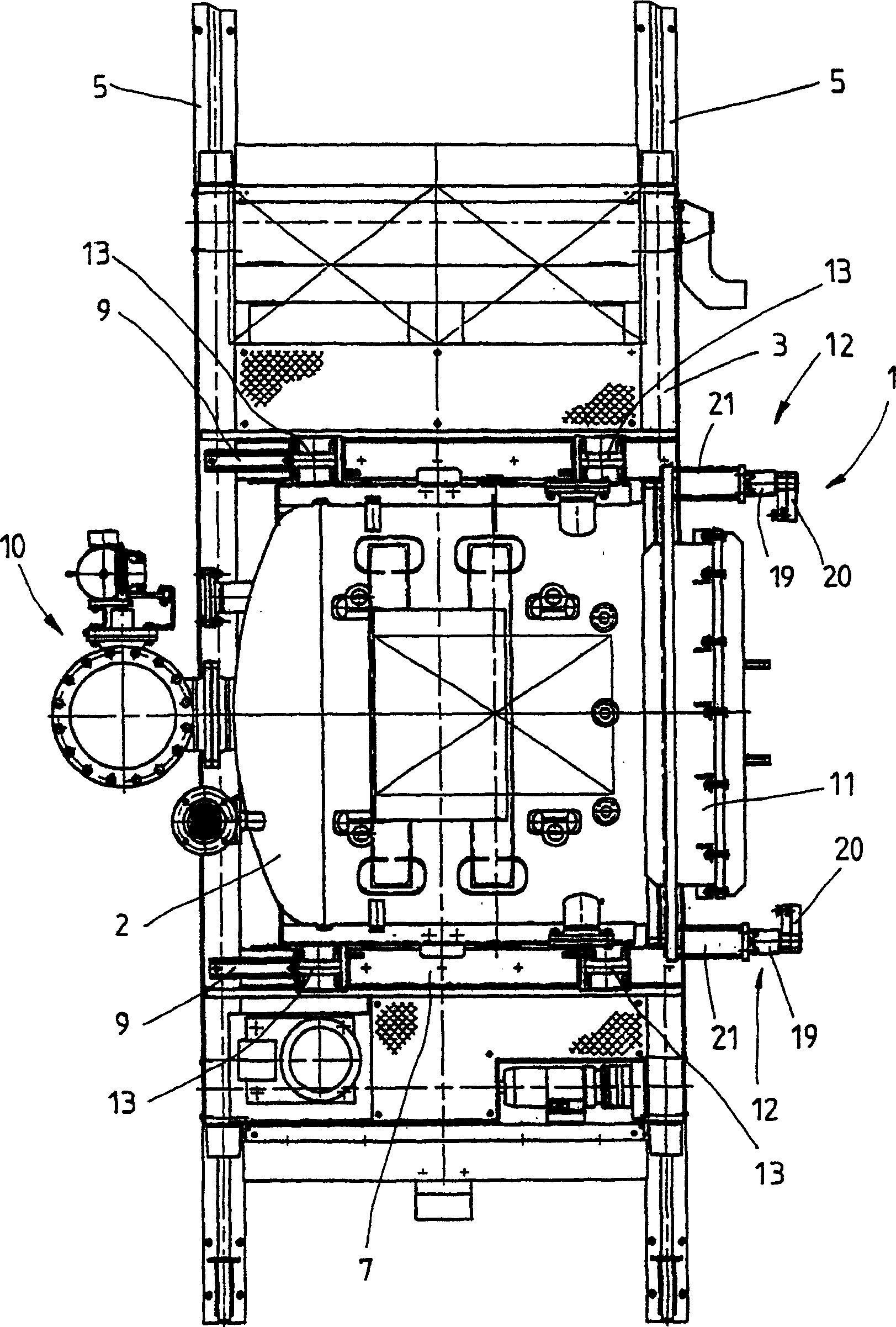

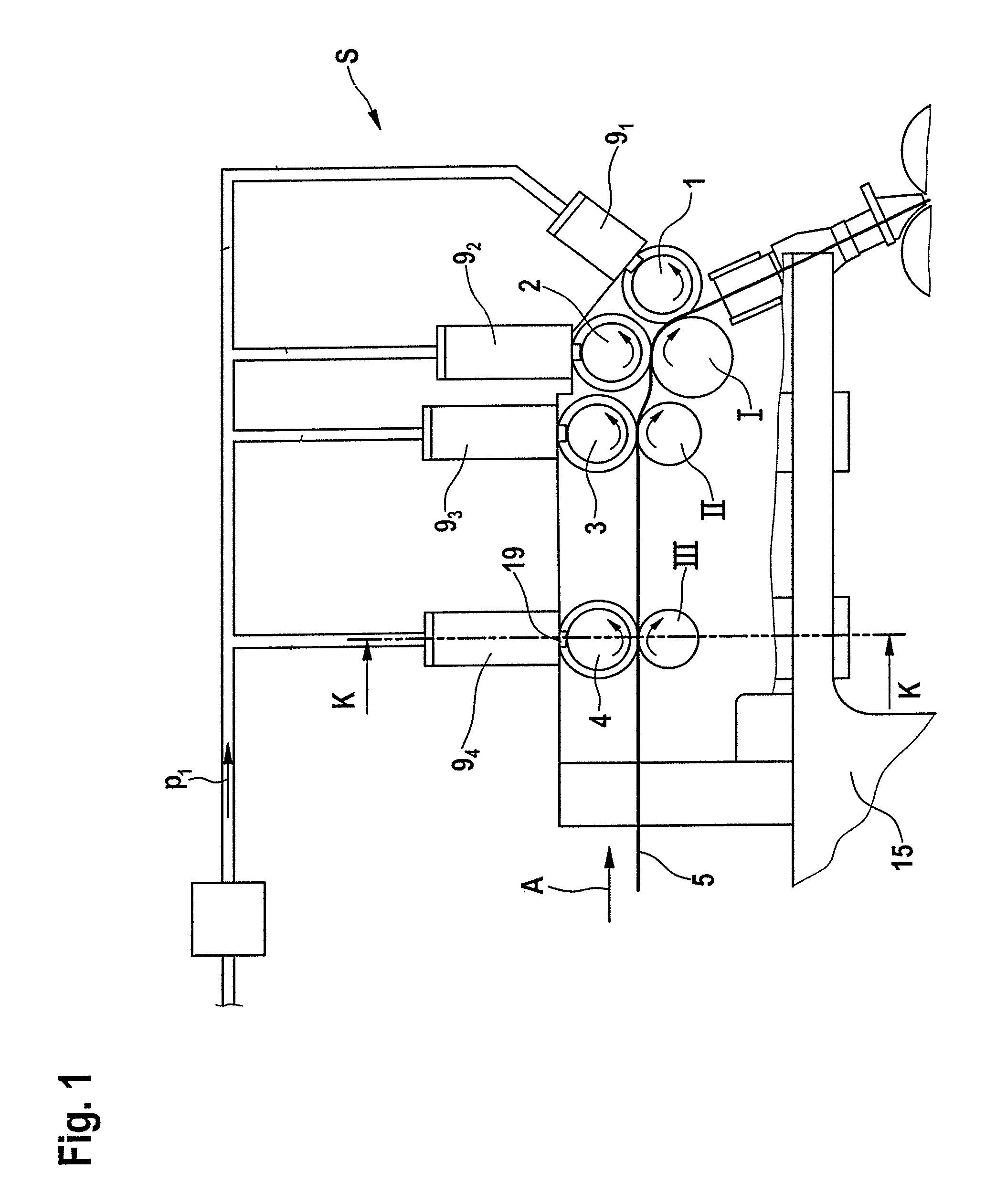

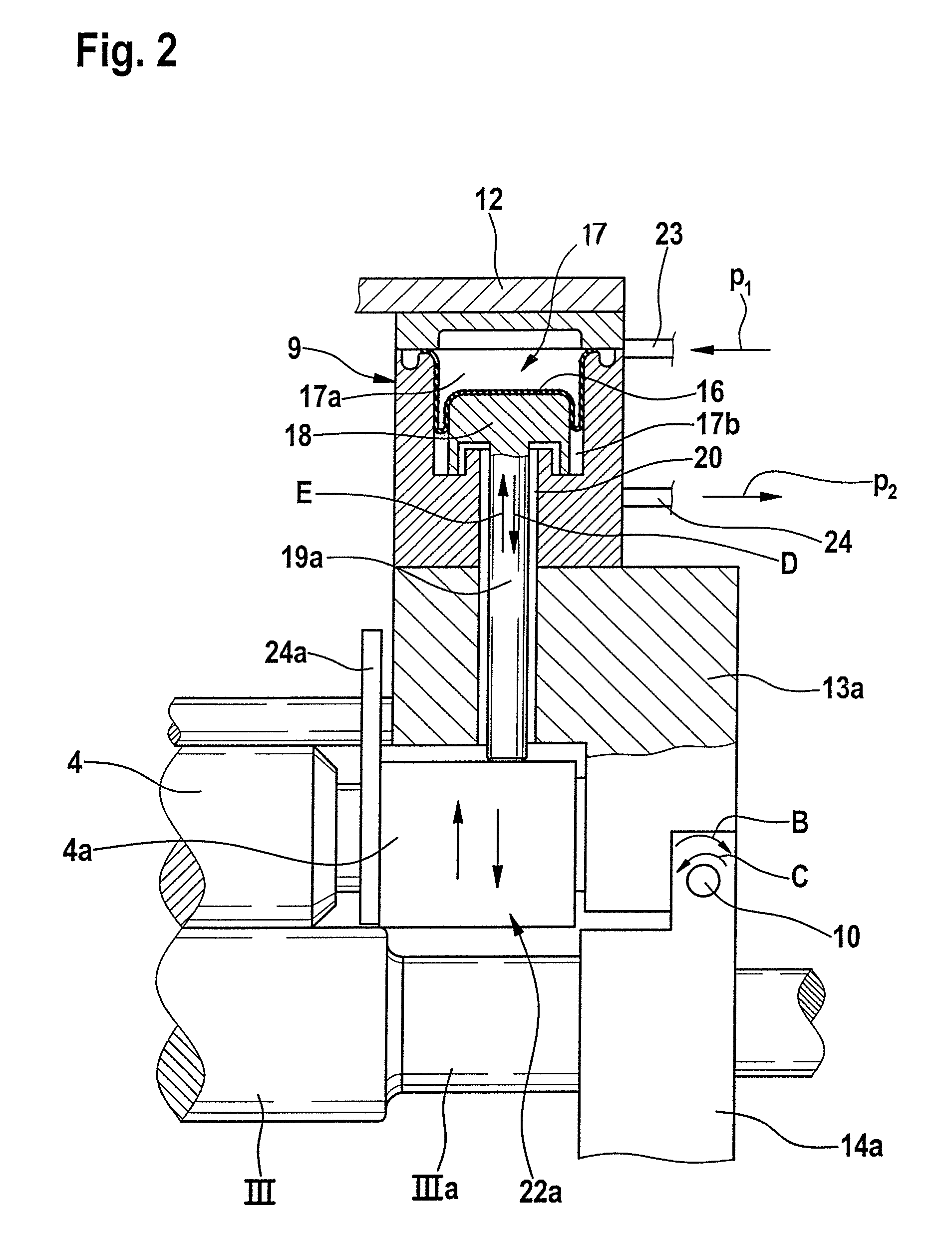

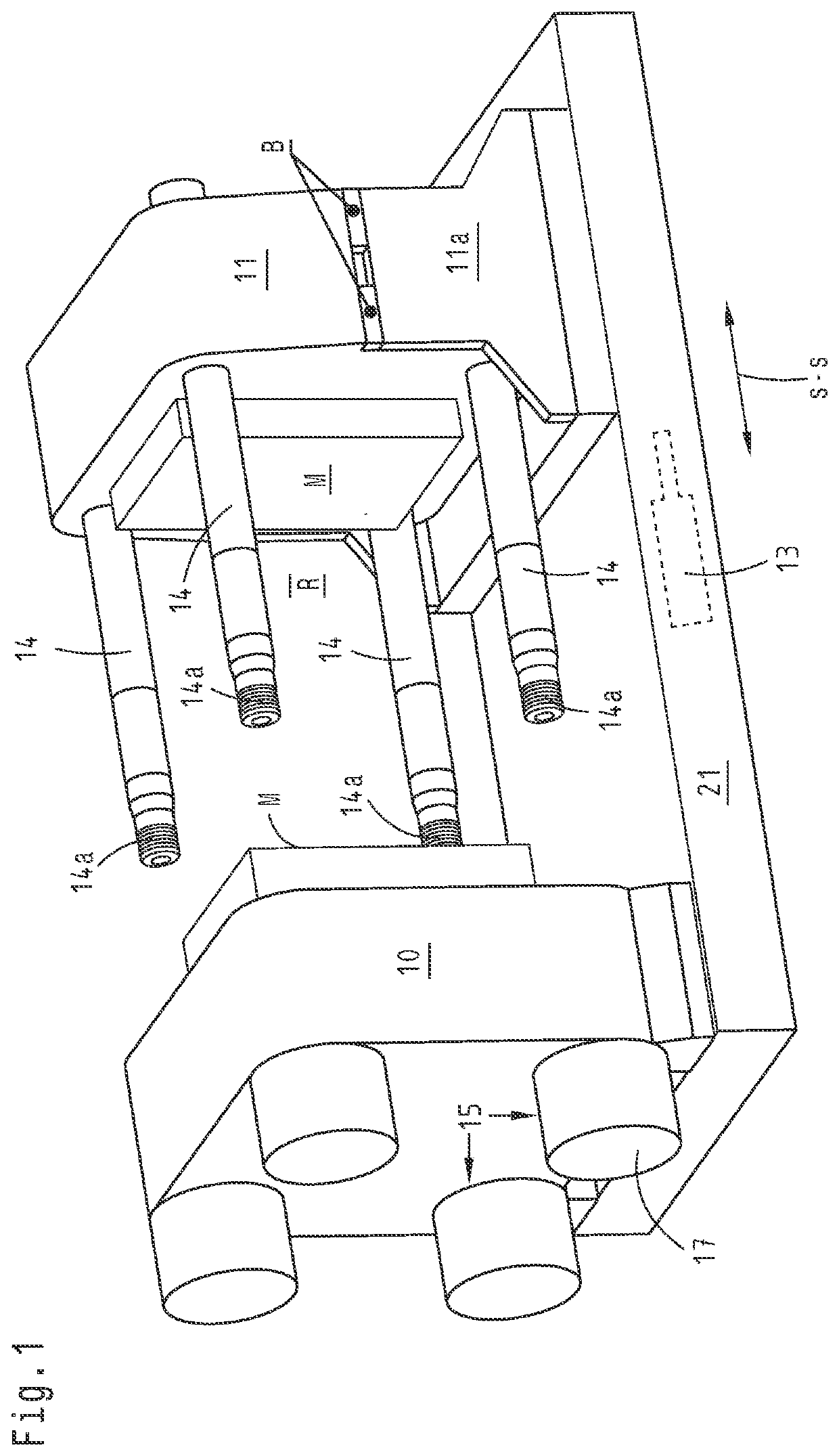

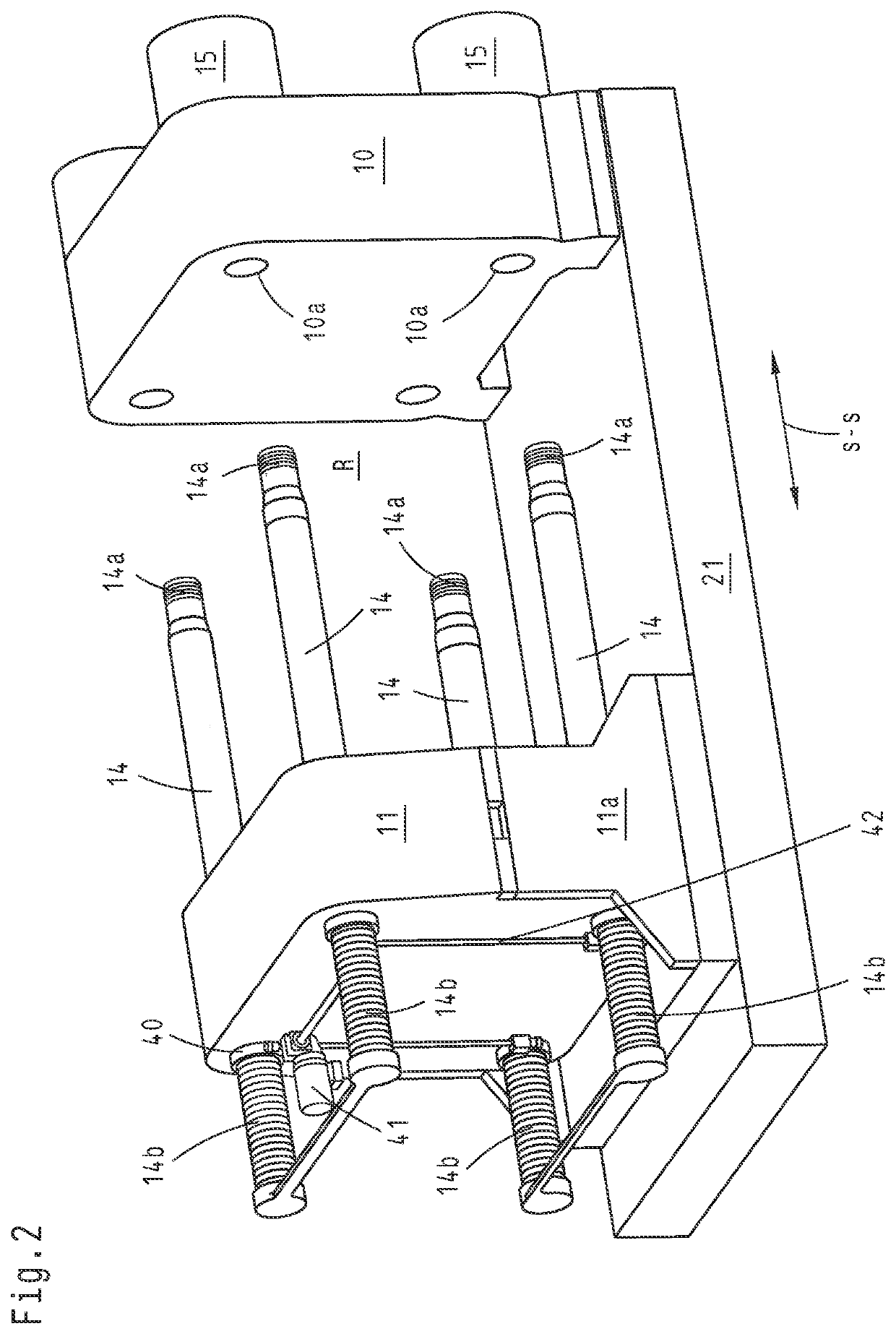

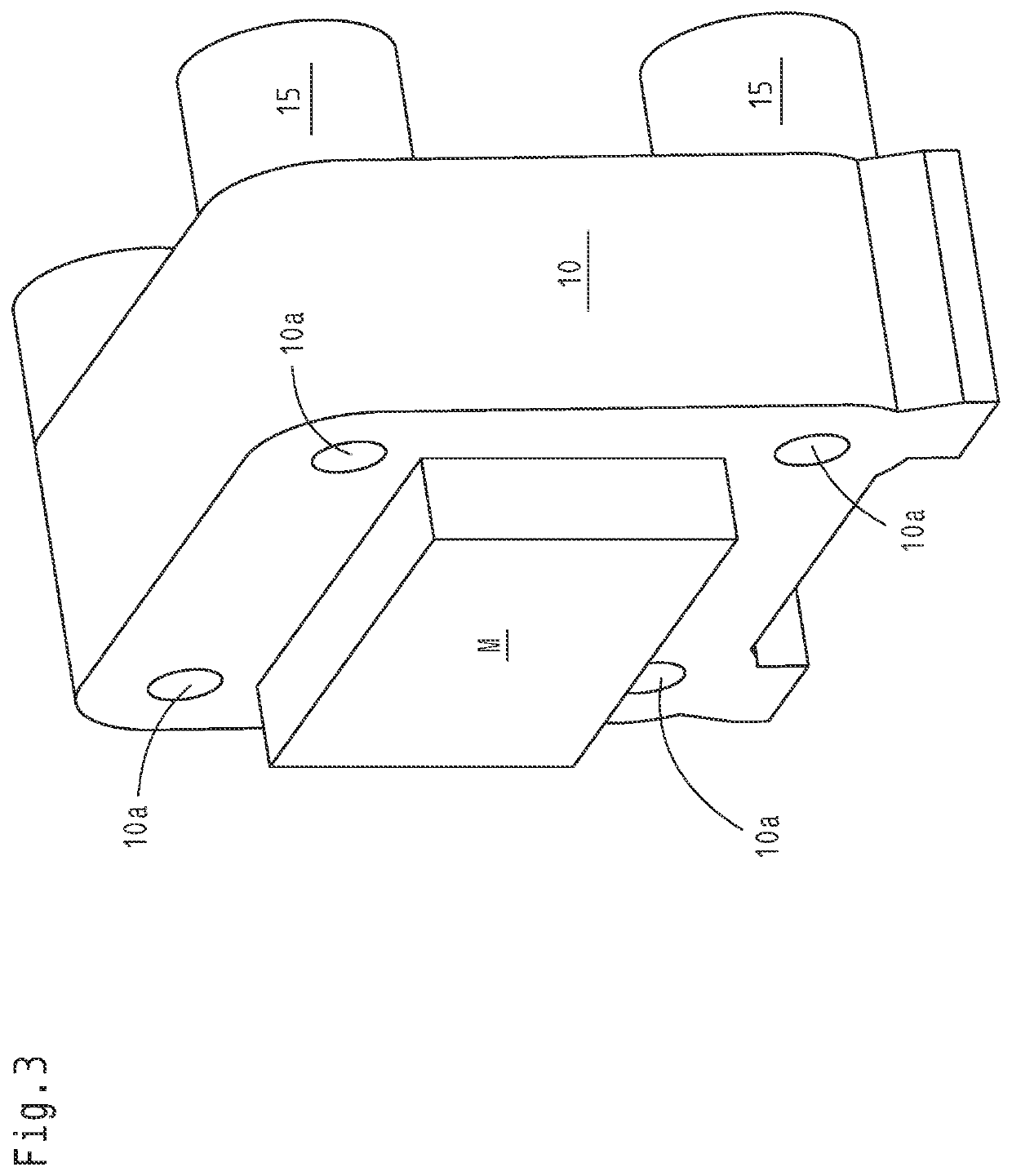

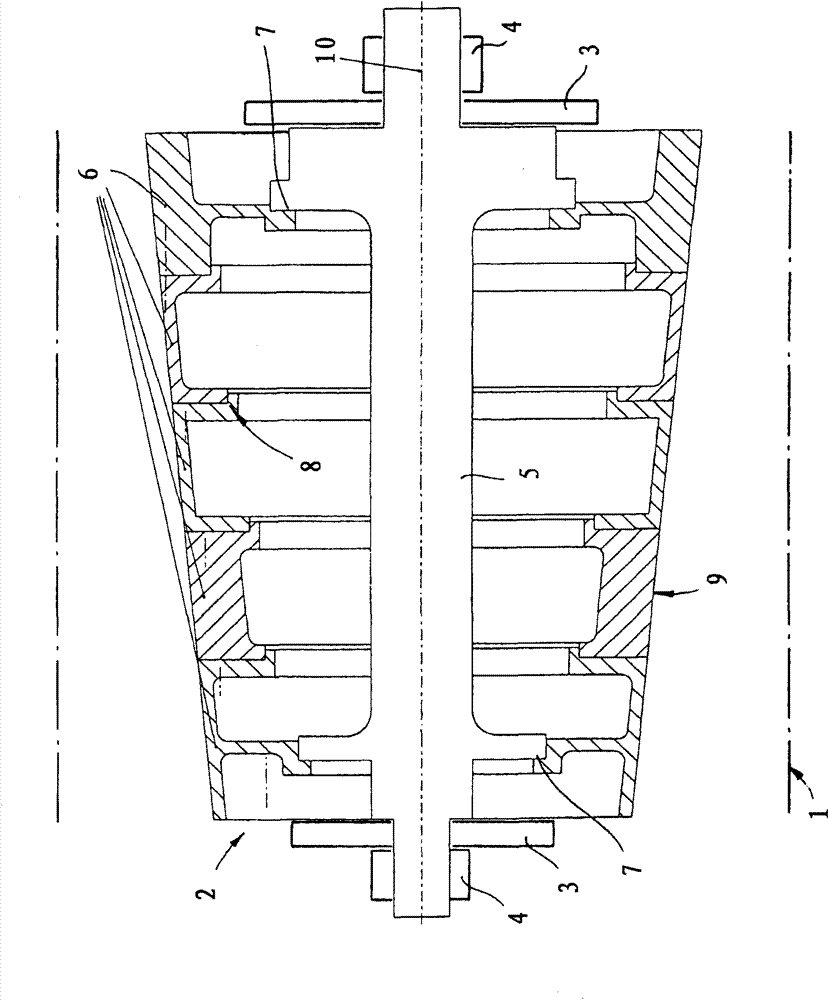

Mold-closing unit for an injection molding machine, and method for locking a force transmission element

The invention relates to a mold-closing unit for an injection molding machine for processing plastics, comprising a mold-moving device for moving the movable mold support into and out of closure of an injection mold. At least one force transmission element is connected to the movable mold support and at its end remote from the movable mold support has a section (14a) which is assigned to the stationary mold support. The stationary mold support (10) is assigned a locking device (15) having a plurality of locking elements (70) which can be moved into interlocking operative connection with the actuatable section (14a). The locking device (15) has at least one actuator (16) which is movable in the closing direction (s-s) and on which, during movement of the actuator, the locking elements (70) are movable transversely to the closing direction (s-s) along a sliding block guide (60) in and out of an interlocking operative connection with the actuatable section (14a). The actuator is at the same time connected to at least one piston (18) of a piston-cylinder unit (17) for applying the closing force.

Owner:ARBURG GMBH & CO KG

Pneumatic spring device for a rail vehicle

The invention is directed to a pneumatic spring device (3) of a rail vehicle (1). The device includes a pneumatic spring bellows (5), which is provided on both ends with a bead ring (6, 7), wherein the bead ring (6, 7) has a core made of two core rings (10, 11, 13, 14) positioned separately in the bead ring and the reinforcement elements (12) are guided in an S shape between the core rings and loop around the latter.

Owner:CONTITECH LUFTFEDERSYST

Turbo-machine for compressing gaseous or liquid fluid

InactiveCN103775355AReduce the total massHigh dimensional accuracyPump componentsBlade accessoriesEngineeringMechanical engineering

A turbomachine for use as a compressor has a tubular housing centered on an axis, a rotor at least generally centered on the axis in the housing, and bearings supporting the rotor in the housing for rotation about the axis. The rotor is formed by a small-diameter shaft extending along and centered on the axis, formed with at least one mounting collar, and carried by the bearings, and by a plurality of annular disks fitted axially together and formed with radially outwardly extending vanes. At least one of the disks is fitted with and secured to the mounting collar.

Owner:ATLAS COPCO ENERGAS

Vacuum clamping or clamping device

ActiveCN105583665BStable frictionResistance to lateral slidingConveyorsPositioning apparatusElastomerMechanical engineering

The invention relates to a vacuum clamping device or clamping device having an adsorption surface to which a workpiece to be held can be adsorbed, wherein the adsorption surface has at least one abutment area where the workpiece is held against the work piece. In order to absorb and hold the workpiece in a positionally stable, protective and slip-proof manner, the contact area includes an elastomer coating.

Owner:J SCHMALZ GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com