Turbo-machine for compressing gaseous or liquid fluid

A technology of turbines and compressors, which is applied to components of pumping devices for elastic fluids, liquid fuel engines, axial flow pumps, etc., and can solve problems such as the maximum allowable speed limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

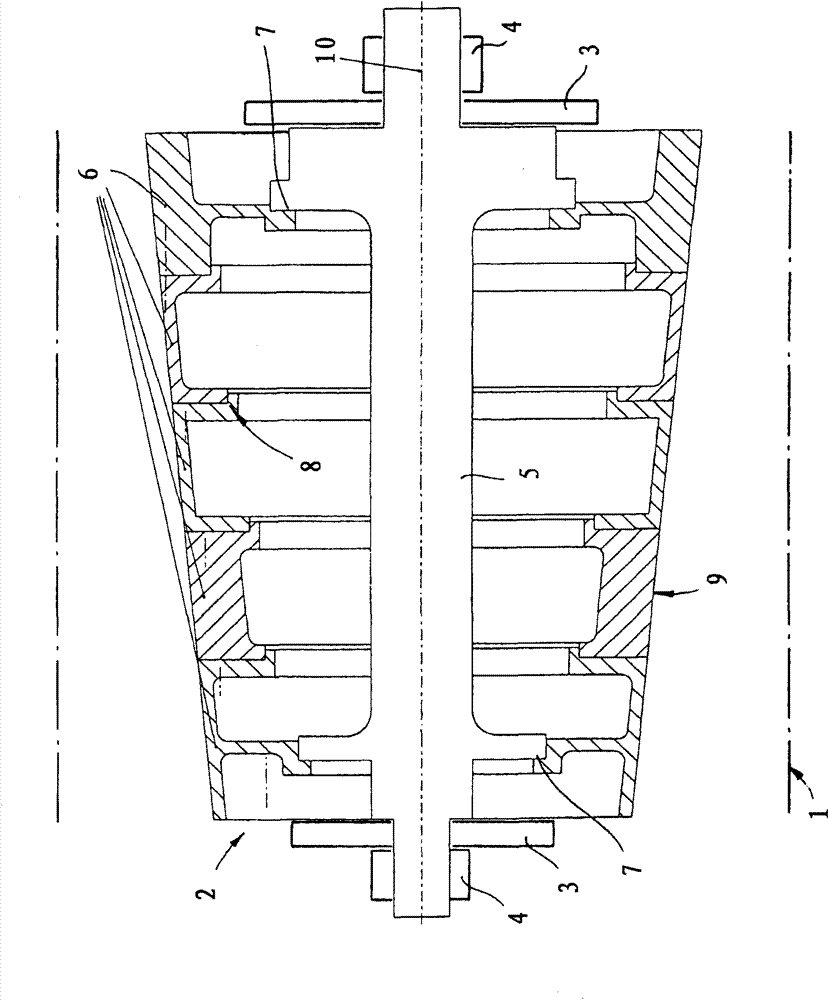

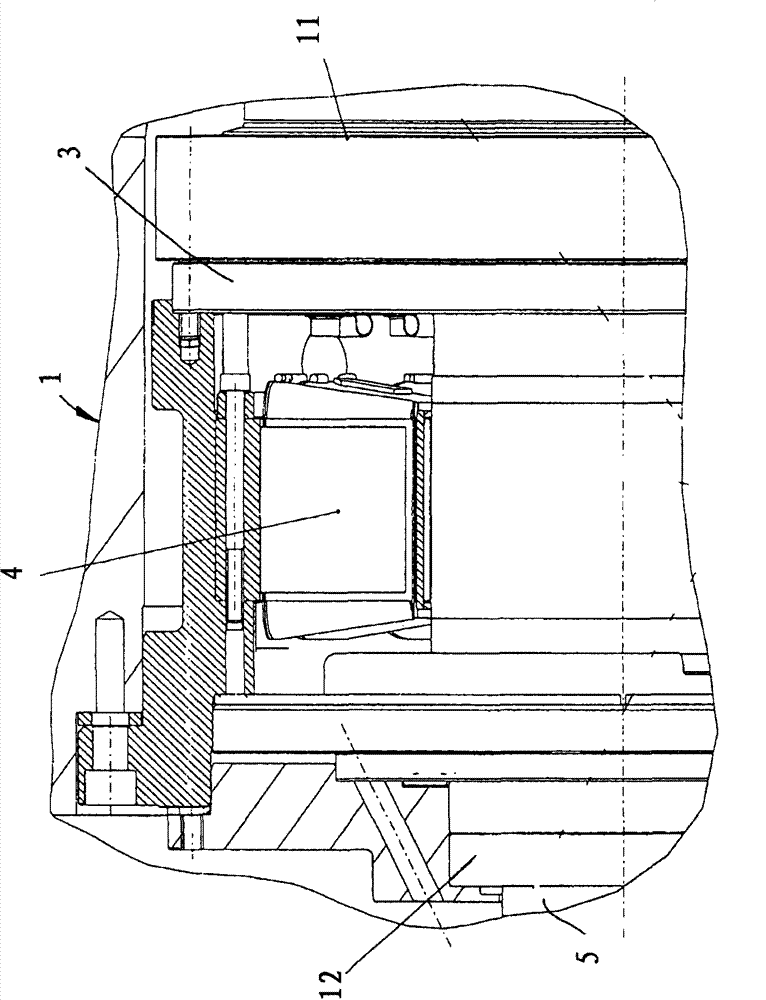

[0022] Such as figure 1 As shown, a turbine for compressing gas or vapor according to the invention has a housing 1 schematically indicated by dot-dash lines, and a rotor 2 rotatably supported in housing 1 on bearings 3 and 4 for rotation about an axis 10 . According to the invention, the rotor 2 has a shaft 5 of small diameter and a set of disks 6 a to 6 e with integrated rotor blades, one of which is schematically indicated at 14 . Two radially outwardly protruding bushes 7a and 7b are integrally formed on the shaft 5 and the rotor 2 is attached to the shaft 5 only at the position of the bushes. Only the two end discs 6a and 6e are fixed to respective bushings 7a and 7b. The shaft 5 is supported in the housing 1 via an axial magnetic bearing 3 and a radial magnetic bearing 4 .

[0023] The disks 6a to 6e of the rotor 2 are formed with stepped shoulders 8 forming radially facing annular surfaces and axially facing annular surfaces that complement each other, ensuring that s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com