High-pressure pump

A technology for high-pressure pumps and pump assemblies, which is applied in the directions of pumps, multi-cylinder pumps, fuel injection pumps, etc., can solve the problem of occupying the structural space of the pump casing, and achieve the effects of compact implementation, reliable orientation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

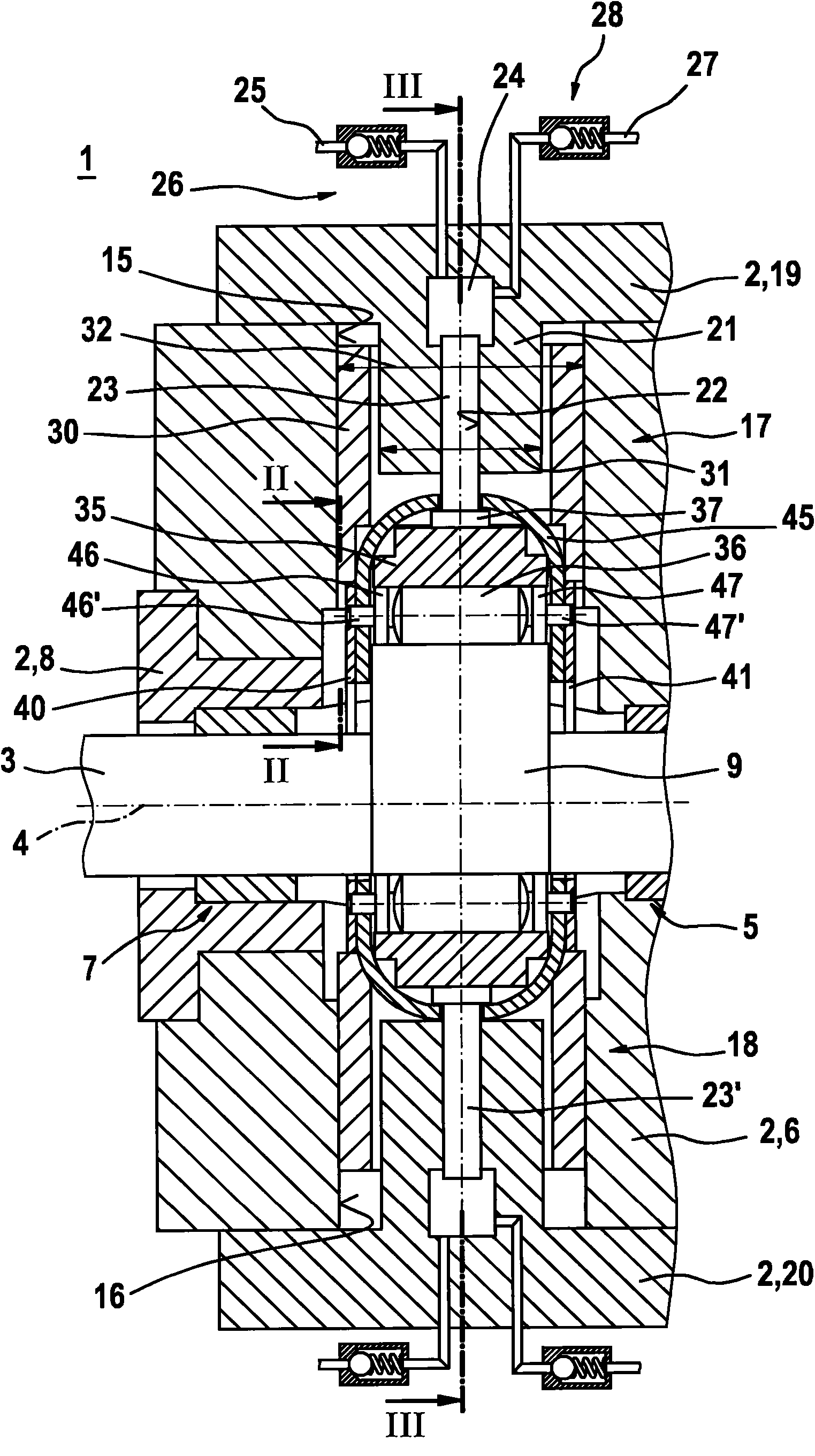

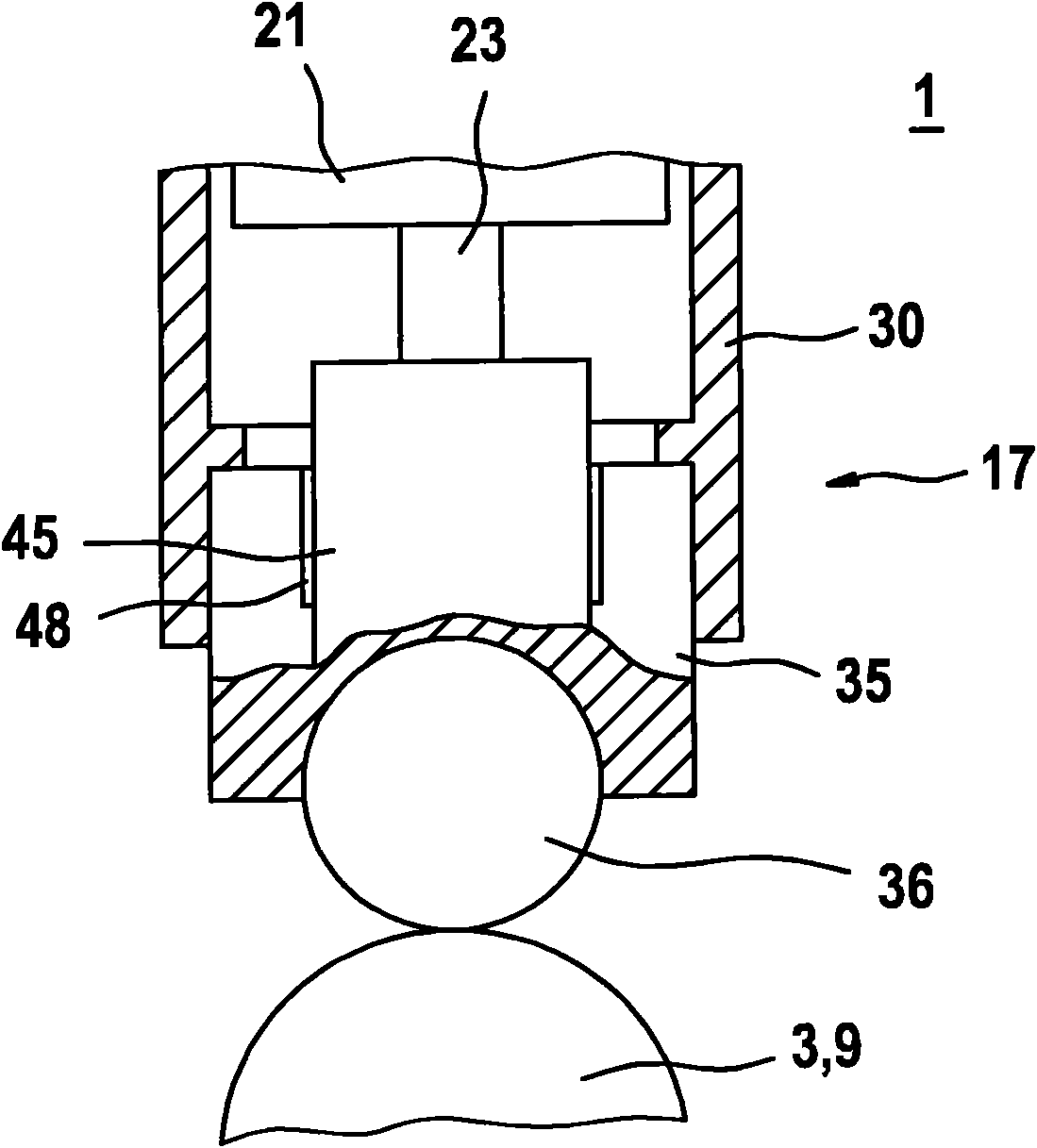

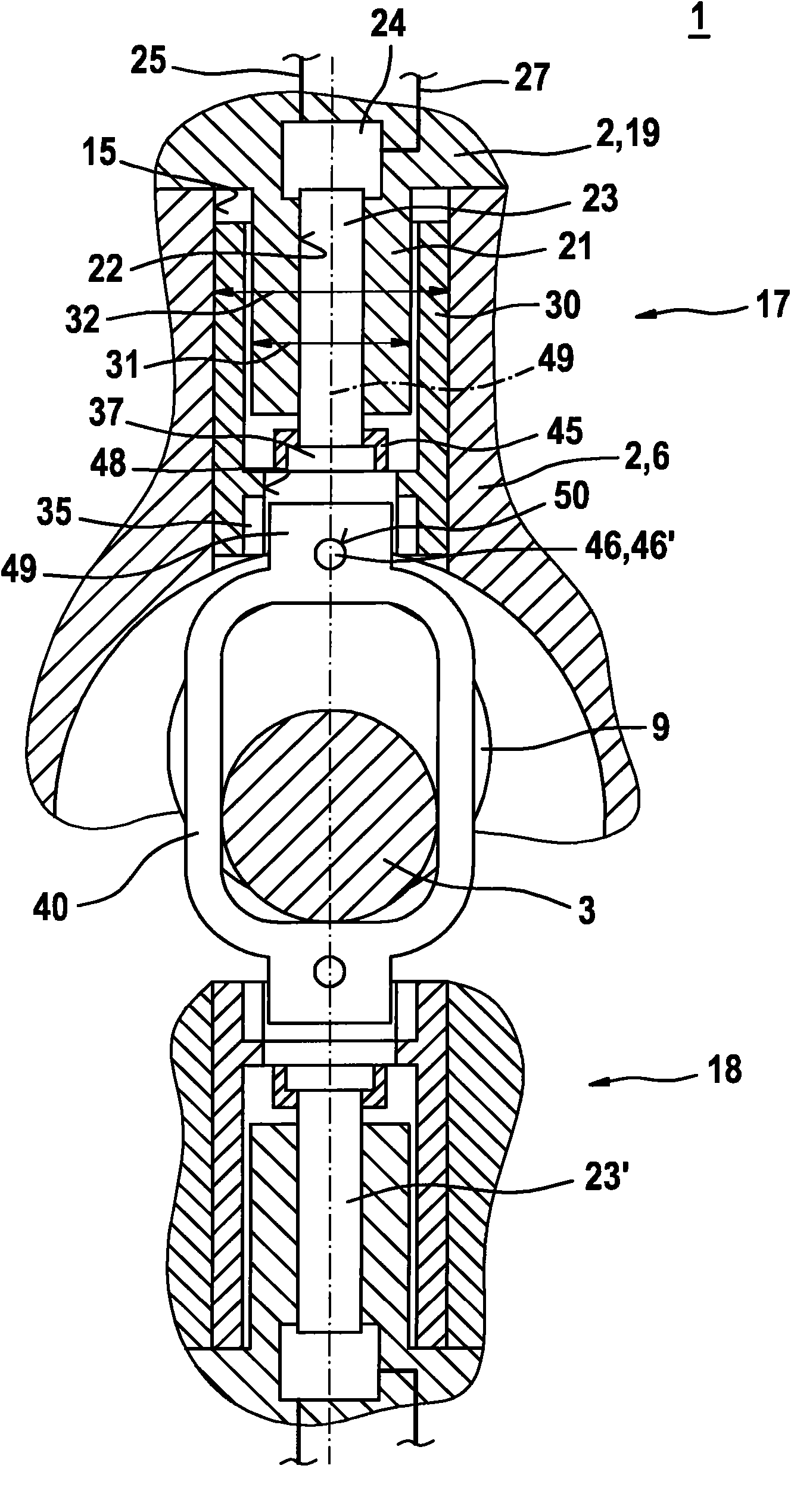

[0018] figure 1 A high-pressure pump 1 according to a first exemplary embodiment of the invention is shown in an axial partial section. The high-pressure pump 1 can be used in particular as a fuel pump for a fuel injection system of an air-compressed self-ignition internal combustion engine. The high-pressure pump 1 is preferably used in a fuel injection system with a fuel distribution plate, the so-called common rail, which stores diesel fuel under high pressure. However, the high-pressure pump 1 according to the invention is also suitable for other uses.

[0019] The high-pressure pump 1 has a multi-part housing 2 . The high-pressure pump 1 also has a drive shaft 3 which rotates about its axis 4 during operation. On the one hand, the drive shaft 3 is supported at bearing points 5 in the base body 6 of the housing 2 . On the other hand, the drive shaft 3 is supported at a bearing point 7 in a flange part 8 of the housing 2 connected to the base body 6 . The two bearing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com