Vacuum Chuck Or Gripping Device

A technology of clamping device and clamping device, which is applied in the directions of positioning device, clamping, transportation and packaging, etc., can solve the problem of lateral sliding of the workpiece, and achieve the effect of reliable production, simple and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the text below and in the figures, the same reference symbols are used in each case for identical and mutually corresponding features.

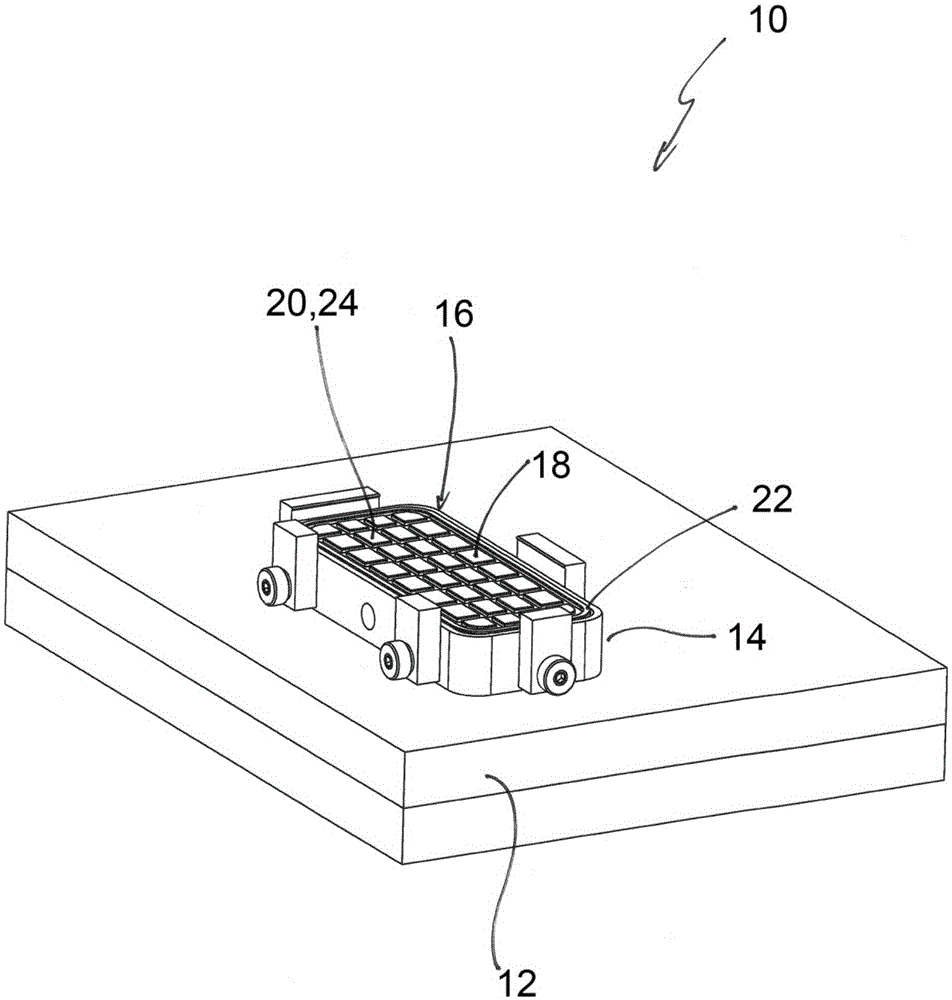

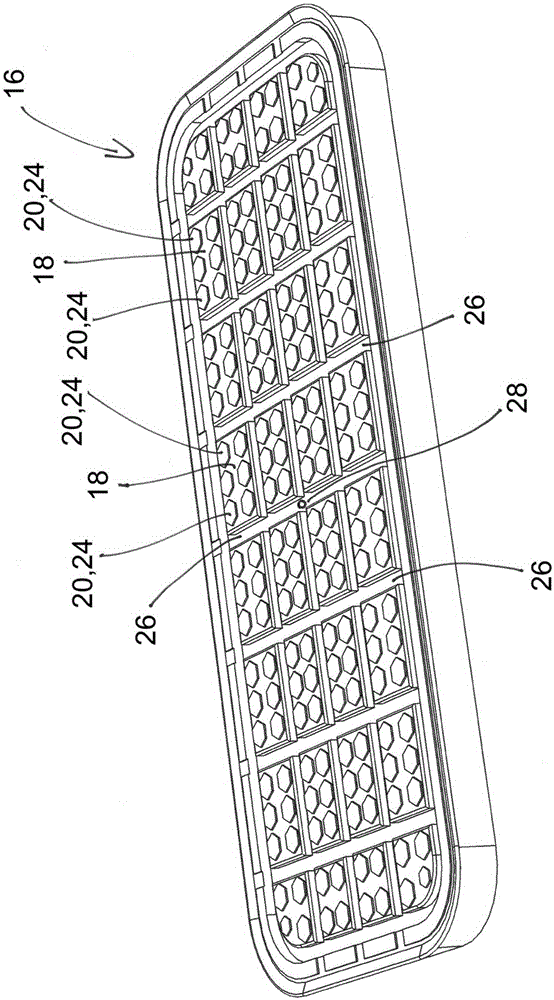

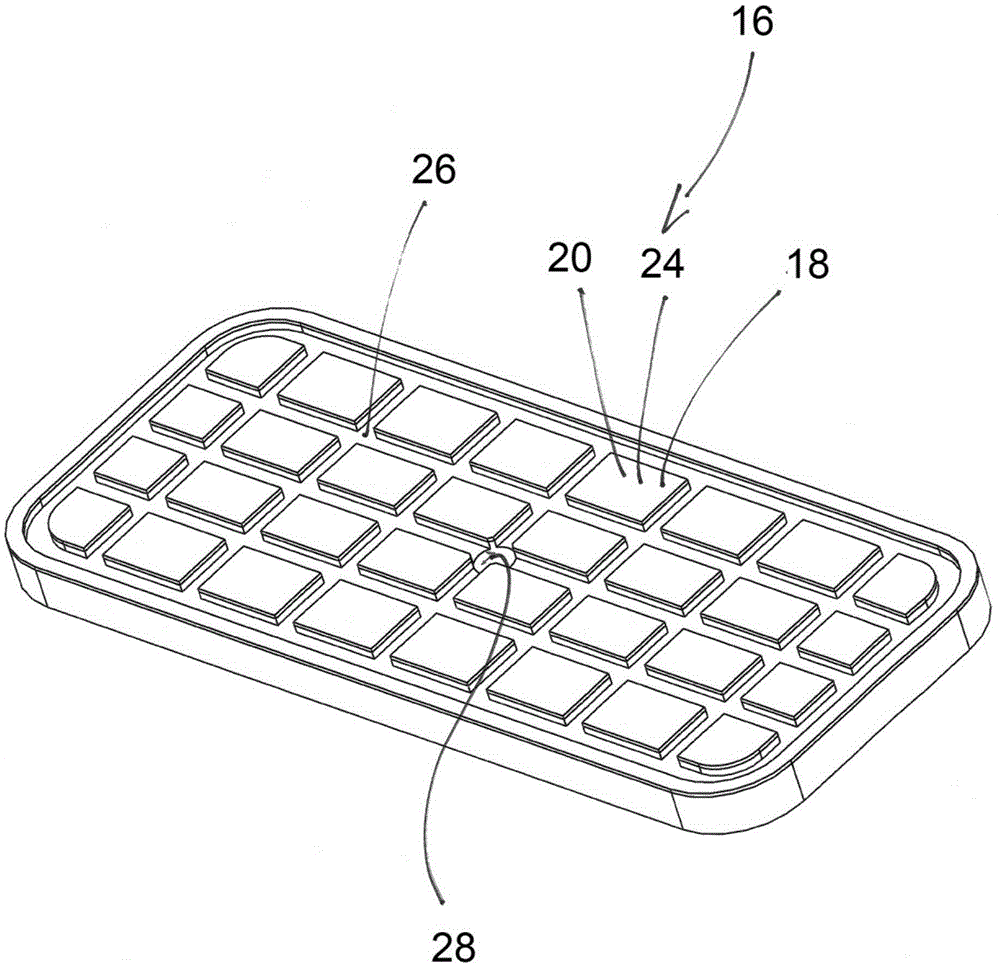

[0026] figure 1 A vacuum clamping device 10 is shown as an example, which is arranged on a table 12 of a processing device, not shown in detail. The vacuum clamping device 10 comprises a housing 14 with a vacuum supply system (not shown in detail), such as a vacuum chamber, arranged in the housing 14 . The housing 14 has an upper side which forms the suction surface 16 of the vacuum clamping device 10 , which is designed as a clamping surface in the example not shown. Adsorption surface 16 has suction port 28 (for example, see figure 2 , 3 ), through the suction port by means of a vacuum supply system, air can be sucked in, and thus the workpiece can be sucked onto the suction surface 16 .

[0027] The suction surface has a plurality of protruding regions 18 which provide contact regions 20 which, during operation of the device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com