Patents

Literature

48results about How to "Suppress lateral vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

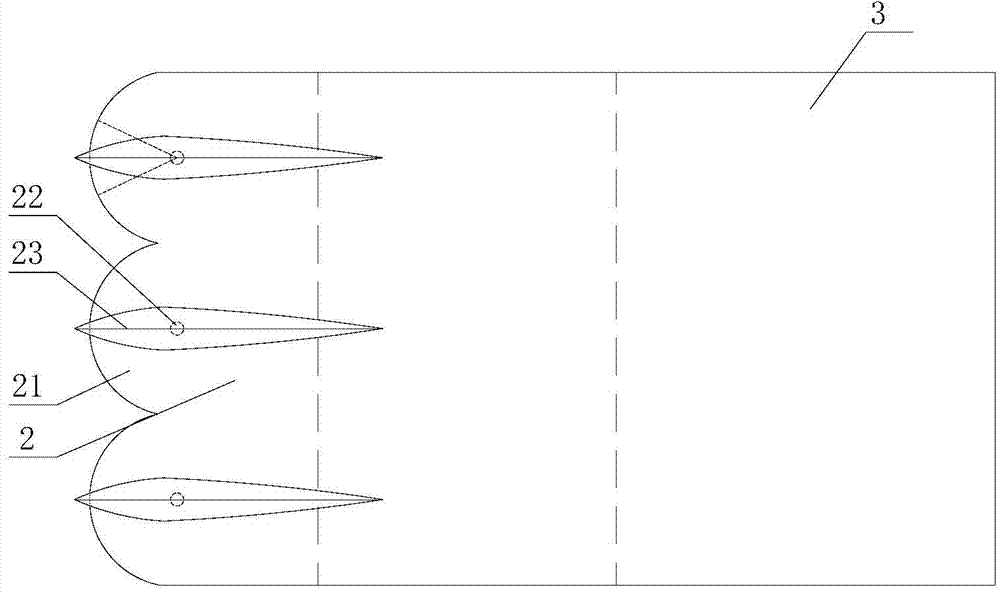

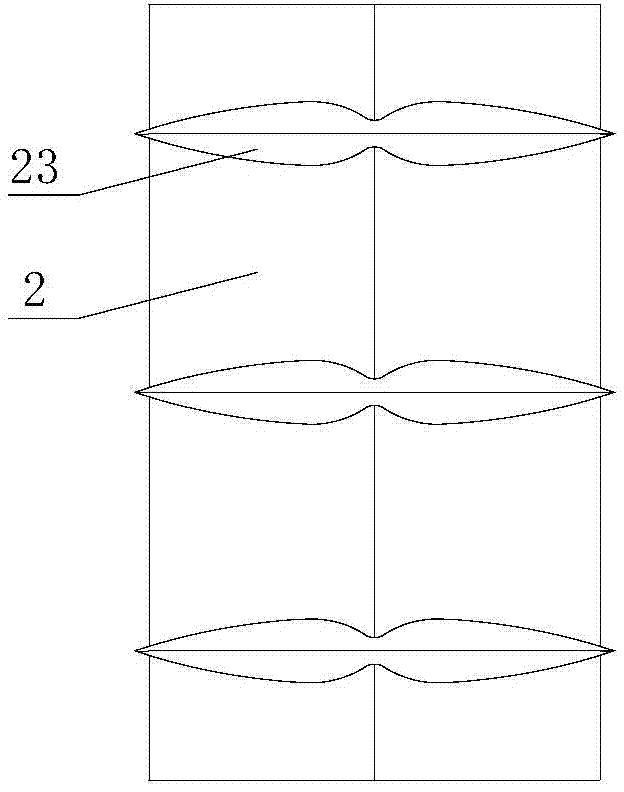

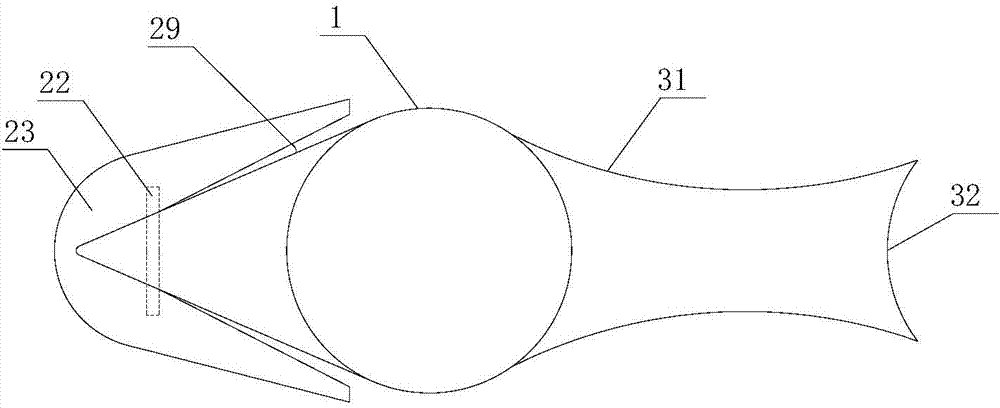

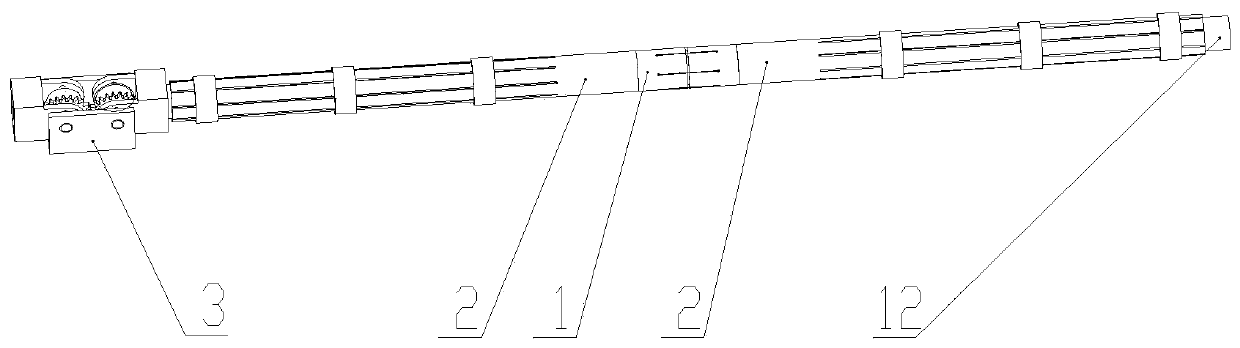

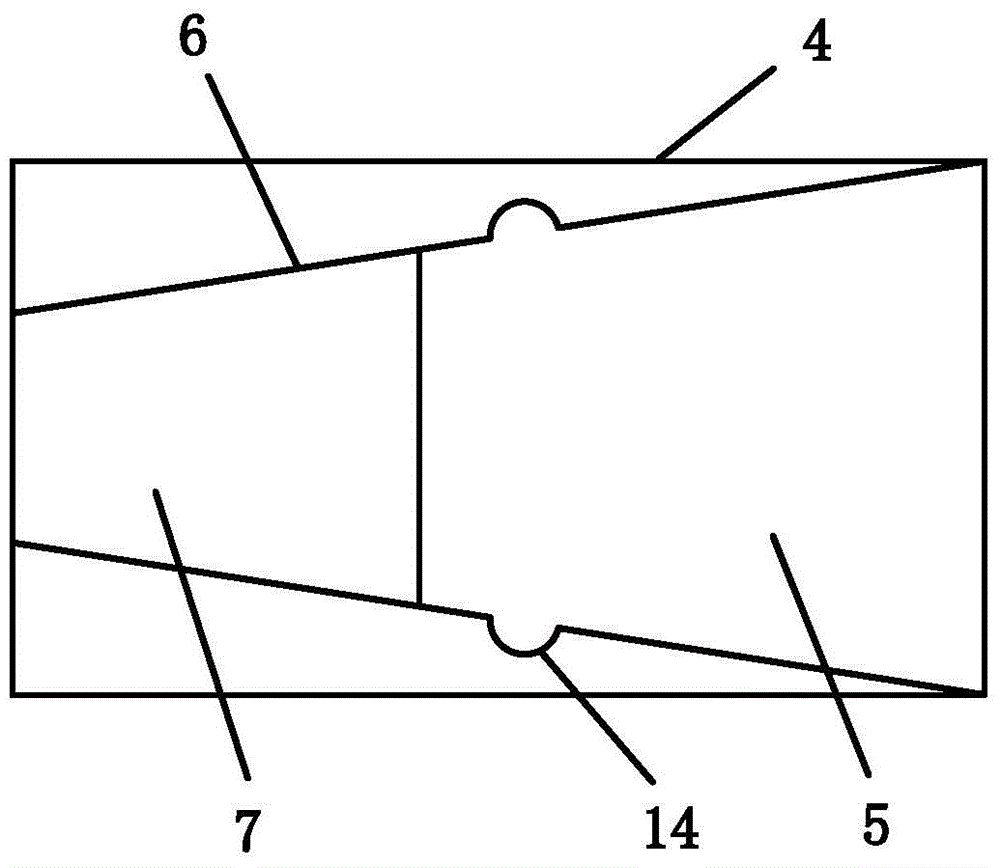

Marine riser vortex-induced vibration suppression device

ActiveCN104747098AReduce resistanceReduce wake effectsPipe laying and repairDrilling rodsVertical tubeSurface ocean

The invention discloses a marine riser vortex-induced vibration suppression device. The marine riser vortex-induced vibration suppression device is arranged on a marine riser. The marine riser vortex-induced vibration suppression device comprises a V-shaped front end panel and a tail fin type fairing. The V-shaped front panel board is arranged on the side, facing the marine current direction, of the marine riser. The tail fin type fairing is arranged on the side, back to the marine current, of the marine riser. The cross section of the V-shaped front end panel is V-shaped, and is tangent to the surface of the marine riser. The marine riser vortex-induced vibration suppression device has the advantages that by arranging V-shaped wing boards on the V-shaped front end panel, swinging in a small range can be achieved along with the current, incoming flow is led to be scattered, meanwhile resistance force on the marine riser due to the incoming flow can be lowered, the vortex-induced vibration can be effectively suppressed, lift force is greatly lowered, and the fatigue life of the riser is prolonged; the vortex-induced vibration suppression device has the advantages of being simple in structure, and convenient to process and install due to blocking.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

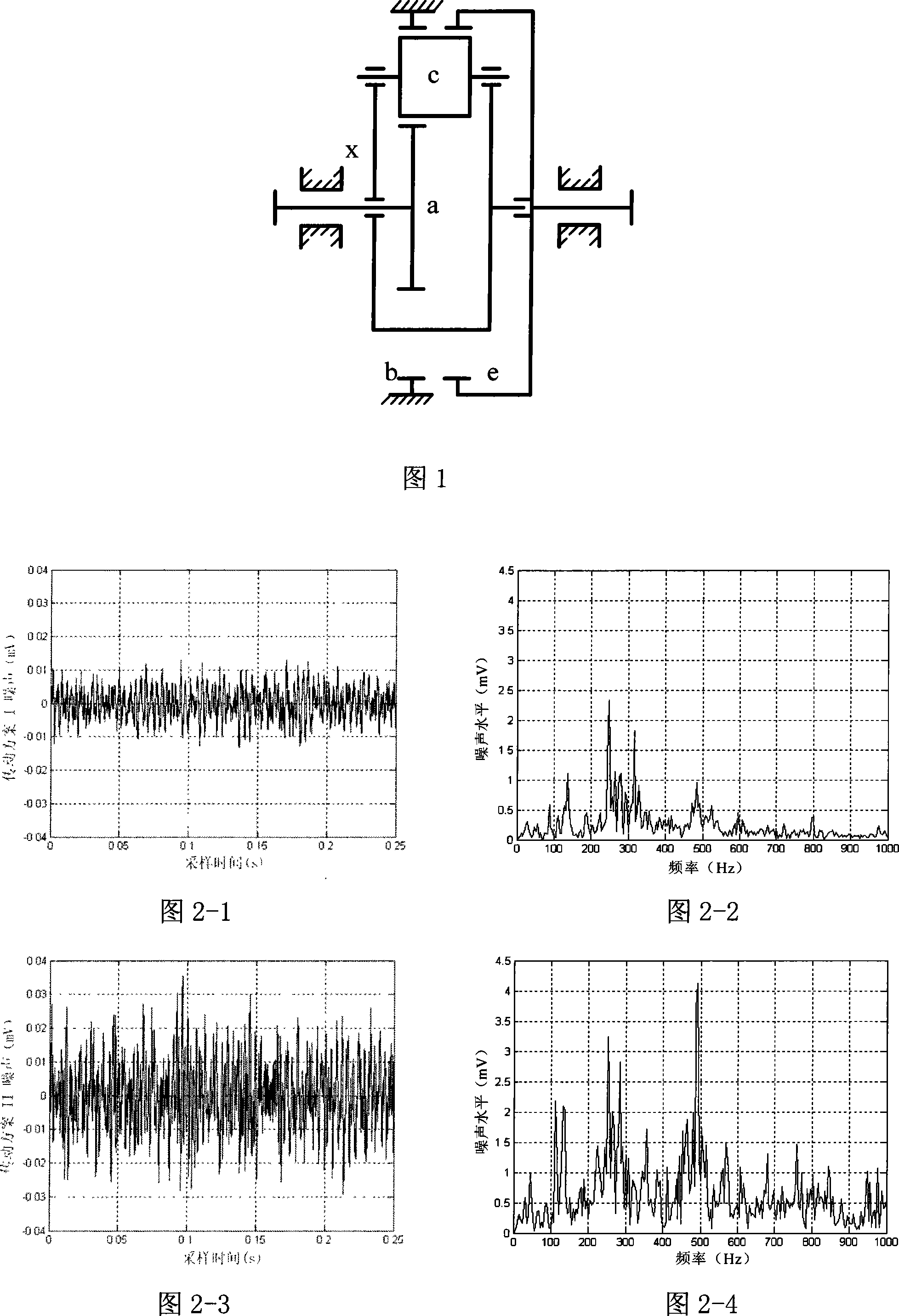

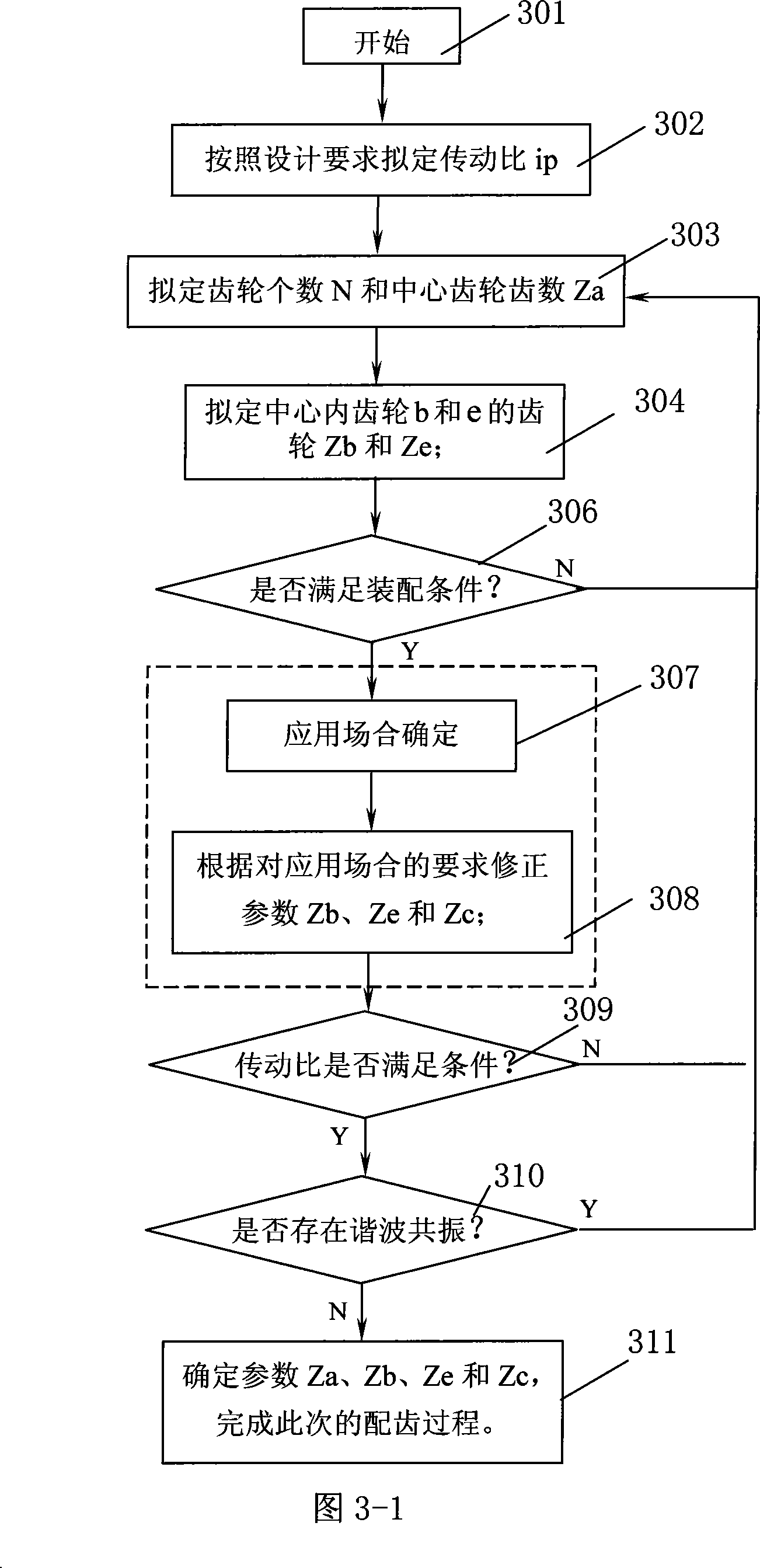

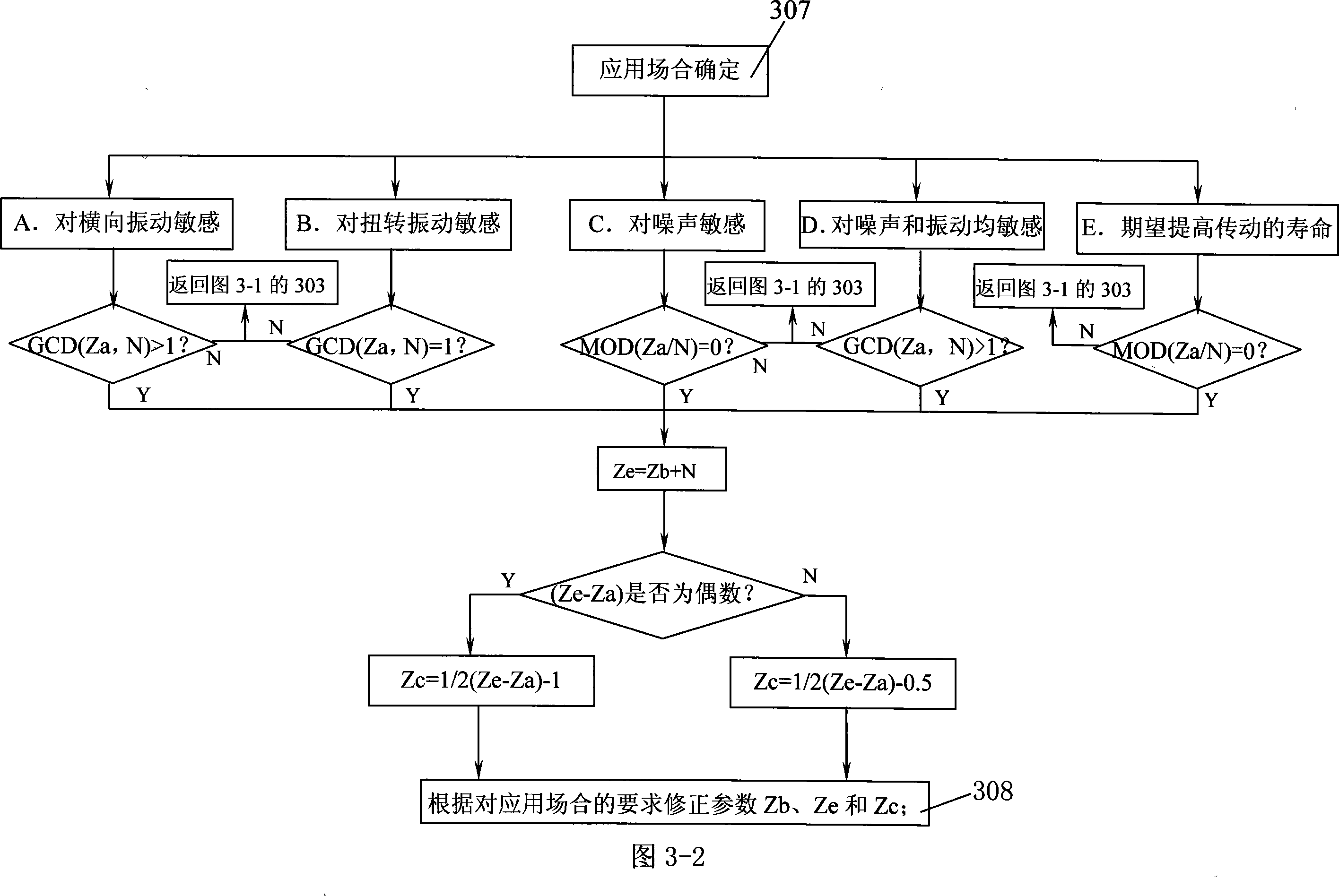

Planetary gear transmission gear-matching method

InactiveCN101216090AClarify the mapping relationshipEasy to match teethToothed gearingsSpecial data processing applicationsHarmonicTooth number

The invention discloses a tooth number determination method for planetary gear transmission, and solves the problems of the prior planetary gear transmission tooth number determination technology that the number of teeth is difficult to be determined, basis of determination is not sufficient and reasonable, vibration and noise are large, etc. The tooth number determination method disclosed by the invention comprises the following steps: (1) studying out a theoretical transmission ratio according to the design conditions; (2) determining the number of teeth of a central gear and the number of planetary gears; (3) judging whether the basic assembly conditions are met; (4) correcting the number of teeth of the central gear according to various requirements for application occasions of the transmission system; (5) further correcting the number of the teeth of the planetary gears according to the number of the teeth of the central gear, and obtaining a studied-out transmission ratio; (6) judging whether the studied-out transmission ratio meets the design requirement; if the design requirements are met, executing the next step; or else, returning to step (2); (7) analyzing vibration performance of the system; judging whether harmonic resonance occurs under a given rotation speed; if harmonic resonance occurs, returning to step (2); or else, taking the tooth number determination proposal as the final result.

Owner:TIANJIN UNIV

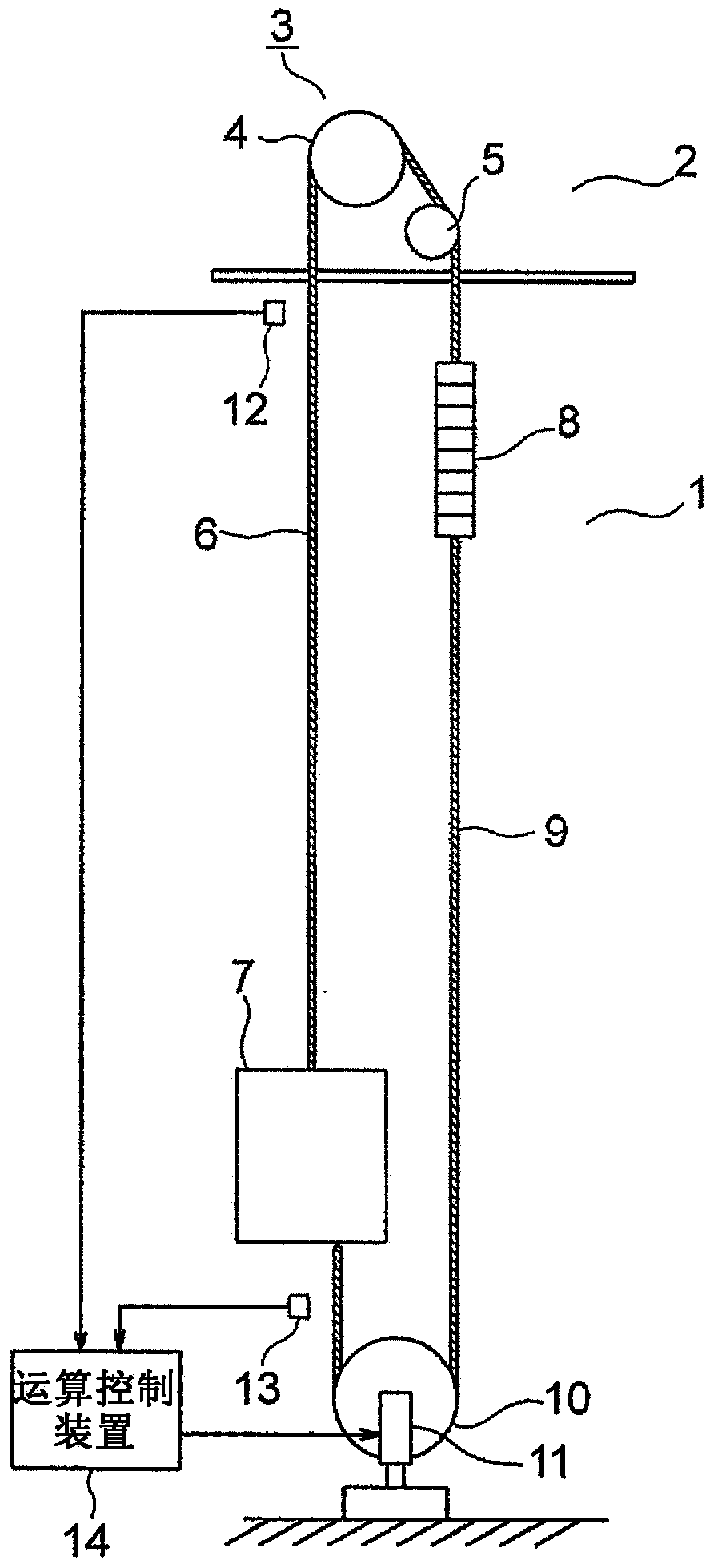

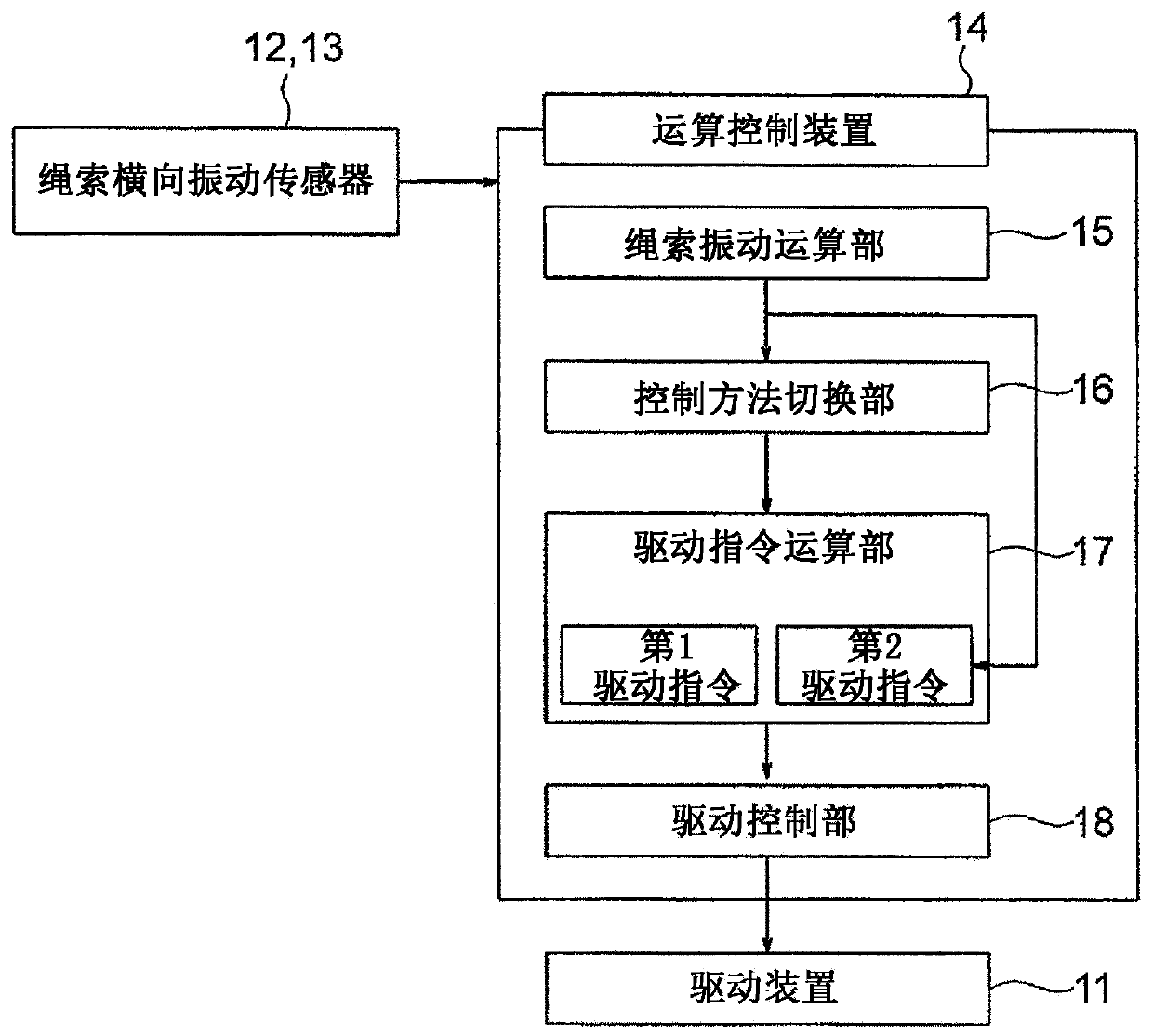

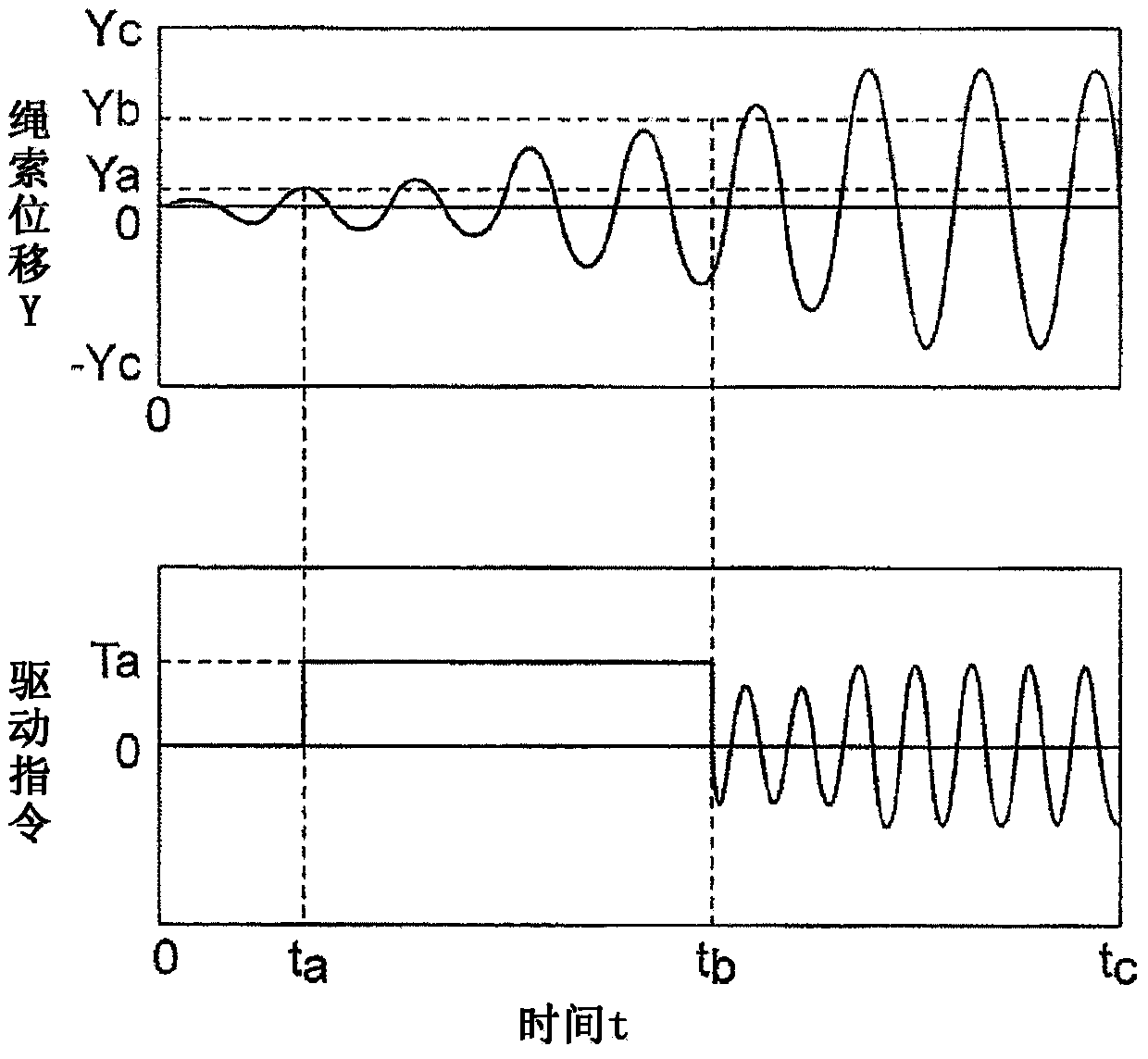

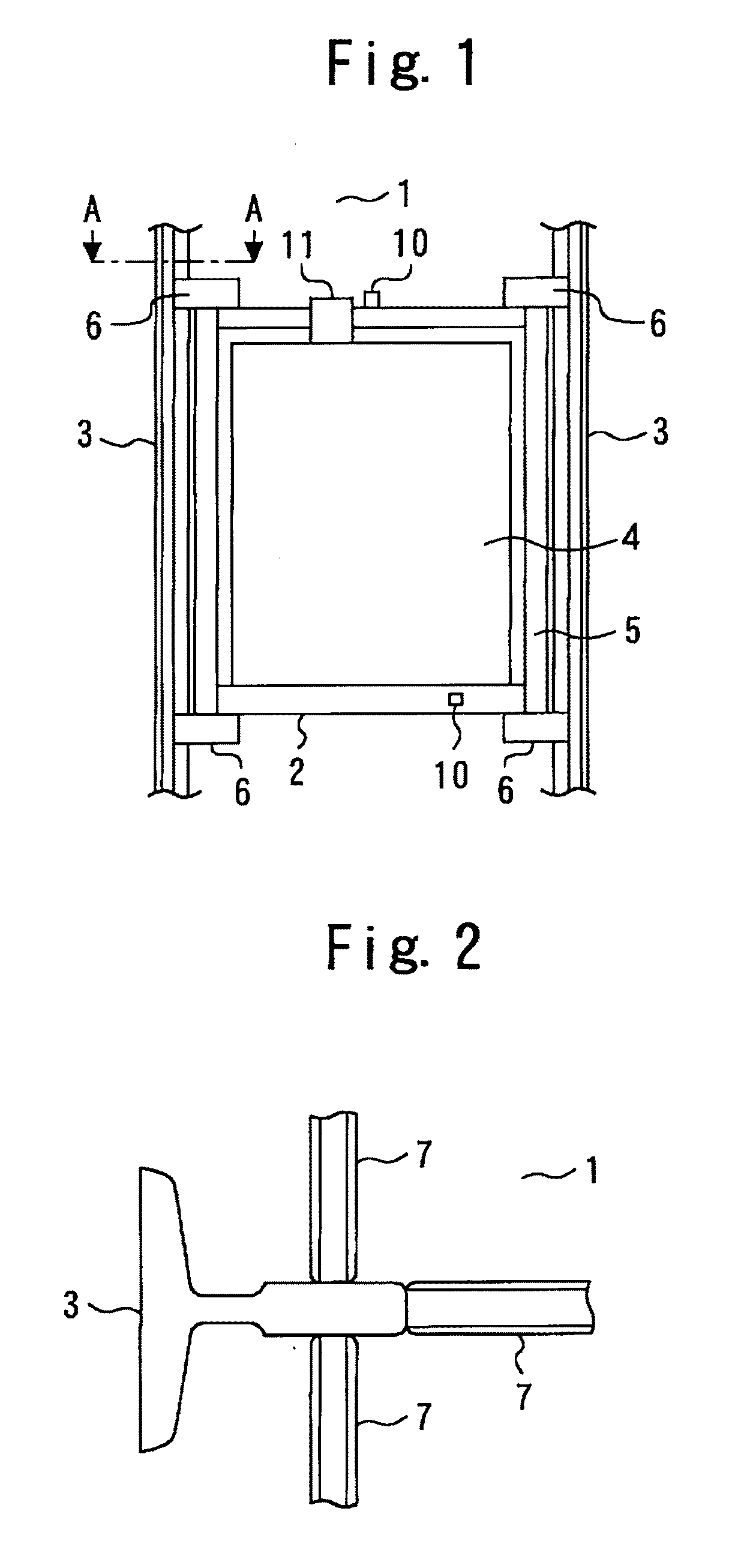

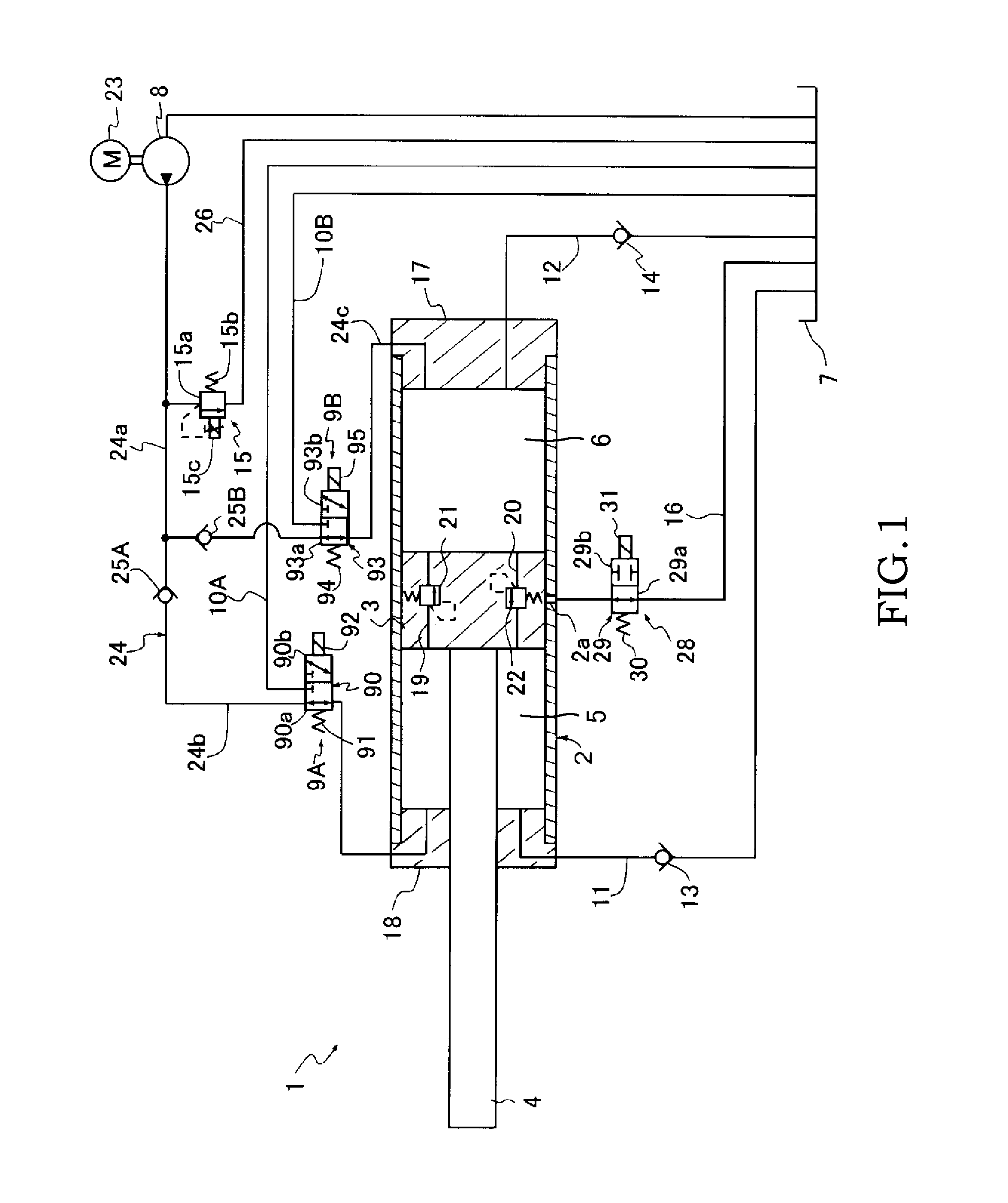

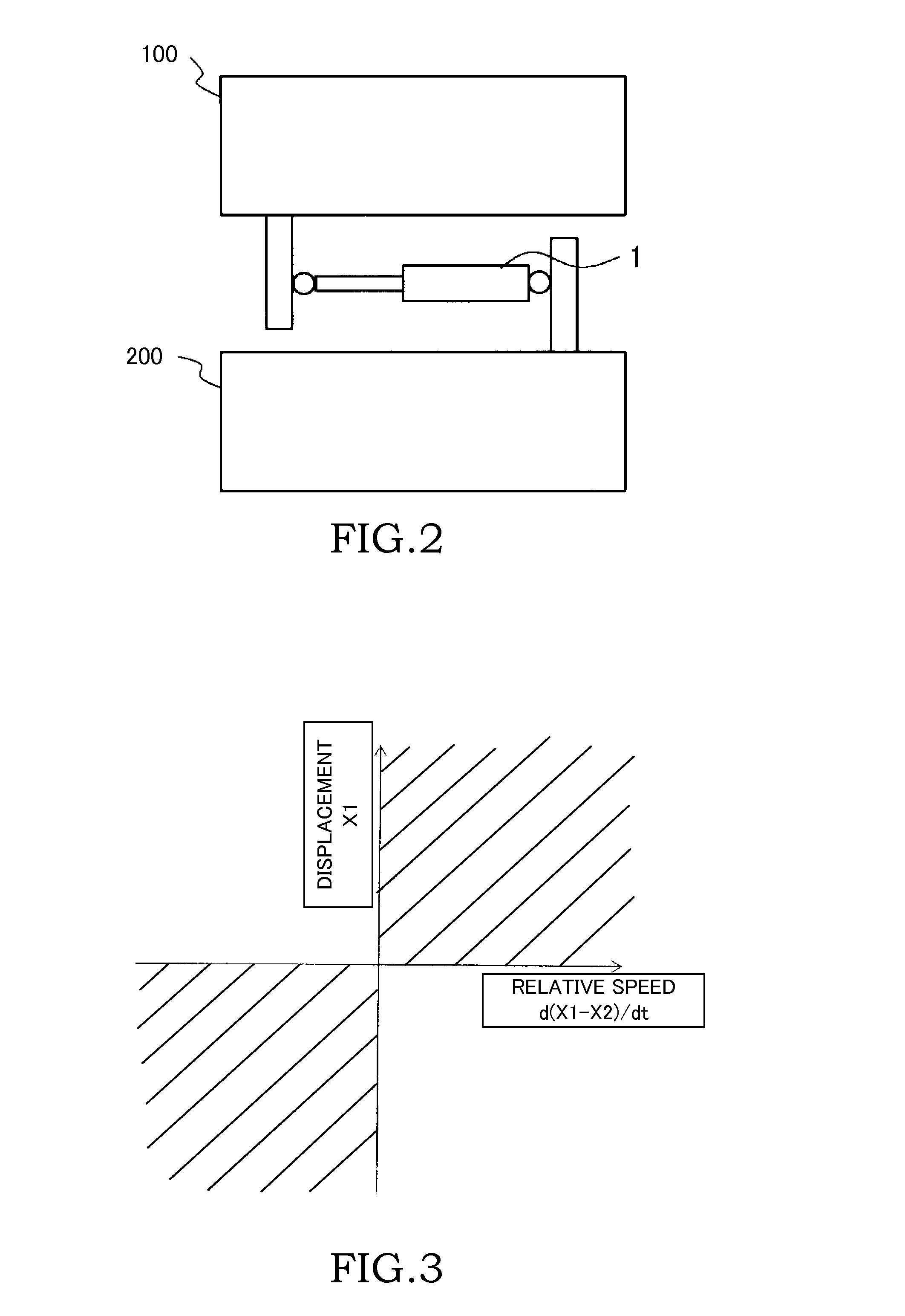

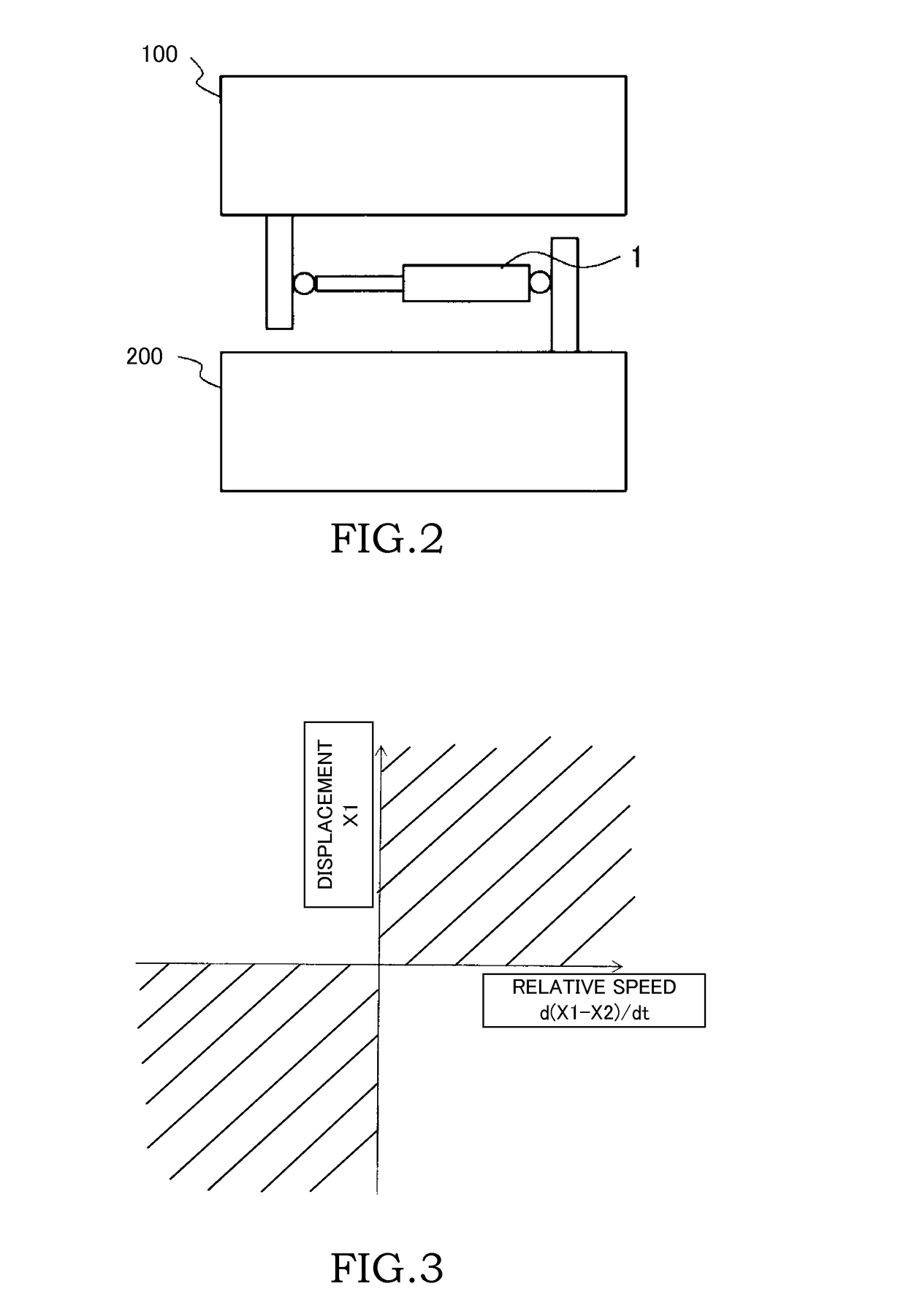

Elevator apparatus and rope sway suppressing method therefor

In an elevator apparatus, an actuating device applies a tension for suppressing a lateral vibration to a rope. A computation controller controls the actuating device by using lateral-vibration information of the rope as an input. Also, the computation controller selectively outputs, to the actuating device, a plurality of actuating commands including a first actuating command for applying the tension to the rope regardless of phase information of the lateral vibration of the rope and a second actuating command for applying a tension fluctuation for damping the lateral vibration to the rope based on the phase information.

Owner:MITSUBISHI ELECTRIC CORP

Enclosure structure with vibration suppression function and method for suppressing vibration of enclosure structure

ActiveCN107956650ALow densityDownwind shock reductionWind motor supports/mountsMachines/enginesEngineeringStructural vibration

The invention discloses an enclosure structure with a vibration suppression function and a method for suppressing vibration of the enclosure structure. The outer surface of the enclosure structure isprovided with heat sources. The heat sources are used for heating an airflow boundary layer at the position of the outer surface of the enclosure structure, and through heating, the density of the airflow boundary layer rho can be lowered, the amplitude is reduced, and transverse vibration is suppressed; the airflow boundary layer at the position of the windward surface of the enclosure structureis heated, the airflow boundary layer density is lowered, and equivalently an airflow buffer layer is arranged at the windward surface; and when the windward incoming flow meets the airflow buffer layer, the turbulence can be weakened, the pulsatility is lowered, and the following wind impact on the enclosure structure is reduced, so that the following wind vibration of the enclosure structure canbe suppressed.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

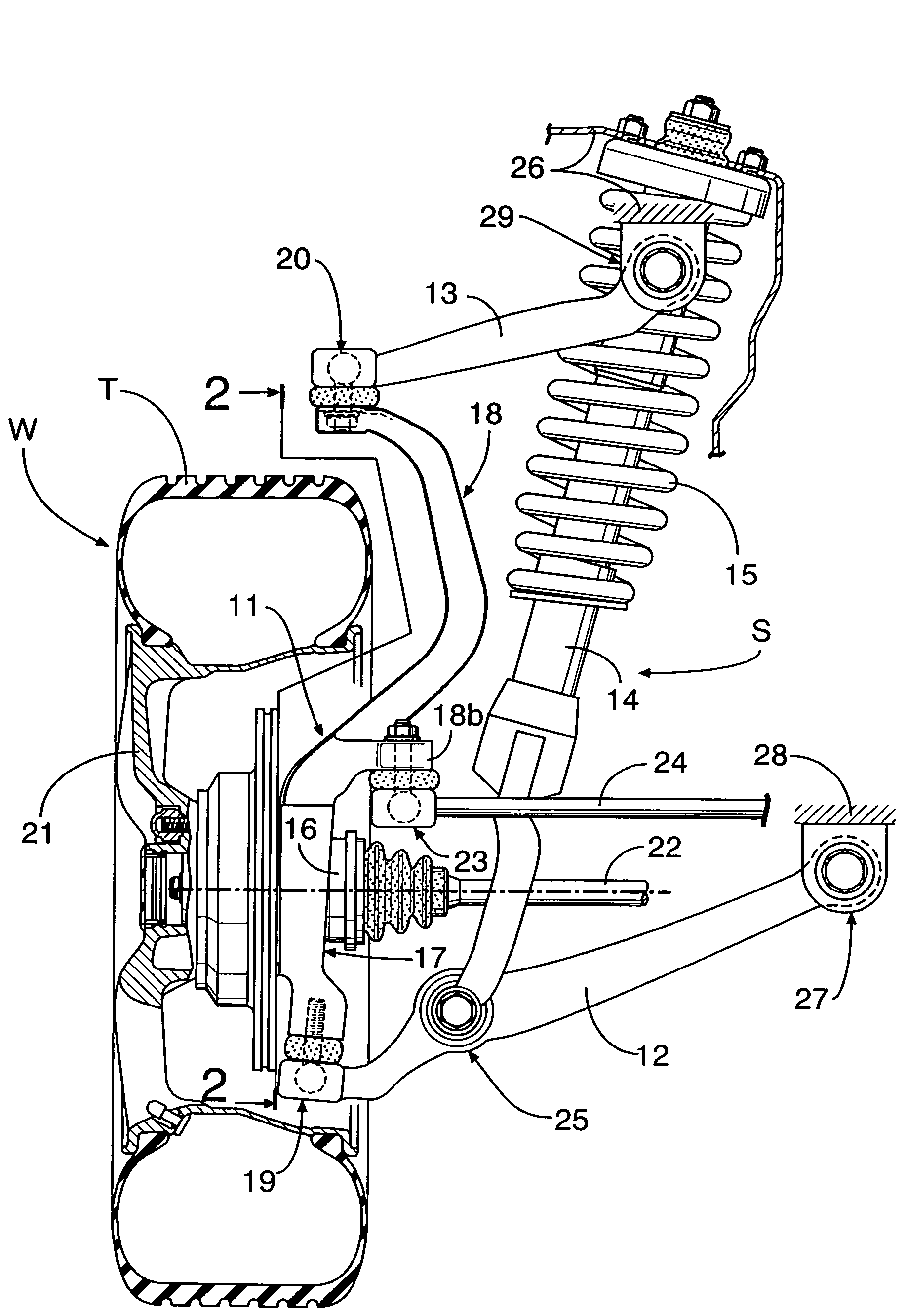

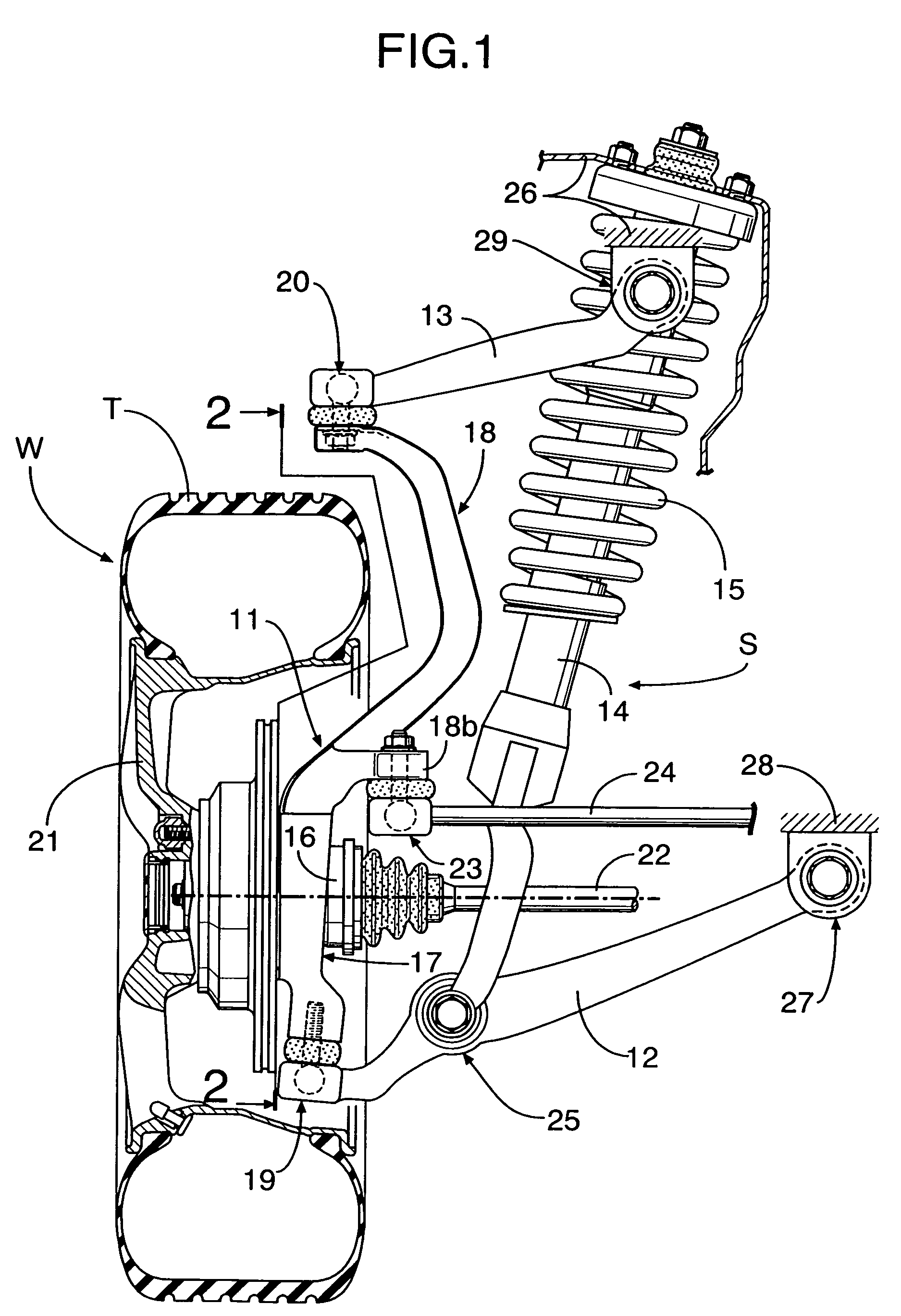

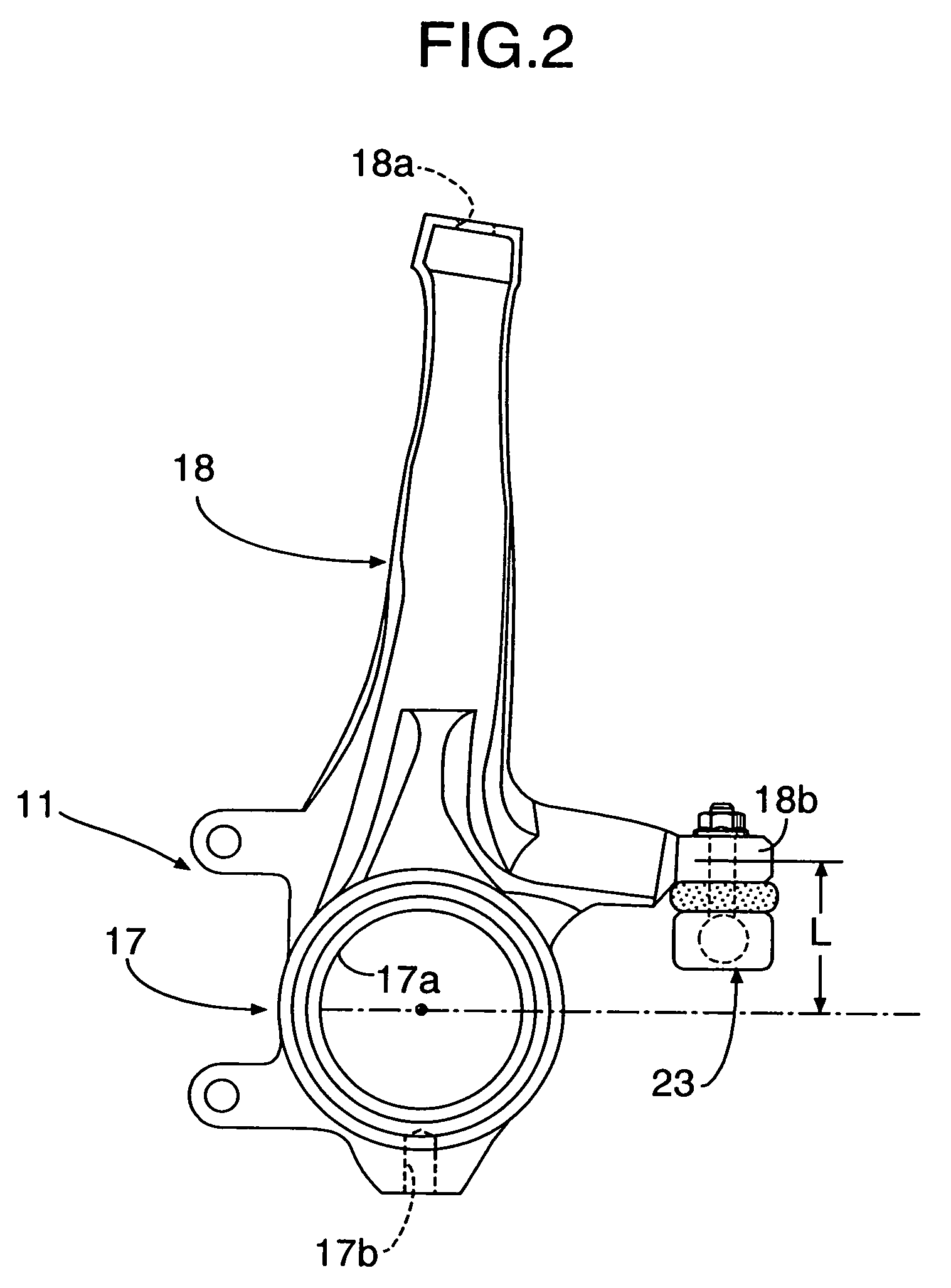

High-mounted double wishbone suspension device

InactiveUS7234712B2Reduce the numberReduce weightSteering linkagesResilient suspensionsDouble wishbone suspensionEngineering

In a high-mounted double wishbone suspension device, an arm portion extending upward from a knuckle main body portion, through which an axle runs, is provided with a tie rod connection portion. A tie rod for turning a wheel is connected to the tie rod connection portion. The distance between the axle and the tie rod connection portion is increased to effectively suppress knuckle lateral vibration centered on the axle by the tie rod. Therefore, it is possible to reduce road noise without increasing the number of components or the weight. In particular, since the tie rod is connected to a joint provided on a lower face of the tie rod connection portion, it is possible to minimize vertical positional change of the tie rod, while suppressing lateral vibration of the knuckle by raising the position of the tie rod connection portion, whereby the arrangement can be easily applied to a conventional vehicle merely by replacing the knuckle alone.

Owner:HONDA MOTOR CO LTD

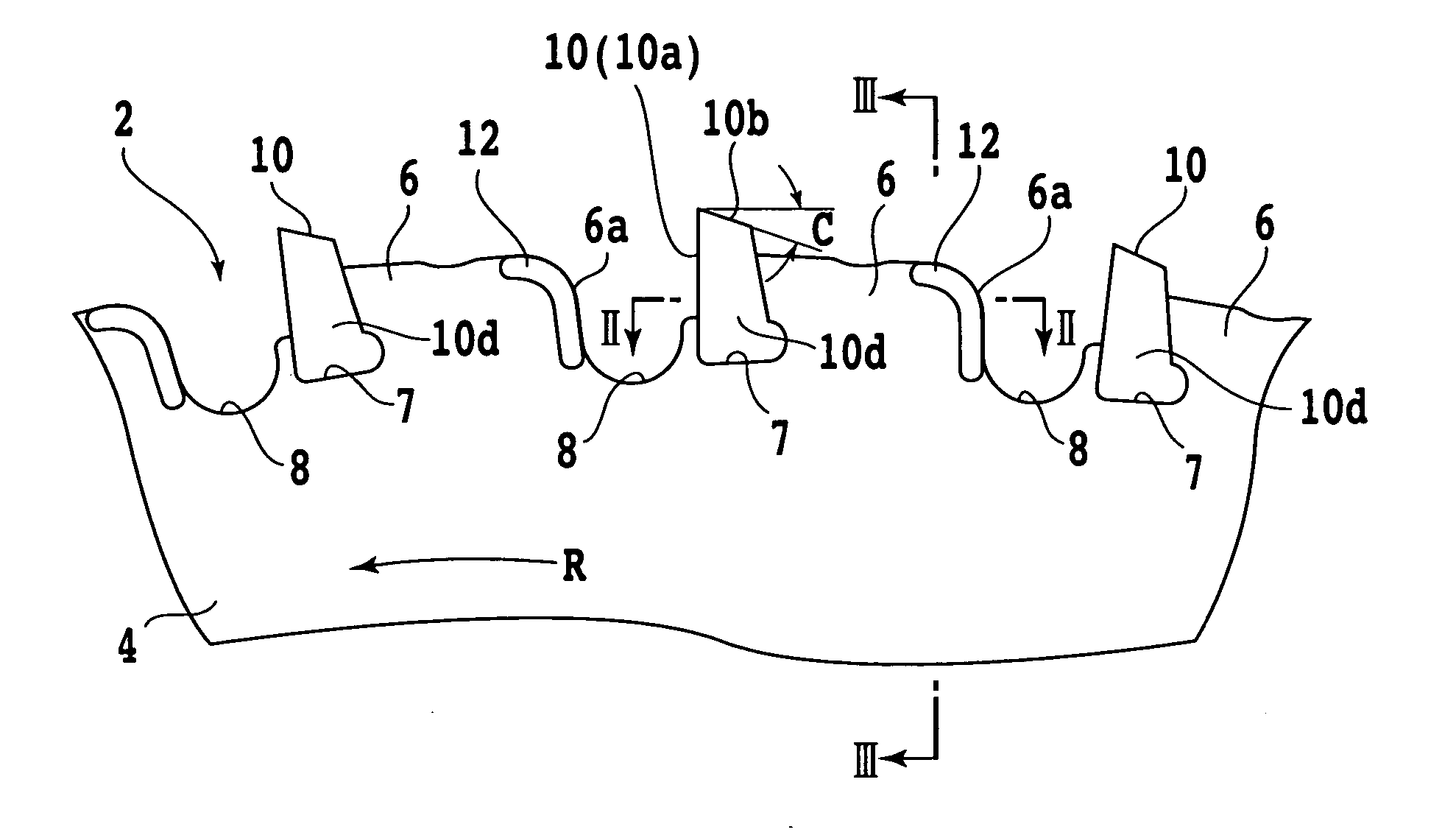

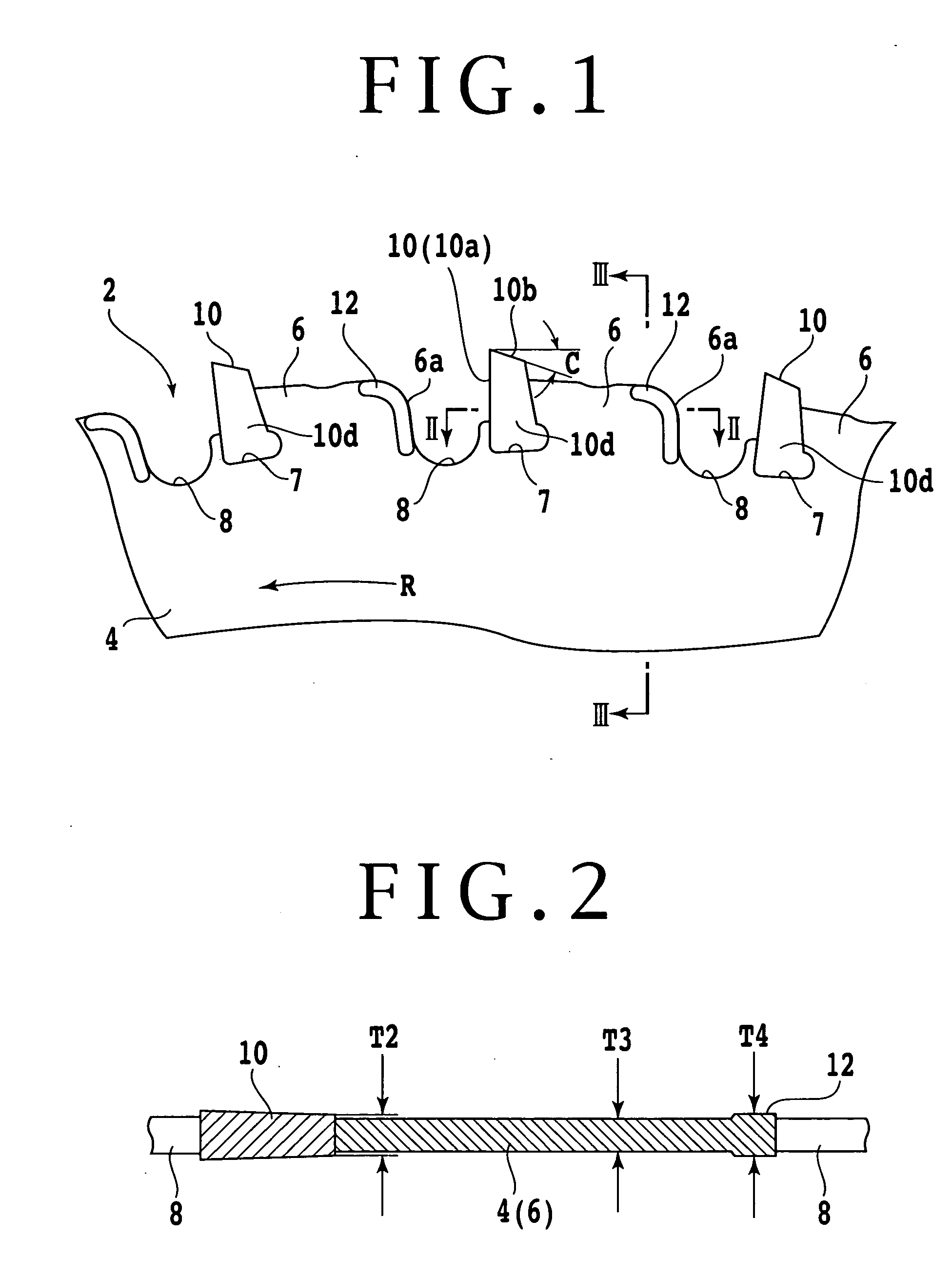

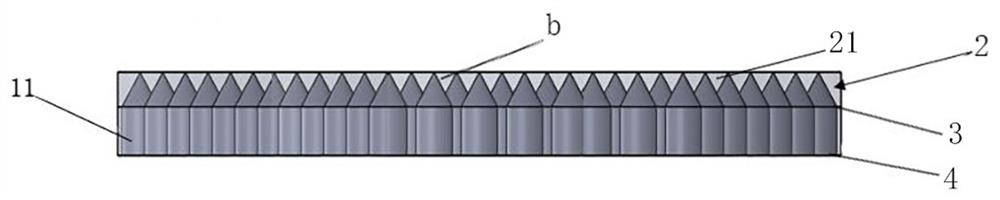

Disk cutter with plurality of thicker portions

InactiveUS20070095190A1Suppress lateral vibrationSimple structureMetal sawing devicesMetal sawing toolsCircular disc

Owner:TENRYU SAW MFG

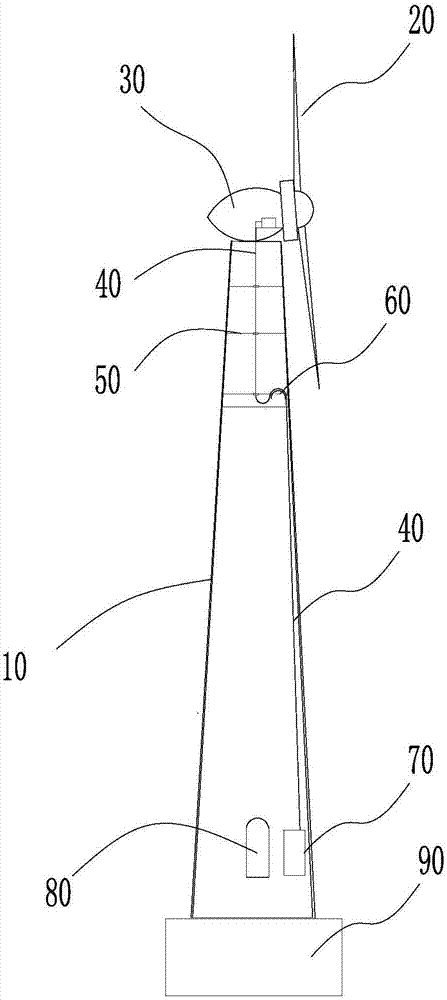

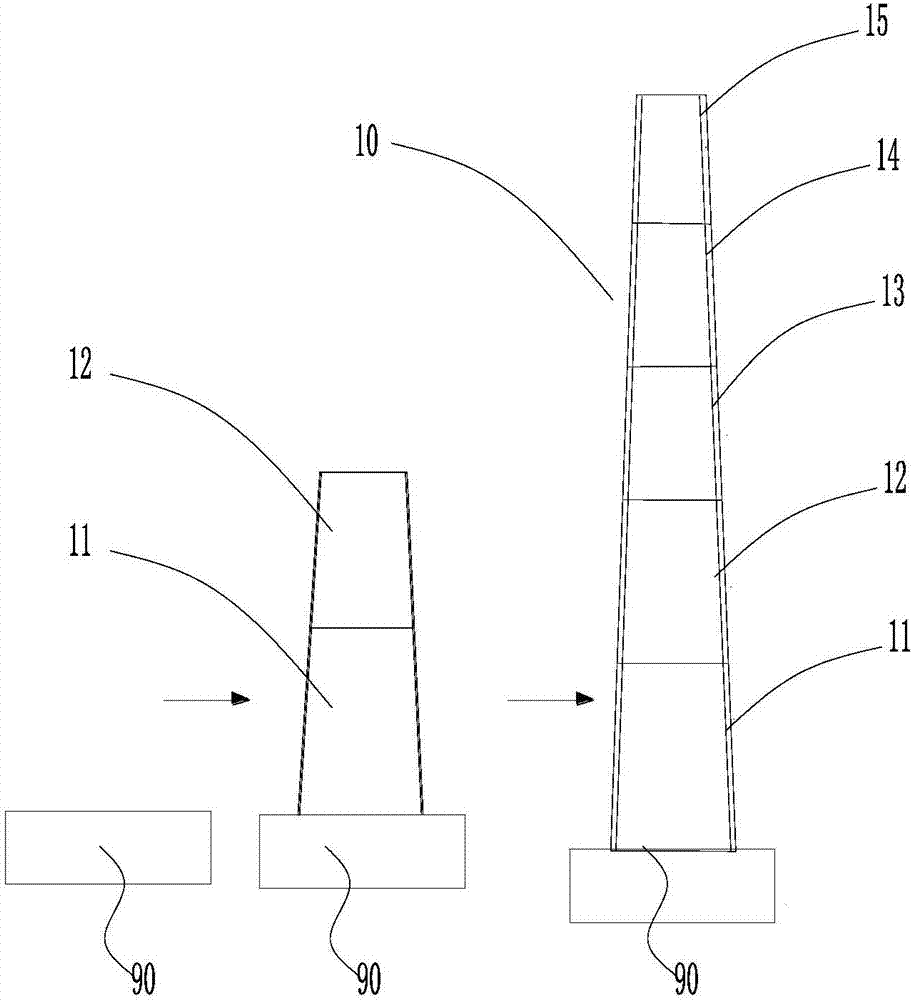

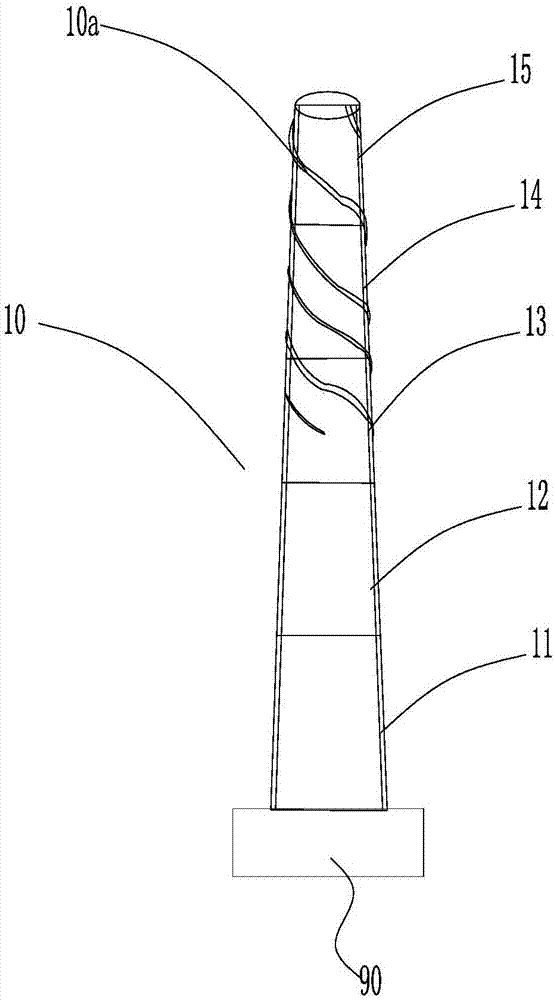

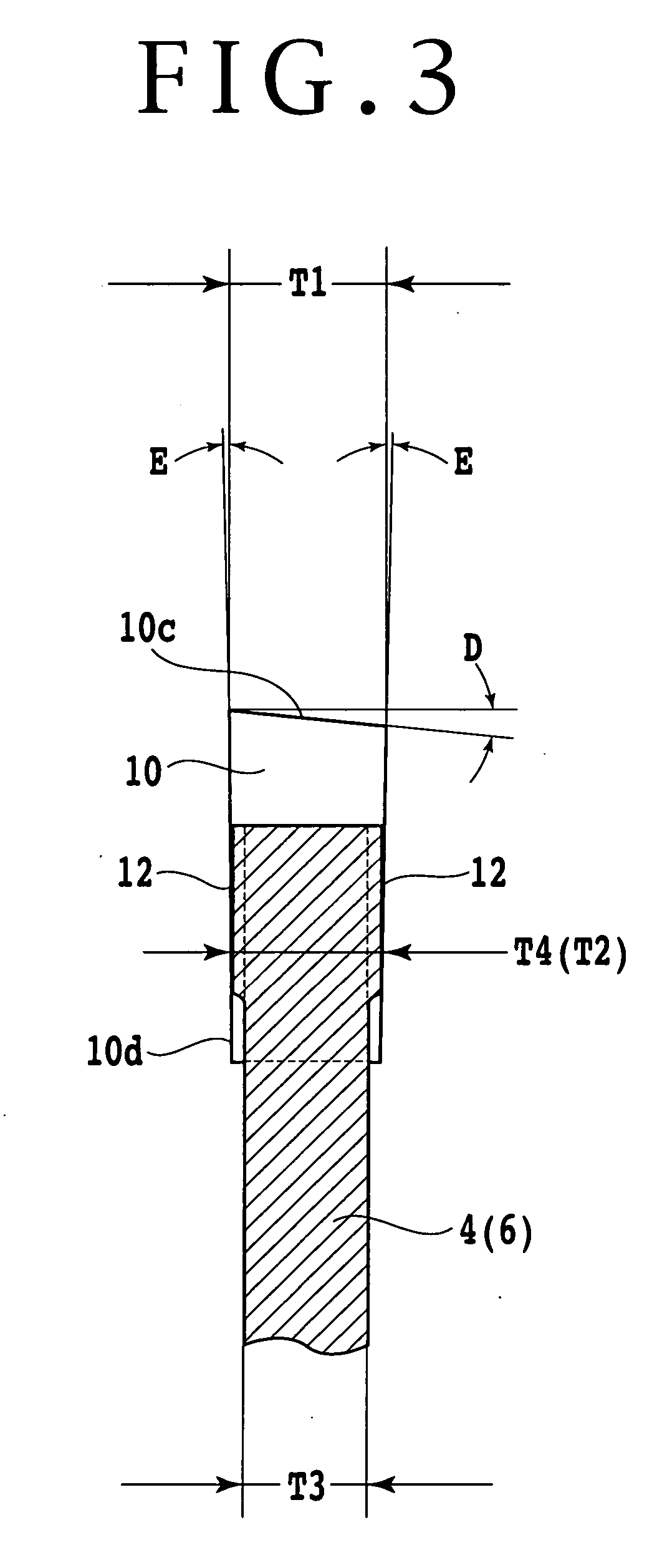

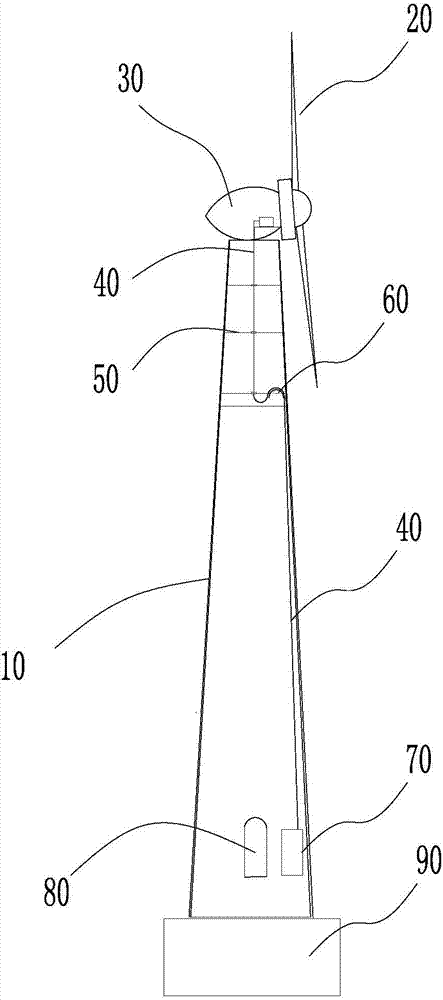

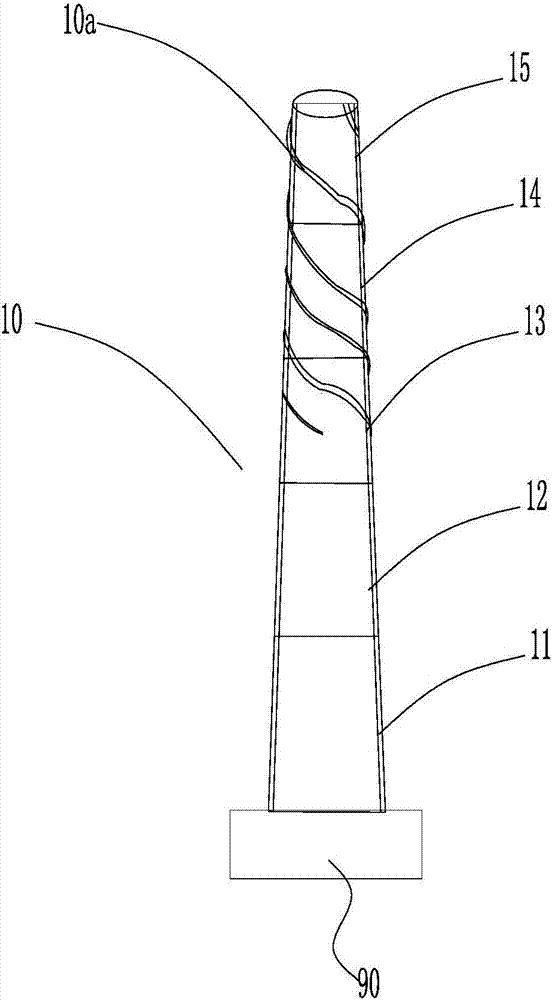

Surrounding body and equipment for inhibiting vibration of enclosure protection structure and method for hoisting tower drum

ActiveCN107461304ASuppress lateral vibrationSuppression of vortex induced vibrationWind motor assemblyWind motor supports/mountsElastomerTower

The invention discloses a surrounding body and equipment for inhibiting vibration of an enclosure protection structure and a method for hoisting a tower drum. The surrounding body can surround the enclosure protection structure, faces the outer surface of the inner side of the enclosure protection structure and is provided with a plurality of elastomers which extrude the enclosure protection structure under the action of an upwind inflow, and during extrusion, an airflow scaling flow passage is formed among the elastomers; and an airflow in the scaling flow passage has the air blowing function to the upper enclosure protection structure boundary layer, so that the airflow, on the upper side, flowing around the wall of the enclosure protection structure is interfered, the boundary layer at the position is destroyed, and formation of a Karman vortex street is inhibited and destroyed. According to the technical scheme of the invention, the natural force is fully utilized, and in the premise of greenness and environmental protection, the optimal turbulent flow breaking effect is achieved, the phenomenon of the Karman vortex street is inhibited, occurrence of vortex-induced vibration is hindered, or vibration is reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

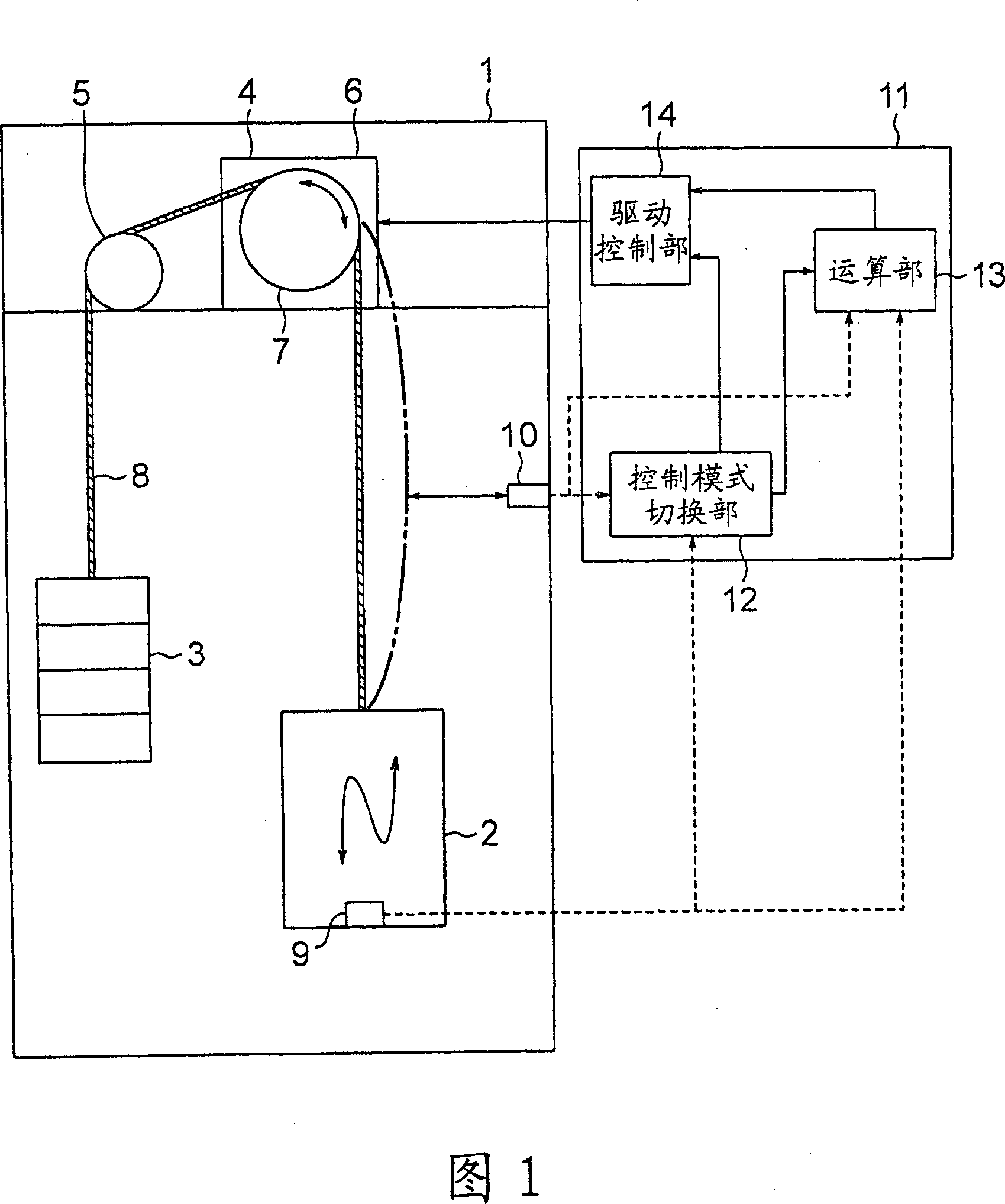

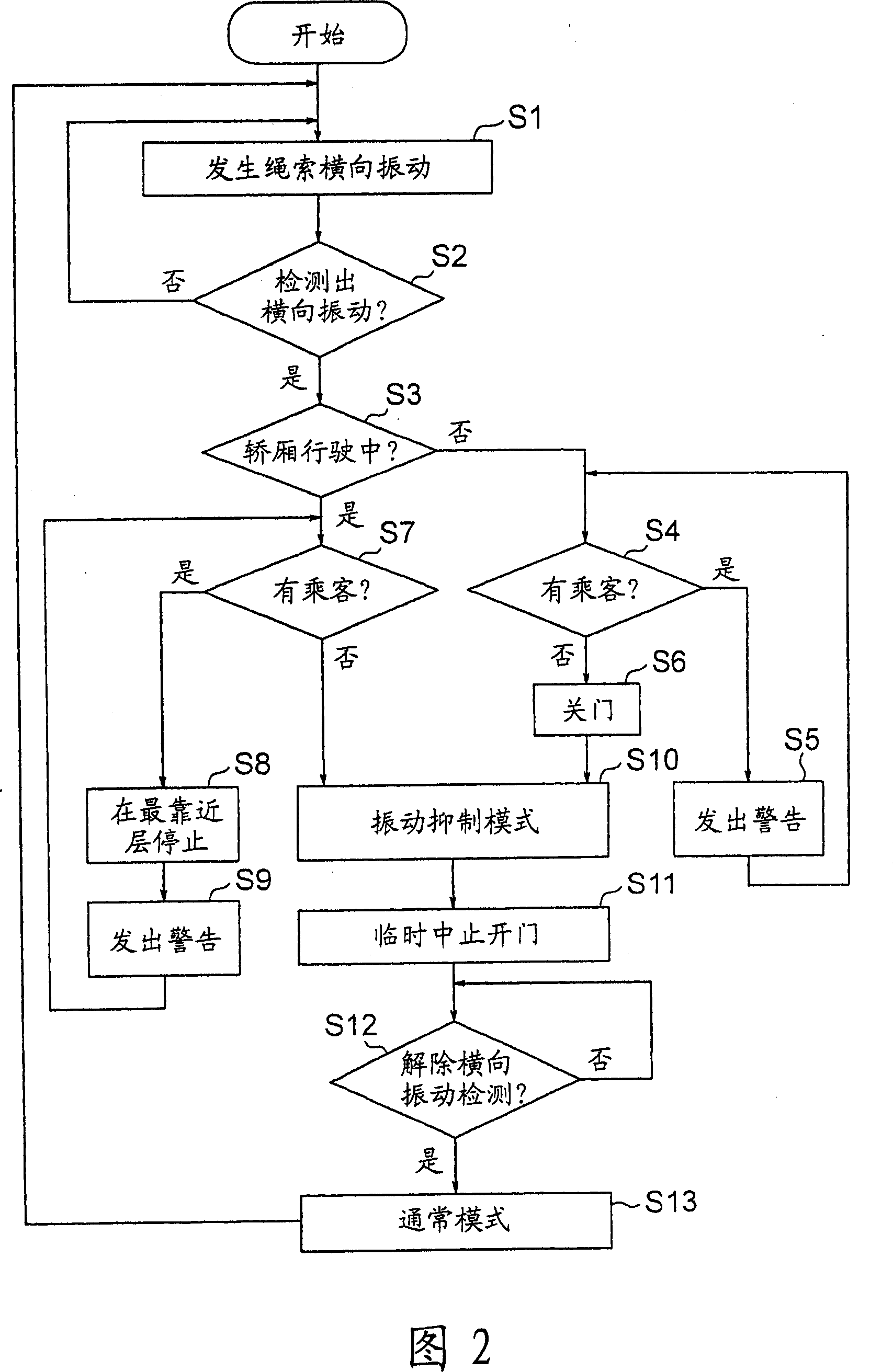

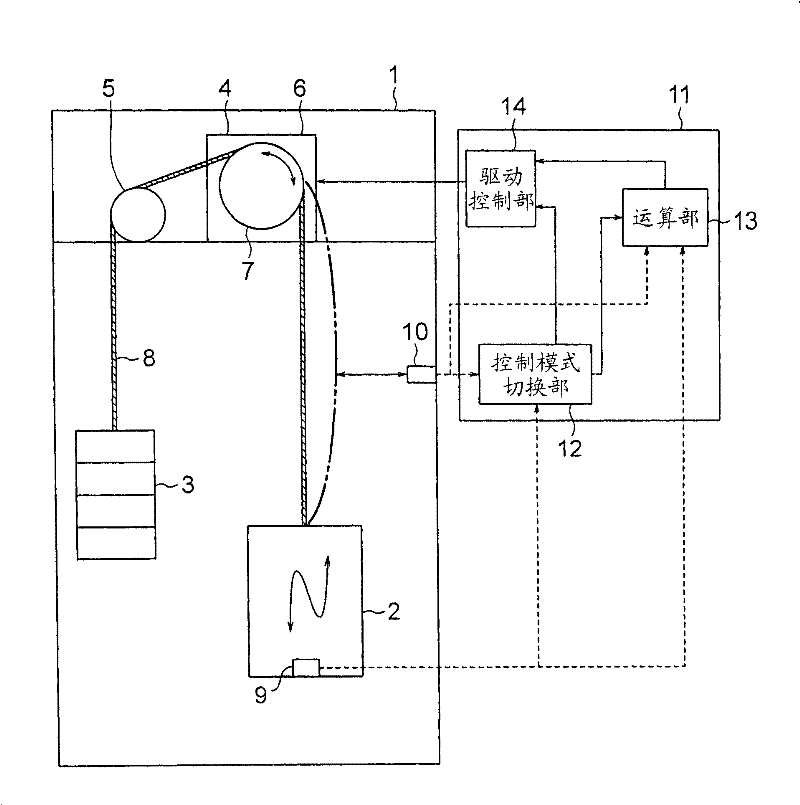

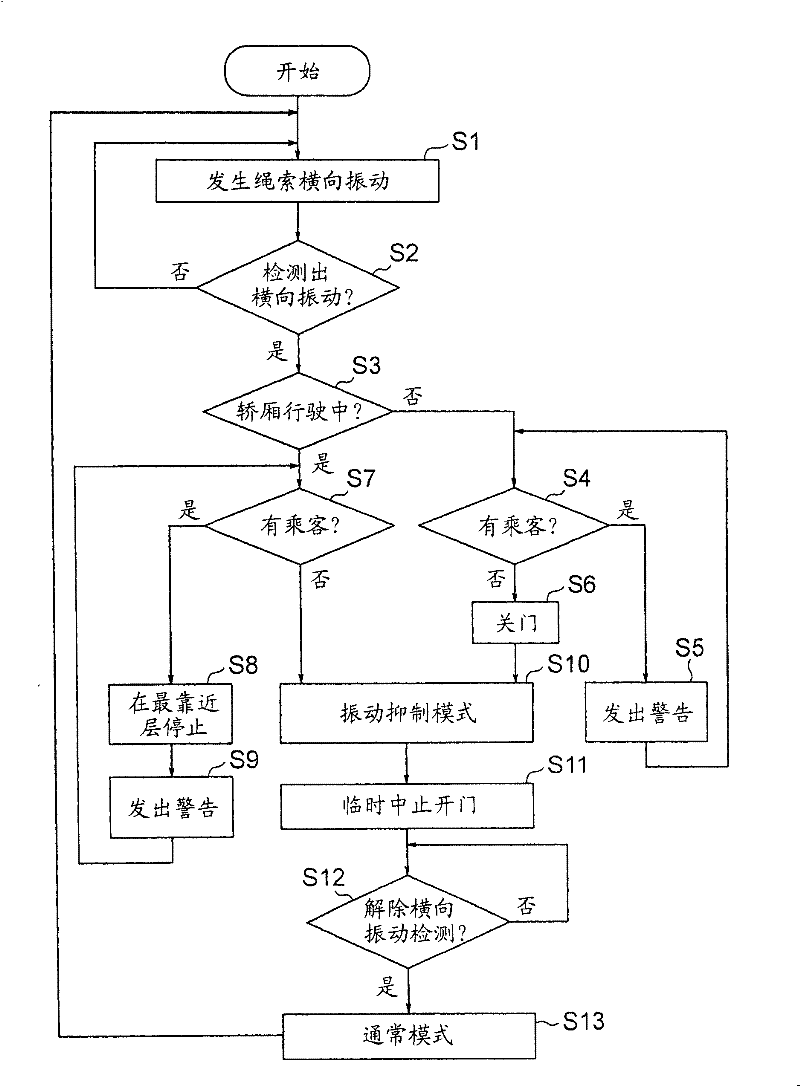

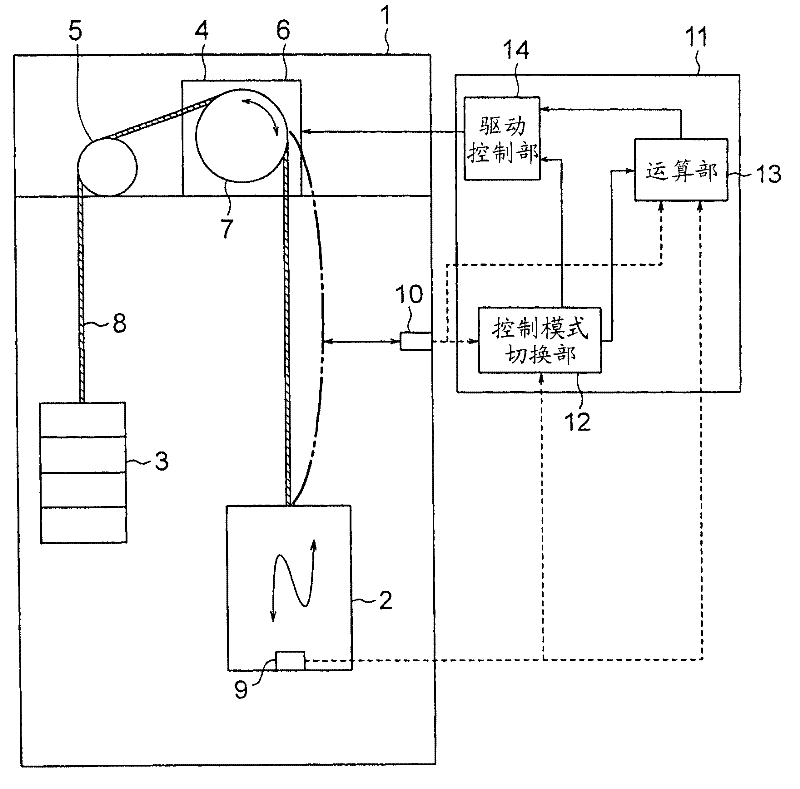

Elevator controller

The elevator control device can prevent deterioration of the ride quality of the car during normal operation, and can more reliably suppress the lateral vibration of the movable connecting body. A control device (11) for an elevator includes a drive control unit (14), a control mode switching unit (12), and a calculation unit (13). When the driving control part (14) changes the rotating speed of the driving pulley (7) in a wave manner, it can limit the change frequency of the rotating speed of the driving pulley (7) in the normal mode within the prescribed low frequency band and can make the driving pulley (7) ) to switch between the vibration suppression mode at a frequency higher than the low frequency band. A control mode switching unit (12) detects lateral vibration of the main rope (8), and switches the control mode of the drive control unit (14) to a vibration suppression mode. A calculation unit (13) calculates a signal for canceling lateral vibration. The drive control unit (14) controls the rotation of the drive pulley (7) based on the information from the calculation unit (13) to suppress lateral vibration in the vibration suppression mode.

Owner:MITSUBISHI ELECTRIC BUILDING SOLUTIONS CORP

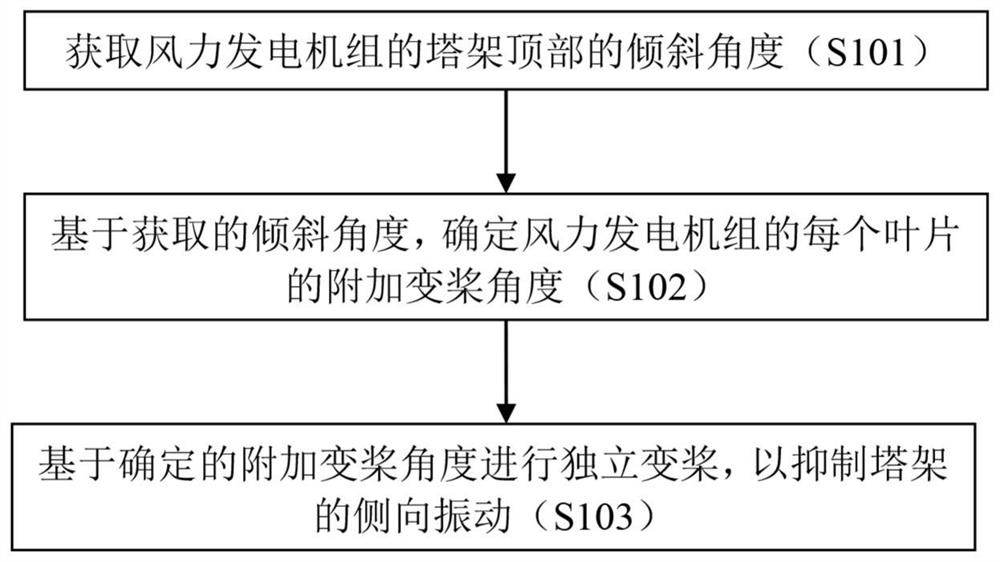

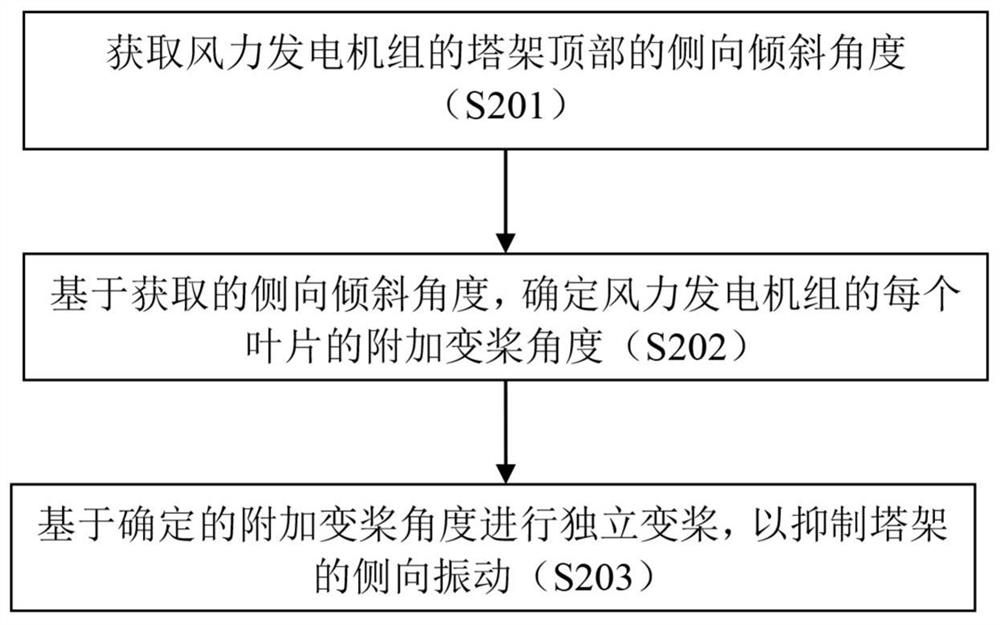

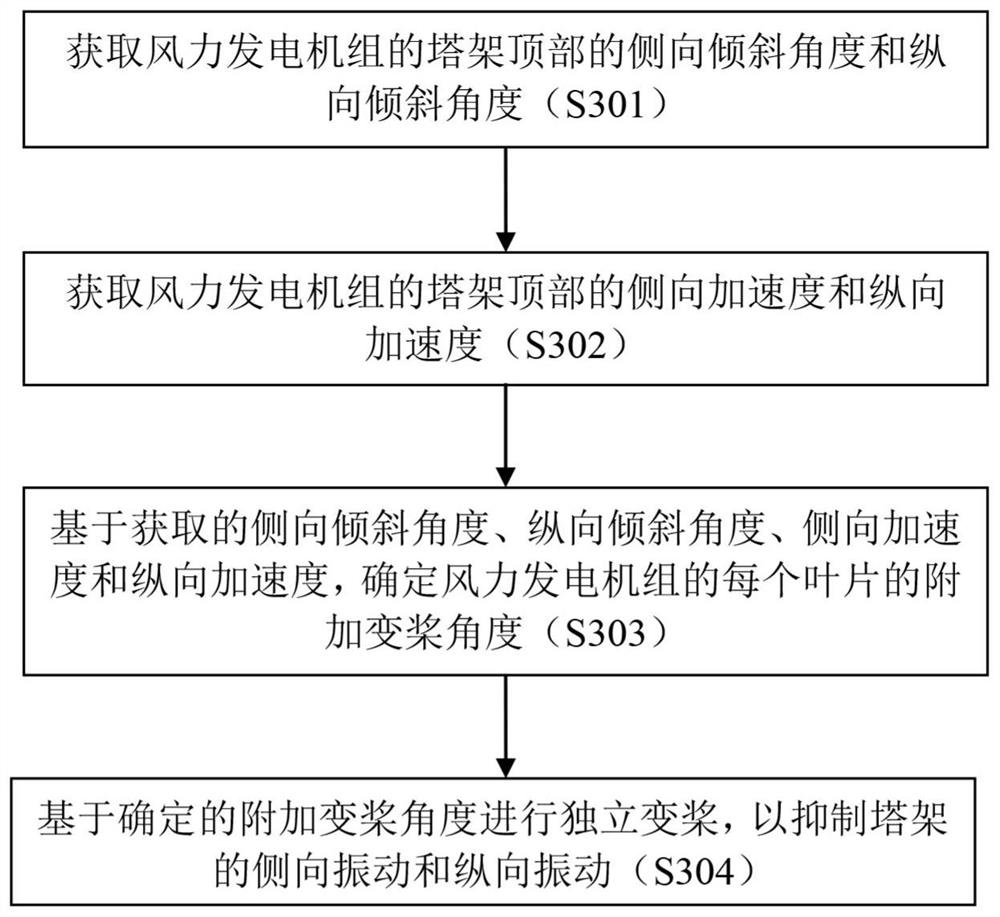

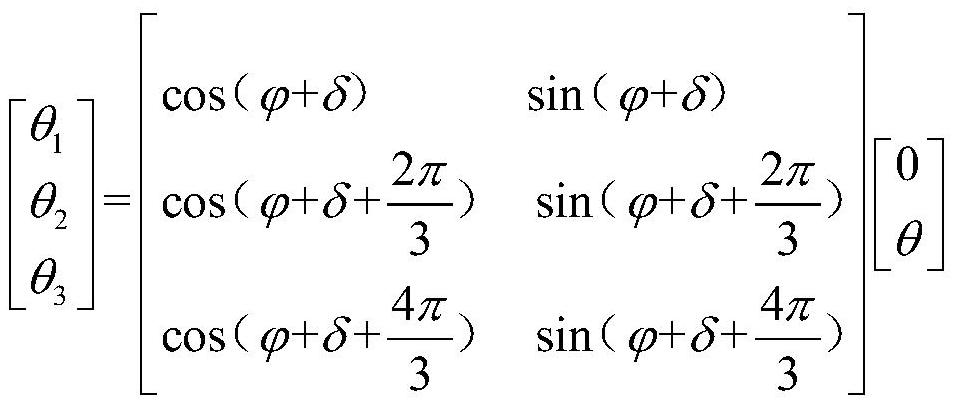

Control method and equipment of wind generating set

ActiveCN112012884ASuppress lateral vibrationReduce vibrationWind motor controlMachines/enginesControl engineeringTower

The invention provides a control method and equipment of a wind generating set. The control method comprises the steps that the inclination angle of the top of a tower of the wind generating set is obtained; determining an additional variable pitch angle of each blade of the wind generating set based on the obtained inclination angle; and performing independent pitch changing based on the determined additional pitch changing angle so as to suppress lateral vibration of the tower. According to the control method and equipment, accurate tower lateral resistance increasing can be conducted through independent variable pitch based on the inclination angle of the top of the tower, and therefore lateral vibration of the tower is well restrained.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

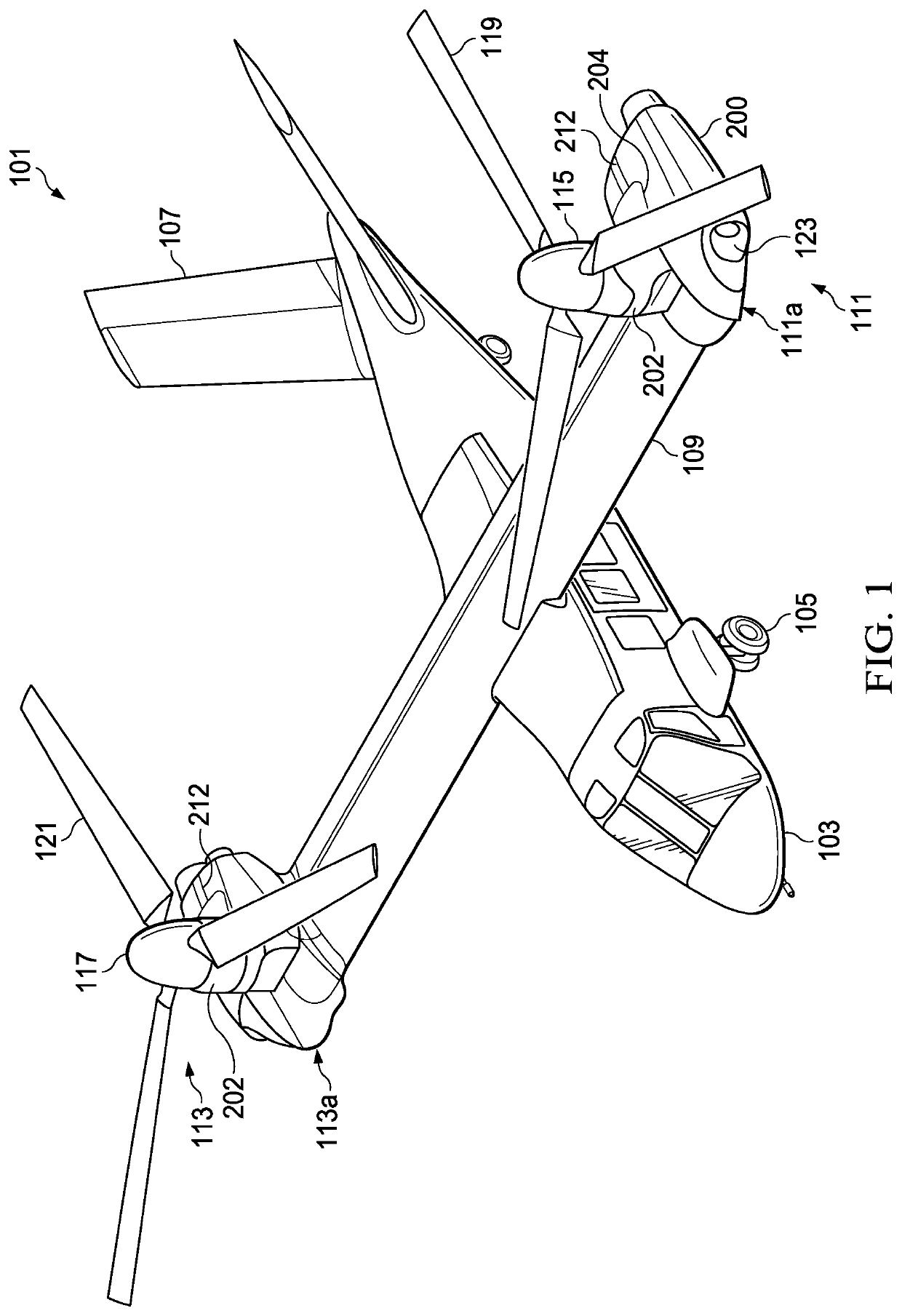

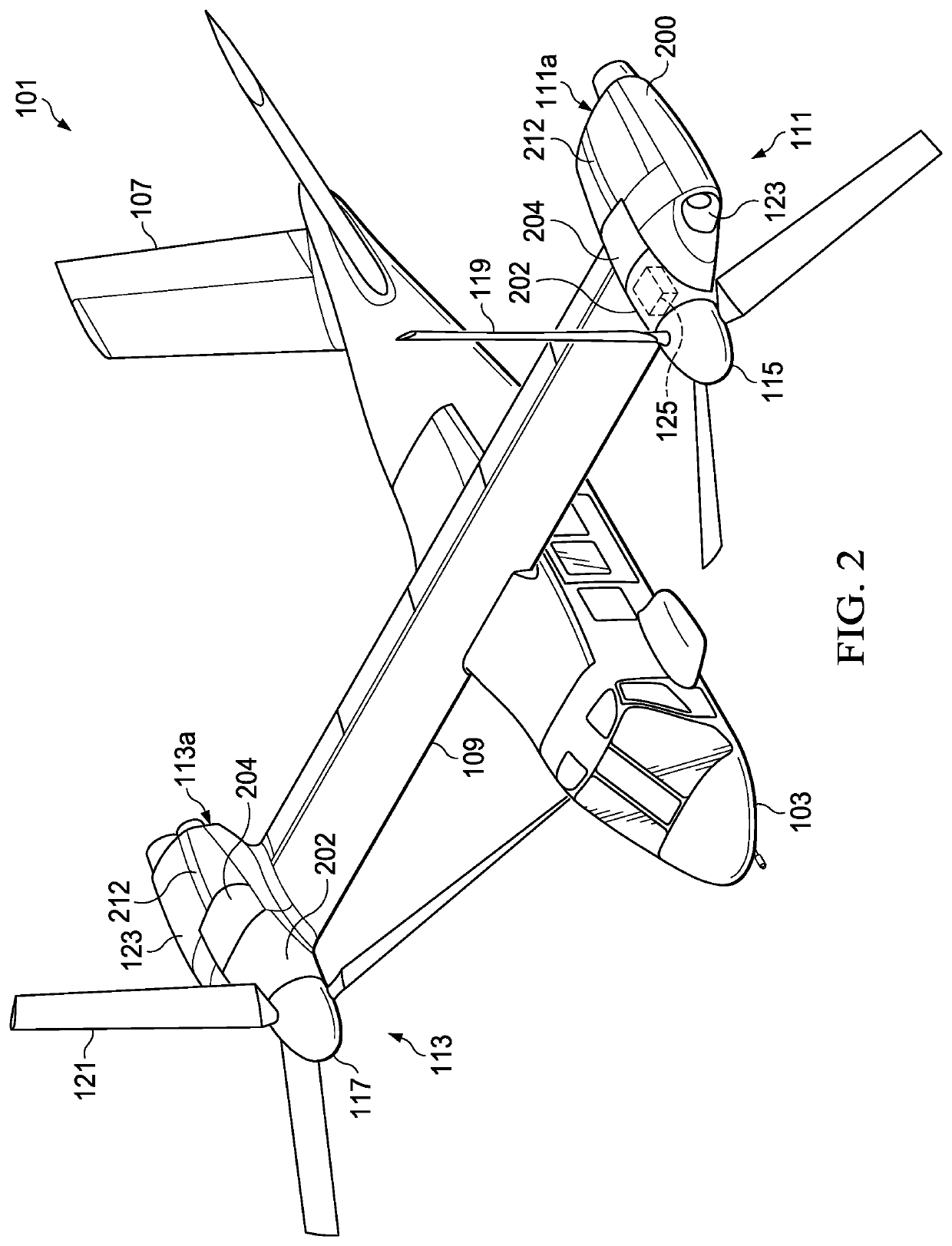

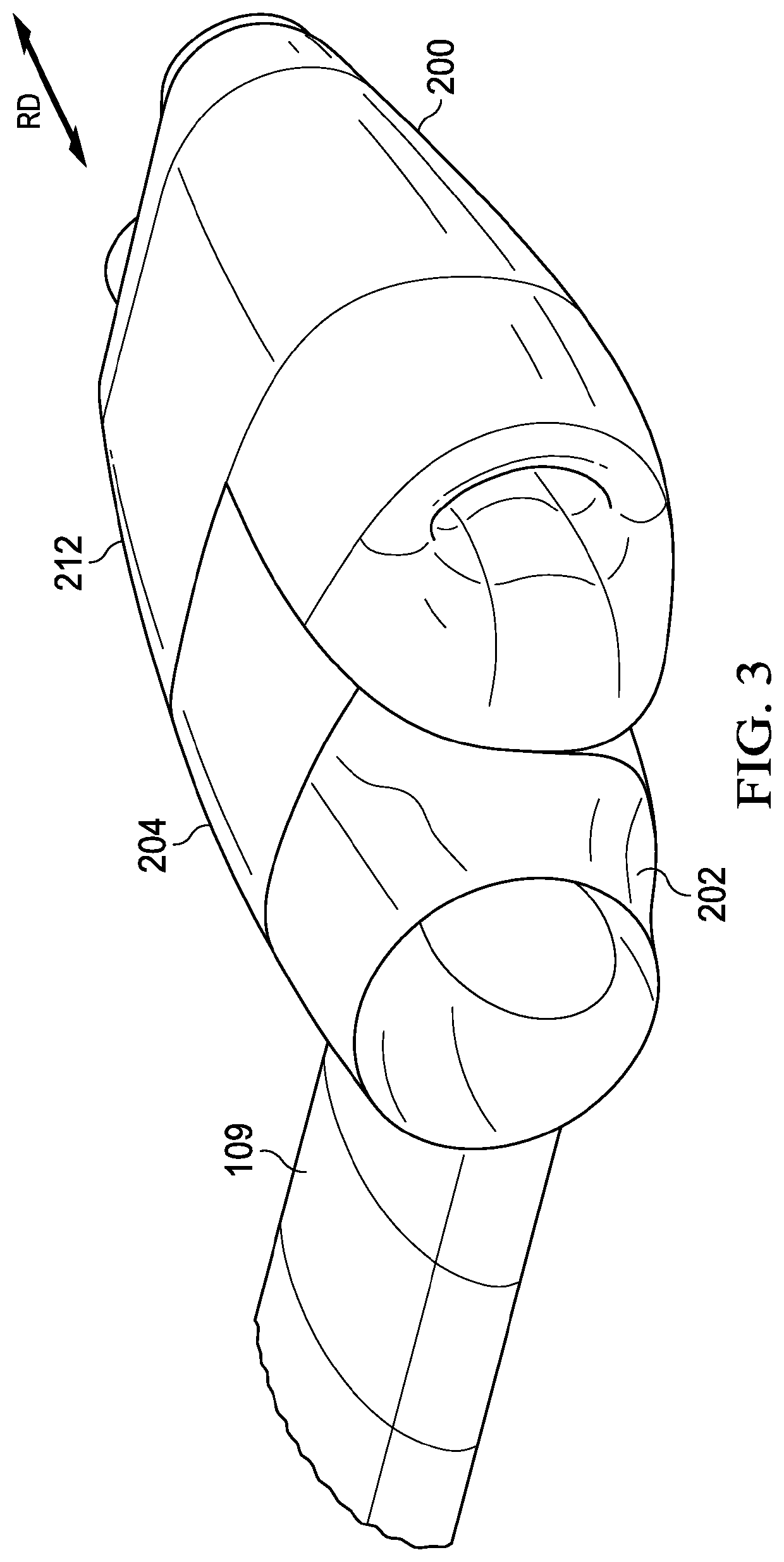

Bogie mechanism for a tiltrotor proprotor door

ActiveUS10539180B2Suppress lateral vibrationDampen non-linear forcesLinear bearingsAircraft accessoriesBogieClassical mechanics

Owner:BELL HELICOPTER TEXTRON INC

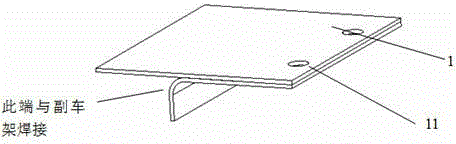

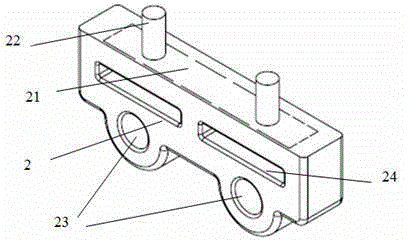

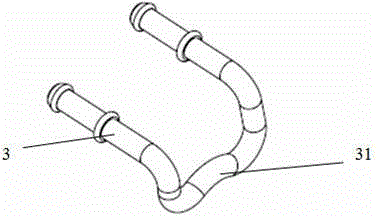

Vibration isolation lifting lug device with exhaust pipe and auxiliary frame connected

ActiveCN104786827AIncrease stiffnessImprove the vibration isolation effectNon-rotating vibration suppressionPropulsion unit gas exhaustVehicle frameVibration isolation

The invention provides a vibration isolation lifting lug device with an exhaust pipe and an auxiliary frame connected. The vibration isolation lifting lug device is composed of a lifting lug installation support, double rectangular composite lifting lugs and a hook. The lifting lug installation support is used for connecting the double rectangular composite lifting lugs with the auxiliary frame. The double rectangular composite lifting lugs are connected with the lifting lug installation support through lifting lug installation bolts. The double rectangular composite lifting lugs are rubber lifting lugs with frameworks inside the lifting lugs as supports and rubber vulcanized, and are of a similar rectangular structure, the lifting lug installation bolts are welded to the upper ends of the double rectangular composite lifting lugs, and two hook installation holes are formed in the lower portions of the double rectangular composite lifting lugs side by side. The hook is of a U-shaped bend structure, the two pipe heads of the open ends horizontally penetrate through the two hook installation holes of the double rectangular composite lifting lugs and are fixed to the rubber lifting lugs, and the U-shaped end is downwards bent and used for being welded to the exhaust pipe. Compared with a traditional exhaust pipe and auxiliary frame vibration reduction structure, vibration noise transferring between the exhaust pipe and the auxiliary frame can be reduced, the rigidity of the auxiliary frame and the vibration reduction lifting lug installation points is improved, and transverse limiting and vibration reduction capacity of the vibration reduction structure are improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

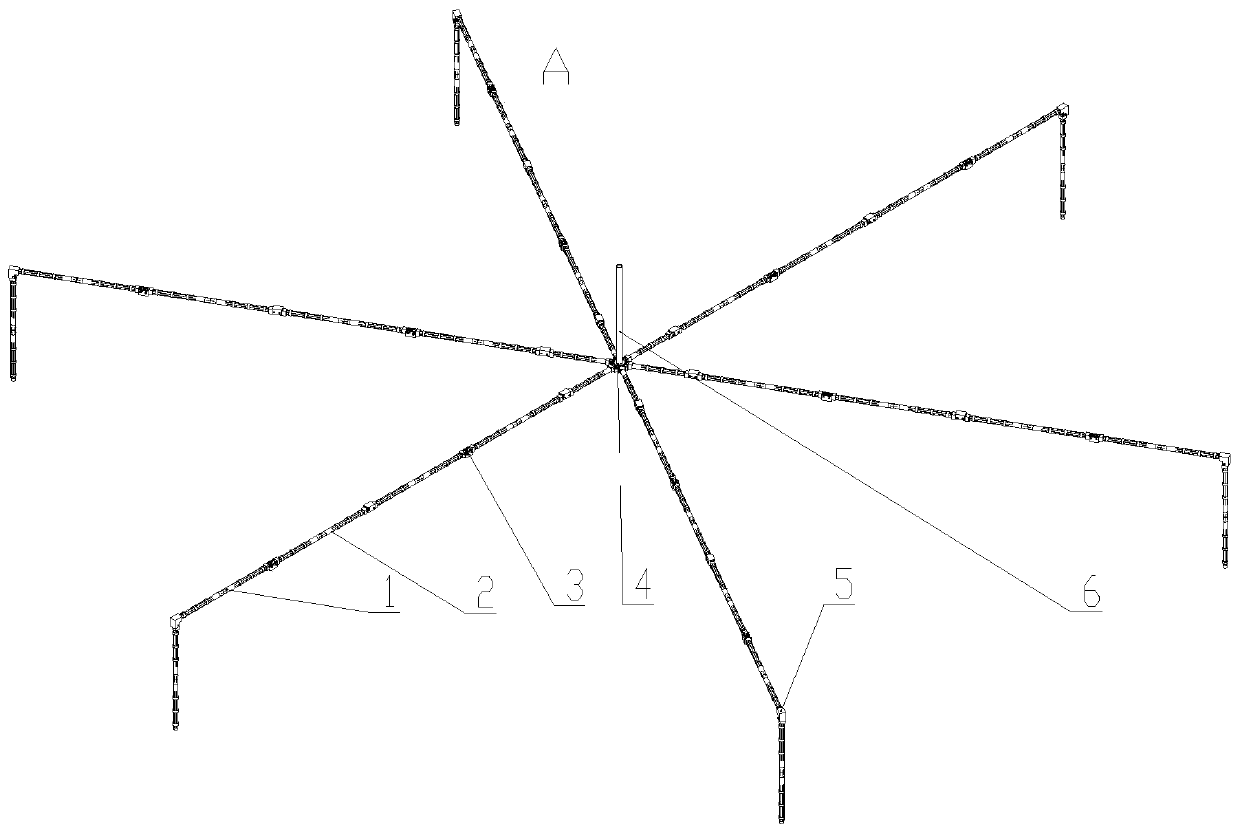

Damping component of large self-unfolding satellite antenna

ActiveCN111129689AImprove effectivenessImprove stabilityCollapsable antennas meansAntenna supports/mountingsSatellite antennasMetal rubber

The invention discloses a damping component of a large self-unfolding satellite antenna, and aims to solve a problem of profile precision errors caused by vibration in an unfolding process of an existing unfolding antenna mechanism and in a posture adjusting process after unfolding. The component comprises a multi-finger-petal friction damper, a self-resetting elastic support friction damper, an elastic driving hinge and a satellite structure rod piece. The multi-finger-petal friction damper controls transverse vibration of the satellite unfolding antenna and comprises a multi-finger-petal rodwhich is pressed on a structural rod piece through an adjustable pressing ring. The self-resetting elastic support friction damper controls axial vibration and comprises a metal rubber, a guide rod,an SMA pull wire and an outer sleeve. The elastic driving hinge provides unfolding power through a volute spring, and an unfolding speed and synchronism are controlled through a gear. The satellite structure rod piece is fixedly connected with other assemblies so that integrity of the unfolded antenna is ensured. The component is used for satellites and space detectors.

Owner:BEIJING UNIV OF TECH

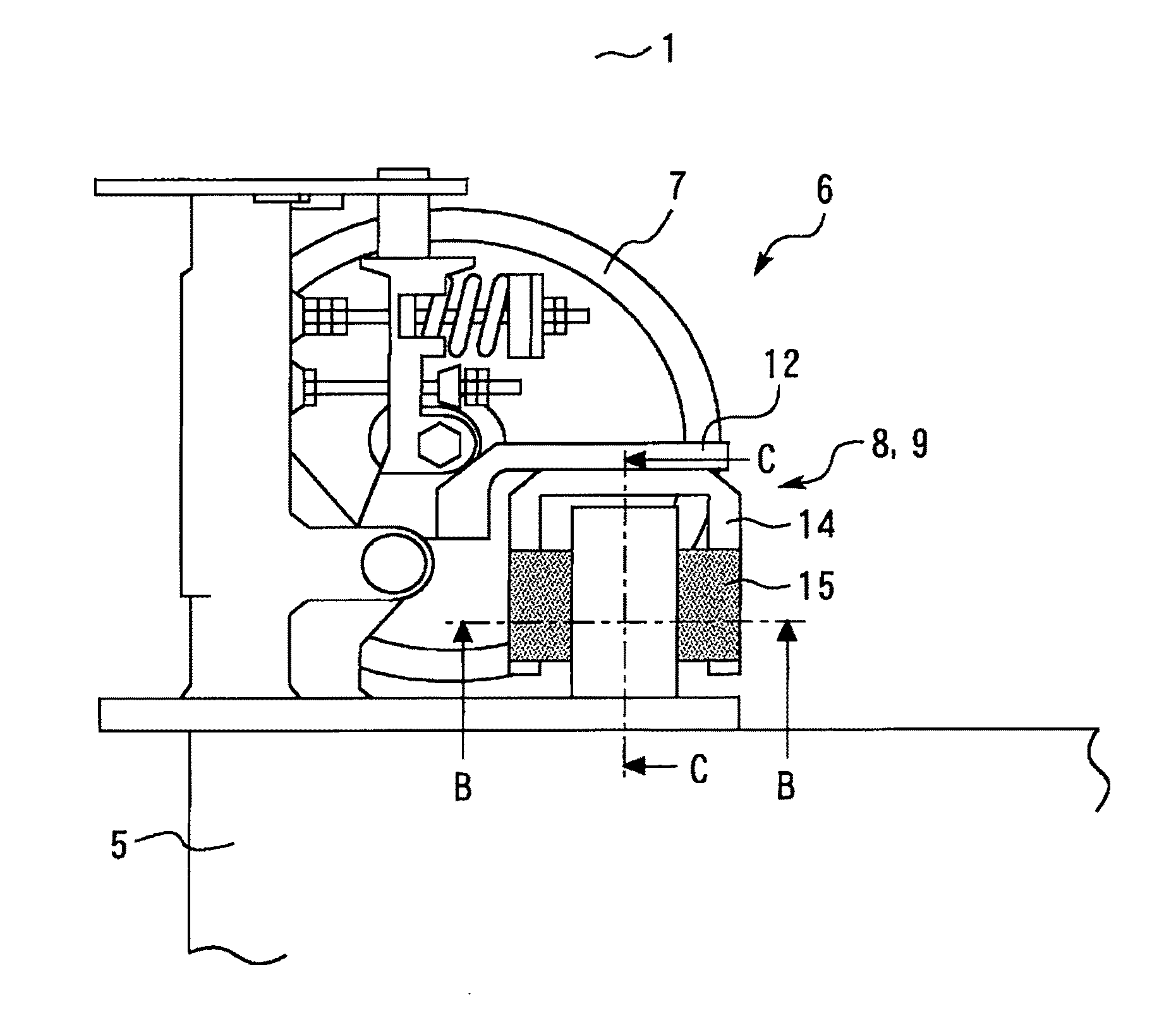

Vibration damping device for elevator

InactiveUS20120103731A1Minute slippage occurring in the coil can be prevented reliablySuppress lateral vibrationElevatorsBuilding liftsBobbinEngineering

A vibration damping device for suppressing transverse vibrations occurring in an elevating body of an elevator is configured so that a coil provided on the actuator moving part side can be held firmly to a bobbin, and a minute slippage occurring in the coil can be prevented reliably.For this purpose, a groove is formed in the wire direction of the coil in the bobbin of the moving part, and the coil is formed by winding the wire in the groove. The coil is integrated as a whole, and the adjacent wires forming the innermost layer of the coil are brought into contact with each other, and are brought into contact with a part of the groove in the transverse cross section.

Owner:MITSUBISHI ELECTRIC CORP

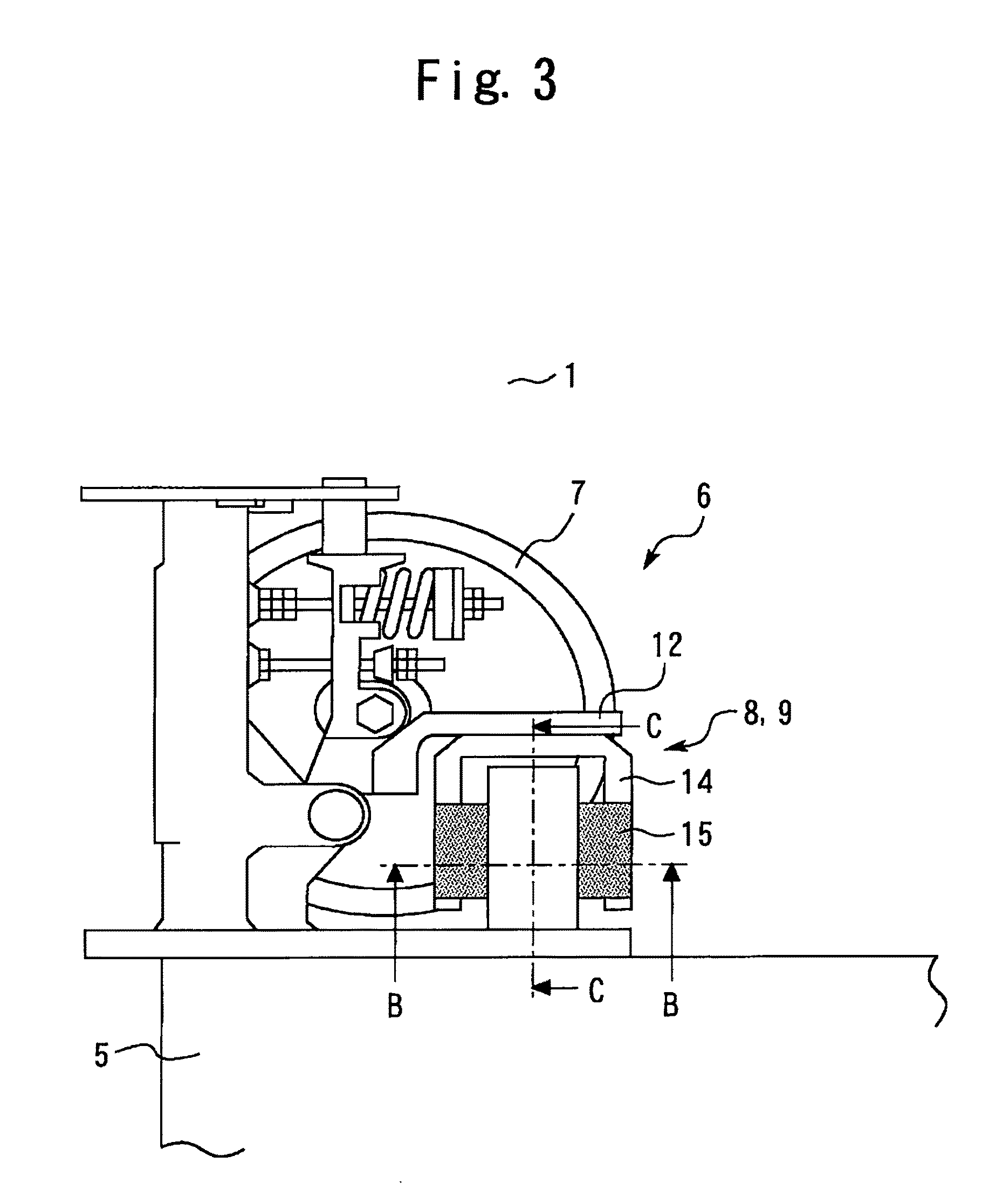

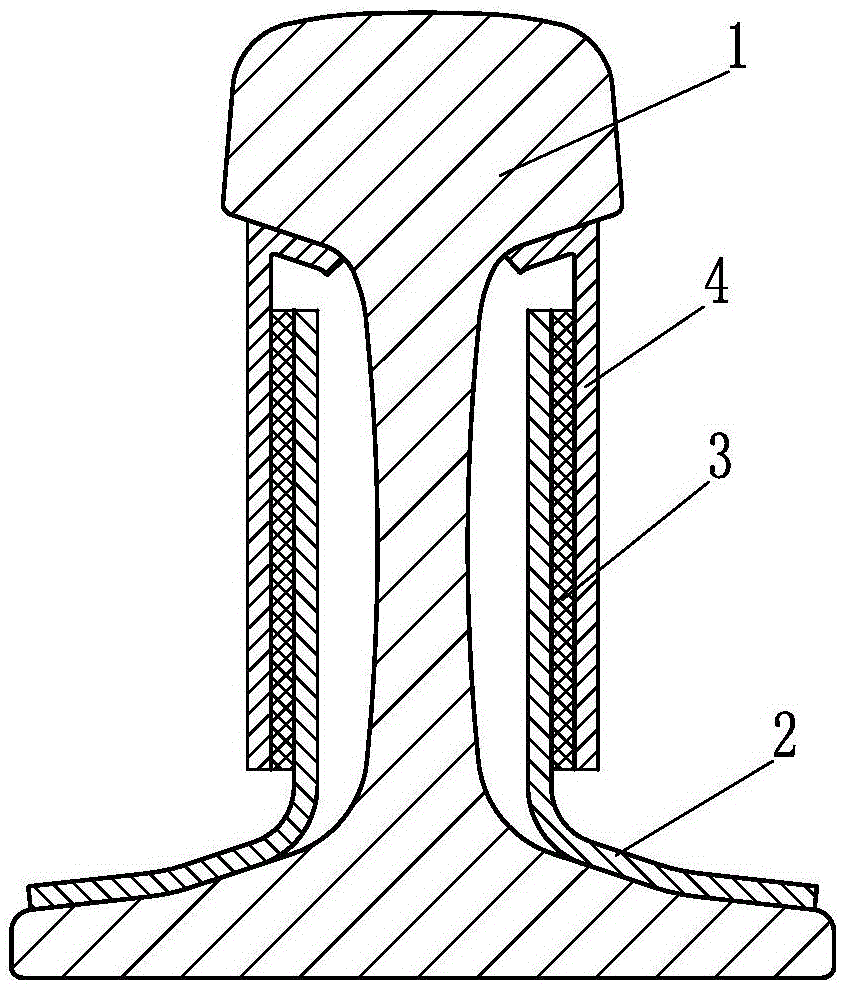

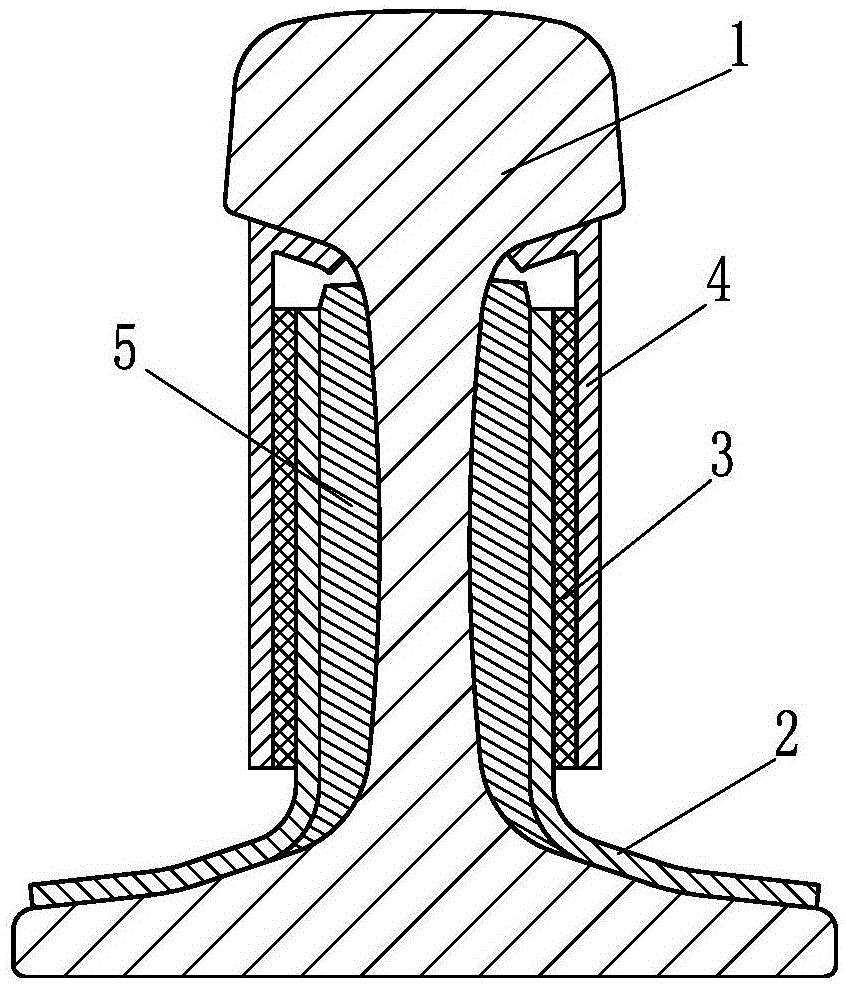

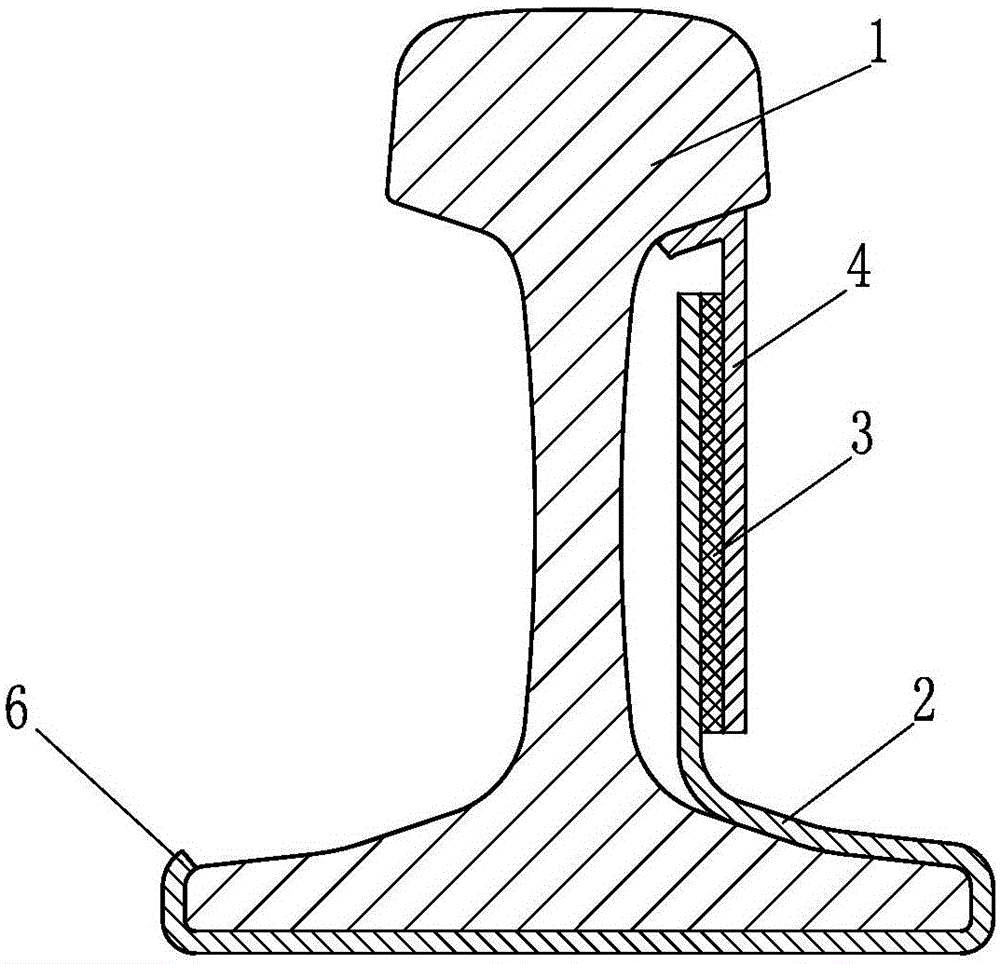

Shear type track vibration and noise reduction device

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH +3

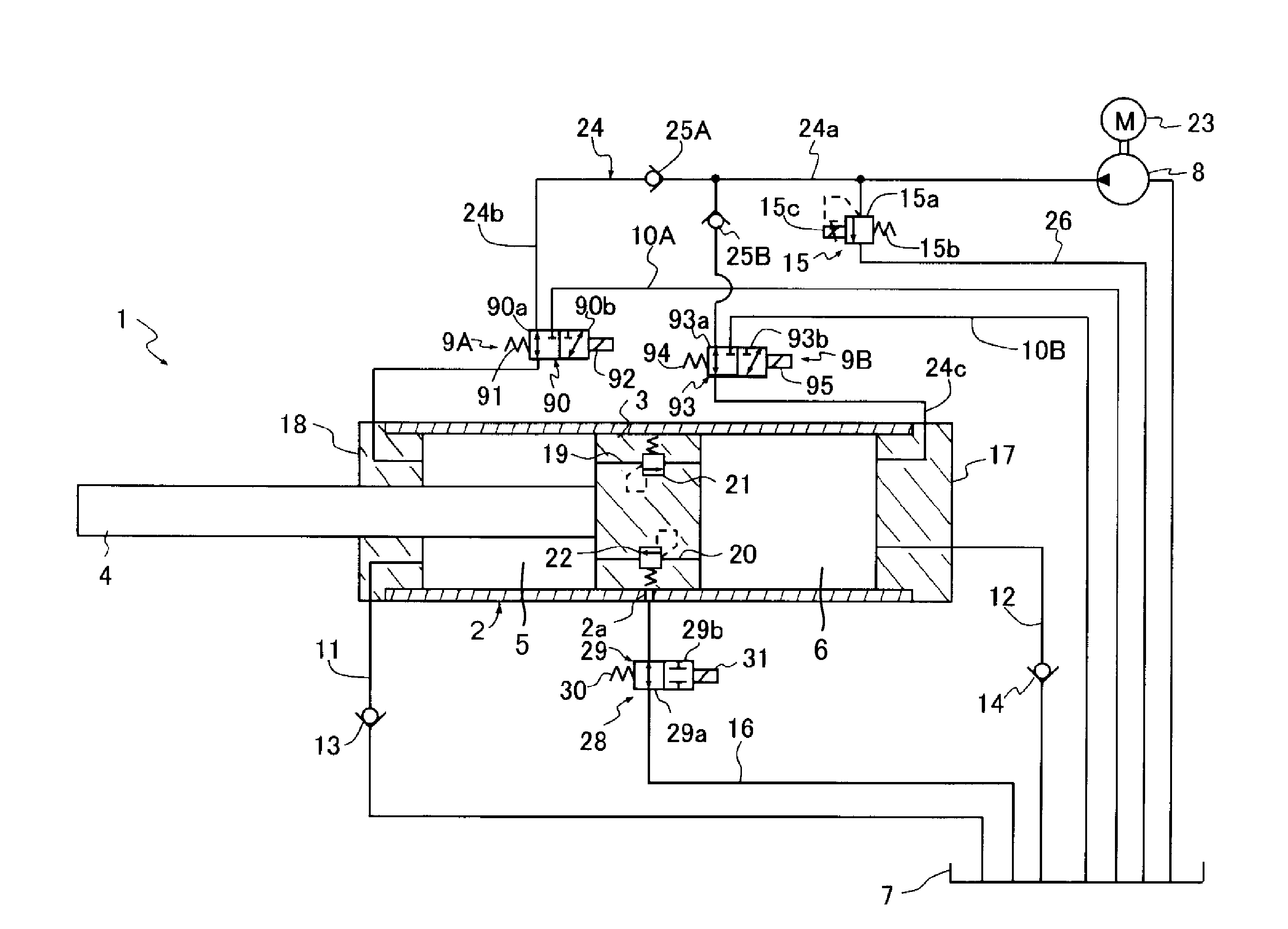

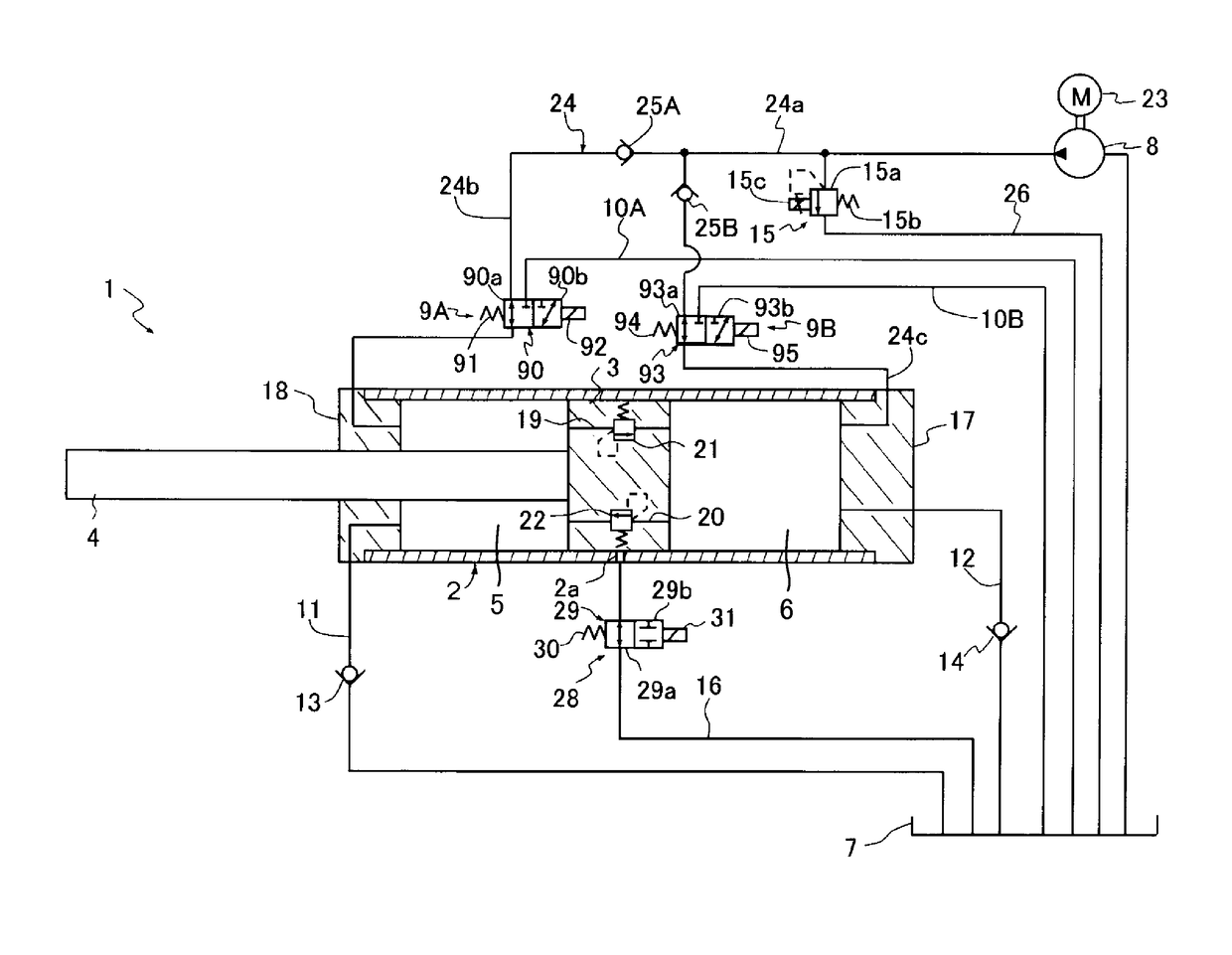

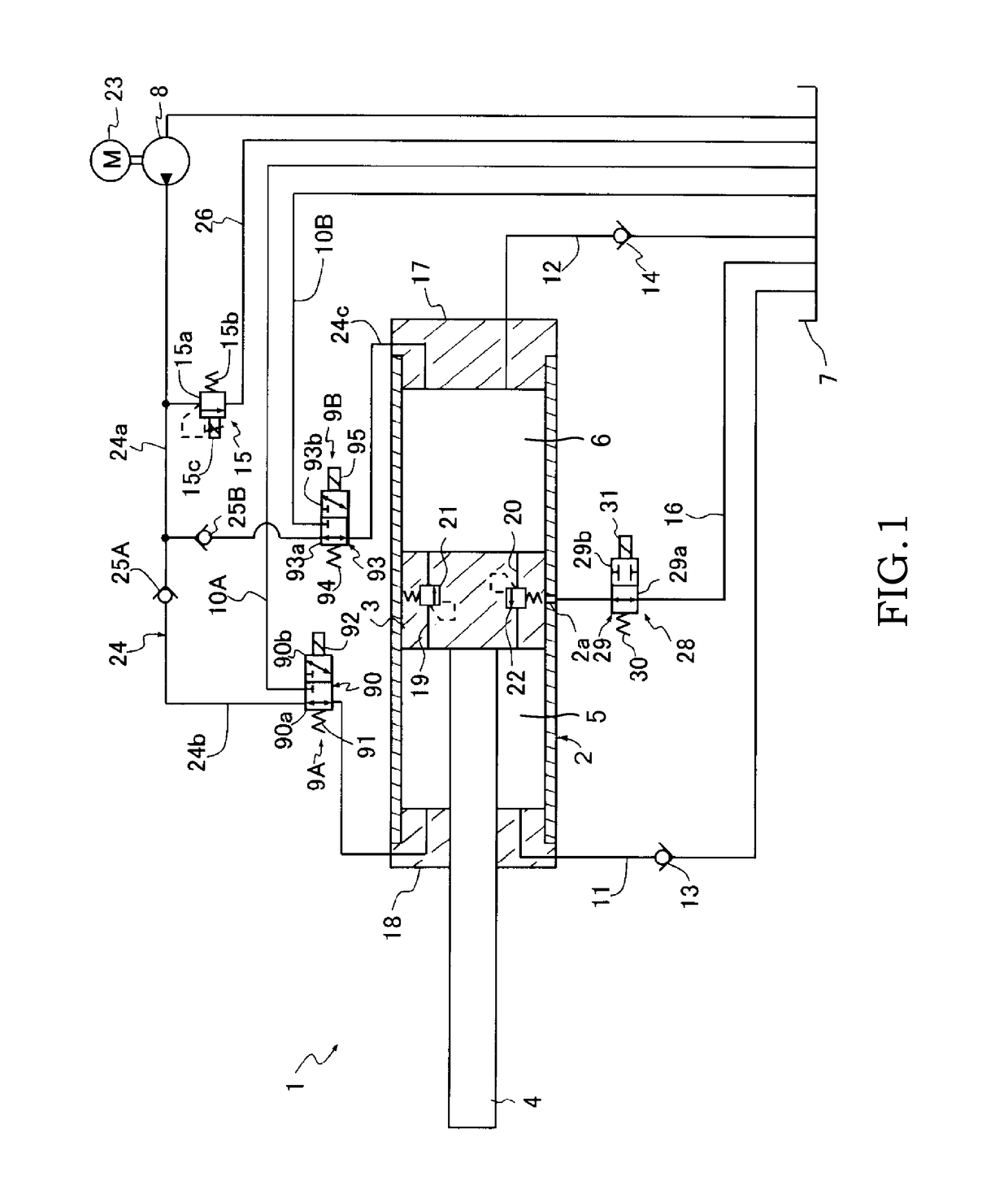

Actuator unit

InactiveUS20150369263A1Suppress lateral vibrationReduce vibrationFluid couplingsSpringsWorking fluidFuel tank

An actuator unit includes two chambers defined in the cylinder; a supply passage allowing a working fluid discharged from the pump to be supplied to the two chambers; a discharge passage allowing the two chambers to communicate with the tank; a direction control valve configured to selectively communicate each of the two chambers with one of the pump and the tank; a control passage that branches from the supply passage on a side of the pump rather than the direction control valve so as to communicate the pump with the tank; a variable relief valve provided on the control passage, the variable relief valve opening so as to allow the working fluid to flow from the supply passage toward the tank when a pressure in the supply passage reaches the valve opening pressure; and a center passage that communicates the tank with an interior of the cylinder.

Owner:KYB CORP

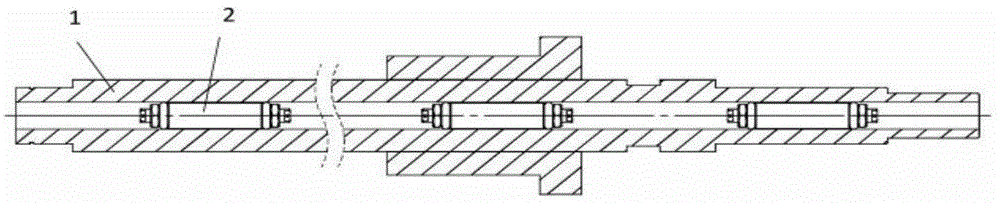

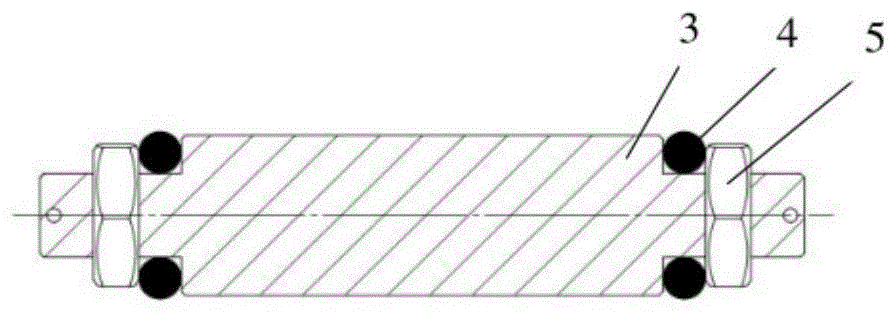

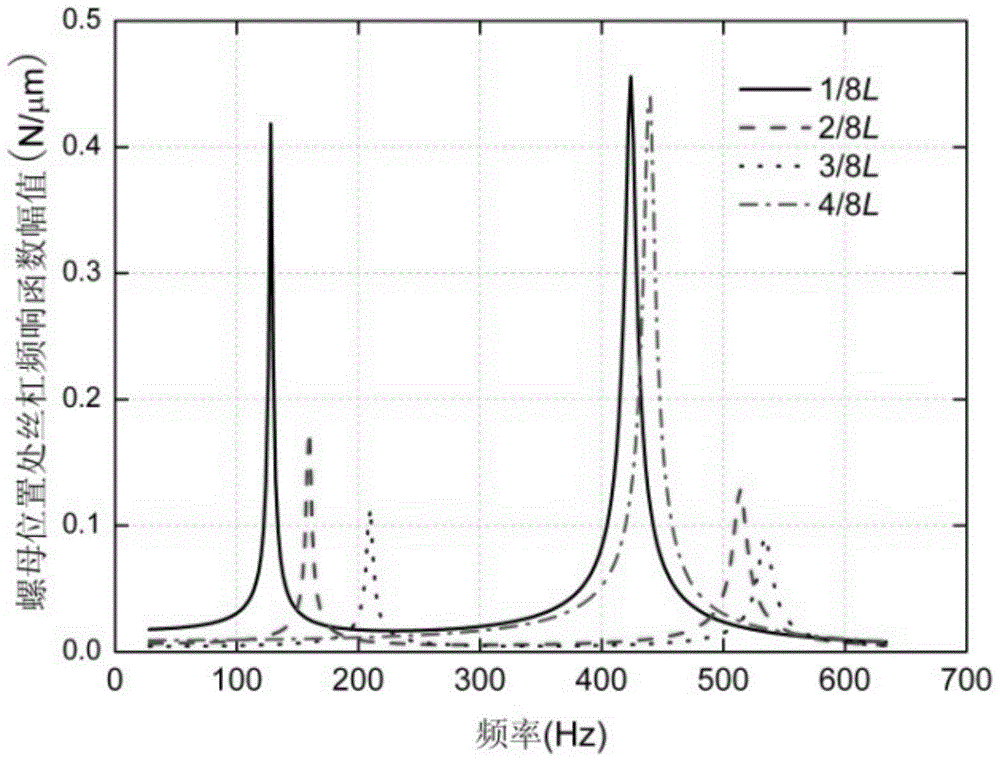

A ball screw pair vibration damping structure

ActiveCN103836138BEffective control of lateral vibrationSuppress lateral vibrationGearingGear vibration/noise dampingVibration attenuationRubber ring

Owner:江苏启尖丝杠制造有限公司

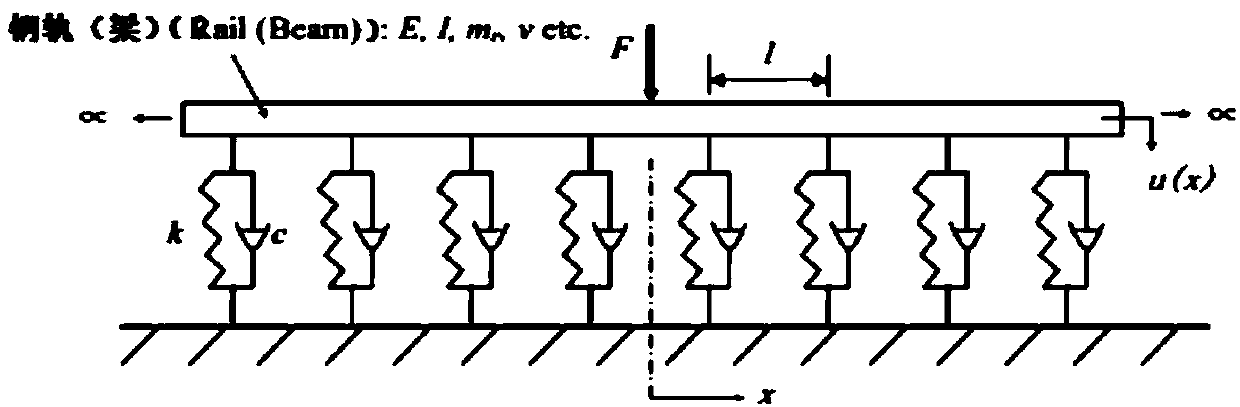

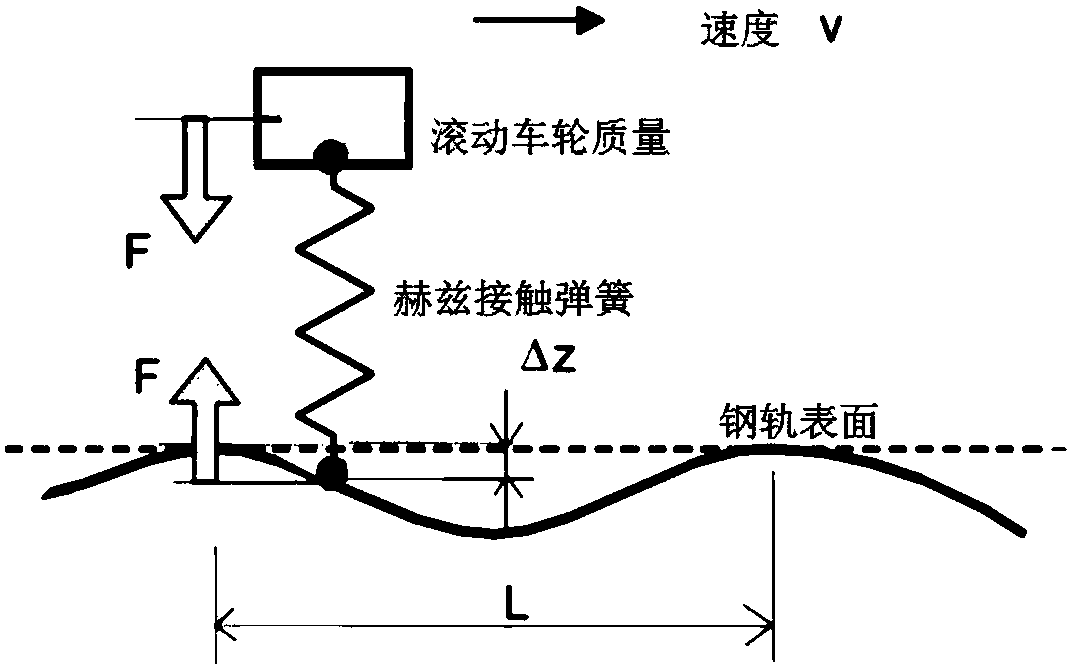

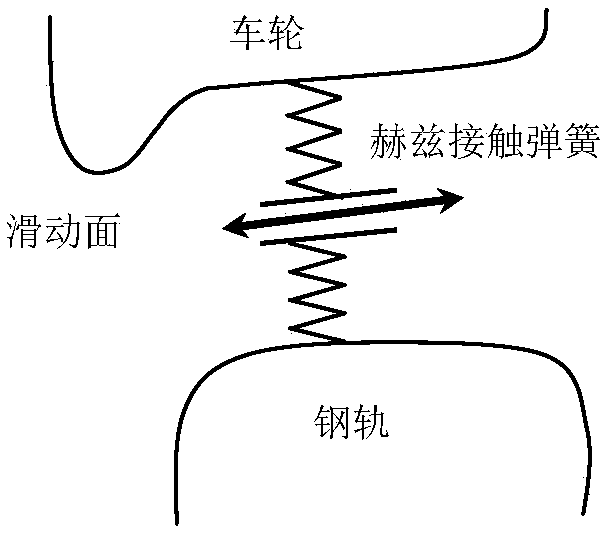

Method for reducing undulatory wear of steel rails

The invention discloses a method for reducing the undulatory wear of steel rails. The steel rails are supported by sleepers and fixed to the sleepers through fasteners in fastened and pressed modes. Tracks of the steel rails guide wheels, and the steel rails and the wheels interact with each other to form a wheel rail system. According to the method for reducing the undulatory wear of the steel rails, the wheel rail flexibility difference and steel rail vibration, particularly in the wheel rail system transverse direction, are reduced. Through the method for reducing the undulatory wear of thesteel rails, vibration noise can be reduced, the undulatory wear of the steel rails is reduced, the wheel rail relation is improved accordingly, wheel rail vibration and noise are reduced, the service lives of the steel rails and the wheels are prolonged, the effectiveness of the track fasteners is improved, and the travelling safety is improved finally.

Owner:洛阳双瑞橡塑科技有限公司

Actuator unit

InactiveUS10087956B2Suppress lateral vibrationReduce vibrationSpringsServomotorsWorking fluidFuel tank

An actuator unit includes two chambers defined in the cylinder; a supply passage allowing a working fluid discharged from the pump to be supplied to the two chambers; a discharge passage allowing the two chambers to communicate with the tank; a direction control valve configured to selectively communicate each of the two chambers with one of the pump and the tank; a control passage that branches from the supply passage on a side of the pump rather than the direction control valve so as to communicate the pump with the tank; a variable relief valve provided on the control passage, the variable relief valve opening so as to allow the working fluid to flow from the supply passage toward the tank when a pressure in the supply passage reaches the valve opening pressure; and a center passage that communicates the tank with an interior of the cylinder.

Owner:KYB CORP

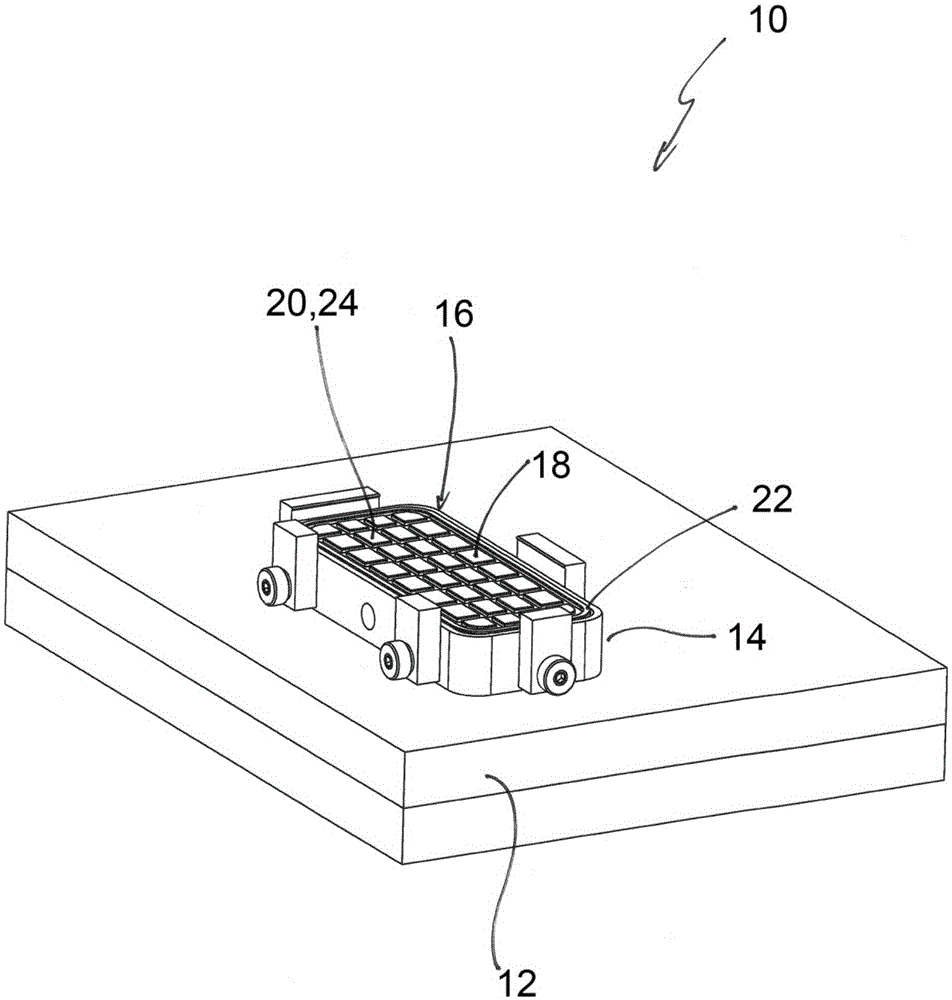

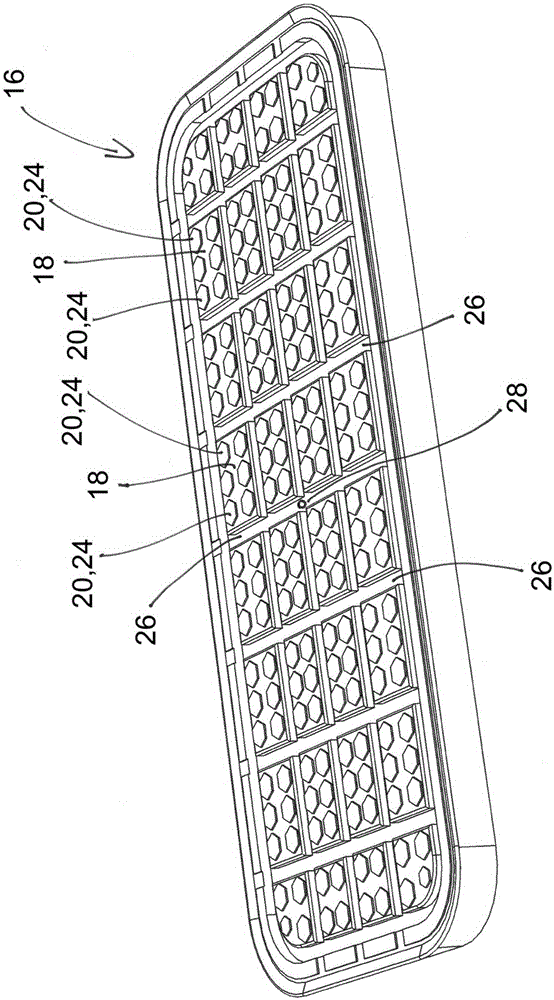

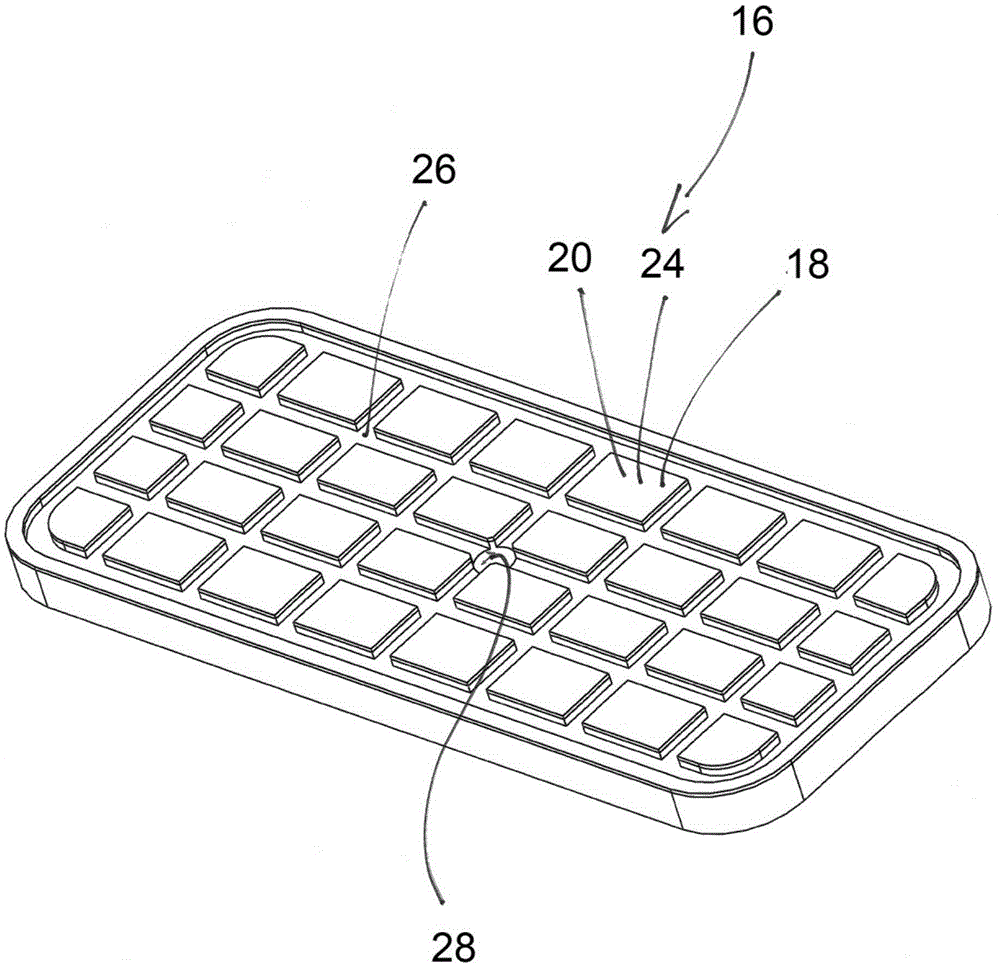

Vacuum Chuck Or Gripping Device

ActiveCN105583665ASimple and reliable productionStable frictionConveyorsPositioning apparatusMechanical engineeringElastomer

The invention relates to a vacuum chuck or gripping device, with a suction surface to which a held workpiece can be sucked, the suction surface has at least one bearing region, which rests while holding the workpiece at this. For positionally stable, friendly and slip-proof suction and holding of the workpiece, the contact region has a coating with an elastomer.

Owner:J SCHMALZ GMBH

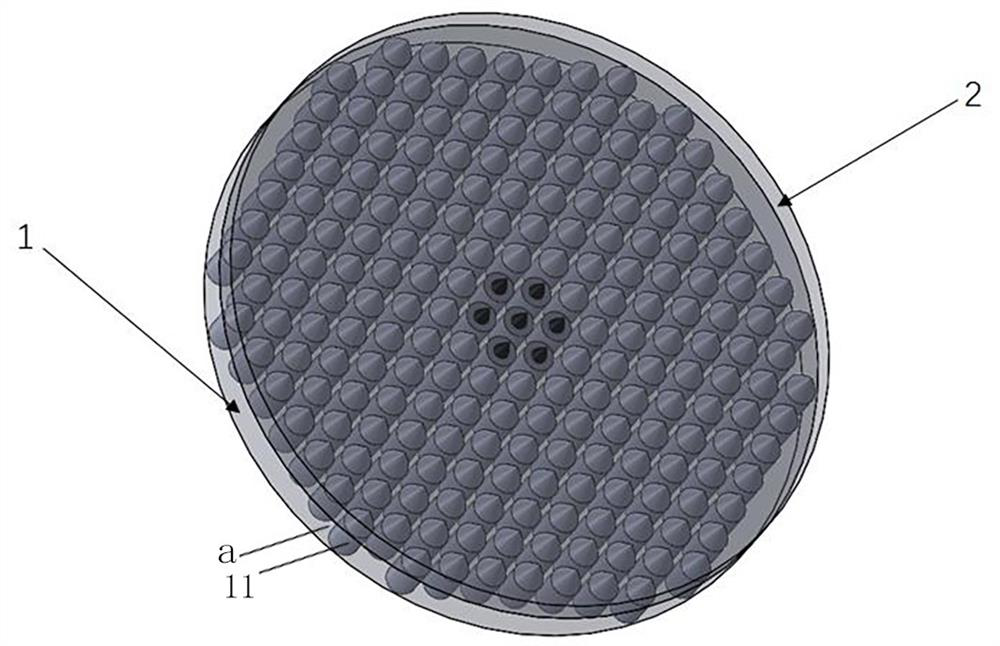

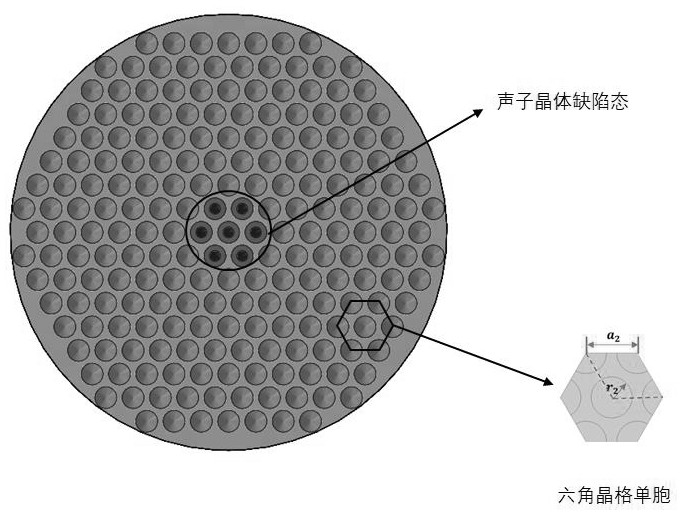

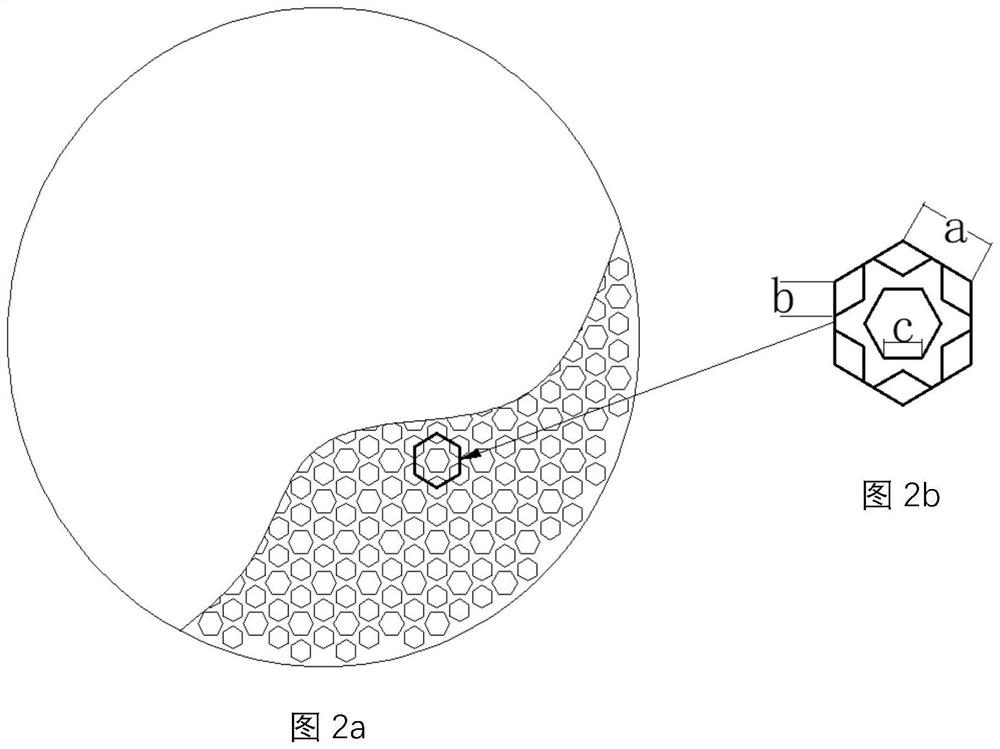

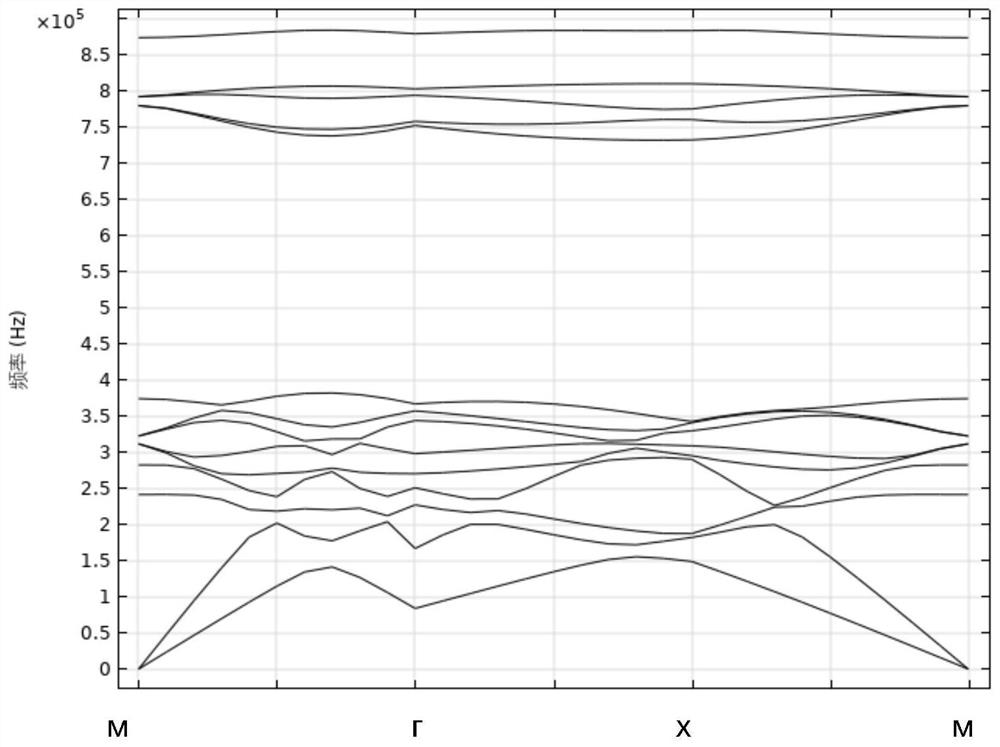

Large-size air coupling transducer based on photonic crystal structure

PendingCN114284425AHigh electromechanical coupling coefficientSuppress lateral vibrationPiezoelectric/electrostrictive devicesPhotonic crystal structureCrystal structure

The invention provides a large-size air coupling transducer based on a photonic crystal structure, and belongs to the field of photonic crystals. The invention discloses a large-size air coupling transducer based on a photonic crystal structure. The large-size air coupling transducer comprises a 1-3 type piezoelectric composite material layer, an acoustic impedance gradient matching layer, an upper electrode arranged between the 1-3 type piezoelectric composite material layer and the acoustic impedance gradient matching layer, and a lower electrode arranged at the bottom of the 1-3 type piezoelectric composite material layer, the 1-3 type piezoelectric composite material layer comprises a plurality of piezoelectric material columns and a polymer phase 1; the acoustic impedance gradient matching layer comprises a plurality of filling cones and a polymer phase 2. According to the large-size air coupling transducer, the phononic crystal structure is combined with the 1-3 type piezoelectric composite material and the gradient matching layer in the transducer, so that transverse vibration is better inhibited when the transducer works, vibration in the thickness direction is purer, and the transducer has better acoustic impedance matching performance with an air medium.

Owner:HANGZHOU DIANZI UNIV

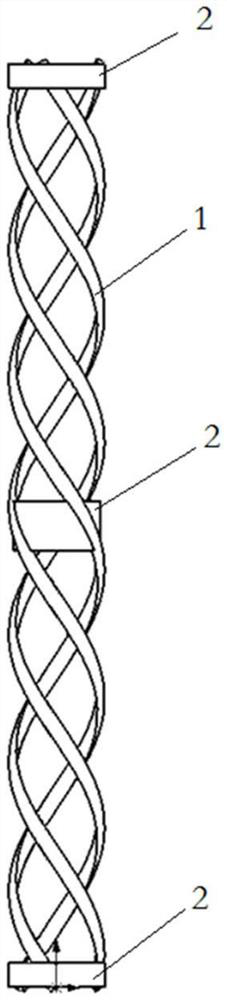

D-shaped fin for vibration reduction of tower

PendingCN114233783ASuppress lateral vibrationReduce the amplitudeNon-rotating vibration suppressionShock absorbersInsulation layerThermal insulation

The invention discloses a D-shaped fin for tower vibration reduction, which comprises spiral structure fins and connecting pieces, and the tops, the middle parts and the bottoms of every three spiral structure fins are respectively connected with one connecting piece to form the D-shaped fin with a spiral structure; the D-shaped fin structures are annularly welded on the tower outer thermal insulation layer at equal intervals through connecting pieces; seen from top to bottom, the three spiral structure fins in each D-shaped fin are arranged at an angle of 120 degrees. The device is suitable for engineering application, large-scale vortexes are broken into small-scale vortexes instead of destroying vortex shedding of a boundary layer of a tower, an original flowing state of fluid on the surface of the tower is destroyed, the fluid is forced to change an original vortex shedding mode, and then the vibration effect of the fluid on a tower body is restrained; the damping device has the characteristics of easiness in processing, easiness in installation, remarkable damping effect and easiness in popularization.

Owner:TIANJIN UNIV

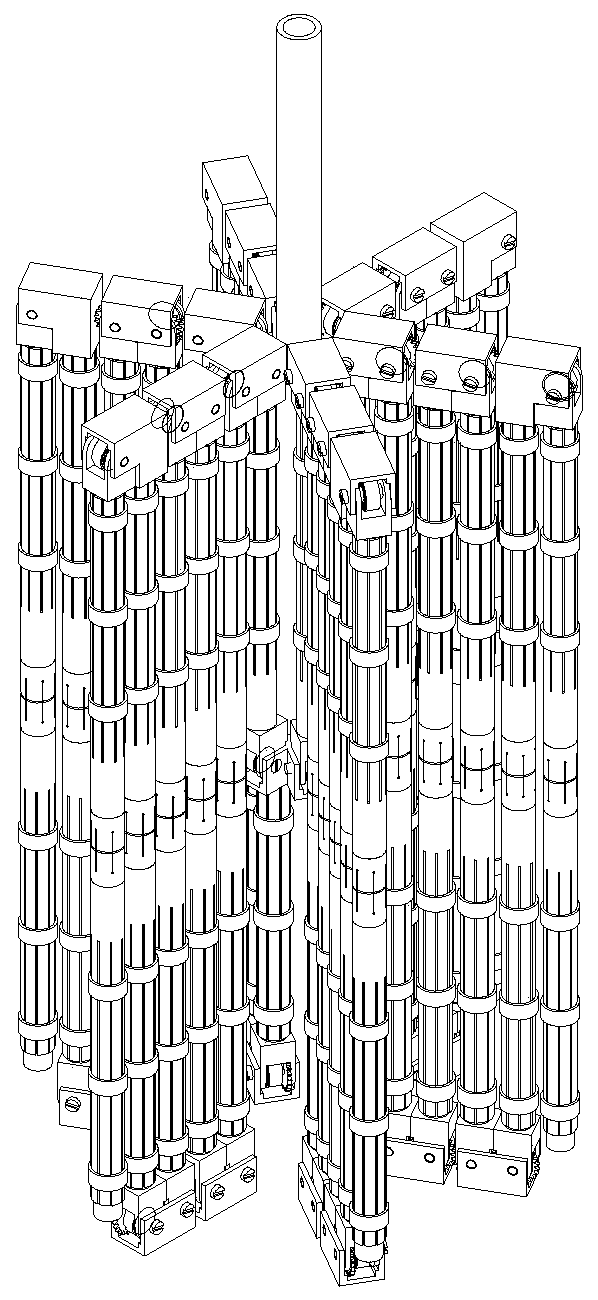

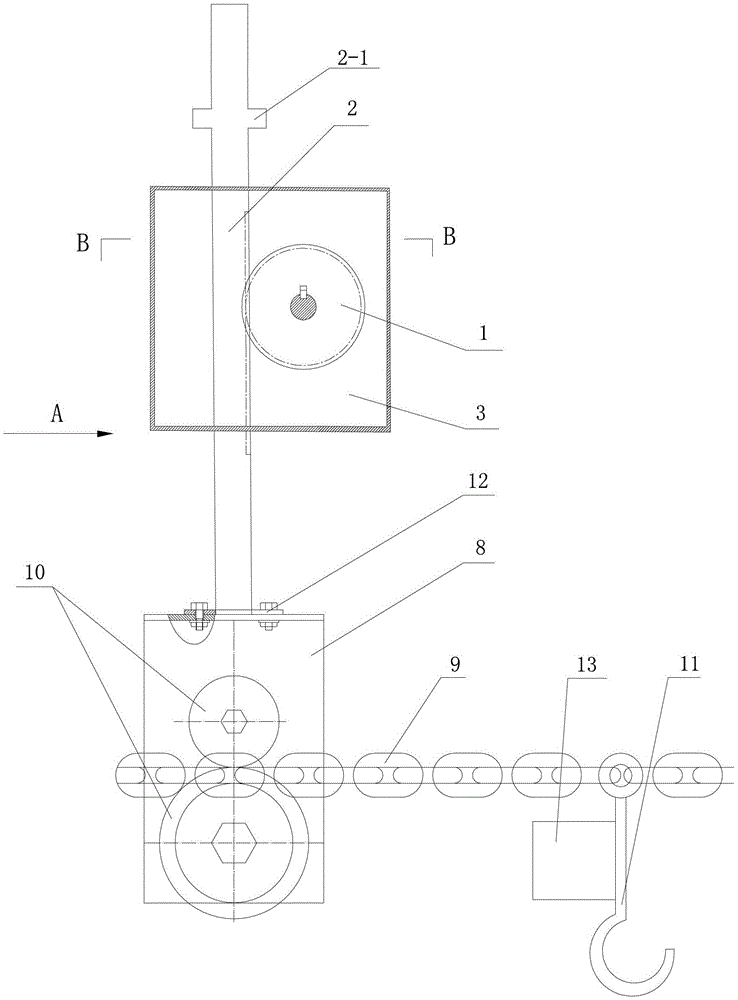

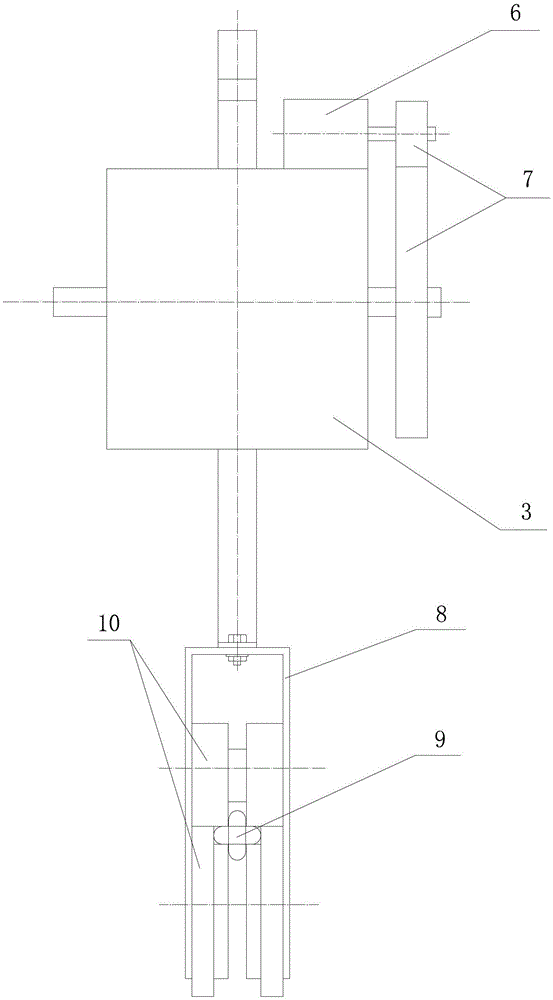

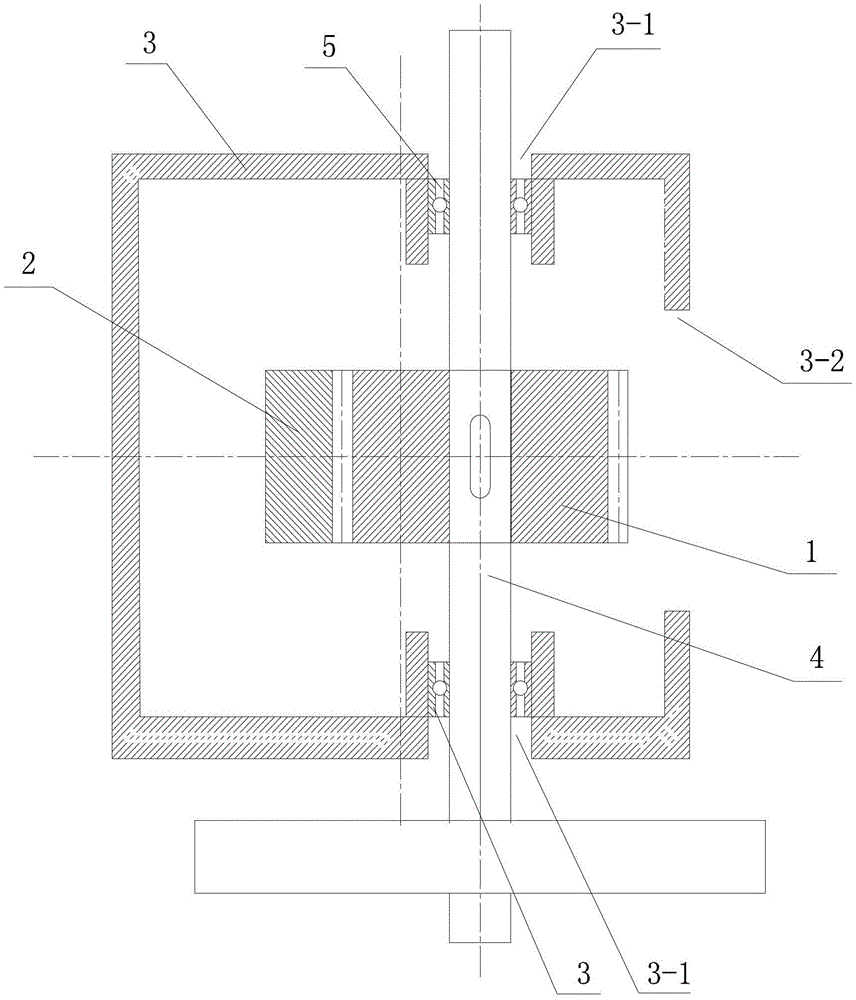

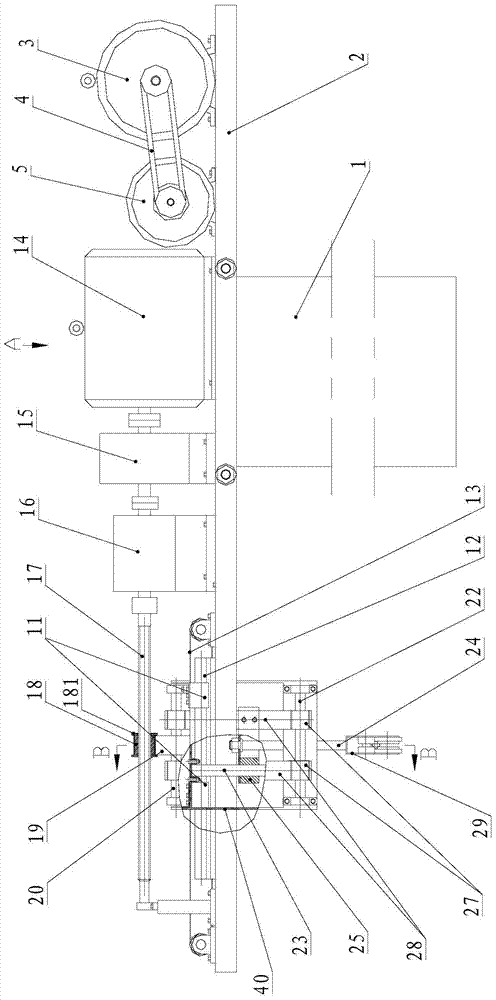

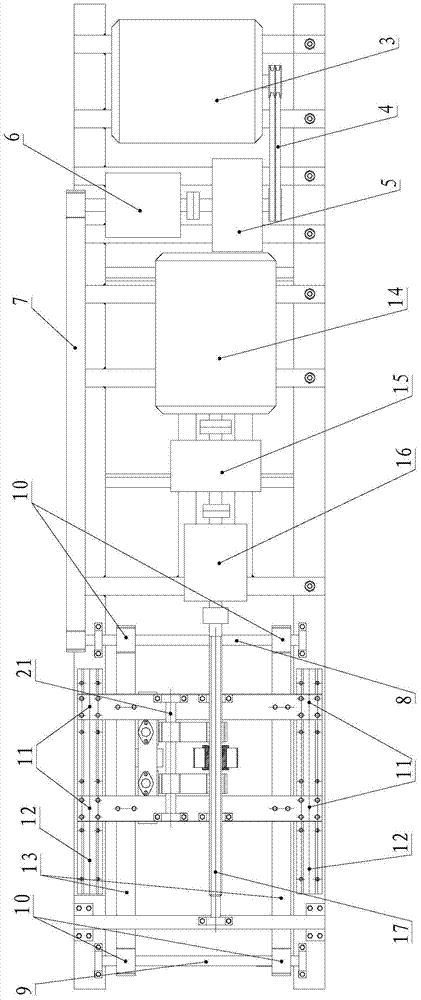

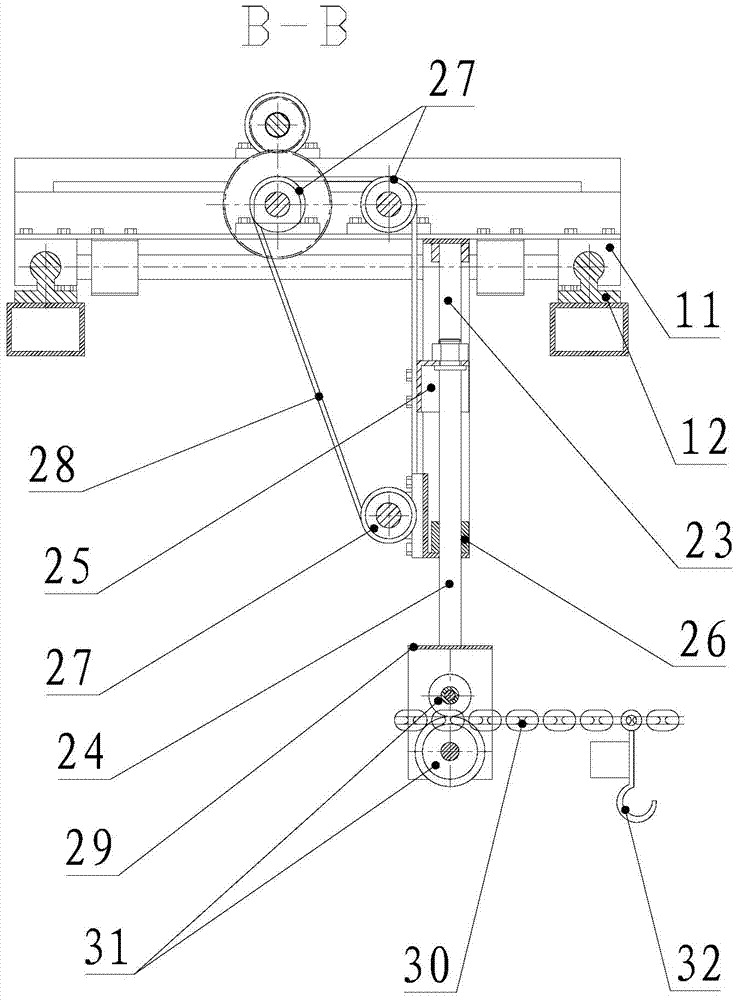

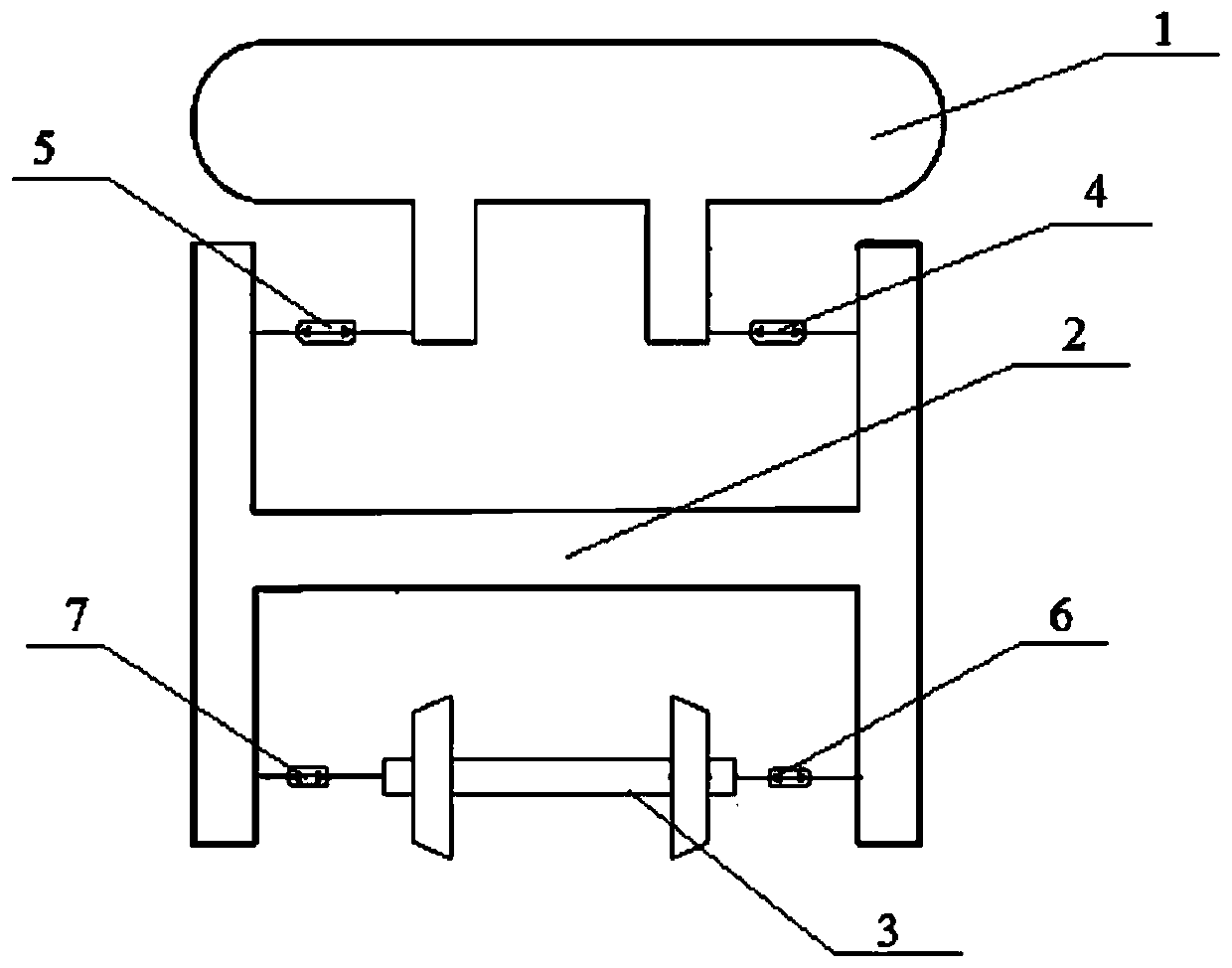

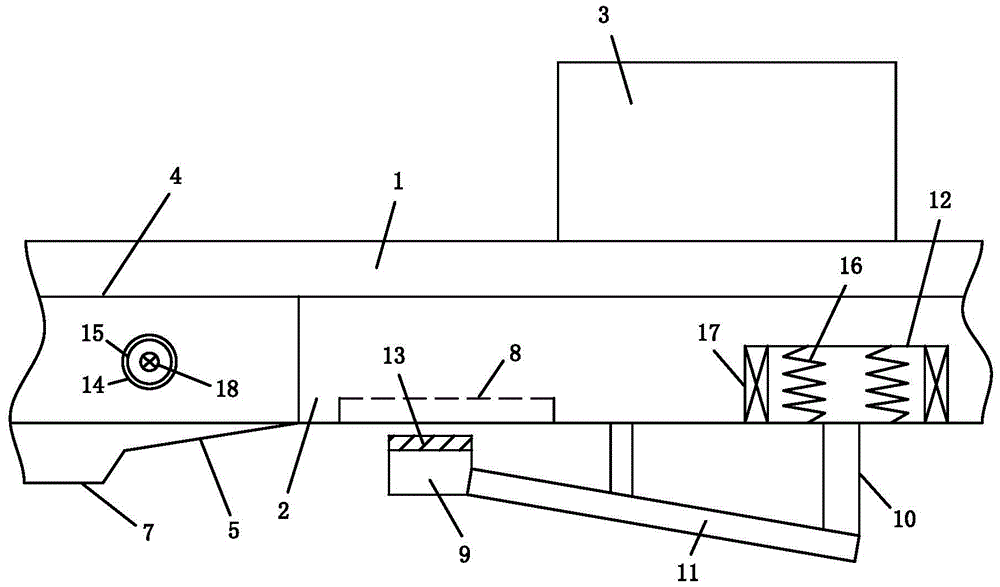

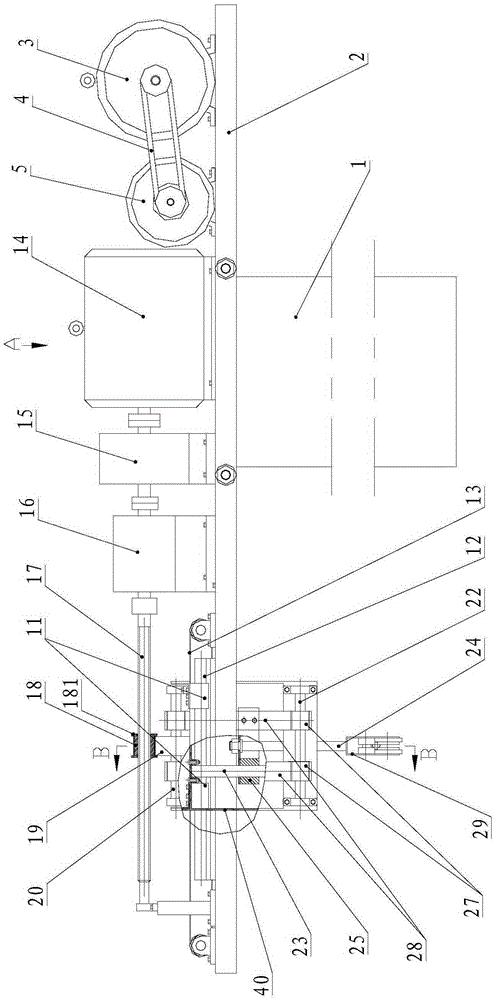

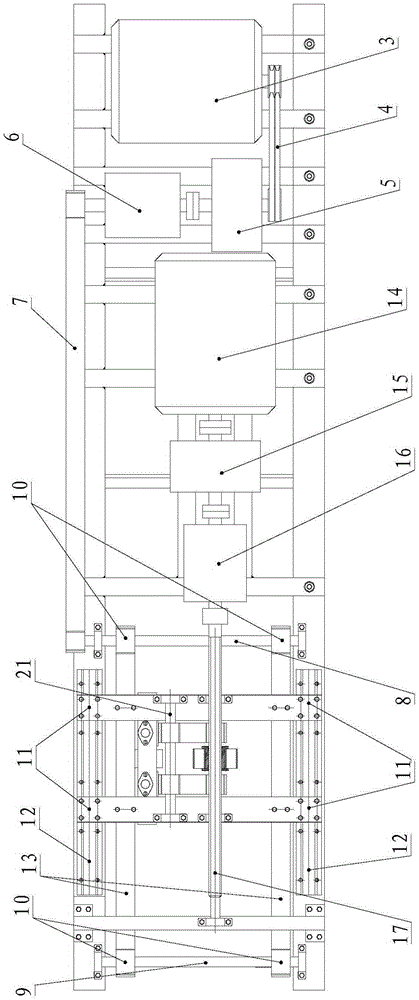

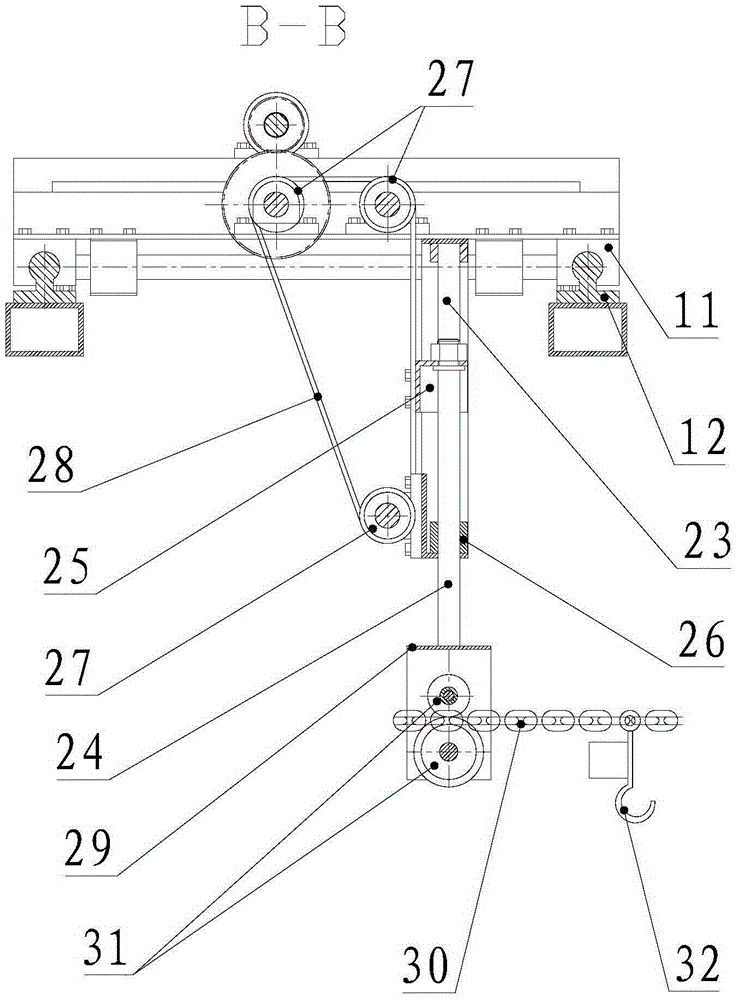

A vertical adjustment vibration damping device and method for a chain freight ropeway

ActiveCN103273925BExtended service lifeSuppress lateral vibrationRope railwaysVibration controlGear wheel

The invention discloses a vertical-adjustment vibration-reduction device and method of a chain freight cableway. The device comprises a vertical adjustment mechanism, a vertical driving mechanism, a cable supporting mechanism, a vibration signal acquisition module and a vibration controller. The vertical adjustment mechanism comprises an adjustment gear and an adjustment toothed bar which is in meshed connection with the adjustment gear, the vertical driving mechanism is installed at one end of a gear shaft of the adjustment gear, and the adjustment toothed bar is vertically installed on the cable supporting mechanism. The bottom of the adjustment toothed bar is fixedly connected with the cable supporting mechanism, the vibration signal acquisition module is installed on the cable supporting mechanism, the vibration controller is installed on the vertical driving mechanism, and the vibration signal acquisition module is in signal connection with the vibration controller. According to the method, after the controller receives and processes vibration signals of the load end of the cable supporting mechanism, the vertical adjustment mechanism is driven to move, vertical adjustment is carried out on the cable supporting mechanism, and vertical adjustment of vibration of the chain freight cableway is achieved. According to the chain freight cableway vertical-adjustment vibration-reduction device and method, service life of the chain freight cableway can be prolonged effectively, and safety and reliability of operation of a whole chain freight cableway system are improved.

Owner:SOUTH CHINA AGRI UNIV

Elevator controller

An elevator controlling device can prevent depravation of riding felling of litter when operating normally, and can more reliably restrain transverse vibration of the movement connection body. The elevator controlling device (11) has a drive control section (14), a control mode switching section (12) and a calculation section (13). The drive control section (14) can switch between the general mode of restraining the variation frequency of the rotate speed of the drive pulley (7) in determined low-frequency band and vibration abatement mode of making the rotate speed varies to a frequency higher than the low-frequency band when varying the rotate speed of the drive pulley (7) in terms of wave. The control mode switching section (12) detects the transverse vibration of the main cordage (8),the control mode of the drive control section (14) is switched to the vibration abatement mode. The calculation section (13) calculates the signal counteracting the transverse vibration. The drive control section (14) control the rotation of the drive pulley (7) to restrain the transverse vibration based on the information from the calculation section (13) when in the vibration abatement mode.

Owner:MITSUBISHI ELECTRIC BUILDING SOLUTIONS CORP

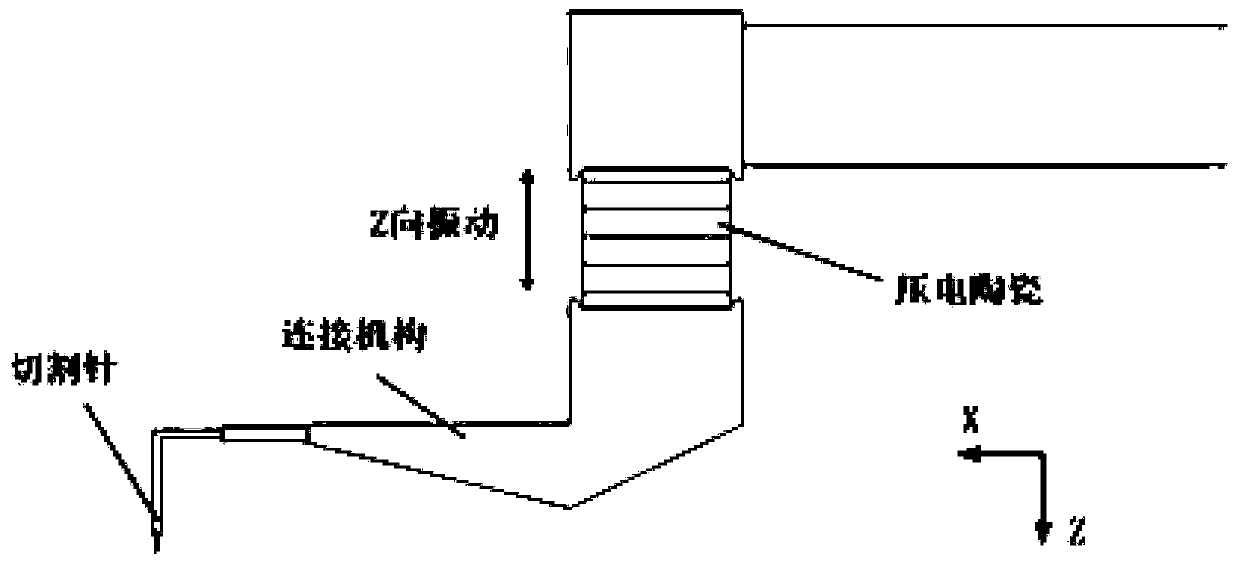

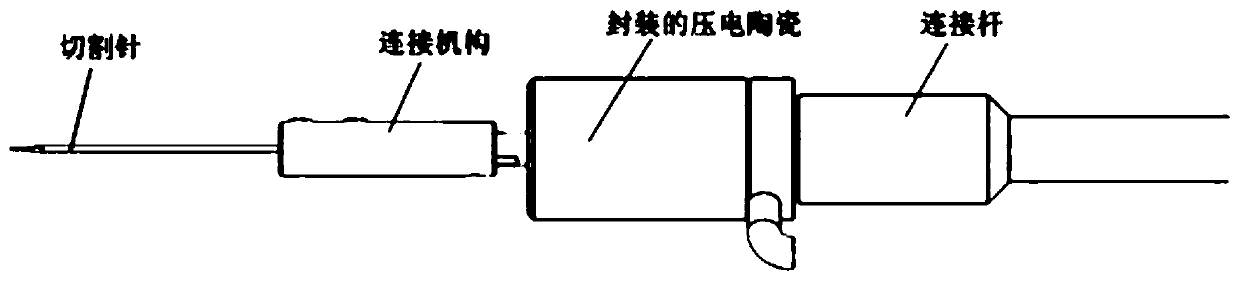

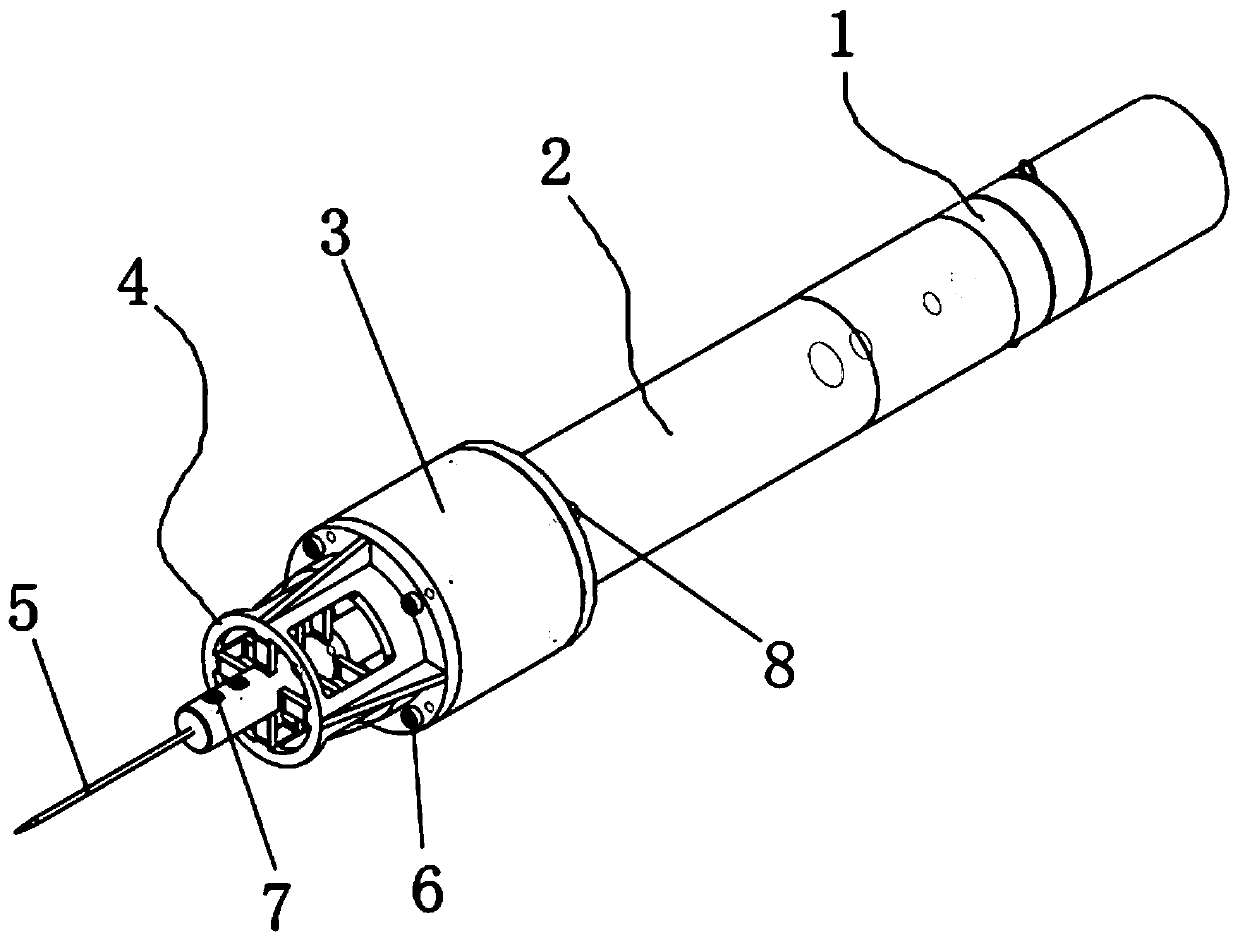

Biological microscopic cutting device based on flexible vibration reduction ultrasonic amplitude transformer

InactiveCN111229576AAvoid disturbanceSmooth vibrationMechanical vibrations separationMetal working apparatusTransformerCut needle

The invention discloses a biological microscopic cutting device based on a flexible vibration reduction ultrasonic amplitude transformer. The biological microscopic cutting device comprises an energyconverter, the amplitude transformer, a connecting ring, a flexible mechanism and a cutting needle, wherein one shaft end of the amplitude transformer is connected with the energy converter, the othershaft end of the amplitude transformer penetrates through the connecting ring to be connected with the flexible mechanism, the amplitude transformer and the flexible mechanism are both connected withthe connecting ring, and the cutting needle is connected with the flexible mechanism. According to the biological microscopic cutting device based on the flexible vibration reduction ultrasonic amplitude transformer, the whole device works under the longitudinal vibration frequency, so that needle point disturbance caused by other vibration modes is avoided, needle point vibration is stabler, andthe cutting precision is improved; by means of the mode by which the flexible mechanism is combined with the amplitude transformer, transverse vibration can be restrained within a smaller range, meanwhile, axial vibration can be amplified, and the cutting precision and performance are improved; and each group of flexible parts in the flexible mechanism are arranged in a circumferential array modeby adopting four flexible hinges, so that the stress is more uniformly distributed in four directions, and the inhibition effect on the transverse vibration is further improved.

Owner:SUZHOU UNIV

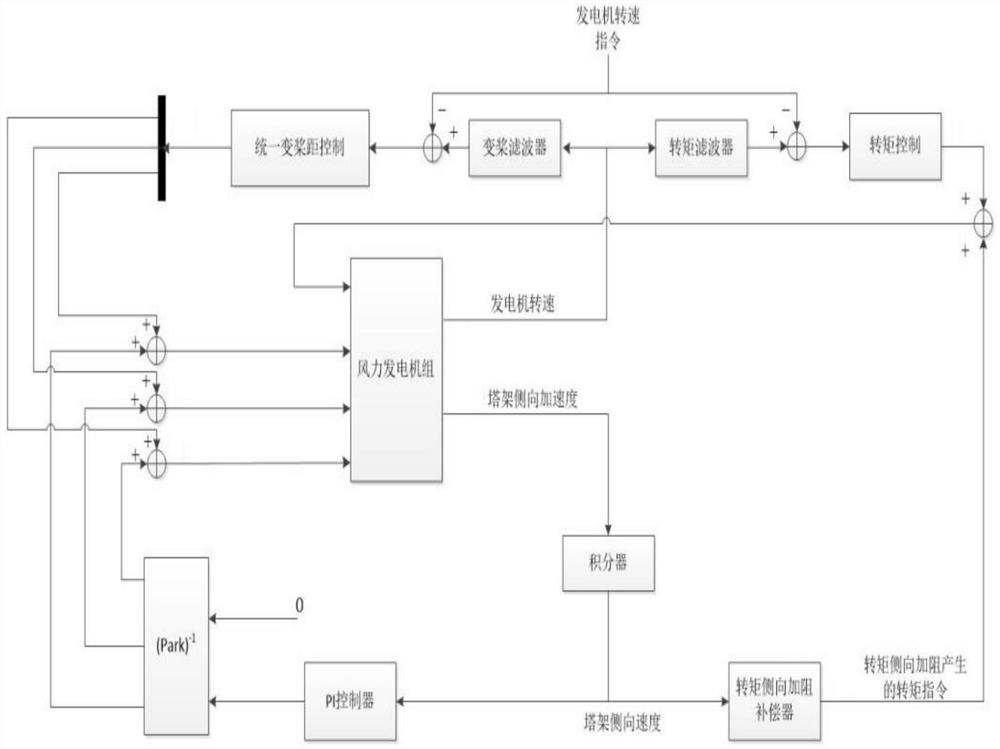

Tower lateral resistance increasing control method and system applied to wind generating set

PendingCN114542373ASuppress lateral vibrationReduce fatigue loadWind motor controlEngine fuctionsIntegratorWind power generator

The invention discloses a tower lateral resistance increasing control method and system applied to a wind generating set, and the method comprises the steps: carrying out the band-pass filtering of a cabin lateral vibration signal, extracting a tower lateral vibration signal, enabling the tower lateral vibration signal to pass through an integrator, obtaining a lateral speed signal, and carrying out the independent variable pitch lateral resistance increasing and / or torque lateral resistance increasing. That is, tower lateral resistance increasing control is achieved through independent variable-pitch lateral resistance increasing or torque lateral resistance increasing, or tower lateral resistance increasing control is achieved through independent variable-pitch lateral resistance increasing and torque lateral resistance increasing at the same time. According to the method, the lateral vibration of the tower can be effectively restrained, the lateral fatigue load of the tower is reduced, and the unit reaches the optimal operation state.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Vibration damping device and method for a chain freight ropeway

ActiveCN105329240BExtended service lifeReduce lateral vibration energyRope railwaysVibration attenuationVibration control

Owner:SOUTH CHINA AGRI UNIV

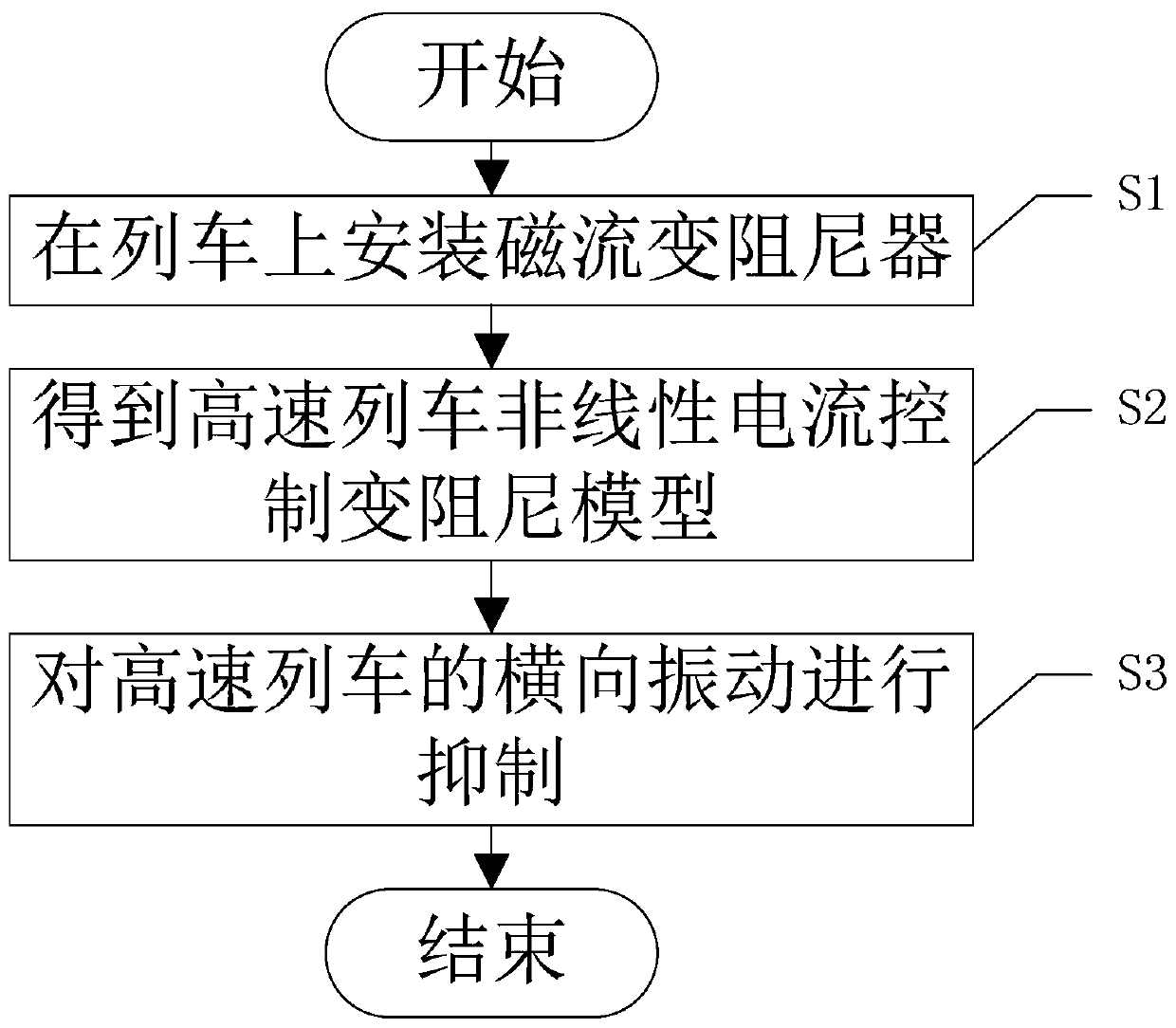

A high-speed train lateral vibration control method based on magnetorheological damping model

ActiveCN110803182BOvercoming Offset EffectsSuppress lateral vibrationBogiesBogie-underframe connectionsBogieVibration control

Owner:SOUTHWEST JIAOTONG UNIV

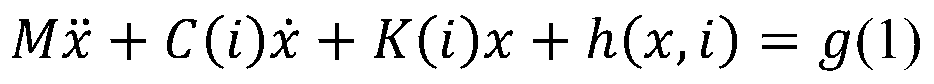

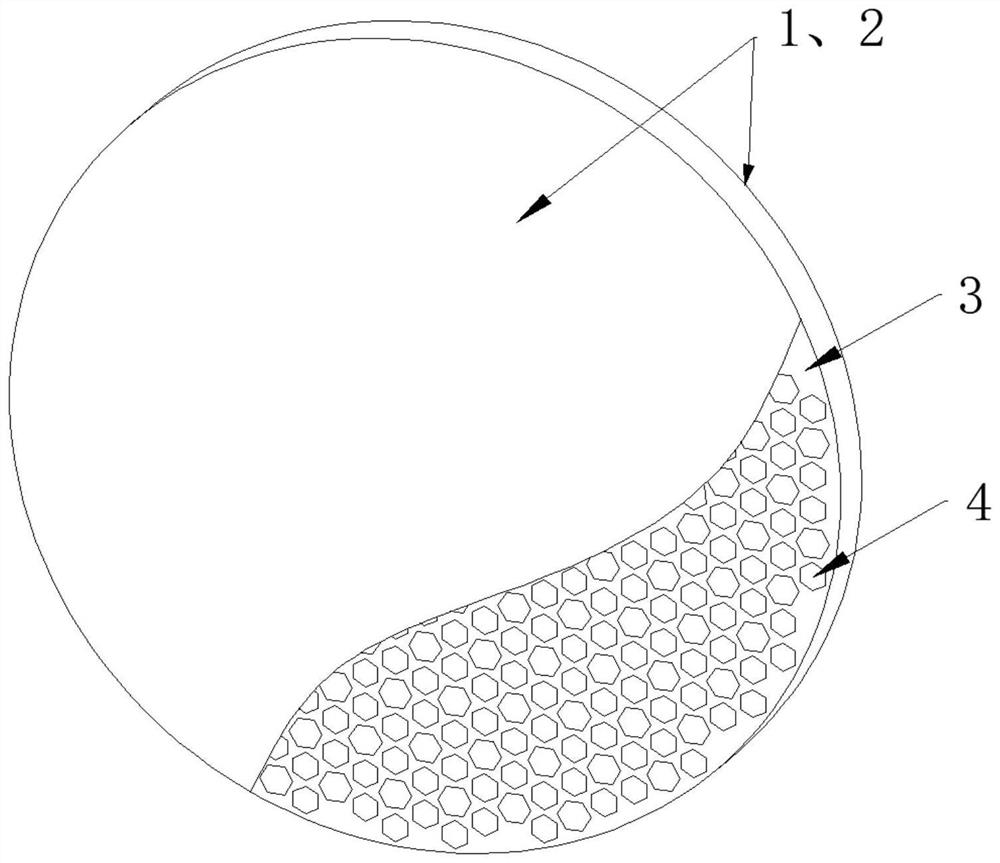

1-3 type piezoelectric composite material based on self-similar photonic crystal structure, and preparation method thereof

PendingCN113921692ASuppress lateral vibrationReduce energy lossPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionPhotonic crystal structureCrystal structure

The invention discloses a 1-3 type piezoelectric composite material based on a self-similar photonic crystal structure, and a preparation method thereof. The piezoelectric composite material comprises an upper electrode, a lower electrode, a polymer phase and a plurality of piezoelectric phases, the piezoelectric phases are polarized in the thickness direction, the piezoelectric phases are piezoelectric columns with hexagonal sections, and the plurality of piezoelectric columns are arranged in a hexagonal lattice form; the polymer phase is filled between the adjacent piezoelectric columns; and the upper electrode and the lower electrode are respectively positioned on the upper surface and the lower surface after the piezoelectric column and the polymer are compounded. Compared with a traditional 1-3 type piezoelectric composite material, the 1-3 type piezoelectric composite material has the advantages that a phonon crystal structure is combined with the 1-3 type piezoelectric composite material, so that transverse vibration of a piezoelectric vibrator during working is well inhibited, vibration in the thickness direction is purer, the working bandwidth is widened due to introduction of a self-similar structure, and the overall working efficiency is higher.

Owner:HANGZHOU DIANZI UNIV

a sports slide

ActiveCN105016039BImprove riding performanceSuppress lateral vibrationMechanical conveyorsEngineeringMechanical engineering

The invention discloses a moving slide rail, which comprises a first slide rail and a second slide rail slidingly sleeved in the first slide rail, a load-bearing mechanism is connected above the second slide rail, and a At least one positioning part, the bottom surface of the positioning part is provided with a first inclined surface inclined downward, the side wall of the positioning part is symmetrically provided with a second inclined surface inclined inwardly, and the end of the first inclined surface is connected with a fixing groove; The front end is provided with a long strip-shaped through hole, and the bottom of the long strip-shaped through hole is provided with a damping sheet and a top block. The damping sheet and the top block are connected with a connecting rod. There is an elastic compression mechanism, and the top block slides and fits with the elastic compression mechanism. The invention can improve the deficiencies of the prior art, and reduces the vibration when the slide rail is locked.

Owner:宁夏巨能机器人股份有限公司

Chain-type freight ropeway vibration attenuation device and method

ActiveCN105329240AAchieve vibration reductionReduce lateral vibration energyRope railwaysVibration attenuationVibration control

The invention discloses a chain-type freight ropeway vibration attenuation device and method. The chain-type freight ropeway vibration attenuation device comprises a horizontal adjusting mechanism, a horizontal drive mechanism, a vertical adjusting mechanism, a vertical drive mechanism, a vibration signal acquisition module and a vibration controller; the vibration signal acquisition module is arranged on a chain-type freight ropeway rope carrying mechanism, and the vibration signal acquisition module is connected with the vibration controller; the vibration controller is respectively connected with the horizontal drive mechanism and vertical drive mechanism, the power output end of the horizontal drive mechanism is connected with the horizontal adjusting mechanism, and the power output end of the vertical drive mechanism is connected with the vertical adjusting mechanism; the rope carrying mechanism is arranged on the vertical adjusting mechanism, and the vertical adjusting mechanism is arranged on the horizontal adjusting mechanism. By adopting the chain-type freight ropeway vibration attenuation device, the lateral vibration energy of a rope carrying mechanism transmission chain can be greatly reduced, the excessively-large lateral vibration of the rope carrying mechanism transmission chain can be inhibited, the service life of the freight ropeway is effectively prolonged, the operation safety and reliability of the entire freight ropeway system can be improved, and the disastrous consequence can be maximally avoided.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com