Shear type track vibration and noise reduction device

A vibration reduction and noise reduction, shearing technology, used in tracks, roads, buildings, etc., can solve problems such as increasing the maintenance cost of the track, reducing the service life of the rail, and accelerating the wear of the rail, and achieves good vibration and noise reduction. The effect of prolonging service life and delaying wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

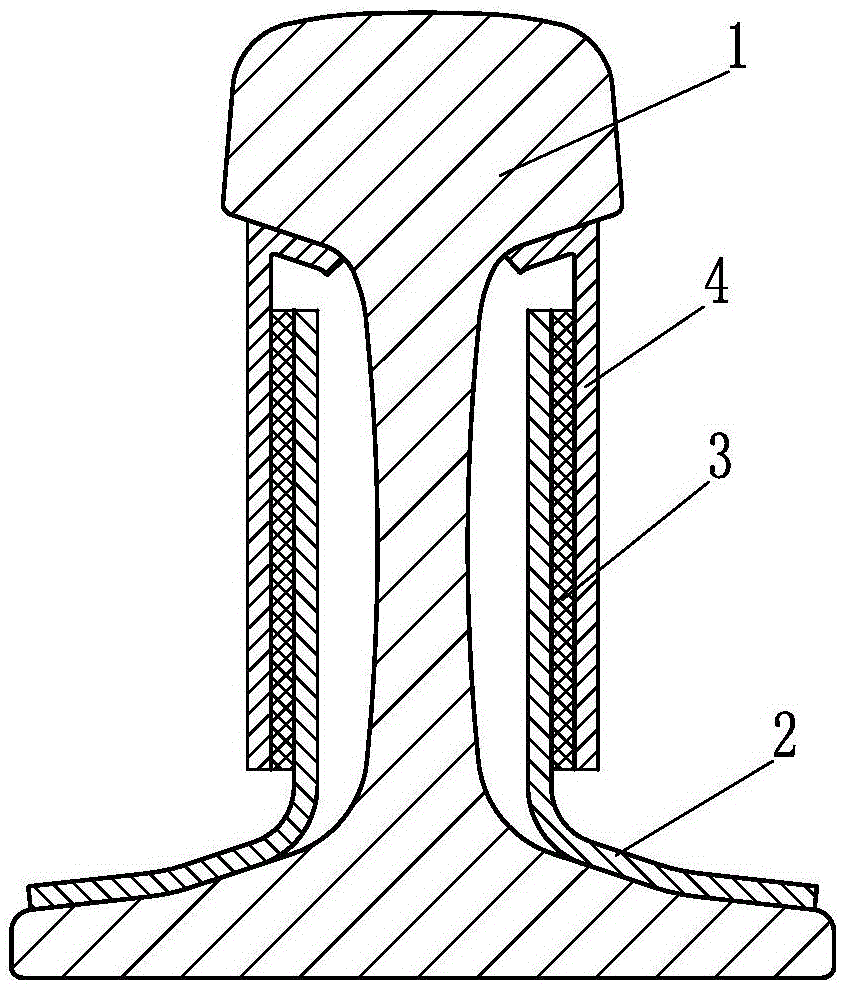

[0029] Such as figure 1 The shearing type track vibration and noise reduction device of the present invention shown in the present invention comprises an upper shearing part 4 and a lower shearing part 2, the upper shearing part 4 is located at the outer side of the lower shearing part 2, and the upper shearing part 4 works tightly The ground is pressed against the rail jaw of the rail 1, the lower shearing part 2 is connected with the rail flange, the shape of the lower shearing part 2 is the same as the surface shape of the rail flange corresponding to the assembly position, and the upper shearing There is a damping layer 3 between the cut pieces 2, and the damping layer 3 connects the upper cut piece 4 and the lower cut piece 2 into one body to form a damping sound insulation board, which covers the rail jaw to the outside of the rail flange part of the rail surface between the ends. Among them, the upper shearing part 4 and the lower shearing part 2 are made of steel plat...

Embodiment 2

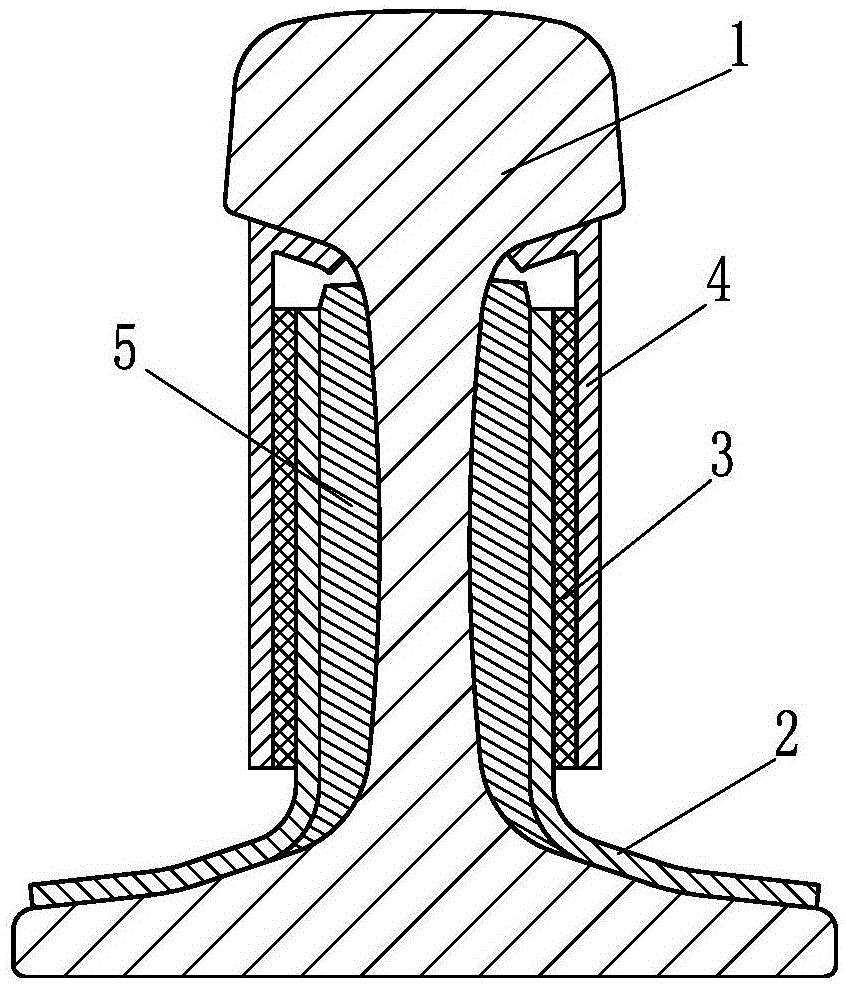

[0034] Such as figure 2 The difference between the shear type rail vibration and noise reduction device of the present invention shown in Embodiment 1 is that, in order to further improve the noise reduction effect, a sound-absorbing material layer 5 is provided between the damping sound insulation board and the rail 1 . Wherein, the sound-absorbing material layer 5 is made of rock wool material.

[0035] The technical solution described in this example, in addition to the various advantages of Embodiment 1, since the sound-absorbing material layer 5 is set between the damping sound-insulating plate and the rail 1, the sound-absorbing material layer 5 basically covers the rail waist of the rail 1 On the surface, when the rail vibrates, the sound-absorbing material layer 5 will absorb the radiation noise of the rail waist, suppress the formation of noise sound waves, and have a stronger ability to block the radiation of rail vibration noise, which improves the performance of t...

Embodiment 3

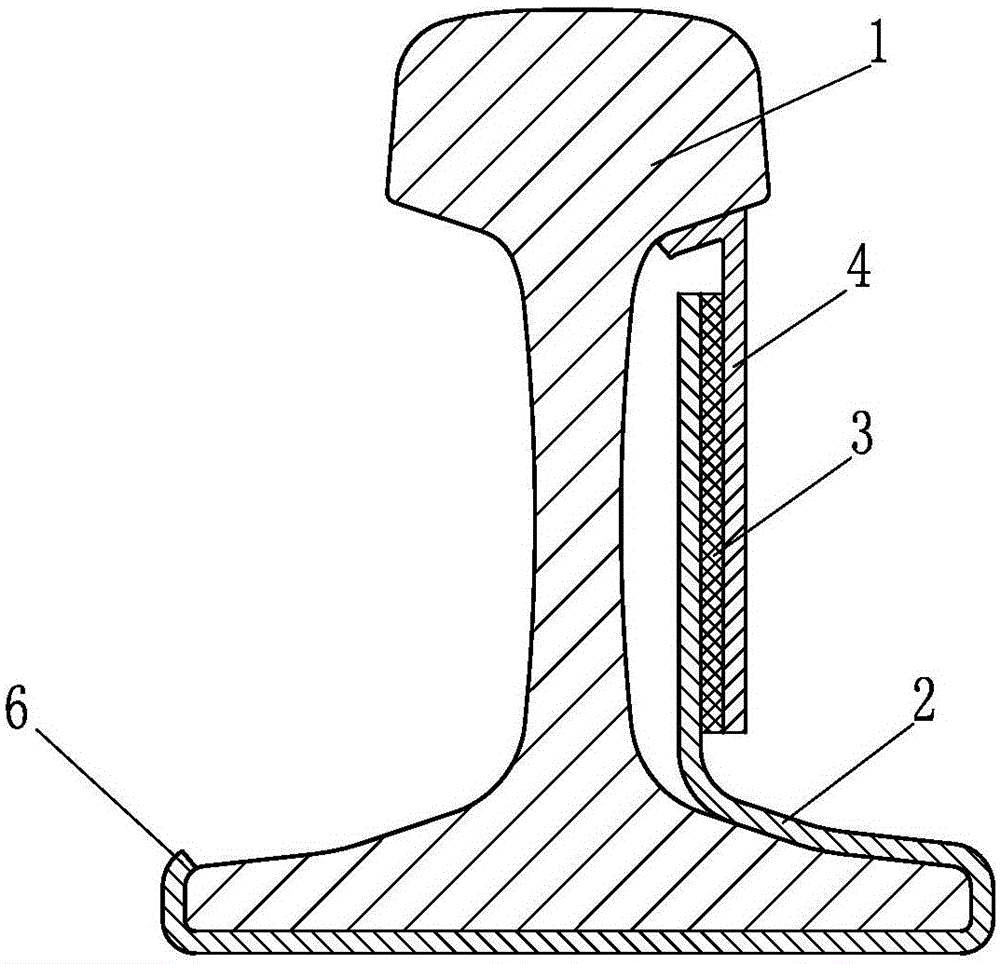

[0038] Such as image 3 The difference between the shearing type rail vibration and noise reduction device of the present invention shown in Embodiment 1 is that the lower shearing part 2 is correspondingly installed on the wing plate and the bottom of the rail 1, and the lower shearing part 2 is provided with a buckle structure6. When assembling with the rail 1, the shearing type rail vibration and noise reduction device of the present invention is fastened together with the rail by using the buckle structure 6 .

[0039] It should be pointed out that when the shear type rail vibration and noise reduction device of the present invention is assembled with the rail, it can be as follows: image 3 The upper shearing part 4 shown is pressed against the rail jaw under the rail head on the right side of the rail, and the buckle structure 6 is fastened to the flange on the left side of the rail. The lower shearing part of the noise reduction device presses against the rail jaw und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com