a sports slide

A sliding rail and movement technology, applied in the field of manipulators, can solve problems such as shortening the service life of sliding rails, strong vibration, rigid impact of sliding parts, etc., and achieve the effect of improving ride comfort and reducing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

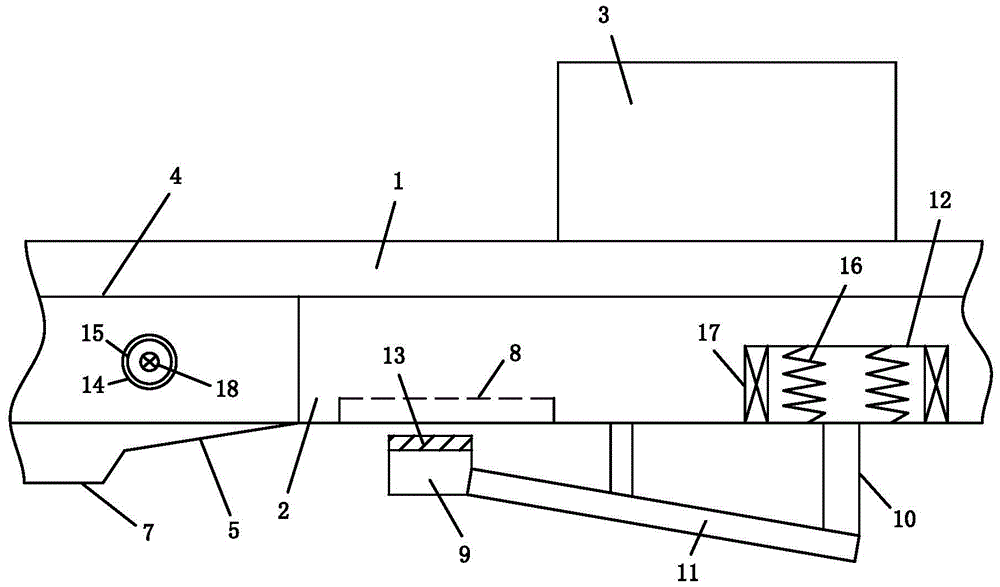

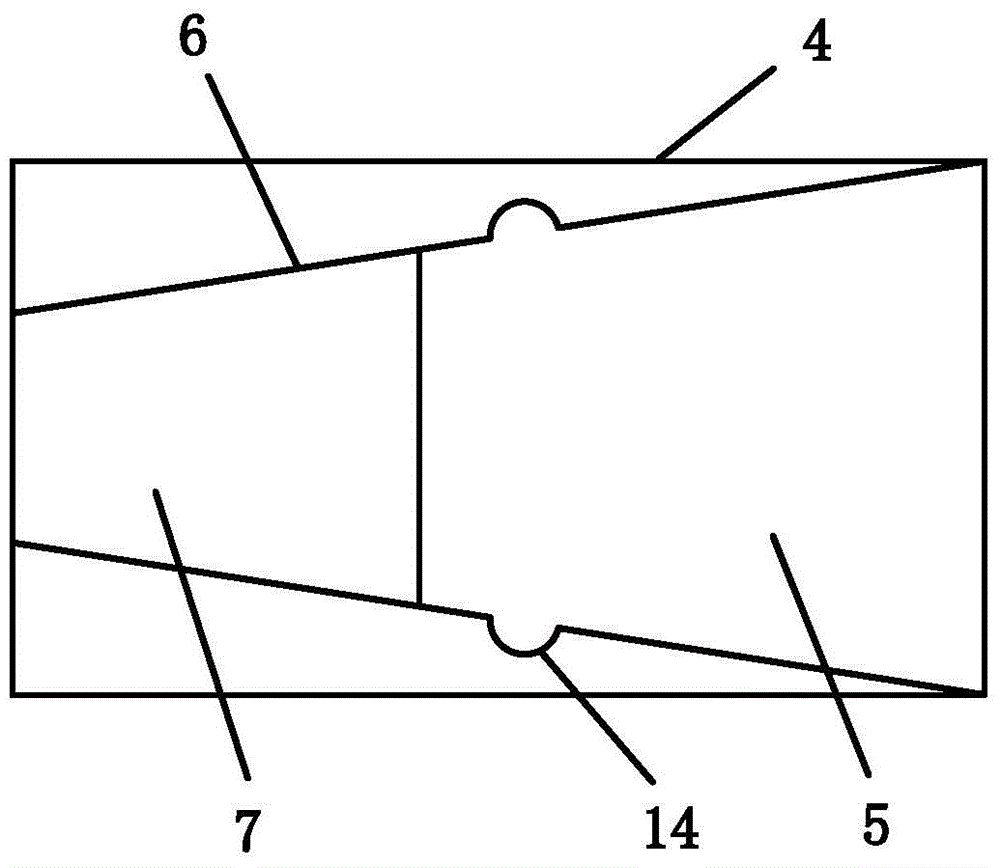

[0015] Reference Figure 1-2 , This embodiment includes a first slide rail 1 and a second slide rail 2 slidingly sleeved in the first slide rail 1. The first slide rail 1 and the second slide rail 2 are connected by ball bearings. The installation angle of the ball bearing An angle of 10° with the horizontal. A load-bearing mechanism 3 is connected above the second slide rail 2. At least one positioning portion 4 is provided in the first slide rail 1. The bottom surface of the positioning portion 4 is provided with a downwardly inclined first inclined surface 5, and a side of the positioning portion 4 The wall is symmetrically provided with a second inclined surface 6 inclined to the inside. The end of the first inclined surface 5 is connected with a fixing groove 7; the front end of the second slide rail 2 is provided with an elongated through hole 8, below the elongated through hole 8 A damping sheet 9 and a top block 10 are provided. The damping sheet 9 and the top block 10...

Embodiment 2

[0021] This embodiment is an improvement made on the basis of Embodiment 1, and the same parts as Embodiment 1 will not be described in detail. Among them, the damping sheet 9 is made by mixing silica gel and graphite according to a ratio of 9.5:1, wherein the particle diameter of graphite is preferably 10 μm-30 μm, the pattern layer 13 is a uniform diamond pattern, and the width of the convex side of the diamond pattern is two The ratio of the lengths of the diagonals is 1:15:23. This preferred solution can realize low-noise and fast locking and positioning.

Embodiment 3

[0023] This embodiment is an improvement made on the basis of Embodiment 1, and the same parts as Embodiment 1 will not be described in detail. Among them, the damping sheet 9 is mixed with styrene-butadiene rubber and graphite according to a ratio of 13:1, wherein the particle diameter of graphite is preferably 3 μm to 5 μm, the pattern layer 13 has 5 parallel stripes, and the ratio of the width of the stripes is 1:3: 4:3:1. This preferred solution can prolong the service life of the damper.

[0024] The working principle of the present invention is that the present invention utilizes the first inclined surface 5 in the positioning portion 4 to buffer the positioning process during positioning and avoid vibration caused by sudden locking positioning. The second inclined surface 6 is used to generate a buffing force on the second slide rail 2, on the one hand, it has a decelerating effect, and on the other hand, it can suppress the lateral vibration generated by the second slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com